Opportunities within the aerospace sector at Beaver Aerospace offer a range of positions spanning engineering, manufacturing, quality control, and administrative support. These roles contribute to the production of components and systems used in aircraft and related technologies. For example, positions may involve designing precision parts, operating specialized machinery, or ensuring adherence to stringent quality standards.

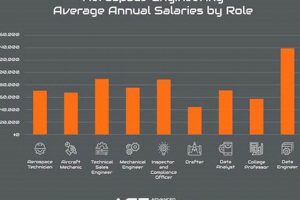

Employment in this field provides access to a technically advanced environment, contributing to advancements in aviation and space exploration. Historically, such positions have been stable and well-compensated due to the specialized nature of the work and the high demand for skilled professionals in the aerospace industry. The sector’s importance lies in its contribution to national security, global transportation, and technological innovation.

The following sections will detail specific job functions, required qualifications, and the overall career prospects associated with working within this company and related fields. Information will also be provided on the company’s mission and values, offering prospective employees insights into the organizational culture.

Securing a position within Beaver Aerospace requires careful preparation and a strategic approach. The following tips offer guidance for individuals seeking employment in this competitive environment.

Tip 1: Research the Company Thoroughly: Gain a comprehensive understanding of Beaver Aerospace’s specific products, services, and market position. Demonstrating knowledge during the application process and interviews signifies genuine interest and initiative.

Tip 2: Highlight Relevant Skills and Experience: Emphasize qualifications that directly align with the desired role. Provide specific examples of accomplishments and quantifiable results from previous positions that demonstrate competence and value.

Tip 3: Tailor Resume and Cover Letter: Customize application materials to reflect the specific requirements outlined in the job description. Generic applications often fail to capture the attention of hiring managers. Use keywords from the job posting to improve searchability.

Tip 4: Prepare for Technical Assessments: Many positions necessitate technical proficiency. Anticipate assessments that evaluate skills in areas such as engineering principles, manufacturing processes, or quality control procedures. Practice common technical questions and review relevant concepts.

Tip 5: Network Within the Aerospace Industry: Attend industry events, join professional organizations, and connect with individuals working at Beaver Aerospace or related companies. Networking can provide valuable insights and potential opportunities.

Tip 6: Demonstrate Problem-Solving Abilities: Aerospace positions often involve addressing complex challenges. Prepare to articulate your problem-solving approach, including the ability to analyze situations, identify solutions, and implement effective strategies.

Tip 7: Emphasize Commitment to Quality and Safety: The aerospace industry operates under stringent quality and safety standards. Highlight any experience in adhering to regulations such as AS9100 or similar quality management systems.

By implementing these strategies, candidates can significantly increase their chances of securing a position within Beaver Aerospace, contributing to advancements in aviation and aerospace technology.

The article will conclude with a summary of career paths and future outlook in the aerospace sector, offering further guidance for aspiring professionals.

1. Engineering Opportunities

Engineering roles at Beaver Aerospace form a cornerstone of its operational capabilities, directly influencing the design, development, and production of aerospace components. These opportunities require specialized expertise and play a crucial role in meeting the stringent demands of the aerospace industry.

- Design Engineering

Design engineers are responsible for creating detailed blueprints and specifications for aerospace parts, ensuring compliance with industry standards and client requirements. This includes utilizing CAD/CAM software, performing stress analysis, and collaborating with manufacturing teams to optimize designs for manufacturability. For example, a design engineer may develop a lighter, more durable bracket for aircraft avionics systems. Their work is essential in ensuring the safety and efficiency of aircraft operations.

- Manufacturing Engineering

Manufacturing engineers focus on improving production processes to enhance efficiency, reduce costs, and maintain quality. This involves selecting appropriate manufacturing techniques, designing tooling and fixtures, and implementing process controls. A manufacturing engineer might optimize the machining process for a turbine blade, thereby reducing cycle time and improving surface finish. This directly impacts the company’s ability to deliver high-quality products on schedule.

- Systems Engineering

Systems engineers take a holistic approach to aerospace projects, integrating various components and subsystems into a cohesive system. They are responsible for defining system requirements, conducting trade studies, and managing interfaces between different elements. For instance, a systems engineer could oversee the integration of a new navigation system into an existing aircraft platform. This requires strong communication and problem-solving skills to ensure seamless integration.

- Quality Engineering

Quality engineers ensure that products meet rigorous quality standards and regulatory requirements. This involves developing and implementing quality control plans, conducting inspections and audits, and analyzing data to identify areas for improvement. A quality engineer may investigate the root cause of a manufacturing defect and implement corrective actions to prevent recurrence. This role is vital in maintaining the reputation and reliability of Beaver Aerospace products.

Collectively, these engineering functions are integral to Beaver Aerospace’s operations. The expertise of engineers directly contributes to the company’s ability to innovate, produce high-quality aerospace components, and meet the evolving needs of the industry. Consequently, these “Engineering Opportunities” represent a critical aspect of what comprises “beaver aerospace jobs.”

2. Manufacturing Positions

Manufacturing positions are a foundational component of “beaver aerospace jobs,” representing the practical application of engineering designs and specifications into tangible aerospace components. The existence of robust manufacturing capabilities directly enables the company to fulfill its operational mandate and meet customer demands. Without skilled manufacturing personnel, the designs and blueprints developed by engineers would remain theoretical, lacking the physical realization necessary for deployment in aircraft and aerospace systems. Examples of manufacturing roles include machinists operating CNC equipment to fabricate precision parts, assembly technicians integrating components into larger assemblies, and welders joining metal structures to meet stringent structural requirements. The accuracy and efficiency of these manufacturing processes directly influence the quality and reliability of the final products, impacting flight safety and operational performance.

Furthermore, the technological advancements in manufacturing techniques, such as additive manufacturing (3D printing) and automated assembly lines, are continually shaping the skill sets required for manufacturing positions. Individuals entering this field must possess adaptability and a willingness to learn new technologies to remain competitive. Consider the shift from manual welding to robotic welding; manufacturing technicians must now be proficient in programming and maintaining robotic systems to ensure consistent weld quality and increased production rates. Therefore, ongoing training and skill development are critical for maintaining a skilled workforce within the manufacturing sector of Beaver Aerospace.

In summary, manufacturing positions are inextricably linked to the success of “beaver aerospace jobs.” These roles translate theoretical designs into practical components, ensuring the safe and efficient operation of aerospace systems. The continued evolution of manufacturing technologies demands a workforce committed to continuous learning and skill development, reinforcing the practical significance of understanding the interplay between manufacturing positions and the broader organizational goals of Beaver Aerospace. This understanding is crucial for both prospective employees and the company to achieve sustained growth and innovation in the aerospace industry.

3. Quality Assurance Roles

Quality Assurance Roles are intrinsic to “beaver aerospace jobs,” functioning as a critical control mechanism that ensures adherence to stringent industry standards and regulatory requirements. These roles directly impact the safety, reliability, and performance of aerospace components and systems, establishing a direct cause-and-effect relationship. Without robust quality assurance processes, even the most innovative engineering designs and efficient manufacturing processes are rendered meaningless, as the final products cannot be guaranteed to meet the necessary specifications for flight readiness.

The significance of quality assurance within “beaver aerospace jobs” is exemplified by the implementation of rigorous inspection protocols at each stage of production. Consider the non-destructive testing (NDT) of critical structural components, such as wing spars. Quality assurance technicians employ techniques like ultrasonic testing and radiographic imaging to detect internal flaws and discontinuities that are invisible to the naked eye. Failure to identify these defects could lead to catastrophic structural failure during flight. Similarly, the calibration and validation of measuring instruments and test equipment are essential to ensure the accuracy and reliability of quality control data. These examples illustrate the practical application of quality assurance principles within “beaver aerospace jobs” and highlight the potential consequences of neglecting these critical processes.

In summary, Quality Assurance Roles are not merely ancillary functions within “beaver aerospace jobs,” but rather integral components that directly safeguard the integrity and reliability of aerospace products. The challenges associated with maintaining high levels of quality assurance in a complex and technologically advanced industry necessitate a highly skilled and dedicated workforce, reinforcing the importance of understanding the connection between these roles and the broader goals of “beaver aerospace jobs.” This understanding is crucial for both prospective employees and the company in fostering a culture of quality and continuous improvement.

4. Technician Careers

Technician careers constitute a vital segment of “beaver aerospace jobs,” providing the hands-on expertise necessary to maintain, repair, and operate complex aerospace systems. Their role is not ancillary but rather foundational, directly affecting the operational readiness and safety of aircraft and related equipment. Without skilled technicians, the theoretical designs of engineers and the refined manufacturing processes would be rendered impractical, as the ongoing maintenance and troubleshooting critical for continuous operation would be absent. This interconnectedness creates a direct cause-and-effect relationship between the availability of competent technicians and the sustained functionality of aerospace assets. Consider the example of an avionics technician diagnosing a faulty radar system on an aircraft; their expertise in using specialized test equipment and interpreting technical manuals directly influences the aircraft’s ability to navigate and operate safely. Therefore, technician careers represent a crucial component of “beaver aerospace jobs.”

Further analysis reveals the practical applications of technician careers within Beaver Aerospace. Examples include aircraft mechanics performing routine inspections and repairs to ensure airworthiness, instrumentation technicians calibrating and maintaining sensitive sensors used in flight testing, and electrical technicians troubleshooting and repairing complex wiring systems. These roles often require specialized certifications and training, reflecting the critical nature of their responsibilities. The demand for skilled technicians is often driven by advancements in aerospace technology; for example, the increasing use of composite materials in aircraft construction necessitates technicians trained in composite repair techniques. This illustrates the dynamic nature of technician careers, requiring ongoing professional development to remain proficient. Furthermore, the stringent regulatory environment governing the aerospace industry necessitates technicians who adhere to strict maintenance procedures and documentation requirements, highlighting the importance of precision and attention to detail.

In summary, technician careers are not merely jobs within the aerospace sector, but integral roles that underpin the safety and operational efficiency of aerospace systems. The challenges associated with maintaining complex equipment, coupled with evolving technological advancements, demand a highly skilled and adaptable workforce. This critical understanding of the connection between technician careers and “beaver aerospace jobs” is essential for fostering a robust and reliable aerospace industry. Potential technicians should consider the significant responsibility and continuous learning involved in this field, while Beaver Aerospace must continue investing in training and development to ensure a qualified technical workforce.

5. Management Structures

The organizational framework within Beaver Aerospace, manifested through its management structures, directly influences the efficiency, innovation, and strategic direction of its operations, consequently impacting the nature and quality of “beaver aerospace jobs.” This framework establishes lines of authority, defines responsibilities, and facilitates communication, all of which are critical for achieving the company’s objectives and fostering a productive work environment. A well-defined management structure ensures resources are allocated effectively, projects are executed efficiently, and employees are aligned with the company’s overall vision.

- Hierarchical Levels and Decision-Making

The number of management layers within Beaver Aerospace affects the speed and accuracy of decision-making processes. A flatter hierarchy can promote agility and empower employees, enabling quicker responses to market changes. However, too few layers may overload managers and hinder strategic oversight. The efficiency of decision-making processes influences the competitiveness of “beaver aerospace jobs” and the company’s ability to adapt to evolving industry demands. For example, expedited approval processes for engineering design changes can result in faster product development cycles.

- Functional Specialization and Collaboration

Management structures often delineate functional areas, such as engineering, manufacturing, and quality control. The degree of specialization within these areas impacts the depth of expertise and the efficiency of operations. However, excessive specialization can hinder cross-functional collaboration and impede innovation. Management must foster communication and coordination between departments to ensure that “beaver aerospace jobs” contribute effectively to shared goals. Regular interdepartmental meetings and project teams are practical examples of this.

- Performance Management and Accountability

Effective management structures incorporate systems for monitoring employee performance, providing feedback, and ensuring accountability. Performance management systems should align individual goals with organizational objectives and provide opportunities for professional development. Clear performance expectations and regular evaluations can enhance employee motivation and improve overall productivity. This, in turn, strengthens the attractiveness and value of “beaver aerospace jobs.” For example, providing employees with specific, measurable, achievable, relevant, and time-bound (SMART) goals tied to company objectives helps ensure accountability.

- Leadership Styles and Employee Engagement

The leadership styles employed by managers within Beaver Aerospace significantly impact employee morale, engagement, and retention. A supportive and empowering leadership style can foster a positive work environment and encourage innovation. Conversely, an authoritarian or micromanaging style can stifle creativity and lead to employee dissatisfaction. The prevailing leadership styles directly affect the attractiveness and sustainability of “beaver aerospace jobs.” For example, leaders who actively solicit and incorporate employee feedback are more likely to foster a culture of continuous improvement.

These facets highlight the critical role of management structures in shaping the character and quality of “beaver aerospace jobs.” A well-designed organizational framework facilitates efficient operations, fosters collaboration, promotes accountability, and enhances employee engagement, ultimately contributing to the company’s success and the attractiveness of its career opportunities. The effectiveness of these structures directly affects the long-term viability and appeal of positions at Beaver Aerospace and influences the overall industry standing.

6. Research and Development

Research and Development (R&D) serves as a crucial catalyst for innovation and technological advancement within Beaver Aerospace, directly influencing the evolution and competitiveness of “beaver aerospace jobs.” The R&D department is tasked with exploring novel concepts, developing advanced materials, and improving existing technologies, ultimately contributing to the creation of cutting-edge products and solutions. This innovative drive directly impacts the types of jobs available, emphasizing roles requiring specialized knowledge in areas such as materials science, advanced manufacturing techniques, and aerospace engineering. Without a robust R&D division, Beaver Aerospace would face stagnation, resulting in a limited scope and diminishing quality of “beaver aerospace jobs.” A direct example is the development of lighter, more durable composite materials for aircraft structures; this innovation not only improves aircraft performance but also necessitates the creation of new engineering and manufacturing roles focused on the application of these materials.

The practical applications stemming from R&D efforts within Beaver Aerospace are diverse and far-reaching. Consider the implementation of computational fluid dynamics (CFD) to optimize aerodynamic designs, or the development of advanced sensor systems for improved aircraft monitoring. These innovations not only enhance product performance but also create a need for skilled engineers and technicians who can operate and maintain these sophisticated technologies. Moreover, the integration of artificial intelligence (AI) and machine learning (ML) into aerospace systems, driven by R&D, generates opportunities for data scientists and software engineers specializing in these domains. The increasing emphasis on sustainability and reduced environmental impact also fuels R&D efforts focused on developing fuel-efficient technologies and alternative propulsion systems, further diversifying “beaver aerospace jobs.”

In conclusion, Research and Development is not merely an isolated function within Beaver Aerospace but an integral component that drives technological progress and expands the scope of “beaver aerospace jobs.” The challenges associated with remaining at the forefront of aerospace innovation require a significant investment in R&D and a commitment to attracting and retaining talented scientists and engineers. Understanding the connection between R&D and “beaver aerospace jobs” is crucial for both prospective employees seeking opportunities in this field and for the company in ensuring its long-term competitiveness and success within the dynamic aerospace industry.

7. Support Staff Needs

The effective functioning of Beaver Aerospace is contingent upon a network of essential support services, thereby establishing a direct relationship between “Support Staff Needs” and the fulfillment of “beaver aerospace jobs.” These roles, while not directly involved in engineering or manufacturing, provide the infrastructure and logistical support necessary for these core functions to operate efficiently. Without adequate support staff, the productivity and effectiveness of engineering, manufacturing, and management personnel would be severely compromised. Examples include administrative assistants managing schedules and communications, IT professionals maintaining critical computer systems, and facilities personnel ensuring a safe and functional work environment. The failure to adequately address “Support Staff Needs” would directly impede the operational effectiveness of “beaver aerospace jobs,” affecting project timelines and overall company performance.

Further analysis reveals the practical implications of underestimating the importance of “Support Staff Needs.” Consider the impact of a malfunctioning IT system on engineering design processes. Without a dedicated IT team to resolve technical issues promptly, engineers may experience significant delays, hindering their ability to meet project deadlines. Similarly, the efficient procurement of materials and supplies, managed by purchasing and logistics personnel, is crucial for maintaining uninterrupted manufacturing operations. Delays in procurement can lead to production bottlenecks, affecting the timely delivery of aerospace components. These examples highlight the interconnectedness between support staff functions and the overall success of “beaver aerospace jobs.” The roles of human resources in talent acquisition, accounting in financial management, and legal counsel in regulatory compliance are additional examples of critical support structures.

In summary, “Support Staff Needs” are not merely peripheral considerations within Beaver Aerospace but integral components that underpin the effective execution of “beaver aerospace jobs.” Recognizing the significance of these roles is crucial for fostering a productive and efficient work environment. Addressing challenges associated with staffing these positions, such as competitive compensation and professional development opportunities, is essential for attracting and retaining qualified personnel. This understanding contributes to the broader theme of organizational effectiveness, highlighting the importance of recognizing and valuing the contributions of all employees, regardless of their specific function within the company.

Frequently Asked Questions About Employment at Beaver Aerospace

The following questions address common inquiries and clarify key aspects of opportunities within the company. It offers further assistance for prospective candidates.

Question 1: What types of roles are typically available?

Available roles often span engineering (design, manufacturing, systems, quality), manufacturing (machinists, technicians, assemblers), quality assurance (inspectors, auditors), and management (project managers, team leads). Opportunities also exist in support functions like IT, HR, and finance.

Question 2: What qualifications are generally required?

Required qualifications vary widely depending on the specific role. Engineering positions typically require a relevant engineering degree (e.g., aerospace, mechanical, electrical). Manufacturing positions may require vocational training, certifications, or an associate’s degree. Quality assurance roles often demand certifications related to quality management systems. Management positions generally require a bachelor’s degree and relevant experience.

Question 3: What is the company culture like?

Beaver Aerospace typically fosters a results-oriented culture that values innovation, precision, and adherence to strict quality and safety standards. Teamwork and collaboration are often emphasized, especially across different functional areas.

Question 4: What is the typical career progression path?

Career progression depends on the individual’s role, skills, and performance. Engineering roles may progress from entry-level positions to senior engineering roles, then to technical leadership or management positions. Manufacturing positions may advance to lead technician roles or supervisory positions. Opportunities for advancement are often available for individuals who demonstrate strong technical skills, leadership potential, and a commitment to continuous learning.

Question 5: What benefits are offered to employees?

Benefits packages generally include health insurance (medical, dental, vision), paid time off (vacation, sick leave), retirement savings plans (401k), life insurance, and disability insurance. Specific benefits offerings may vary.

Question 6: How can I apply for a role?

Application procedures typically involve submitting a resume and cover letter through the company’s online careers portal. Some positions may also require completing an online application form and/or submitting a portfolio of relevant work samples.

These FAQs provided a summary of basic questions and answers. These inquiries often related to employment and working environment.

A summary of the important benefits of working at Beaver Aerospace including competitive compensation, opportunities for professional growth, and the chance to contribute to technologically advanced projects will follow.

Concluding Remarks on Beaver Aerospace Opportunities

The preceding analysis underscores the diverse and interconnected nature of “beaver aerospace jobs.” From engineering and manufacturing to quality assurance and essential support roles, each position plays a crucial part in the company’s overall operations and its contribution to the aerospace industry. The importance of skills, qualifications, and a commitment to quality and safety have been consistently highlighted. Additionally, the analysis examined management structures, research and development, and typical employee benefits, with the intent to offer comprehensive insight.

Potential candidates seeking employment should consider the information presented, recognizing the requirements and opportunities within this technical domain. The aerospace sector demands skilled professionals dedicated to excellence and continuous improvement. Exploring Beaver Aerospace may represent a step toward a challenging and rewarding career, contributing to advances in aviation and aerospace technology and should remain committed to future technological enhancements to maintain leading-edge.