Positions within the aerospace engineering field in Dubai encompass a range of roles related to the design, development, testing, and maintenance of aircraft, spacecraft, and related systems located within the Emirate. These employment opportunities can span various specializations, including aerodynamics, propulsion, structural analysis, and avionics. For example, an engineer might be involved in optimizing the performance of a commercial airliner’s wings or developing new technologies for unmanned aerial vehicles.

These roles contribute significantly to the growth of Dubai’s aviation sector and its overall economic diversification strategy. Historically, Dubai has invested heavily in developing its aviation infrastructure, making it a major hub for international travel and logistics. The demand for skilled professionals in this sector is fueled by the ongoing expansion of airlines, airports, and aerospace-related industries within the region. The presence of such specialized roles demonstrates a commitment to technological advancement and innovation.

The following sections will delve into the specific sectors offering these opportunities, the required educational qualifications and skills, the salary expectations associated with such roles, and the best strategies for successfully pursuing a career within this dynamic industry.

Strategies for Securing Aerospace Engineering Positions in Dubai

Successfully navigating the job market for aerospace engineering roles within Dubai requires strategic preparation and proactive engagement. This section outlines essential guidelines to enhance prospects.

Tip 1: Focus on Relevant Qualifications: Possessing a bachelor’s or master’s degree in aerospace engineering, or a closely related field, is fundamental. Supplement formal education with specialized certifications relevant to areas such as airworthiness, structural analysis, or avionics systems.

Tip 2: Cultivate Industry-Specific Skills: Proficiency in industry-standard software such as CATIA, ANSYS, or MATLAB is highly valued. Develop practical experience through internships or research projects that align with the demands of the Dubai aerospace sector, specifically concerning aircraft maintenance, design modifications or material science.

Tip 3: Network Strategically: Actively participate in industry events, conferences, and online forums to connect with professionals working within Dubai’s aviation and aerospace industries. Building relationships with individuals in these sectors can provide valuable insights and potential job leads.

Tip 4: Research the Local Market: Understand the specific needs and priorities of aerospace companies operating in Dubai. Tailor applications and resumes to highlight relevant skills and experiences that align with these requirements. Research major employers such as Emirates, Etihad Engineering, or the Dubai Aviation Engineering Projects (DAEP) to identify potential opportunities.

Tip 5: Highlight International Experience: Given Dubai’s international business environment, showcasing experience working on global projects or with diverse teams can be advantageous. Emphasize cross-cultural communication skills and adaptability.

Tip 6: Address Visa and Legal Requirements: Familiarize yourself with the visa and work permit regulations for expatriates seeking employment in Dubai. Engage with relevant authorities or immigration consultants to ensure compliance with all legal requirements.

Tip 7: Prepare for Technical Interviews: Anticipate rigorous technical interviews that assess theoretical knowledge and practical problem-solving abilities. Review fundamental aerospace engineering principles and prepare to discuss past projects in detail.

Adhering to these recommendations can significantly increase the likelihood of successfully obtaining a sought-after position within Dubai’s thriving aerospace engineering landscape.

The subsequent sections will provide further guidance on salary expectations, common challenges, and strategies for long-term career advancement in this dynamic field.

1. Market Demand

The demand for qualified aerospace engineers in Dubai is intrinsically linked to the Emirate’s ambitious growth strategies within the aviation and aerospace sectors. The ongoing expansion of airlines, maintenance facilities, and related industries creates a consistent need for skilled professionals to support these operations.

- Airline Expansion and Fleet Modernization

The growth of major airlines based in Dubai, such as Emirates, directly impacts the demand for aerospace engineers. As these airlines expand their fleets with new aircraft and implement modernization programs, there is a greater need for engineers specializing in aircraft maintenance, structural integrity, and performance optimization. For example, the introduction of new aircraft types necessitates engineers with expertise in those specific models.

- Maintenance, Repair, and Overhaul (MRO) Sector Growth

Dubai’s strategic location and advanced infrastructure have fostered a thriving MRO sector. This sector requires a significant number of aerospace engineers for tasks such as aircraft inspections, repairs, modifications, and component overhauls. The increasing complexity of modern aircraft necessitates engineers with specialized skills in areas like avionics, composite materials, and non-destructive testing.

- Government Investment in Aerospace Infrastructure

The Dubai government’s ongoing investment in airport infrastructure, aerospace research and development, and aviation-related education directly stimulates the demand for aerospace engineers. Projects such as the expansion of Dubai International Airport and Al Maktoum International Airport, as well as initiatives to promote aerospace innovation, require engineers with expertise in airport design, air traffic management, and advanced aerospace technologies.

- Aerospace Manufacturing and Technology Initiatives

Dubai is actively seeking to diversify its economy by fostering aerospace manufacturing and technology initiatives. This includes encouraging the development of local aerospace component manufacturers and attracting foreign aerospace companies to establish operations in the Emirate. These efforts create opportunities for aerospace engineers in areas such as design, manufacturing, materials science, and quality control.

In summary, the sustained market demand for aerospace engineers in Dubai is driven by a confluence of factors, including airline expansion, MRO sector growth, government investment, and aerospace manufacturing initiatives. This demand creates a competitive job market for qualified professionals seeking to contribute to the Emirate’s thriving aviation and aerospace industries, therefore increasing the opportunity for “aerospace engineering jobs in dubai”.

2. Required Qualifications

The attainment of specific qualifications directly determines access to aerospace engineering positions within Dubai. These credentials represent a fundamental prerequisite, influencing both the initial screening process and subsequent career progression. A Bachelor’s or Master’s degree in Aerospace Engineering, or a closely related field such as Mechanical Engineering with an aerospace specialization, typically forms the baseline requirement. The absence of such a degree effectively precludes candidacy for most technical roles, illustrating a direct cause-and-effect relationship.

Beyond academic qualifications, practical skills and industry certifications enhance employability. Proficiency in Computer-Aided Design (CAD) software, such as CATIA or SolidWorks, and simulation tools like ANSYS, is frequently mandated. Possession of certifications related to airworthiness, aircraft maintenance, or specific aircraft systems demonstrates a commitment to professional development and specialized knowledge. For instance, an engineer seeking a role in structural analysis may benefit from certification in Finite Element Analysis (FEA). Real-world examples demonstrate that candidates with certifications are often favored due to their demonstrable skills and industry-recognized competence.

In summary, required qualifications act as a gatekeeper, significantly influencing an individual’s prospects within Dubai’s aerospace engineering sector. The possession of relevant academic credentials, technical skills, and industry certifications not only satisfies minimum requirements but also positions candidates for enhanced career opportunities. A comprehensive understanding of these prerequisites is essential for anyone seeking to navigate and succeed in this competitive field. Potential challenges include keeping skills current with evolving technology, emphasizing continuous professional development and certifications.

3. Visa Regulations

Visa regulations constitute a fundamental aspect of securing positions within Dubai’s aerospace engineering sector for foreign nationals. These regulations establish the legal framework governing entry, residence, and employment, thereby directly influencing the ability of international talent to contribute to the Emirate’s aviation industry. Compliance with these regulations is mandatory and often complex.

- Employment Visa Sponsorship

Dubai operates under a sponsorship system, wherein employers must sponsor foreign nationals for employment visas. For aerospace engineering positions, this requires the sponsoring company to demonstrate the necessity of hiring a foreign national, typically requiring evidence that qualified local candidates are unavailable. The visa application process involves submitting documentation related to the applicant’s qualifications, experience, and the company’s credentials. Failure to secure employer sponsorship effectively bars foreign nationals from legally working in Dubai.

- Educational Attestation and Equivalence

Visa applications for aerospace engineering roles necessitate the attestation and equivalence of educational qualifications. Degrees obtained from foreign universities must be attested by relevant authorities in both the country of origin and the UAE. Furthermore, the qualifications must be deemed equivalent to UAE standards. This process ensures that foreign-educated engineers possess the requisite knowledge and skills to meet the demands of the local aerospace industry. Discrepancies in educational equivalence can lead to visa application rejection.

- Medical Fitness Requirements

Applicants for employment visas in Dubai are subject to medical fitness assessments. These assessments are designed to identify individuals with communicable diseases or other health conditions that may pose a risk to public health. For aerospace engineering positions, this is particularly relevant due to the safety-critical nature of the work. Failure to meet the medical fitness requirements will result in visa denial.

- Labor Law Compliance

Visa regulations are intertwined with UAE labor laws, which govern the rights and responsibilities of employers and employees. Employers sponsoring foreign nationals for aerospace engineering positions must adhere to these labor laws, ensuring fair wages, working conditions, and termination procedures. Non-compliance with labor laws can result in penalties for employers and jeopardize the visa status of employees.

In conclusion, visa regulations serve as a critical determinant for foreign nationals seeking aerospace engineering roles in Dubai. Compliance with sponsorship requirements, educational attestation processes, medical fitness standards, and labor law provisions is essential for navigating the visa application process successfully. These regulations underscore the importance of careful planning and adherence to legal requirements when pursuing career opportunities in Dubai’s aerospace industry.

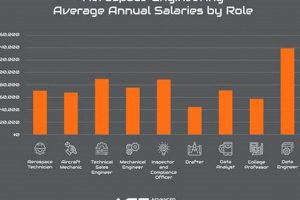

4. Salary Expectations

Compensation associated with aerospace engineering positions in Dubai is directly influenced by several factors, including experience level, educational qualifications, specialization, and the specific employer. An engineer with a master’s degree and five years of experience in structural analysis can command a higher salary than a recent graduate with a bachelor’s degree, illustrating a direct correlation between qualifications and earning potential. Understanding prevailing salary trends is crucial for both job seekers and employers, impacting talent acquisition and retention strategies. For instance, offering a competitive compensation package is essential to attract highly skilled engineers from international markets.

The significance of salary expectations as a component of positions within Dubai’s aerospace engineering sector extends beyond mere remuneration. Competitive compensation reflects the value placed on specialized skills and expertise, thereby contributing to employee satisfaction and productivity. Furthermore, transparency in salary ranges promotes fairness and equity within the workplace. Real-world examples underscore the impact of compensation on employee morale; a survey conducted by a local aerospace firm revealed that engineers who perceived their salaries as fair were more likely to be engaged and committed to their work. Conversely, perceived pay inequity can lead to dissatisfaction and increased employee turnover.

In summary, realistic salary expectations are integral to the success of both individuals and organizations operating in Dubai’s aerospace engineering landscape. They function as a crucial mechanism for attracting and retaining talent, fostering employee satisfaction, and promoting a fair and equitable work environment. Challenges may arise in accurately assessing the value of specialized skills and navigating fluctuating market conditions. A proactive approach to understanding industry benchmarks and adjusting compensation strategies accordingly is essential for sustained success.

5. Industry Sectors

The array of opportunities available to aerospace engineers in Dubai is significantly shaped by the diverse range of industry sectors operating within the Emirate. Understanding these sectors provides crucial context for those seeking positions, enabling them to target their efforts effectively. The aviation and aerospace landscape in Dubai encompasses not only airlines but also maintenance, repair, and overhaul (MRO) providers, manufacturing entities, and governmental agencies. Each sector presents distinct career paths and skill requirements, influencing both the nature and availability of aerospace engineering positions in Dubai.

- Commercial Aviation

Commercial aviation represents a substantial employer of aerospace engineers in Dubai. Airlines such as Emirates require engineers for a variety of roles, including fleet maintenance, performance optimization, and the integration of new technologies. These engineers work on ensuring the airworthiness and operational efficiency of aircraft, contributing directly to the safe and reliable transportation of passengers and cargo. For example, an aerospace engineer might be involved in optimizing fuel consumption on long-haul flights or troubleshooting complex avionics systems.

- Maintenance, Repair, and Overhaul (MRO)

The MRO sector in Dubai is a rapidly growing area, providing extensive employment opportunities for aerospace engineers. Companies specializing in aircraft maintenance, repair, and overhaul services require engineers for tasks such as structural inspections, engine overhauls, and modifications to aircraft systems. These engineers ensure that aircraft meet stringent safety standards and regulatory requirements. A specific example includes performing non-destructive testing on aircraft wings to detect potential cracks or corrosion.

- Aerospace Manufacturing and Component Supply

Dubai is actively fostering the development of aerospace manufacturing capabilities. This sector includes companies involved in the production of aircraft components, such as structural parts, interiors, and avionics systems. Aerospace engineers in this sector work on design, manufacturing processes, and quality control, contributing to the local production of aerospace components. A real-world instance involves an engineer optimizing the manufacturing process for composite aircraft panels.

- Governmental and Regulatory Agencies

Governmental and regulatory agencies, such as the Dubai Civil Aviation Authority, employ aerospace engineers to ensure compliance with safety regulations and to oversee the development of aviation infrastructure. These engineers play a crucial role in setting standards for aircraft maintenance, air traffic management, and airport operations. For instance, an engineer might be involved in conducting safety audits of airlines or evaluating proposed changes to air traffic control procedures.

In summary, the industry sectors present in Dubai offer diverse opportunities for aerospace engineers, each with its unique focus and skill requirements. Commercial aviation emphasizes operational efficiency, MRO centers on maintenance and repair, manufacturing focuses on component production, and governmental agencies ensure regulatory compliance. Understanding the nuances of each sector is paramount for aerospace engineers seeking to align their skills and career aspirations with the appropriate opportunities in Dubai.

6. Career Progression

Career progression within aerospace engineering positions in Dubai is a multifaceted process, influenced by experience, education, specialization, and performance. It represents the advancement opportunities available to individuals within this sector and necessitates strategic planning and continuous skill development.

- Technical Specialization

Advancement often involves developing expertise in a specific area of aerospace engineering, such as aerodynamics, propulsion, or avionics. This specialization enhances an engineers value to employers and opens doors to more complex and challenging projects. For instance, an engineer initially involved in routine maintenance tasks may progress to leading structural analysis teams for aircraft modifications after acquiring specialized knowledge in composite materials. This transition exemplifies the direct link between technical expertise and upward mobility within Dubai’s aerospace sector.

- Management Roles

Career progression frequently leads to management positions, where engineers oversee projects, teams, or departments. These roles require strong leadership, communication, and organizational skills, in addition to technical proficiency. An example would be an engineer transitioning from a design engineer to a project manager responsible for coordinating the development of a new aircraft component. This shift indicates a move towards strategic decision-making and resource allocation within aerospace engineering jobs in Dubai.

- Advanced Education and Certifications

Pursuing advanced degrees, such as a Master’s or Doctorate, or obtaining industry-recognized certifications can significantly enhance career prospects. These credentials demonstrate a commitment to professional development and provide engineers with specialized knowledge and skills that are highly valued by employers. An engineer obtaining a certification in airworthiness regulations, for instance, may be promoted to a senior compliance role, illustrating how continuing education fuels career advancement in Dubai.

- International Experience

Dubai’s position as a global aviation hub means that international experience is highly valued. Engineers who have worked on projects in different countries or with multinational teams often have a competitive advantage. This experience demonstrates adaptability, cross-cultural communication skills, and a broader understanding of aerospace engineering practices. Engineers who have previously worked on projects involving international collaborations, for example, are often considered strong candidates for management roles overseeing international projects in Dubai.

These facets collectively contribute to career progression within aerospace engineering positions in Dubai. While technical specialization builds expertise, management roles demand leadership, advanced education enhances credentials, and international experience broadens perspectives. Strategic integration of these aspects optimizes the potential for upward mobility within this sector, contributing to the continued growth and innovation of aerospace engineering jobs in Dubai.

Frequently Asked Questions

The following addresses common inquiries regarding employment within the aerospace engineering sector in Dubai. Information provided aims to offer clarity on relevant aspects, including qualifications, visa requirements, and industry practices.

Question 1: What is the fundamental educational requirement for securing aerospace engineering positions in Dubai?

A Bachelor’s degree in Aerospace Engineering or a closely related field is generally considered the minimum educational requirement. Advanced degrees, such as a Master’s or Doctorate, may be advantageous for specialized roles or career advancement. Certain positions may specify particular areas of specialization within aerospace engineering as prerequisites.

Question 2: Are there specific software proficiencies that enhance candidacy?

Proficiency in industry-standard software such as CATIA, ANSYS, MATLAB, and similar Computer-Aided Design (CAD) and simulation tools is highly recommended. Employers frequently seek candidates with demonstrated experience using these tools in practical aerospace engineering applications.

Question 3: How does the visa sponsorship process typically function for foreign nationals?

Foreign nationals generally require sponsorship from a Dubai-based employer to obtain a work visa. The sponsoring employer is responsible for initiating and managing the visa application process, which involves submitting documentation related to the applicant’s qualifications, experience, and the company’s credentials. Compliance with UAE labor laws is essential.

Question 4: What role does professional certification play in career advancement?

Professional certifications, such as those related to airworthiness, aircraft maintenance, or specific aircraft systems, can significantly enhance career prospects. These certifications demonstrate specialized knowledge and skills, making candidates more competitive in the job market.

Question 5: What are typical avenues for career progression within the aerospace engineering sector in Dubai?

Career progression commonly involves advancing to more specialized technical roles, project management positions, or leadership roles within engineering departments. Continued professional development through advanced education and certifications is often necessary for upward mobility.

Question 6: How important is familiarity with local regulations in the aviation sector?

Familiarity with Dubai’s specific aviation regulations and compliance requirements is highly valuable, particularly for positions related to aircraft maintenance, safety, and airworthiness. Understanding these regulations demonstrates a commitment to industry best practices and ensures adherence to local legal standards.

The aforementioned questions and responses offer foundational insights into the aerospace engineering sector in Dubai. Prospective candidates are advised to conduct thorough research and consult with relevant professionals for comprehensive guidance.

The subsequent section will address common challenges encountered when seeking aerospace engineering jobs, offering strategies for mitigation.

Conclusion

This exploration of aerospace engineering jobs in dubai has illuminated key aspects of this dynamic sector. Demand is driven by airline expansion and MRO growth, while required qualifications emphasize advanced degrees and specialized skills. Visa regulations present a framework for international talent, and salary expectations reflect the value placed on expertise. A range of industry sectors, from commercial aviation to governmental agencies, offers diverse opportunities. Career progression involves technical specialization and leadership advancement.

Successfully navigating the opportunities within aerospace engineering jobs in dubai requires proactive engagement and a commitment to continuous professional development. The Emirate’s dedication to aviation innovation suggests a promising future for skilled professionals who are prepared to contribute to its ongoing success. Focused preparation and understanding of the market are essential for those seeking to establish a fulfilling career within this field.

![Top States: Best States for Aerospace Jobs in [Year] Innovating the Future of Flight with Reliable Aviation Solutions Top States: Best States for Aerospace Jobs in [Year] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-441-300x200.jpg)

![Find Indeed Aerospace Jobs: Your [Area] Career Innovating the Future of Flight with Reliable Aviation Solutions Find Indeed Aerospace Jobs: Your [Area] Career | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-431-300x200.jpg)