Quantifiable data reflecting the consequences and effects of aerospace engineering endeavors, often encompassing economic, societal, and technological domains, are crucial for evaluating the field’s progress. For instance, metrics measuring job creation stemming from aerospace manufacturing or the reduction in air travel time due to aerodynamic advancements exemplify these types of data.

The availability and analysis of such data are paramount for informed decision-making by government agencies, research institutions, and private companies. These metrics support strategic planning, resource allocation, and the assessment of the return on investment in aerospace projects. Historically, the compilation and interpretation of these figures have provided a basis for understanding the contributions of the field and justifying continued support for its development.

The following sections will delve into specific areas where the consequences of advancements within the domain have been meticulously measured and analyzed, demonstrating the broad reach of this critical engineering discipline.

Guidance on Interpreting Aerospace Engineering Consequence Metrics

Effective interpretation of the field’s consequence metrics is crucial for stakeholders to understand its value and direct future development. The following points provide guidance for extracting meaningful insights from this data.

Tip 1: Establish a Clear Baseline. Before assessing the data, define the baseline conditions against which progress will be measured. For example, when evaluating the fuel efficiency gains from new aircraft designs, specify the baseline aircraft model and operating conditions used for comparison.

Tip 2: Consider Multiple Metrics. Reliance on a single metric can provide a skewed understanding. A comprehensive evaluation necessitates considering a range of indicators, encompassing economic benefits, environmental impact, and social consequences.

Tip 3: Account for External Factors. Changes in the metrics may not solely reflect advancements in the field but may also be influenced by external variables such as economic cycles, geopolitical events, and regulatory changes. Adjustments for these factors are often necessary.

Tip 4: Verify Data Sources and Methodologies. The credibility of the data relies on the rigor of its collection and analysis. Investigate the data sources, methodologies, and potential biases to ensure the validity of the results.

Tip 5: Understand the Time Horizon. The consequences of advancements within the domain often manifest over long periods. Short-term metrics may not capture the full extent of the impact; therefore, consider the time horizon when interpreting the data.

Tip 6: Contextualize the Data. Place the findings within the broader context of aerospace engineering trends, technological advancements, and societal needs. Isolated data points lack meaning without appropriate contextualization.

Careful attention to these principles will facilitate a more thorough and nuanced comprehension of the field’s implications. This understanding is vital for guiding strategic investments, fostering innovation, and maximizing the benefits derived from this critical sector.

The subsequent sections will elaborate on the application of these interpretation techniques in specific case studies and industry analyses.

1. Economic Growth

Aerospace engineering directly contributes to economic growth through several interconnected channels. The development, manufacturing, and maintenance of aircraft, spacecraft, and related technologies generate substantial economic activity. Investment in research and development within the field fosters innovation, leading to new products and services that create new markets and expand existing ones. For example, the commercial aircraft manufacturing sector, with companies like Boeing and Airbus, generates significant revenue and supports numerous jobs within their respective supply chains. This tangible output is readily measured and directly reflected in national and international economic indicators.

Furthermore, the skills and knowledge acquired through aerospace engineering education and training contribute to a highly skilled workforce. This workforce not only supports the aerospace industry itself, but also spills over into other high-technology sectors, driving innovation and productivity across the economy. The industry stimulates growth in related fields such as materials science, electronics, and computer science. The development of composite materials for aircraft, initially driven by aerospace requirements, has found applications in various sectors, from automotive to sporting goods, illustrating the broad applicability of aerospace-driven innovations.

In conclusion, aerospace engineering’s effect on economic growth is significant and multifaceted. It directly generates economic activity through manufacturing and related services, creates a highly skilled workforce applicable to various industries, and stimulates innovation across multiple sectors. Understanding the quantifiable effects of aerospace engineering on economic growth is vital for informing government policies and investment decisions, ensuring continued support for a sector with substantial societal and economic benefits. Quantifying these benefits through robust statistical analysis underscores the strategic importance of aerospace engineering.

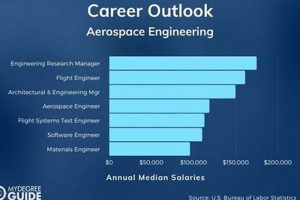

2. Job Creation

Aerospace engineering activities exert a considerable effect on job creation across various sectors. This effect is a significant component of the overall consequence metrics, reflecting the industry’s role as a major employer of highly skilled labor. The development, manufacture, operation, and maintenance of aircraft, spacecraft, and related systems necessitate a diverse workforce. The establishment of a direct causal relationship between aerospace projects and employment figures is crucial for demonstrating the tangible benefits of investment in this sector. For example, the construction of a new aircraft manufacturing plant invariably leads to the creation of thousands of jobs, spanning engineering, production, quality control, and logistics.

Beyond direct employment, aerospace engineering also stimulates indirect job creation. The supply chain supporting the aerospace industry comprises a vast network of companies that provide materials, components, and specialized services. An increase in aerospace manufacturing output, therefore, generates additional demand for these goods and services, resulting in further employment opportunities. For instance, a contract to produce aircraft engines not only creates jobs at the engine manufacturer, but also at the companies that supply the raw materials, machined parts, and testing services. This ripple effect highlights the broader effect on employment beyond the immediate confines of aerospace firms. The practical consequence of understanding this effect lies in the ability to more accurately assess the true economic contribution of aerospace projects.

Job creation arising from activities in this field represents a vital metric. While accurately attributing employment gains solely to aerospace activities can be challenging due to the complex interconnectedness of industries, statistically sound methodologies enable a reasonable assessment. Monitoring these statistics informs policy decisions, justifies public investment in aerospace research and development, and underscores the significance of fostering a skilled workforce to support the continued expansion of the aerospace sector. This understanding links job creation to broader economic and societal benefits, highlighting the enduring consequence of this important engineering discipline.

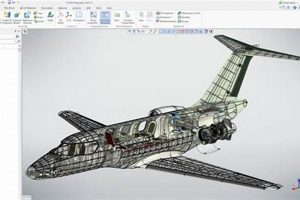

3. Technological Advancements

Technological advancements constitute a central component of the aerospace engineering impact metrics. Progress in materials science, propulsion systems, aerodynamics, avionics, and related fields demonstrably translates into quantifiable benefits. For example, the development of more fuel-efficient jet engines leads directly to reduced fuel consumption for airlines, resulting in lower operating costs and a decreased carbon footprint. Measuring the specific reduction in fuel consumption, coupled with the financial savings and environmental improvements, provides concrete values illustrating the effect of this technological advancement. The implementation of advanced composite materials in aircraft structures reduces weight, enhancing fuel efficiency and payload capacity. The specific weight reduction and the resultant performance gains become key data points for quantifying the advancement’s effect.

The introduction of sophisticated avionics and automation technologies enhances flight safety and operational efficiency. The widespread adoption of automatic landing systems, for instance, has demonstrably reduced the number of landing accidents, particularly in adverse weather conditions. Documenting the reduction in accident rates and the associated cost savings allows for a clear illustration of the advancement’s effect. Furthermore, advancements in satellite technology have revolutionized communication, navigation, and Earth observation capabilities. Increased bandwidth and improved signal accuracy directly benefit various sectors, including telecommunications, agriculture, and disaster response. Quantifying the enhanced capabilities and the economic benefits generated across these sectors offers insight into the broad scope of technological progress.

In conclusion, the measurable effects of aerospace engineering’s technological advancements underscore its importance. While challenges exist in isolating the sole impact of specific advancements due to the integrated nature of aerospace systems, robust statistical methodologies provide valuable assessments. Monitoring these performance improvements, cost reductions, safety enhancements, and broader economic benefits offers a vital foundation for guiding strategic investments, fostering continued innovation, and maximizing the positive effect of aerospace engineering on society. Accurately evaluating and documenting this progress highlights the strategic importance of the field.

4. Safety Improvements

Improvements in safety are a primary objective of aerospace engineering, and the resulting statistics provide critical metrics for evaluating progress in the field. These statistics offer quantifiable evidence of the effectiveness of engineering designs, operational procedures, and technological advancements aimed at reducing risks and enhancing the well-being of passengers, crew, and the public. These are core elements for evaluating the overall effect and merit of aerospace advancements.

- Reduction in Accident Rates

The most direct measure of safety improvement is the decrease in accident rates across various types of aerospace operations. Statistical analysis of accident data, categorized by aircraft type, flight phase, and cause, reveals trends in safety performance. A consistent downward trend in accident rates, correlated with the introduction of new technologies or engineering solutions, demonstrates the tangible impact of these efforts. For example, the development and implementation of enhanced ground proximity warning systems (EGPWS) have demonstrably reduced controlled flight into terrain (CFIT) accidents, showcasing a clear link between engineering innovation and safety outcomes. These metrics are critical for justifying further investment and research into related areas.

- Enhanced Reliability of Aircraft Systems

The reliability of aircraft systems directly affects safety by minimizing the likelihood of malfunctions or failures during flight. Mean Time Between Failures (MTBF) and other reliability metrics provide quantitative assessments of system performance. Improvements in materials, manufacturing processes, and maintenance procedures contribute to enhanced system reliability, resulting in fewer in-flight emergencies and increased operational safety. For instance, the transition from mechanical to digital flight control systems has significantly improved system reliability, reducing the probability of control system failures and enhancing the overall safety of flight operations. Statistics on this transition provides important effect on the overall industry’s performance.

- Improvements in Air Traffic Management

Advanced air traffic management (ATM) systems play a crucial role in preventing mid-air collisions and optimizing airspace utilization. Statistical analyses of air traffic flow, separation distances, and incident reports provide metrics for evaluating the effectiveness of ATM technologies and procedures. The implementation of technologies like Automatic Dependent Surveillance-Broadcast (ADS-B) enhances situational awareness for both pilots and air traffic controllers, contributing to safer and more efficient flight operations. Quantifiable data on reduced near-miss incidents and improved traffic flow efficiency provide evidence of the advancements’ success.

- Enhanced Crew Resource Management

Crew resource management (CRM) training and procedures are designed to improve communication, coordination, and decision-making within flight crews, ultimately reducing the risk of human error. Statistical analysis of flight data recorders (FDR) and cockpit voice recorders (CVR) provides insights into crew performance and the effectiveness of CRM training programs. Reduced instances of communication breakdowns and improved decision-making processes, as reflected in flight data analysis, demonstrate the positive effect of CRM on flight safety. Such data supports the efficacy of CRM protocols.

In summary, safety improvements stemming from aerospace engineering efforts are quantifiable through a range of statistics, including accident rates, system reliability metrics, ATM performance indicators, and measures of crew performance. These statistical measures not only validate the effectiveness of engineering solutions but also provide valuable insights for identifying areas where further improvements are needed. The continual monitoring and analysis of safety-related statistics are essential for ensuring the sustained safety and reliability of aerospace operations, and the ongoing advancement of the field as a whole. These figures directly represent the positive effect of aerospace engineering on the human condition, reinforcing its importance in society.

5. Environmental Effects

Environmental consequences constitute a critical facet of aerospace engineering effect metrics. The operation of aircraft and spacecraft, along with their manufacture and disposal, generates diverse environmental impacts. These consequences encompass air and noise pollution, greenhouse gas emissions, and the depletion of natural resources. The quantification of these environmental effects is essential for understanding the full consequences of activities in the field and for informing strategies aimed at mitigating their negative impacts. Statistical assessments of fuel consumption, emissions levels, noise levels, and resource utilization provide tangible indicators of environmental performance. For example, studies assessing the contribution of aviation to overall greenhouse gas emissions offer insights into the industry’s carbon footprint, which can then inform the development of more sustainable technologies and operational practices.

Efforts to minimize these consequences are increasingly integrated into aerospace engineering design and development processes. The development of more fuel-efficient engines, the utilization of sustainable aviation fuels (SAF), and the implementation of noise reduction technologies exemplify these efforts. Measuring the actual reductions in emissions and noise levels resulting from these innovations provides demonstrable evidence of their effectiveness. Furthermore, the adoption of sustainable manufacturing practices, such as the use of recycled materials and the minimization of waste, contributes to a reduced environmental footprint. Quantifying the reductions in resource consumption and waste generation, using metrics like lifecycle assessments (LCA), is essential for evaluating the environmental benefits of these practices. These practical applications demonstrate a proactive approach to mitigating negative outcomes.

In conclusion, the assessment of environmental effects is inextricably linked to aerospace engineering assessment metrics. The accurate quantification and analysis of environmental consequences are essential for informing decision-making, driving technological innovation, and promoting sustainable practices within the aerospace sector. Meeting the ongoing need to balance technological progress with environmental responsibility relies on robust metrics and a commitment to minimizing the environmental footprint of activities in this essential engineering discipline. A future of reduced impact is dependent on reliable statistic capture and analysis.

6. Defense Capabilities

The advancement and maintenance of national defense capabilities are inextricably linked to aerospace engineering. The statistics that quantify the effect of advancements in this field are critical in assessing and optimizing defense strategies. These statistics serve as a crucial feedback mechanism, informing resource allocation, guiding technological development, and evaluating the effectiveness of defense systems. The relevance is due to the reliance of the defense sector on cutting-edge aerospace technologies.

- Enhanced Surveillance and Reconnaissance

Aerospace engineering enables the development of advanced surveillance and reconnaissance platforms, including satellites, unmanned aerial vehicles (UAVs), and high-altitude aircraft. Statistical data on the operational range, sensor resolution, and data transmission rates of these platforms provide quantifiable measures of their effectiveness in gathering intelligence and monitoring potential threats. Increased coverage area, improved data accuracy, and reduced response times directly enhance situational awareness and decision-making capabilities. Consider, for example, the operational success rates of satellite-based surveillance systems or the data processing efficiency of advanced reconnaissance aircraft.

- Improved Strike Capabilities

Aerospace engineering is central to the design and development of advanced strike weapons, including missiles, precision-guided munitions, and strategic bombers. Statistics on the range, accuracy, and payload capacity of these weapons provide metrics for evaluating their effectiveness in deterring aggression and projecting force. Enhanced precision targeting, increased standoff range, and reduced collateral damage are critical performance parameters that contribute to improved strike capabilities. Quantifying these improvements allows for a clear assessment of the strategic advantage conferred by aerospace advancements. A key example is the statistical increase in the success rate of precision-guided munitions compared to older, less sophisticated weapons systems.

- Advanced Air Mobility and Transport

Aerospace engineering facilitates rapid deployment and logistical support for military forces through the development of advanced air mobility and transport aircraft. Statistics on the payload capacity, range, speed, and reliability of these aircraft provide measures of their effectiveness in moving troops and equipment to distant locations. Enhanced airlift capabilities, reduced deployment times, and improved logistical efficiency directly contribute to increased operational readiness and response capabilities. Consider the statistical improvements in troop deployment times achieved through the introduction of new transport aircraft or the enhanced logistical support enabled by advanced cargo management systems.

- Development of Countermeasures and Defensive Systems

Aerospace engineering plays a crucial role in the development of countermeasures and defensive systems designed to protect against aerial threats, including missile defense systems, electronic warfare capabilities, and advanced radar systems. Statistics on the detection range, tracking accuracy, and interception rate of these systems provide metrics for evaluating their effectiveness in neutralizing potential attacks. Enhanced early warning capabilities, improved target discrimination, and increased defensive coverage contribute to a more secure airspace and reduced vulnerability to enemy action. As a point of consideration, look to the statistical analysis of missile interception rates by advanced defense systems.

These facets of defense capabilities demonstrate the importance of aerospace engineering. The statistical analysis of these advancements directly informs defense planning, resource allocation, and technological development. This interrelation between aerospace engineering, statistical evaluation, and defense strategy highlights the sector’s importance in maintaining national security and promoting international stability. The continuous monitoring and analysis of these metrics are essential for ensuring that defense capabilities remain at the forefront of technological innovation, providing a robust and credible deterrent against potential threats.

7. Scientific Discovery

Aerospace engineering serves as a crucial enabler of scientific discovery, with the impact of this synergy reflected in quantitative metrics across various domains. These metrics demonstrate the contribution of engineering advancements to expanding human knowledge and understanding of the universe. The progress in instrumentation, data acquisition, and remote sensing, facilitated by aerospace innovation, directly correlates with advancements in scientific understanding.

- Space-Based Observatories

Space-based telescopes and observatories, enabled by aerospace engineering, offer unparalleled views of the cosmos, free from atmospheric distortion. Data from these observatories, such as the Hubble Space Telescope and the James Webb Space Telescope, have revolutionized astrophysics, cosmology, and planetary science. The number of peer-reviewed publications, the frequency of citations, and the impact factor of journals publishing these findings serve as quantifiable measures of their effect on scientific discovery. Discoveries such as the characterization of exoplanet atmospheres and the observation of distant galaxies directly translate into advancements in fundamental scientific knowledge.

- Planetary Exploration

Robotic missions to other planets, facilitated by aerospace engineering, provide invaluable data about the composition, geology, and potential habitability of these worlds. Missions to Mars, such as the Mars rovers and orbiters, have revealed details about the planet’s past and present environment, informing our understanding of planetary evolution and the potential for life beyond Earth. Scientific output from these missions is quantified through the number of scientific publications, presentations at conferences, and the creation of new planetary maps and datasets. These data fuel scientific advancements, from understanding the geological history of Mars to informing the search for extraterrestrial life.

- Earth Observation

Satellites equipped with advanced sensors, developed through aerospace engineering, enable continuous monitoring of Earth’s environment, climate, and resources. Data from these satellites contribute to a wide range of scientific disciplines, including climatology, oceanography, ecology, and geology. Quantitative measures of scientific advancement include the accuracy of climate models, the precision of weather forecasting, and the effectiveness of resource management strategies informed by satellite data. For example, data on deforestation rates, ice sheet melt, and ocean acidification, gathered by Earth-observing satellites, drive scientific research and inform policy decisions related to climate change mitigation.

- Microgravity Research

The unique microgravity environment of space, accessed through aerospace platforms like the International Space Station (ISS), enables scientific experiments that are impossible to conduct on Earth. Research in areas such as materials science, biology, and medicine benefits from the absence of gravitational forces, leading to new discoveries and technological innovations. The number of experiments conducted, the publications generated, and the patents filed as a result of microgravity research serve as quantifiable measures of its effect on scientific advancement. Investigations into protein crystallization, fluid dynamics, and bone loss in space contribute to a deeper understanding of fundamental scientific principles and potential solutions to terrestrial challenges.

These examples demonstrate that space-based scientific endeavors produce significant data that propels understanding across various fields. By measuring the output from the fields space-based programs, a clear connection between investments in aerospace engineering and advances in the realm of scientific discovery is shown.

Frequently Asked Questions

This section addresses common queries concerning the use and interpretation of quantitative metrics that reflect the effects of aerospace engineering activities. A comprehensive understanding of these data is crucial for informed decision-making within the industry and in related policy arenas.

Question 1: What constitutes aerospace engineering effect statistics?

The term encompasses quantifiable data points that reflect the consequencesboth positive and negativeof aerospace engineering endeavors. These metrics can include economic indicators, environmental impact assessments, safety records, technological advancement measures, and contributions to scientific knowledge. The purpose is to provide an empirical basis for evaluating the effectiveness and value of aerospace activities.

Question 2: Why are these data considered vital?

These data provide crucial insights for resource allocation, policy formulation, and strategic planning. Government agencies, private companies, and research institutions rely on these metrics to assess the return on investment, justify funding requests, and guide the development of future aerospace technologies. Without a clear understanding of the consequences, decision-making becomes speculative and potentially misdirected.

Question 3: What are the primary sources for these statistics?

Data originates from a variety of sources, including government agencies such as NASA, the FAA, and the Department of Defense; international organizations like the UN and ICAO; industry associations such as the Aerospace Industries Association (AIA); academic research institutions; and private consulting firms specializing in aerospace analysis.

Question 4: How can the data be applied to assess environmental impact?

Statistics related to fuel consumption, emissions levels, noise pollution, and the use of sustainable materials provide quantifiable assessments of the aerospace industry’s environmental consequences. These data enable the monitoring of progress toward sustainability goals, the evaluation of new technologies designed to minimize environmental effects, and the compliance with environmental regulations.

Question 5: Are there challenges in accurately measuring these effects?

Indeed. Establishing direct causal links between specific aerospace engineering activities and broad consequences, such as economic growth or societal benefits, can be complex. External factors, data limitations, and methodological challenges can introduce uncertainty into the measurements. Rigorous statistical techniques and transparent reporting practices are essential for mitigating these challenges.

Question 6: How can stakeholders use these statistics to shape the future of the aerospace industry?

By closely monitoring effect statistics, stakeholders can identify trends, anticipate future challenges, and make informed decisions about investment, innovation, and policy. This proactive approach enables the aerospace industry to maximize its positive contributions to society while minimizing its negative consequences. Ultimately, it ensures that the aerospace sector remains a vital engine of economic growth, technological progress, and scientific discovery.

The appropriate use of these statistics enables informed decision making.

The following section will explore case studies that exemplify the use of these metrics in real-world scenarios.

Conclusion

This exposition has explored the multifaceted domain of aerospace engineering impact statistics, highlighting their significance in quantifying the contributions and consequences of this field. Through the examination of economic growth, job creation, technological advancements, safety improvements, environmental effects, defense capabilities, and scientific discovery, it becomes evident that these metrics are indispensable for evaluating the broad societal effects of aerospace activities. Their thorough and transparent application is a necessity for responsible progress.

Continued refinement and diligent application of aerospace engineering impact statistics are crucial for informed decision-making and strategic planning. These data serve as a vital compass, guiding the industry toward sustainable innovation, enhanced safety, and responsible resource allocation. The enduring advancement of this field relies on a commitment to accurately measuring and interpreting its effects, ensuring that aerospace engineering continues to serve the interests of society while minimizing any potential negative consequences.