Positions focused on the application, development, and maintenance of specialized materials designed to protect aircraft and spacecraft surfaces from environmental stressors and operational wear are essential to the aerospace industry. These roles involve tasks such as surface preparation, coating application using various techniques (spraying, dipping, etc.), inspection for defects, and adherence to stringent quality control standards. For example, a technician might apply a ceramic coating to a turbine blade to enhance its heat resistance, thereby extending its lifespan.

The maintenance and enhancement of aircraft and spacecraft longevity, performance, and safety are directly linked to these specialized vocations. Historically, advancements in material science have driven the need for professionals skilled in the precise application of protective layers. These surface treatments mitigate corrosion, reduce drag, and provide thermal protection, thereby contributing to more efficient and reliable air and space travel. This directly impacts operational costs, fuel efficiency, and passenger safety standards within the sector.

The subsequent sections will delve into specific types of opportunities available within this specialized field, the necessary qualifications and training pathways, and the evolving technological landscape impacting roles in this domain. Details regarding salary expectations, career progression opportunities, and the geographic distribution of these positions will also be presented.

Guidance for Pursuing Opportunities in Protective Surface Application for Aviation and Spacecraft

The following recommendations provide a structured approach for individuals seeking roles focused on specialized surface treatments designed for use on aircraft and spacecraft, and associated operational tasks. Attention to these points can increase competitiveness in this technically demanding domain.

Tip 1: Prioritize Relevant Education and Certification: A foundational understanding of material science, chemistry, or engineering is highly beneficial. Seek certifications such as those offered by NACE International (AMPP) or similar organizations related to surface treatment and inspection to demonstrate competency.

Tip 2: Gain Hands-On Experience: Practical experience is crucial. Seek internships or entry-level positions in aerospace manufacturing or maintenance facilities. This allows for direct exposure to coating application techniques, surface preparation methods, and quality control procedures.

Tip 3: Develop Expertise in Specialized Application Techniques: Proficiency in various coating application methods, such as spray application, plasma spraying, vapor deposition, or electrochemical deposition, is essential. Focus on mastering one or two specific techniques that are commonly used in the aerospace industry.

Tip 4: Understand Aerospace Materials and Standards: Familiarize oneself with common aerospace materials (e.g., aluminum alloys, titanium, composites) and the stringent industry standards governing surface treatment processes (e.g., MIL-SPEC, AMS specifications). Knowledge of these standards is paramount for ensuring compliance and safety.

Tip 5: Cultivate Strong Attention to Detail: Protective surface treatments require precision and accuracy. Develop a meticulous approach to all tasks, including surface preparation, coating application, and inspection. Small imperfections can have significant consequences in aerospace applications.

Tip 6: Stay Abreast of Technological Advancements: The field is constantly evolving with the development of new materials, application techniques, and inspection methods. Engage in continuous learning through industry publications, conferences, and professional development courses.

Tip 7: Network with Industry Professionals: Attend industry events and join professional organizations to connect with experienced professionals in the field. Networking can provide valuable insights, mentorship opportunities, and access to job leads.

Adherence to these guidelines can significantly enhance prospects within the field of protective surface application in the aviation and space sectors, where demand for skilled professionals remains robust.

The final section will address potential challenges and strategies for long-term career success in this specialized vocational path.

1. Application Techniques

The efficacy and longevity of specialized surface treatments on aircraft and spacecraft are inextricably linked to the method of their application. The choice of application technique significantly impacts the performance, durability, and overall effectiveness of the protective layer. Therefore, a thorough understanding of various coating processes is essential for personnel involved in these positions.

- Spray Application

Spray application, involving atomizing the coating material and propelling it onto the surface, is a widely used method. This technique requires skilled operators to control factors like spray gun distance, angle, and material flow rate. Improper spray application can lead to uneven coating thickness, runs, sags, or orange peel texture, all of which compromise protection. For example, applying a thermal barrier coating too thinly on a turbine blade hot section will result in premature failure due to insufficient heat resistance.

- Electrodeposition

Electrodeposition uses an electrical current to deposit a coating onto a conductive substrate. This method provides excellent control over coating thickness and uniformity, even on complex geometries. However, it is limited to materials that can be ionized and deposited in an electrolytic bath. Anodic coatings on aluminum alloys, for example, provide corrosion resistance through the controlled oxidation of the metal surface, increasing its durability in harsh environments.

- Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD)

CVD and PVD are advanced techniques used to deposit thin films with exceptional properties. CVD involves chemical reactions of gaseous precursors on the substrate surface, while PVD involves the physical vaporization of the coating material. These methods are used to create coatings with high hardness, wear resistance, and thermal stability. For instance, titanium nitride (TiN) coatings deposited via PVD are used to protect cutting tools used in aerospace component manufacturing, enhancing their lifespan and performance.

- Brush and Roller Application

While less common for critical aerospace components, brush and roller application may be used for certain touch-up or repair tasks. This technique requires careful attention to detail to ensure uniform coverage and avoid leaving brush marks or roller textures. It is primarily suited for coatings with self-leveling properties and is typically used for less demanding applications, such as applying protective coatings to the exterior of aircraft fuselages.

These diverse application methods highlight the breadth of knowledge required for professionals in specialized surface treatment vocations. The selection of the appropriate technique depends on factors such as the coating material, substrate material, desired coating properties, component geometry, and budget constraints. Mastery of these techniques is critical for ensuring the long-term performance and safety of aircraft and spacecraft.

2. Material Science

The application of material science principles forms the bedrock of effective surface treatment implementation within the aerospace sector. Professionals engaged in protective coating roles must possess a fundamental understanding of material properties, behavior under stress, and chemical compatibility. The selection of appropriate coating materials is directly dependent on the material composition of the substrate and the operational environment to which the aerospace component will be subjected. For instance, the coefficient of thermal expansion mismatch between a coating and the substrate material can lead to cracking and delamination under fluctuating temperatures, rendering the protective layer ineffective. Therefore, knowledge of material science directly impacts the longevity and performance of protective treatments, ultimately influencing the safety and reliability of aircraft and spacecraft.

Further illustrating this point, consider the application of chromate conversion coatings on aluminum alloys. Material science explains the electrochemical processes involved in the formation of the protective chromate layer, providing a scientific basis for controlling the process parameters to achieve optimal corrosion resistance. The understanding of alloying elements in the aluminum substrate and their interaction with the chromate solution is critical for producing a uniform and adherent coating. Likewise, the development of novel coating materials, such as graphene-enhanced polymers or self-healing coatings, necessitates a deep understanding of nanoscale material behavior and their interaction with the surrounding environment. These advanced materials are specifically designed to address challenges like extreme temperatures, radiation exposure, and micrometeoroid abrasion encountered in space environments, furthering operational lifespan and reliability.

In summary, material science provides the theoretical and practical framework for selecting, applying, and evaluating protective coatings in the aerospace industry. The effectiveness of specialized surface treatment vocations hinges on the ability to apply these principles to real-world challenges, mitigating risks associated with environmental degradation and operational stresses. Therefore, continuous learning and development in material science are essential for professionals seeking to excel in this domain, ensuring that protective surface treatments remain at the forefront of aerospace innovation and safety protocols.

3. Quality Control

Quality control is an indispensable element within the domain of positions focused on aircraft and spacecraft surface treatments. The effectiveness of protective coatings is directly dependent on rigorous adherence to quality standards at every stage of the application process, from initial surface preparation to final inspection. Deficiencies in quality control can lead to premature coating failure, corrosion, structural weakness, and ultimately, catastrophic consequences in flight. A lack of proper surface cleaning, for example, can prevent adequate coating adhesion, resulting in peeling or blistering under operational stresses. Therefore, quality control protocols act as a safeguard, mitigating potential risks and ensuring the integrity of aerospace components.

Implementation involves a comprehensive array of testing methods, both destructive and non-destructive, to verify coating thickness, adhesion strength, chemical resistance, and other critical properties. Non-destructive testing techniques, such as ultrasonic testing and eddy current inspection, allow for the evaluation of coating integrity without compromising the component’s structural integrity. Destructive testing, on the other hand, provides quantifiable data on coating performance under simulated operational conditions. An example would be subjecting coated samples to accelerated corrosion testing to assess their long-term durability in harsh environments. Data gathered during quality control procedures informs process adjustments, material selection, and training programs, driving continuous improvement in coating application techniques and material formulations. Regular auditing and certification processes, conforming to industry standards such as AS9100, ensure that quality management systems are consistently maintained and effectively implemented.

In conclusion, quality control is inextricably linked to the success and safety of specialized surface treatment vocations. It is not merely a post-application inspection process, but rather an integrated system encompassing all stages of the coating process. The implementation of robust quality control measures ensures that protective coatings meet stringent performance requirements, safeguarding aircraft and spacecraft against degradation and ensuring the safety of passengers and crew. The evolution of quality control technologies and methodologies remains paramount for addressing the increasingly complex demands of the aerospace industry.

4. Environmental Regulations

Environmental regulations exert a substantial influence on specialized surface treatment roles within the aerospace sector. Regulations implemented by agencies such as the Environmental Protection Agency (EPA) and similar international bodies directly impact the selection of coating materials, application methods, and waste disposal procedures. The phased elimination of hexavalent chromium, a potent carcinogen previously widely used in corrosion-resistant coatings, exemplifies this effect. The resultant need for alternative, environmentally compliant coatings drives innovation in material science and necessitates retraining of personnel in application techniques for these new materials. Failure to comply with environmental regulations can result in significant fines, operational disruptions, and reputational damage for aerospace manufacturers and maintenance facilities. Consequently, a thorough understanding of and adherence to these regulations is a critical competency for these positions.

The pursuit of environmentally sustainable practices extends beyond material composition. Regulatory frameworks also mandate the implementation of processes to minimize volatile organic compound (VOC) emissions during coating application. This has led to the adoption of high-solids coatings, waterborne coatings, and powder coatings, all of which reduce VOC emissions compared to traditional solvent-based coatings. Furthermore, regulations govern the disposal of coating waste, including spent solvents, contaminated rags, and discarded spray equipment. Proper waste management procedures, such as solvent recycling and hazardous waste disposal, are essential for minimizing environmental impact and ensuring regulatory compliance. Environmental compliance officers and technicians specializing in waste management are increasingly integral roles within aerospace organizations to ensure these stringent regulations are followed.

In summary, environmental regulations are not merely external constraints but fundamental drivers of innovation and operational practices within specialized surface treatment vocations. Understanding and complying with these regulations is not only a legal obligation but also a crucial aspect of responsible environmental stewardship. As environmental concerns continue to grow, the demand for professionals skilled in environmentally compliant coating technologies and waste management practices is expected to increase, solidifying the importance of environmental awareness within the specialized surface treatment field.

5. Safety Protocols

Strict adherence to established safety protocols is paramount in positions involving the application, maintenance, and development of surface treatments for aircraft and spacecraft. The nature of materials utilized, the application processes employed, and the operational environment necessitate rigorous safety measures to protect personnel and prevent environmental contamination.

- Hazardous Material Handling

Many coating materials, such as solvents, epoxy resins, and specialized chemicals, pose significant health hazards through inhalation, skin contact, or ingestion. Safety protocols dictate the use of personal protective equipment (PPE), including respirators, gloves, eye protection, and protective clothing, to minimize exposure. Proper handling procedures, including spill containment and emergency response plans, are essential components of hazardous material management. For example, technicians working with chromate conversion coatings must adhere to strict protocols to prevent exposure to hexavalent chromium, a known carcinogen.

- Ventilation and Air Quality Control

The application of coatings often generates airborne particles and vapors that can pose respiratory hazards. Ventilation systems, including local exhaust ventilation (LEV) and air filtration systems, are critical for maintaining air quality within coating facilities. Safety protocols specify regular monitoring of air quality and adherence to permissible exposure limits (PELs) for hazardous substances. Failure to maintain adequate ventilation can lead to chronic respiratory illnesses and other health problems among coating applicators.

- Fire and Explosion Prevention

Many coating materials, particularly solvents and thinners, are flammable or explosive. Safety protocols mandate the implementation of fire prevention measures, such as the use of explosion-proof equipment, proper grounding of electrical systems, and the storage of flammable materials in designated fire-resistant cabinets. Fire suppression systems, including sprinkler systems and fire extinguishers, must be readily available and regularly inspected. A spark from static electricity, for example, can ignite flammable vapors, leading to a fire or explosion within a coating facility.

- Confined Space Entry Procedures

The application or removal of coatings may require entry into confined spaces, such as fuel tanks or aircraft fuselages. Confined space entry procedures mandate the implementation of comprehensive safety protocols, including atmospheric testing, ventilation, and the use of safety harnesses and lifelines. A designated entry supervisor must be present to monitor the entry and ensure the safety of personnel inside the confined space. Oxygen deficiency or the presence of toxic gases within a confined space can quickly lead to asphyxiation or other serious health consequences.

These facets of safety protocols are inextricably linked to the daily operations of personnel in specialized surface treatment roles. Rigorous adherence to these protocols is not only a legal requirement but also an ethical obligation, ensuring the health and safety of workers and the integrity of the aerospace industry as a whole.

6. Equipment Maintenance

Equipment maintenance constitutes an integral function within specialized surface treatment operations for aircraft and spacecraft. The reliability and precision of coating application depend heavily on the proper functioning of equipment used for surface preparation, coating application, and inspection. Effective maintenance programs minimize downtime, ensure consistent coating quality, and prolong the lifespan of critical equipment, thereby impacting overall operational efficiency and cost-effectiveness in relevant positions.

- Spray System Calibration

Precise calibration of spray systems, including spray guns, pumps, and atomizers, is essential for achieving uniform coating thickness and minimizing material waste. Calibration procedures involve verifying flow rates, pressure settings, and spray patterns against established standards. A miscalibrated spray gun may result in uneven coating distribution, leading to localized corrosion or premature wear on the coated component. Regular maintenance and calibration schedules prevent such discrepancies, safeguarding the integrity of the applied coating and reducing material consumption.

- Filtration System Maintenance

Air filtration systems are critical for removing contaminants from the compressed air used in spray application and for maintaining air quality within coating facilities. Clogged or improperly maintained filters can reduce air pressure, introduce contaminants into the coating material, and create hazardous working conditions. Filter replacement schedules, pressure monitoring, and leak detection are essential components of filtration system maintenance. Contamination from unfiltered air can result in coating defects, reduced adhesion, and potential health hazards for coating applicators.

- Automated System Diagnostics

Automated coating systems, including robotic spray booths and automated dipping lines, rely on sophisticated sensors and control systems to ensure precise and repeatable coating application. Diagnostic procedures involve monitoring sensor performance, verifying control system parameters, and troubleshooting any malfunctions that may arise. Regular diagnostic checks prevent deviations from established coating procedures, ensuring consistent coating quality and minimizing the risk of equipment failure. Undetected malfunctions can lead to coating defects, production delays, and costly repairs.

- Surface Preparation Equipment Servicing

Surface preparation equipment, such as abrasive blasting machines and chemical etching tanks, requires regular servicing to maintain optimal performance. Abrasive blasting machines require periodic replacement of nozzles and abrasives, while chemical etching tanks require monitoring and adjustment of chemical concentrations. Improperly maintained surface preparation equipment can result in inadequate surface cleaning or etching, leading to poor coating adhesion and premature coating failure. Regular servicing prevents these issues, ensuring the proper preparation of surfaces for subsequent coating application.

Effective equipment maintenance is therefore inextricably linked to the quality and reliability of surface treatments applied in the aerospace industry. These tasks must be performed by skilled personnel with comprehensive understanding of the coating processes and equipment involved. Neglecting equipment maintenance can lead to a cascade of problems, compromising the integrity of coatings and jeopardizing the safety and performance of aircraft and spacecraft.

7. Research and Development

Research and development (R&D) forms a crucial element shaping the landscape of vocations centered on protective surface treatments for the aerospace sector. It fuels innovation in coating materials, application techniques, and performance assessment methodologies. Positions involving protective surface applications are therefore influenced by advancements originating from R&D activities, demanding professionals who can adapt to and implement cutting-edge technologies. These specialized vocations evolve in tandem with innovations developed and refined through intensive research efforts.

- Material Innovation and Formulation

R&D efforts concentrate on synthesizing novel coating materials that offer enhanced performance characteristics. Examples include the development of self-healing coatings that automatically repair damage, reducing the need for frequent maintenance, and the formulation of ceramic coatings with improved thermal barrier properties, enabling engines to operate at higher temperatures and increasing efficiency. Individuals holding positions focused on these treatments must understand the underlying chemical and physical principles to effectively apply and assess the performance of these materials. The creation and implementation of these materials directly influence job responsibilities.

- Application Technique Optimization

R&D efforts are focused on optimizing existing coating application techniques and developing new methods to improve coating uniformity, adhesion, and efficiency. Examples include the refinement of plasma spray techniques to create denser and more durable coatings, and the development of automated coating systems that reduce human error and material waste. Those applying specialized surface treatments must stay informed about such advancements to optimize their workflow and contribute to improving the overall efficiency of coating processes. It’s the responsibility of the coating appliers to adapt the techniques.

- Performance Evaluation and Testing

R&D contributes to developing sophisticated testing methodologies for evaluating the performance of coatings under simulated aerospace conditions. This involves conducting accelerated aging tests, evaluating resistance to corrosion, erosion, and extreme temperatures, and assessing the impact of radiation exposure. Such information is vital to improving coating materials. Individuals involved in these specialized surface treatment vocations benefit from being able to interpret testing data to assess the suitability of coatings for specific applications and to troubleshoot any performance issues that may arise.

- Regulatory Compliance and Sustainability

R&D efforts support the development of environmentally friendly coating materials and application processes that comply with increasingly stringent regulations. This includes finding alternatives to hazardous substances, reducing volatile organic compound (VOC) emissions, and minimizing waste generation. Personnel involved in surface treatment applications must be aware of the regulatory landscape and adept at using and disposing of materials in a manner that minimizes environmental impact, therefore needing to understand sustainable practices.

These advancements significantly shape the demands and expectations for professionals in this field. As coatings research progresses, those applying specialized surface treatments are expected to possess a strong understanding of the underlying science and the ability to adapt to new technologies and processes. This requires continuous learning and professional development, underscoring the symbiotic relationship between R&D and vocations focused on the safeguarding of aircraft and spacecraft surfaces.

Frequently Asked Questions Regarding Aerospace Coatings Positions

The following section addresses common inquiries and misconceptions pertaining to employment within the field of aerospace coatings. It offers clarity on aspects such as required qualifications, career progression, and industry standards.

Question 1: What specific educational background is typically required for entry-level aerospace coating technician positions?

While a bachelor’s degree in materials science, chemistry, or engineering is advantageous, many entry-level positions require an associate’s degree or vocational training in a related field. Certification from organizations such as NACE International (AMPP) demonstrating proficiency in surface preparation and coating application is often highly valued.

Question 2: Are there significant physical demands associated with aerospace coating operations?

Yes, these positions often involve prolonged periods of standing, lifting, and working in confined spaces. Additionally, the use of personal protective equipment (PPE), such as respirators and protective suits, can add to the physical demands. Candidates should be capable of meeting these physical requirements.

Question 3: What are the primary safety concerns within aerospace coating environments?

The primary safety concerns revolve around exposure to hazardous chemicals, flammable materials, and airborne particulates. Strict adherence to safety protocols, proper use of PPE, and implementation of adequate ventilation systems are crucial for mitigating these risks.

Question 4: How can one advance their career in the field of aerospace coatings?

Career advancement typically involves acquiring specialized certifications, gaining expertise in advanced coating techniques, and developing strong leadership skills. Progression to supervisory roles or specialized positions in research and development is possible with experience and ongoing professional development.

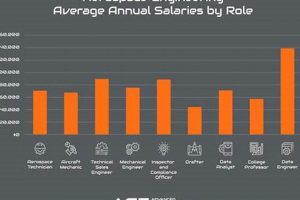

Question 5: What is the general compensation range for aerospace coating professionals?

Compensation varies based on experience, education, certifications, and geographic location. Entry-level positions may offer hourly wages, while experienced professionals in specialized roles can earn significantly higher salaries. Researching salary benchmarks for specific positions and locations is recommended.

Question 6: What is the impact of automation on aerospace coatings positions?

While automation is becoming increasingly prevalent, it is not expected to eliminate the need for skilled technicians. Rather, it will likely shift the focus towards operating and maintaining automated coating systems, requiring professionals to develop expertise in robotics, programming, and data analysis.

These FAQs highlight key considerations for individuals interested in pursuing or advancing their careers within this specialized domain. Proactive engagement with the discussed aspects can enhance professional success.

The succeeding section will provide guidance on resources for further exploring training and employment possibilities.

Concluding Remarks on Opportunities in Aircraft and Spacecraft Surface Treatment

This exploration has highlighted the multi-faceted nature of vocations centered on the application, maintenance, and development of protective surface treatments for aircraft and spacecraft. These “aerospace coatings jobs” demand a blend of technical proficiency, adherence to stringent safety and environmental regulations, and a commitment to continuous learning in a rapidly evolving technological landscape. The criticality of these roles in ensuring the longevity, performance, and safety of aerospace assets cannot be overstated.

As the aerospace industry continues to advance, the demand for skilled professionals in surface treatment is expected to remain robust. Individuals seeking to enter or advance within this field are encouraged to pursue relevant education, acquire specialized certifications, and remain abreast of emerging technologies. The integrity and reliability of air and space travel depend significantly on the expertise and dedication of those fulfilling these vital functions; thus, their continued growth is essential. A proactive approach to skill development and industry engagement will enhance prospects for long-term success within this technically demanding and impactful domain.