Positions within the technological manufacturing eXchange (TMX) sector focusing on air and space vehicle design, construction, and maintenance represent opportunities for individuals with diverse skill sets. These careers encompass roles ranging from engineering and manufacturing to project management and quality assurance, all contributing to the advancement of flight and space exploration technologies. For example, a systems engineer could be designing the navigation system for a new aircraft, while a manufacturing technician could be assembling components for a satellite.

The significance of these roles stems from the critical nature of the aerospace industry in global transportation, communication, and national defense. Professionals in this area contribute to innovations that improve flight safety, reduce environmental impact, and enable space exploration. Historically, demand in this field has fluctuated with technological advancements and geopolitical events, but the long-term trajectory points toward sustained growth driven by increasing global connectivity and the ongoing exploration of space.

The following sections will provide a detailed analysis of the specific skills, educational requirements, and potential career paths available, while also discussing factors impacting growth within this technologically advanced domain.

The following guidance aims to assist individuals seeking to establish or advance their careers within organizations leveraging the TMX platform for aerospace projects. Emphasis is placed on strategies for maximizing visibility, demonstrating relevant skills, and targeting opportunities aligned with long-term professional goals.

Tip 1: Develop Specialized Technical Expertise: Focus on acquiring in-demand skills such as CAD/CAM software proficiency, materials science knowledge, or avionics systems understanding. Certification programs and advanced coursework can validate expertise and enhance marketability.

Tip 2: Cultivate Cross-Functional Competencies: Demonstrate an ability to collaborate effectively across disciplines, including engineering, manufacturing, and supply chain management. Experience working on integrated project teams strengthens a candidate’s appeal.

Tip 3: Leverage TMX Networking Features: Actively participate in relevant industry forums and connect with professionals working on aerospace initiatives via the platform. Building relationships with potential employers can lead to unadvertised opportunities.

Tip 4: Optimize Online Professional Profiles: Ensure online profiles, such as LinkedIn and TMX profiles, accurately reflect skills, experience, and career aspirations. Tailor profiles to highlight achievements relevant to the desired roles.

Tip 5: Target Companies with TMX Integration: Research organizations actively utilizing the TMX platform for aerospace projects and tailor applications to reflect an understanding of their specific needs and challenges. Demonstrate how expertise can contribute to their objectives.

Tip 6: Showcase Project Portfolio: Develop a portfolio showcasing relevant projects, highlighting contributions and measurable results. Include detailed descriptions of tasks performed, technologies employed, and outcomes achieved. Visual aids such as design schematics or simulation results can further enhance impact.

Tip 7: Stay Informed on Industry Trends: Remain abreast of emerging technologies, regulatory changes, and market developments within the aerospace sector. Demonstrating awareness of industry trends positions candidates as proactive and forward-thinking.

These recommendations emphasize the importance of specialized skill development, strategic networking, and a proactive approach to career management. By implementing these strategies, individuals can increase their visibility and competitiveness within this technologically advanced domain.

The following sections will explore specific career paths and educational requirements relevant to opportunities within this dynamic field.

1. Technical Skill Requirements

Technical proficiency forms the bedrock of success within the technological manufacturing eXchange (TMX) aerospace sector. Positions within this domain demand specialized expertise, ranging from fundamental engineering principles to advanced software and hardware competencies. The specific requirements vary depending on the role, but a common thread is the need for continuous learning and adaptation to evolving technologies.

- CAD/CAM Proficiency

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) skills are essential for creating and optimizing designs, as well as generating instructions for manufacturing processes. Aerospace engineers utilize CAD software to design aircraft components, while CAM software translates these designs into machine-readable code for automated manufacturing equipment. A lack of proficiency can lead to design flaws, manufacturing inefficiencies, and increased production costs.

- Materials Science Knowledge

A deep understanding of materials science is crucial for selecting the appropriate materials for aerospace applications. This includes knowledge of material properties such as strength, weight, corrosion resistance, and thermal behavior. Selecting the wrong material can lead to structural failures, reduced performance, and safety hazards. For example, choosing a material that is not resistant to extreme temperatures could compromise the integrity of an aircraft during flight.

- Avionics Systems Expertise

Expertise in avionics systems, encompassing electronic systems used on aircraft, is vital for designing, developing, and maintaining aircraft navigation, communication, and control systems. This includes knowledge of radar, communication systems, flight management systems, and autopilot systems. Insufficient knowledge can lead to malfunctions, navigation errors, and safety risks. A qualified avionics technician can diagnose and repair complex electronic systems to ensure safe and efficient operation.

- Programming and Simulation Skills

Programming and simulation skills are increasingly important for developing and testing aerospace systems. This includes proficiency in programming languages such as Python or MATLAB, as well as the ability to use simulation software to model the behavior of aircraft and spacecraft. These skills are vital for optimizing designs, identifying potential problems, and reducing the need for expensive physical prototypes. For instance, computational fluid dynamics (CFD) simulations can be used to analyze the airflow around an aircraft wing and optimize its aerodynamic performance.

These facets underscore the critical role of specialized technical skills in ensuring the design, manufacturing, and operation of safe and efficient aircraft and spacecraft within the TMX ecosystem. The continued advancement of aerospace technology necessitates a workforce equipped with these competencies to drive innovation and maintain a competitive edge.

2. Regulatory Compliance Adherence

Adherence to stringent regulatory frameworks is a non-negotiable component within the Technological Manufacturing eXchange (TMX) aerospace sector. This compliance is driven by the inherent risks associated with air and space travel, and its absence can result in catastrophic consequences. Governing bodies such as the Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) establish and enforce comprehensive standards covering aircraft design, manufacturing, maintenance, and operations. For individuals in the roles that involve TMX, understanding and fulfilling these requirements is not merely a procedural matter, but a fundamental aspect of their responsibilities, directly impacting safety and legal liability. For instance, aerospace engineers utilizing TMX platforms for collaborative design must ensure that their designs meet all applicable airworthiness directives and safety standards.

The TMX ecosystem facilitates regulatory compliance by providing a centralized platform for managing documentation, tracking revisions, and ensuring traceability throughout the product lifecycle. This includes maintaining detailed records of materials used, manufacturing processes, and inspection results. Furthermore, the collaborative nature of the platform allows for real-time communication and coordination between various stakeholders, including regulatory agencies, manufacturers, and suppliers. As an example, if a new regulation impacting aircraft safety is issued, the TMX platform can be used to disseminate this information to all relevant parties and track the implementation of necessary changes. Data integrity and security are essential within the TMX environment, as regulatory bodies often require access to audit trails to verify compliance.

Therefore, the connection between regulatory compliance and opportunities in this domain is clear: expertise in regulatory standards and procedures is a critical skill for individuals seeking to advance their careers. Challenges in achieving and maintaining compliance stem from the complexity of the regulatory landscape, the need for continuous updates and training, and the potential for human error. Success in this environment requires a commitment to meticulous documentation, robust quality control processes, and a proactive approach to identifying and addressing potential risks. The emphasis on regulatory adherence underscores the critical role of personnel in maintaining the integrity and safety of aerospace operations within the TMX framework.

3. Innovative Project Participation

Participation in innovative projects directly impacts career trajectories within the technological manufacturing eXchange (TMX) aerospace sector. Such involvement provides opportunities to develop cutting-edge skills, contribute to advancements in aerospace technology, and enhance professional visibility.

- Advanced Materials Research

Engagement in projects focused on the development and application of advanced materials, such as carbon fiber composites or shape memory alloys, offers individuals opportunities to acquire expertise in material science, manufacturing processes, and testing methodologies. For example, contributing to a project that integrates lightweight composites into aircraft structures can significantly reduce fuel consumption and improve performance. This participation not only enhances technical skills but also positions individuals as experts in emerging technologies.

- Autonomous Systems Development

Contributing to the development of autonomous systems, including unmanned aerial vehicles (UAVs) or autonomous flight control systems, provides valuable experience in robotics, artificial intelligence, and sensor technologies. These projects often involve complex algorithms, real-time data processing, and advanced control systems. Participation in such initiatives allows individuals to develop skills in software engineering, systems integration, and testing, making them highly sought after by aerospace companies.

- Space Exploration Technologies

Involvement in projects related to space exploration, such as the design and development of spacecraft, launch vehicles, or satellite systems, offers exposure to a wide range of engineering disciplines, including propulsion systems, thermal management, and radiation shielding. For example, working on a project that develops a new type of rocket engine or designs a life support system for a spacecraft can provide invaluable experience in cutting-edge aerospace technologies and position individuals as leaders in the field.

- Sustainable Aviation Initiatives

Contributing to projects aimed at developing sustainable aviation technologies, such as electric aircraft, biofuels, or noise reduction technologies, provides opportunities to address critical environmental challenges and develop expertise in green technologies. These initiatives often involve collaborations between aerospace companies, research institutions, and government agencies. Participation in such projects allows individuals to develop skills in renewable energy, environmental engineering, and policy development, making them valuable assets in the aerospace industry.

These examples illustrate how participation in innovative projects within the TMX aerospace sector can significantly enhance an individual’s career prospects. By acquiring expertise in emerging technologies, contributing to advancements in aerospace technology, and demonstrating a commitment to innovation, individuals can position themselves as leaders in this dynamic and rapidly evolving field.

4. Cross-Disciplinary Collaboration

Cross-disciplinary collaboration is a foundational element for success within the Technological Manufacturing eXchange (TMX) aerospace sector. Given the intricate nature of aerospace projects, which often span multiple engineering domains, manufacturing processes, and regulatory requirements, the ability to effectively collaborate across disciplines is paramount.

- Integrated Design and Engineering

Aerospace projects typically require the seamless integration of design and engineering efforts across various specialties, including aerodynamics, structural analysis, propulsion systems, and avionics. For example, the design of an aircraft wing necessitates close collaboration between aerodynamicists who optimize the wing’s shape for lift and drag, structural engineers who ensure the wing can withstand flight loads, and manufacturing engineers who develop efficient manufacturing processes. Effective collaboration ensures that design decisions consider all relevant factors and lead to a cohesive and optimized final product. The TMX platform facilitates this by providing a central location for sharing designs, simulation results, and other critical information.

- Manufacturing and Quality Assurance

The transition from design to manufacturing requires close collaboration between design engineers and manufacturing specialists to ensure that designs can be efficiently and reliably produced. Quality assurance teams must also be integrated to ensure that manufactured components meet stringent quality standards. For instance, the manufacturing of a turbine blade for a jet engine requires close coordination between design engineers who specify the blade’s geometry and material properties, manufacturing engineers who develop the casting and machining processes, and quality assurance specialists who inspect the blade for defects. The TMX platform’s workflow management tools help to streamline these processes and ensure that all stakeholders are informed.

- Supply Chain Management and Logistics

Aerospace projects often involve complex global supply chains, requiring close collaboration between manufacturers, suppliers, and logistics providers. Effective collaboration is essential for ensuring that components are delivered on time and meet quality requirements. For example, the production of an aircraft may involve suppliers from multiple countries providing components such as engines, avionics, and landing gear. The TMX platform enables real-time communication and data sharing between these entities, facilitating efficient supply chain management and reducing the risk of delays or disruptions.

- Regulatory Compliance and Certification

Achieving regulatory compliance and obtaining certification for aerospace products requires close collaboration between engineers, quality assurance teams, and regulatory agencies. This collaboration ensures that all aspects of the product, from design to manufacturing to testing, meet the stringent requirements of regulatory bodies such as the FAA or EASA. For instance, the certification of a new aircraft requires extensive testing and documentation, as well as close collaboration with regulatory inspectors. The TMX platform provides a secure and auditable environment for managing regulatory documentation and facilitating communication between stakeholders.

In summary, cross-disciplinary collaboration is not merely a desirable attribute but a fundamental requirement for success in these highly complex projects. The TMX platform plays a vital role in facilitating this collaboration by providing a centralized hub for communication, data sharing, and workflow management. Individuals seeking to advance their careers should prioritize developing strong communication, teamwork, and problem-solving skills.

5. Supply Chain Integration

Within the Technological Manufacturing eXchange (TMX) framework, the efficacy of supply chain integration profoundly influences the success of aerospace operations. Professionals holding positions that involve the TMX must comprehend and effectively manage the complexities inherent in coordinating a global network of suppliers, manufacturers, and distributors. Efficient supply chain integration directly impacts project timelines, cost control, and the overall quality of aerospace products.

- Global Sourcing and Procurement Optimization

Aerospace manufacturing relies on a global network of specialized suppliers for components ranging from raw materials to sophisticated avionics. TMX roles necessitate the strategic sourcing and procurement of these materials at competitive prices while ensuring consistent quality and timely delivery. Optimizing procurement processes through the TMX platform involves identifying reliable suppliers, negotiating favorable contracts, and implementing robust quality control measures. For instance, a supply chain manager on the TMX might leverage data analytics to identify alternative suppliers in different geographic regions to mitigate risks associated with geopolitical instability or supply chain disruptions.

- Real-Time Visibility and Traceability

Effective supply chain integration requires real-time visibility into the location and status of components throughout the supply chain. The TMX platform facilitates this by providing a centralized system for tracking orders, monitoring inventory levels, and managing logistics. This enhanced visibility allows for proactive identification of potential delays or disruptions and enables rapid response measures to minimize their impact. For example, if a critical component is delayed due to unforeseen circumstances, the TMX platform can be used to reroute shipments or identify alternative sources to maintain project timelines.

- Collaborative Forecasting and Demand Planning

Accurate demand forecasting is essential for optimizing inventory levels and avoiding stockouts or overstocking. TMX roles involve collaborating with suppliers and customers to develop accurate demand forecasts and implement efficient demand planning processes. The TMX platform facilitates this collaboration by providing a shared platform for sharing forecast data, tracking order patterns, and managing inventory levels. By improving demand forecasting accuracy, organizations can reduce inventory costs, improve customer service, and minimize waste.

- Risk Management and Contingency Planning

Aerospace supply chains are vulnerable to a variety of risks, including natural disasters, geopolitical instability, and supplier bankruptcies. TMX roles involve identifying and mitigating these risks through proactive risk management and contingency planning. The TMX platform can be used to assess supplier risks, develop contingency plans, and track the implementation of risk mitigation measures. For example, if a critical supplier is located in a region prone to earthquakes, the TMX platform can be used to identify alternative suppliers and develop contingency plans to ensure continued supply in the event of a disruption.

The integration of supply chain processes within the TMX framework is therefore essential for optimizing efficiency, reducing costs, and mitigating risks. Professionals operating in roles that use the TMX must possess a thorough understanding of supply chain dynamics and be adept at leveraging the platform’s capabilities to manage complex global supply networks effectively.

6. Quality Assurance Protocols

Quality assurance protocols are integral to roles within the technological manufacturing eXchange (TMX) aerospace sector. The aerospace industry’s stringent safety and performance requirements necessitate rigorous quality control at every stage of design, manufacturing, and maintenance. The implementation and adherence to these protocols are not merely procedural; they are foundational to ensuring the reliability and airworthiness of aircraft and spacecraft. For example, a quality assurance engineer utilizing the TMX platform would be responsible for verifying that all components meet specified tolerances and material properties, as well as documenting these verifications in accordance with industry regulations. This includes meticulous tracking of materials, processes, and inspection results, all managed through the TMX system to maintain traceability and accountability.

The TMX platform serves as a centralized hub for managing quality-related data and workflows, facilitating collaboration among various stakeholders involved in the aerospace supply chain. This integration streamlines the process of identifying and addressing potential quality issues, reducing the risk of defects and ensuring that products meet required standards. For instance, if a supplier reports a non-conformance issue with a batch of fasteners, the TMX platform can be used to immediately notify all affected parties, initiate corrective actions, and track the resolution of the issue. This level of visibility and control is essential for maintaining quality standards and preventing costly delays or rework. Furthermore, the platform supports automated testing and validation processes, reducing the reliance on manual inspections and improving the accuracy and efficiency of quality control activities. This could involve using TMX integrated software to run simulations of flight systems, verifying compliance with safety regulations before physical prototypes are even built.

In summary, a comprehensive understanding of quality assurance protocols is not only beneficial but essential for professionals seeking opportunities that involve the TMX platform. The TMX enhances quality by providing a framework for standardization, traceability, and collaboration, addressing challenges such as complexity in the supply chain. In essence, this integration underpins safety, reliability, and regulatory compliance within the aerospace industry, making it a central consideration for career advancement. As such, professionals seeking positions in the Technological Manufacturing eXchange Aerospace domain benefit greatly from a thorough understanding of quality assurance, and the TMX platforms integration with those processes.

Frequently Asked Questions Regarding Technological Manufacturing eXchange (TMX) Opportunities in Aerospace

The following addresses common inquiries pertaining to careers facilitated through the TMX platform within the aerospace sector. The information provided is intended to offer clarity regarding skill requirements, industry trends, and potential career pathways.

Question 1: What specific technical skills are most in-demand for positions accessed via the TMX platform in aerospace?

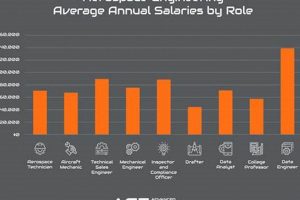

Demand is consistently high for proficiency in CAD/CAM software, materials science, avionics systems, and programming languages relevant to aerospace engineering. Expertise in simulation software and data analysis is also increasingly valued. Employers often seek candidates with certifications validating these skills.

Question 2: How does regulatory compliance impact career opportunities in the TMX aerospace sector?

Regulatory compliance is paramount. Positions requiring knowledge of FAA or EASA regulations are consistently available. Professionals who demonstrate a thorough understanding of airworthiness standards, safety regulations, and quality control procedures are highly sought after.

Question 3: What are the primary benefits of participating in innovative projects within the TMX ecosystem?

Participation in innovative projects provides opportunities to develop cutting-edge skills, contribute to technological advancements, and enhance professional visibility. Involvement in research and development projects related to advanced materials, autonomous systems, or sustainable aviation can significantly boost career prospects.

Question 4: How does cross-disciplinary collaboration influence job performance within the TMX aerospace sector?

Effective cross-disciplinary collaboration is critical. Aerospace projects necessitate seamless integration of design, engineering, manufacturing, and quality assurance efforts. Individuals who can effectively communicate and collaborate across disciplines are highly valued.

Question 5: What role does supply chain integration play in career opportunities facilitated through the TMX platform?

Supply chain integration is essential for efficient aerospace operations. Professionals with expertise in global sourcing, procurement optimization, real-time visibility, and risk management are in demand. Understanding how to leverage the TMX platform for supply chain management is a valuable asset.

Question 6: How does the TMX platform facilitate quality assurance in the aerospace industry?

The TMX platform provides a centralized hub for managing quality-related data and workflows. It facilitates collaboration among stakeholders, streamlines the identification and resolution of quality issues, and supports automated testing and validation processes. Professionals with expertise in quality assurance protocols and TMX platform utilization are highly sought after.

In summary, individuals seeking to advance their careers within the technologically advanced manufacturing exchange (TMX) aerospace sector should prioritize acquiring specialized technical skills, demonstrating a commitment to regulatory compliance, participating in innovative projects, and developing strong collaborative abilities. The TMX platform serves as a valuable tool for connecting professionals with opportunities and facilitating efficient operations.

The subsequent analysis will delve into projected future trends impacting employment in the described technologically advanced manufacturing exchange (TMX) aerospace sector.

Conclusion

This exploration of TMX aerospace jobs has illuminated the sector’s core demands, emphasizing the critical role of technical expertise, regulatory compliance, collaborative skills, and quality assurance. The technologically advanced manufacturing exchange serves as a central platform, connecting professionals with opportunities while streamlining complex processes within the aerospace supply chain. The analysis has detailed the specific skills and knowledge required to succeed in various roles, as well as the importance of continuous learning and adaptation in this rapidly evolving field.

As technology advances and global demand for aerospace solutions increases, the need for qualified professionals in this sector will continue to grow. Individuals who proactively develop the necessary skills, embrace innovation, and demonstrate a commitment to safety and quality will be well-positioned to thrive. A thorough understanding of the TMX platform and its capabilities is increasingly essential for navigating and excelling in this dynamic industry. Continued focus on these areas is crucial for both individual career advancement and the sustained success of the aerospace sector as a whole.

![Find Top Aerospace Jobs in Phoenix, AZ - [Your Company Name] Innovating the Future of Flight with Reliable Aviation Solutions Find Top Aerospace Jobs in Phoenix, AZ - [Your Company Name] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/01/th-729-300x200.jpg)