Opportunities with a global engineering business specializing in manufacturing aircraft parts in a South Carolina location are the focus. These positions involve contributing to the production of advanced aerospace components within a specific facility. The roles encompass a range of activities, from skilled manufacturing to engineering and administrative functions supporting plant operations.

The availability of these roles is significant because it represents potential economic growth and job creation in the local community. Furthermore, such employment provides individuals with avenues for professional development within the aerospace industry, a sector characterized by technological innovation and high standards. This location benefits from being part of a larger network, potentially offering stability and career advancement opportunities.

Further information includes details regarding job openings, required skills, application procedures, and the company’s presence in this geographical area. Specific details can be found online.

Successfully pursuing roles at this location requires careful preparation and a strategic approach. The following guidelines provide essential advice for prospective candidates:

Tip 1: Research the Company Culture. Thoroughly investigate organizational values and working environment. Utilize platforms such as Glassdoor or LinkedIn to gain insights from current or former employees. Alignment with the company’s culture can significantly impact job satisfaction and career progression.

Tip 2: Tailor the Application Materials. Generic resumes and cover letters are unlikely to succeed. Customize these documents to highlight relevant skills and experience directly applicable to the specific job description. Emphasize achievements and quantify accomplishments whenever possible.

Tip 3: Prepare for Technical Interviews. Many positions require specialized technical knowledge. Anticipate questions related to manufacturing processes, engineering principles, or quality control procedures relevant to aerospace component production. Refresh relevant technical skills and be prepared to provide detailed explanations.

Tip 4: Highlight Relevant Certifications and Training. Certifications or training programs specific to aerospace manufacturing, quality assurance, or safety protocols can significantly enhance candidacy. Include these credentials prominently on the resume and be prepared to discuss their relevance during the interview.

Tip 5: Demonstrate Problem-Solving Abilities. Aerospace manufacturing often presents complex challenges. Illustrate problem-solving skills by providing specific examples of successfully resolving technical issues or improving processes in previous roles. Quantify the impact of these solutions whenever possible.

Tip 6: Emphasize Safety Consciousness. Safety is paramount in aerospace manufacturing. Demonstrate a strong understanding of safety protocols and a commitment to maintaining a safe working environment. Highlight any experience with safety training or certifications.

Tip 7: Network Strategically. Utilize professional networking platforms such as LinkedIn to connect with individuals working at the facility or in similar roles. Informational interviews can provide valuable insights into the company’s operations and culture.

By adhering to these recommendations, prospective candidates can significantly increase their chances of securing a position. Success requires preparation, attention to detail, and a demonstration of relevant skills and experience.

Further information pertains to application deadlines and contact information for recruitment.

1. Manufacturing Excellence

The pursuit of manufacturing excellence is directly linked to employment. Opportunities at the South Carolina facility are fundamentally shaped by the organization’s commitment to optimizing production processes and achieving superior product quality. This emphasis necessitates a workforce capable of upholding and enhancing these standards.

- Process Optimization

This facet focuses on the continuous improvement of manufacturing workflows. Employees are expected to identify inefficiencies, implement streamlining measures, and adapt to evolving technological advancements. Examples include the introduction of lean manufacturing principles, automation initiatives, and statistical process control. Positions requiring process optimization skills are critical for maintaining operational efficiency.

- Quality Assurance

Quality assurance ensures adherence to stringent aerospace industry standards. Roles in this area involve rigorous inspection, testing, and documentation of manufactured components. Examples of activities include non-destructive testing, dimensional analysis, and root cause analysis of defects. Employees working in quality assurance safeguard product integrity and regulatory compliance.

- Skilled Labor

Manufacturing excellence relies on a skilled workforce capable of operating and maintaining complex machinery, interpreting technical drawings, and executing precise manufacturing processes. Examples include machinists, fabricators, and assembly technicians possessing specialized training and certifications. These skilled workers are essential for translating engineering designs into tangible aerospace components.

- Continuous Training

Sustained manufacturing excellence requires a commitment to ongoing employee training and development. Programs aimed at enhancing technical skills, promoting safety awareness, and fostering a culture of continuous improvement are essential. Examples include apprenticeship programs, vendor-specific training, and internal certification initiatives. Investment in employee development ensures a workforce equipped to meet evolving manufacturing challenges.

The convergence of these facets directly impacts the skill sets sought. Positions within the facility demand individuals capable of contributing to and maintaining a culture of manufacturing excellence. This includes a commitment to process improvement, quality assurance, technical proficiency, and continuous learning.

2. Engineering Innovation

Engineering innovation is a critical component of the operational landscape. Available roles are influenced by the organization’s pursuit of advancements in aerospace component design, manufacturing techniques, and material science. A workforce capable of driving and implementing these innovations is essential for maintaining competitiveness and technological leadership.

- Research and Development

Research and development initiatives are foundational to engineering innovation. Roles in this area involve conducting experiments, developing prototypes, and exploring novel materials and processes relevant to aerospace manufacturing. Examples include the development of advanced composite materials, the optimization of aerodynamic designs, and the integration of additive manufacturing techniques. Employees engaged in R&D contribute to the long-term technological trajectory of the facility.

- Design Engineering

Design engineering translates theoretical concepts into practical designs for aerospace components. Roles encompass creating detailed drawings, performing structural analysis, and ensuring compliance with industry regulations. Examples include the design of lightweight aircraft structures, the development of efficient engine components, and the integration of advanced sensor systems. Design engineers are responsible for ensuring the functionality, safety, and manufacturability of aerospace components.

- Process Engineering

Process engineering focuses on optimizing manufacturing workflows to improve efficiency, reduce costs, and enhance product quality. Roles involve analyzing existing processes, identifying bottlenecks, and implementing innovative solutions. Examples include the automation of repetitive tasks, the development of advanced tooling and fixtures, and the implementation of statistical process control techniques. Process engineers are critical for driving continuous improvement in manufacturing operations.

- Materials Engineering

Materials engineering centers on the selection, testing, and application of materials used in aerospace components. Roles involve characterizing material properties, evaluating performance under various conditions, and developing new material combinations. Examples include the development of high-strength alloys, the application of protective coatings, and the integration of composite materials. Materials engineers ensure that components meet stringent performance and durability requirements.

The skill sets sought for roles at the facility reflect the emphasis on engineering innovation. Positions demand individuals with expertise in research and development, design engineering, process engineering, and materials engineering. A commitment to continuous learning and a passion for technological advancement are essential for success.

3. Local Employment

The presence of a global aerospace manufacturer in Orangeburg, South Carolina, has a direct and measurable impact on local employment. The availability of jobs within this facility contributes to the economic vitality of the region and provides opportunities for residents to pursue careers in the aerospace industry.

- Job Creation

The establishment and expansion of the facility directly generate new employment opportunities for individuals residing in the surrounding areas. These positions span various skill levels, from entry-level manufacturing roles to highly specialized engineering positions. The influx of new jobs can stimulate economic growth and reduce unemployment rates within the local community.

- Economic Impact

Beyond direct job creation, the facility’s operations have a broader economic impact. Employees spend their wages locally, supporting businesses and services within the community. The company also contributes to the local tax base, providing revenue for public services such as schools, infrastructure, and emergency services. The economic activity spurred by the facility benefits various sectors within the region.

- Skills Development

The facility provides opportunities for local residents to develop valuable skills in the aerospace industry. Training programs, apprenticeships, and on-the-job learning enable individuals to acquire technical expertise and advance their careers. The availability of these skill-building opportunities enhances the employability of the local workforce and supports the long-term economic competitiveness of the region.

- Community Engagement

The company’s presence in Orangeburg fosters community engagement and social responsibility. Initiatives such as sponsoring local events, supporting educational programs, and partnering with community organizations demonstrate a commitment to the well-being of the region. This community involvement strengthens the bond between the company and the local population, fostering a positive and mutually beneficial relationship.

The relationship between the aerospace manufacturer and the surrounding community is symbiotic. The facility provides employment and economic opportunities for local residents, while the community provides a workforce and a supportive environment for the company’s operations. This mutually beneficial relationship contributes to the long-term prosperity of both the company and the region.

4. Aerospace Sector

The global aerospace sector provides the overarching context for opportunities at the South Carolina facility. This industry is characterized by stringent regulatory requirements, demanding technical specifications, and a continuous drive for innovation, all of which significantly shape the skills and qualifications sought by employers.

- Regulatory Compliance

The aerospace sector operates under a rigorous regulatory framework established by agencies such as the FAA (Federal Aviation Administration) and EASA (European Union Aviation Safety Agency). Manufacturing processes, materials, and component designs must adhere to these stringent standards to ensure safety and reliability. Positions require knowledge of these regulations and the ability to implement compliance procedures. The facility must maintain certifications and undergo regular audits to ensure adherence to regulatory requirements.

- Technical Expertise

The manufacturing of aerospace components demands a high level of technical expertise in areas such as materials science, structural engineering, and manufacturing processes. Employees must possess specialized skills in areas such as CNC machining, composite fabrication, and non-destructive testing. Positions require a strong understanding of engineering principles and the ability to interpret technical drawings and specifications. The facility benefits from employing skilled engineers and technicians capable of meeting demanding technical requirements.

- Quality Assurance

Quality assurance is paramount in the aerospace sector due to the critical nature of aircraft components. Manufacturing processes must be carefully controlled and monitored to ensure that parts meet stringent quality standards. Positions require a meticulous attention to detail and a commitment to quality control procedures. The facility implements comprehensive quality management systems to minimize defects and ensure product reliability.

- Continuous Innovation

The aerospace sector is characterized by a continuous drive for innovation, with companies constantly seeking to improve aircraft performance, reduce fuel consumption, and enhance passenger safety. Positions require a willingness to embrace new technologies and a commitment to continuous learning. The facility actively invests in research and development to drive innovation in manufacturing processes and component designs.

These facets highlight the demanding nature and the high expectations that come with working in a field. The skills required reflect a deep knowledge and understanding of processes, materials, and standards, all in the aim of manufacturing some of the most safety-critical products.

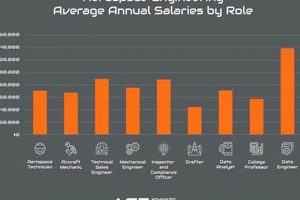

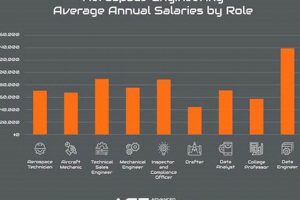

5. Skills Demand

The availability of opportunities is directly correlated with the specific skill sets required to perform effectively in the aerospace manufacturing environment. Positions at the Orangeburg, South Carolina, facility necessitate a blend of technical proficiencies, problem-solving capabilities, and adherence to industry standards. The demand for these skills arises from the complex manufacturing processes, stringent quality requirements, and continuous innovation that characterize the aerospace sector. For example, Computer Numerical Control (CNC) machinists are in constant demand due to the need for precise component manufacturing. Quality assurance inspectors are also critical, ensuring that parts meet exacting specifications. Engineering roles, particularly in design and materials, require specialized knowledge and experience to develop and optimize aerospace components.

The consequences of a mismatch between skills demand and the available workforce can be significant. Deficiencies in critical skills can lead to production delays, quality control issues, and reduced operational efficiency. Consequently, the company invests in training programs, apprenticeships, and partnerships with local educational institutions to cultivate a skilled workforce. Furthermore, the ability to attract and retain talent with the necessary skills is essential for the facility’s long-term success. Companies frequently seek individuals with certifications in areas such as aerospace quality management (e.g., AS9100) or specific manufacturing techniques (e.g., welding certifications). These certifications demonstrate a commitment to professional development and a mastery of essential skills.

Understanding the skills demand landscape is crucial for both job seekers and the organization itself. Prospective employees can tailor their education, training, and experience to align with the specific requirements of available positions. The organization can use this knowledge to develop targeted recruitment strategies and training programs that address skill gaps and ensure a steady supply of qualified personnel. Failure to recognize and address skills demand can impede productivity, innovation, and overall competitiveness in the global aerospace market.

Frequently Asked Questions

The following questions address common inquiries regarding employment opportunities. These answers aim to provide clarity and guidance for prospective candidates.

Question 1: What types of positions are typically available?

Positions span various disciplines, including manufacturing, engineering, quality assurance, and administrative support. Specific openings depend on current operational needs. Detailed job descriptions, including responsibilities and qualifications, are posted on the company’s career website.

Question 2: What are the essential qualifications for engineering roles?

Engineering positions generally require a bachelor’s degree in a relevant engineering discipline, such as aerospace, mechanical, or materials engineering. Experience in aerospace manufacturing or a related field is often preferred. Specific skills depend on the role, but may include proficiency in CAD software, structural analysis, or materials characterization.

Question 3: Does the company offer training or apprenticeship programs?

The company recognizes the importance of skills development and may offer training or apprenticeship programs, depending on the needs of the organization. These programs provide opportunities for individuals to gain practical experience and develop technical skills relevant to the aerospace industry. Details can be found on the website.

Question 4: What is the application process?

The application process typically involves submitting a resume and cover letter online through the company’s career website. Selected candidates may be invited for interviews, which may include technical assessments. Thorough preparation and a clear demonstration of relevant skills are essential for success.

Question 5: What is the work environment like?

The work environment emphasizes safety, quality, and teamwork. Employees are expected to adhere to strict safety protocols and contribute to a culture of continuous improvement. The facility values collaboration and provides opportunities for professional development. Details regarding organizational culture are accessible on professional networking sites.

Question 6: How can I stay informed about new job openings?

Regularly monitoring the company’s career website is the most effective way to stay informed about new job openings. Individuals can also sign up for job alerts or follow the company on professional networking platforms such as LinkedIn.

These questions and answers provide a foundational understanding. Further inquiries should be directed to the company’s human resources department.

The upcoming section delves into career advancement.

Conclusion

This article has provided an overview of opportunities in South Carolina. It has examined the factors influencing employment prospects, including manufacturing excellence, engineering innovation, local economic impact, the demands of the aerospace sector, and the specific skills required for success. Understanding these elements is crucial for individuals seeking positions within this environment.

The availability of positions contributes to both individual career paths and the regional economy. Continued investment in skills development and a commitment to manufacturing excellence will be critical for the long-term success of both the facility and its employees. Further investigation into current openings and application requirements is recommended for those seeking employment.