This academic pursuit provides individuals with the specialized knowledge and skills necessary to support aerospace engineers in the design, development, testing, and production of aircraft and spacecraft. It is a credential that signifies competency in areas such as materials science, aerodynamics, computer-aided design (CAD), and electronic systems, tailored for application within the aerospace sector. For example, a holder of this qualification might be involved in the fabrication of composite components for an aircraft wing or the testing of propulsion systems in a laboratory setting.

The attainment of this qualification presents numerous advantages. It provides a pathway to a rewarding career in a technologically advanced and constantly evolving field. Individuals gain access to opportunities in research and development, manufacturing, and maintenance within both governmental agencies and private aerospace companies. Historically, the increasing complexity of aerospace systems has driven the demand for skilled technicians capable of bridging the gap between theoretical engineering principles and practical application. The benefits extend to economic stability, as the aerospace industry consistently offers competitive salaries and benefits packages.

The following sections will delve deeper into the specific coursework involved in obtaining this qualification, the potential career paths available upon graduation, and the crucial role technicians play in advancing the frontiers of aerospace technology.

Guidance for Pursuing a Qualification in Aerospace Engineering Technology

The attainment of a credential in aerospace engineering technology necessitates focused preparation and strategic planning. The following tips are designed to maximize the likelihood of success in this challenging and rewarding field.

Tip 1: Strengthen Foundational Skills: A solid understanding of mathematics and physics is crucial. Prioritize coursework in algebra, trigonometry, calculus, and introductory physics to establish a strong base upon which to build specialized aerospace knowledge.

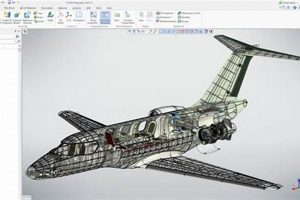

Tip 2: Cultivate Computer-Aided Design (CAD) Proficiency: Familiarity with CAD software is essential for aerospace engineering technicians. Seek opportunities to learn and practice using industry-standard CAD programs such as AutoCAD, SolidWorks, or CATIA. Many online resources and community college courses offer introductory CAD training.

Tip 3: Gain Hands-On Experience: Practical experience enhances theoretical knowledge. Explore internships, volunteer positions, or part-time jobs in aerospace-related fields. Even seemingly basic tasks, such as assisting with aircraft maintenance or assembling model rockets, can provide valuable insights.

Tip 4: Understand Materials Science Fundamentals: A thorough grasp of materials science is vital, given the critical role of materials in aerospace applications. Focus on the properties of metals, composites, and other materials used in aircraft and spacecraft construction. Consider enrolling in a materials science course or independently studying relevant textbooks.

Tip 5: Develop Strong Communication Skills: Effective communication is paramount in collaborative aerospace projects. Practice clear and concise writing, active listening, and persuasive speaking. Seek opportunities to present technical information to diverse audiences. Participate in team projects and learn to navigate complex discussions.

Tip 6: Network with Industry Professionals: Attend aerospace industry events, join professional organizations such as the American Institute of Aeronautics and Astronautics (AIAA), and connect with aerospace engineers and technicians online. Networking can open doors to internships, mentorships, and job opportunities.

Tip 7: Maintain a Growth Mindset: The aerospace field is characterized by continuous innovation. Adopt a mindset focused on lifelong learning, embracing new technologies, and adapting to evolving industry standards. Regularly seek out opportunities for professional development, such as attending workshops, conferences, and training courses.

Adherence to these guidelines increases the likelihood of not only acquiring a qualification in aerospace engineering technology, but also thriving in a demanding and dynamic career. Proactive preparation and a commitment to continuous learning are keys to long-term success.

The subsequent analysis will focus on common career trajectories available to graduates of such programs, providing a comprehensive overview of the professional landscape.

1. Technical Proficiency

Technical proficiency forms the bedrock of competence for an aerospace engineering technician. It represents the practical application of theoretical knowledge acquired during the pursuit of this qualification. This aptitude is indispensable for effective contribution within the aerospace sector.

- Instrumentation and Measurement

This facet encompasses the ability to accurately utilize and interpret data from a variety of instruments used in aerospace testing and maintenance. For example, a technician may employ strain gauges to measure stress on aircraft components or use oscilloscopes to diagnose electrical system malfunctions. Proficiency ensures accurate data collection, which informs critical decisions about aircraft safety and performance.

- Blueprint Reading and Interpretation

Aerospace technicians frequently work with complex blueprints and technical drawings. The capacity to accurately read, interpret, and translate these documents into tangible actions is paramount. An error in interpreting a blueprint could lead to the incorrect assembly of a critical aircraft component, with potentially catastrophic consequences. Therefore, meticulous attention to detail is crucial.

- Materials Fabrication and Repair

The aerospace industry utilizes a diverse range of materials, each with unique properties and manufacturing requirements. Technicians must possess the skills to fabricate, assemble, and repair components using materials such as aluminum alloys, composites, and titanium. This includes welding, riveting, machining, and composite layup techniques. The ability to execute these tasks with precision ensures the structural integrity and reliability of aircraft and spacecraft.

- Troubleshooting and Diagnostics

Aerospace systems are inherently complex, and malfunctions are inevitable. Technical proficiency includes the ability to systematically diagnose and troubleshoot these issues, using a combination of logical reasoning, diagnostic tools, and technical documentation. This skill is essential for minimizing downtime, ensuring efficient maintenance, and maintaining the safety of flight operations. For instance, a technician may use a fault tree analysis to identify the root cause of a hydraulic system failure.

These facets of technical proficiency collectively define the core skillset expected of a graduate holding a aerospace engineering technician degree. Mastering these skills allows graduates to immediately contribute to the design, manufacturing, and maintenance of advanced aerospace systems, thereby underpinning the safety and innovation within the industry. This degree provides the theoretical foundation, but technical proficiency ensures its effective application.

2. Practical application

Practical application is a cornerstone component of an aerospace engineering technician qualification, representing the bridge between theoretical knowledge and the tangible execution of engineering tasks. It is the demonstrable ability to translate principles learned in the classroom into effective action within a real-world aerospace context.

- Manufacturing and Assembly Processes

This facet involves the hands-on execution of manufacturing and assembly techniques utilized in the construction of aircraft and spacecraft. Examples include the precise fitting of structural components, the application of aerospace-grade adhesives, and the installation of electrical wiring harnesses. A graduate must demonstrate competency in these processes to ensure that manufactured components meet stringent quality and safety standards.

- Testing and Evaluation Procedures

Practical application extends to the performance of rigorous testing and evaluation procedures on aerospace systems. This encompasses non-destructive testing (NDT) methods to identify hidden defects, wind tunnel testing to assess aerodynamic performance, and vibration testing to evaluate structural integrity. The accurate execution and interpretation of test results are crucial for validating designs and ensuring operational safety.

- Maintenance and Repair Operations

A significant aspect of practical application lies in the maintenance and repair of existing aircraft and spacecraft. This includes troubleshooting mechanical and electrical systems, replacing worn or damaged components, and performing routine inspections. Technicians must demonstrate the ability to diagnose problems efficiently, implement effective repairs, and adhere to strict maintenance schedules to maintain airworthiness.

- Computer-Aided Design (CAD) and Manufacturing (CAM)

Proficiency in CAD and CAM software is essential for practical application. Technicians utilize these tools to create detailed engineering drawings, simulate manufacturing processes, and generate instructions for computer-controlled machinery. The ability to effectively use CAD/CAM software enables efficient design iteration, accurate manufacturing, and seamless integration between design and production phases.

The integration of these practical skills, fostered through a robust aerospace engineering technician program, enables graduates to contribute meaningfully to all phases of aerospace operations. The ability to apply learned knowledge is what differentiates a qualified technician from someone with solely theoretical understanding, ultimately leading to enhanced safety, efficiency, and innovation within the aerospace industry.

3. Industry Standards

Adherence to established industry standards is paramount for graduates holding an aerospace engineering technician qualification. These standards, codified by regulatory bodies and professional organizations, dictate the practices, procedures, and performance criteria that govern all aspects of aerospace design, manufacturing, and maintenance. Proficiency in these standards is not merely a desirable attribute but a fundamental requirement for ensuring safety, reliability, and interoperability within the global aerospace ecosystem.

- Federal Aviation Regulations (FARs) and European Aviation Safety Agency (EASA) Regulations

These regulations, promulgated by government agencies, mandate specific requirements for aircraft design, operation, and maintenance. An aerospace engineering technician must possess a thorough understanding of the applicable FARs or EASA regulations pertaining to their area of specialization. For example, a technician involved in aircraft maintenance must adhere to strict procedures for documenting repairs and ensuring compliance with airworthiness directives. Failure to comply with these regulations can result in severe penalties, including fines, license revocation, and criminal charges.

- Aerospace Standards (AS) Developed by SAE International

SAE International, a professional organization, develops and publishes a wide range of consensus-based aerospace standards (AS) that address various aspects of aerospace engineering. These standards cover topics such as materials specifications, manufacturing processes, testing methods, and quality control procedures. For instance, AS9100 is a widely recognized quality management standard for the aerospace industry. A graduate with relevant qualification must be familiar with and adhere to these AS standards to ensure that their work meets the highest levels of quality and performance.

- American Society for Testing and Materials (ASTM) Standards

ASTM International develops and publishes voluntary consensus standards for a wide range of materials, products, systems, and services. These standards are frequently referenced in aerospace applications, particularly in relation to materials testing and characterization. For example, ASTM standards define the procedures for testing the tensile strength, fatigue resistance, and corrosion resistance of aerospace materials. Aerospace technicians must be proficient in applying these ASTM standards to ensure the integrity and reliability of aerospace components.

- Military Specifications (MIL-SPECs)

Military specifications (MIL-SPECs) are a set of standards and requirements established by the U.S. Department of Defense for products and services used by the military. These specifications often exceed the requirements of commercial standards and are designed to ensure the highest levels of performance and reliability in demanding environments. Aerospace technicians working on military aircraft or spacecraft must be thoroughly familiar with the applicable MIL-SPECs and adhere to them rigorously.

In summary, a comprehensive understanding and diligent application of these industry standards are indispensable for any individual holding an aerospace engineering technician qualification. These standards provide a framework for ensuring safety, quality, and interoperability within the aerospace industry, and adherence to them is essential for maintaining the integrity of aerospace systems and safeguarding the lives of those who depend on them.

4. Safety Protocols

Stringent adherence to safety protocols is a defining characteristic of the aerospace industry, and mastery of these protocols is an essential outcome of an aerospace engineering technician degree program. The lives of flight crews, passengers, and ground personnel depend on the meticulous application of safety principles at every stage of aircraft design, manufacturing, testing, and maintenance.

- Hazard Identification and Risk Assessment

Aerospace technicians are trained to identify potential hazards associated with their work activities, such as exposure to hazardous materials, operation of heavy machinery, and work at heights. They learn to conduct thorough risk assessments to determine the likelihood and severity of potential accidents and implement appropriate control measures to mitigate those risks. For instance, a technician working with composite materials must understand the risks associated with inhaling composite dust and take precautions such as wearing respirators and working in well-ventilated areas. The ability to proactively identify and mitigate hazards is critical for preventing accidents and injuries.

- Personal Protective Equipment (PPE) and Safe Work Practices

Aerospace engineering technician programs emphasize the proper use of personal protective equipment (PPE), such as safety glasses, hearing protection, and protective clothing. Technicians are trained to select the appropriate PPE for specific tasks and to use it correctly. They also learn and practice safe work procedures, such as lockout/tagout procedures for de-energizing equipment, proper lifting techniques to prevent back injuries, and safe handling of hazardous materials. Consistent adherence to these practices minimizes the risk of injury and illness.

- Emergency Procedures and Response

Aerospace technicians are trained to respond effectively to emergencies, such as fires, chemical spills, and medical emergencies. They learn how to activate alarm systems, evacuate buildings, and provide first aid. They also participate in regular emergency drills to practice their response skills. Knowledge of emergency procedures and the ability to remain calm and act decisively in a crisis can save lives and minimize damage.

- Compliance with Regulatory Requirements

The aerospace industry is heavily regulated, and safety protocols are often mandated by government agencies and industry organizations. Aerospace engineering technician programs ensure that graduates are familiar with relevant regulations, such as those promulgated by the Federal Aviation Administration (FAA) and the Occupational Safety and Health Administration (OSHA). Technicians are trained to comply with these regulations in all their work activities, ensuring that aircraft are maintained to the highest safety standards and that workplaces are safe for all employees.

The commitment to safety instilled by an aerospace engineering technician degree extends beyond mere compliance; it fosters a safety-conscious culture in which every technician takes personal responsibility for preventing accidents and promoting a safe working environment. This proactive approach to safety is essential for maintaining the integrity of the aerospace industry and protecting the lives of those who rely on its products and services.

5. Problem-solving

Problem-solving is an indispensable skill cultivated through an aerospace engineering technician qualification. The inherent complexity of aerospace systems necessitates a robust capacity to diagnose and resolve technical challenges effectively. This aptitude directly impacts the safety, efficiency, and reliability of aircraft and spacecraft operations.

- Fault Isolation and Diagnostics

Graduates with this qualification are equipped to systematically identify and isolate the root cause of malfunctions in complex aerospace systems. This involves utilizing diagnostic tools, interpreting technical documentation, and applying logical reasoning to narrow down potential sources of error. For example, a technician might employ a multimeter to trace a faulty electrical circuit or utilize specialized software to analyze sensor data and identify anomalies in a flight control system. Accurate fault isolation minimizes downtime and prevents cascading failures.

- Component Repair and Replacement Strategies

Problem-solving extends to the development and implementation of effective repair and replacement strategies for damaged or malfunctioning components. This may involve selecting appropriate replacement parts, performing precision repairs using specialized tools and techniques, and verifying the functionality of repaired systems through rigorous testing. For instance, a technician might repair a damaged composite panel on an aircraft wing using composite patching techniques or replace a worn-out hydraulic actuator with a new unit, ensuring proper installation and calibration.

- System Optimization and Performance Enhancement

Aerospace engineering technicians also apply problem-solving skills to optimize system performance and enhance efficiency. This can involve identifying areas for improvement in existing designs, implementing modifications to enhance fuel efficiency or reduce emissions, and troubleshooting performance issues that arise during operation. For example, a technician might analyze engine performance data to identify opportunities for optimizing fuel-air mixture or modify aerodynamic surfaces to reduce drag and improve lift. Such improvements enhance the overall operational effectiveness of aerospace systems.

- Adaptation to Unforeseen Circumstances

The aerospace environment is often unpredictable, and technicians must be able to adapt to unforeseen circumstances and develop creative solutions to unexpected problems. This might involve troubleshooting a system failure in a remote location with limited resources, improvising repairs using available materials, or developing alternative operational procedures to overcome unexpected challenges. The ability to think critically and adapt to changing conditions is crucial for maintaining safe and reliable aerospace operations in dynamic environments.

These facets underscore the critical link between problem-solving abilities and the aerospace engineering technician qualification. The capacity to effectively diagnose, repair, optimize, and adapt is essential for ensuring the continued safety and advancement of aerospace technology. The rigorous training inherent in this qualification equips graduates with the practical skills and analytical mindset required to excel in this demanding field.

6. Continuous learning

Continuous learning is not merely an adjunct to an aerospace engineering technician qualification; it is an intrinsic and indispensable element for sustained professional efficacy. The aerospace field, characterized by its rapid technological advancements and stringent regulatory requirements, necessitates that technicians actively engage in ongoing education and skill enhancement throughout their careers.

- Adaptation to Emerging Technologies

The introduction of new materials, manufacturing processes, and digital tools demands that aerospace technicians proactively acquire new knowledge and skills. For instance, the increasing use of composite materials in aircraft construction necessitates technicians to learn specialized repair techniques and quality control procedures specific to these materials. Similarly, the adoption of advanced diagnostic software requires continuous training to effectively troubleshoot and maintain complex aircraft systems. Failure to adapt to these emerging technologies can render a technician’s skills obsolete and compromise their ability to perform essential tasks.

- Compliance with Evolving Regulatory Standards

Regulatory agencies, such as the Federal Aviation Administration (FAA) and the European Aviation Safety Agency (EASA), regularly update their regulations and standards to reflect technological advancements and address emerging safety concerns. Aerospace technicians must remain current with these changes to ensure compliance and maintain airworthiness. This may involve attending training courses, reviewing regulatory updates, and participating in industry workshops. A commitment to continuous learning ensures that technicians are aware of the latest regulatory requirements and can implement them effectively in their work.

- Professional Development and Advancement

Continuous learning is crucial for career progression within the aerospace industry. Technicians who actively seek out opportunities to enhance their knowledge and skills are more likely to be promoted to positions of greater responsibility and influence. This may involve pursuing advanced certifications, completing specialized training programs, or earning a higher-level degree. Demonstrating a commitment to lifelong learning signals to employers that a technician is motivated, adaptable, and capable of contributing to the ongoing success of the organization.

- Mitigation of Skill Degradation

Without continuous engagement in learning activities, skills acquired during initial training can atrophy over time. This is particularly true for tasks that are performed infrequently or that require specialized knowledge. Regular refresher courses, hands-on practice, and participation in professional development activities can help mitigate skill degradation and ensure that technicians maintain the competence required to perform their duties safely and effectively. This proactive approach to skill maintenance is essential for upholding the highest standards of safety and quality within the aerospace industry.

In essence, continuous learning is not an option but a professional imperative for those holding an aerospace engineering technician qualification. It is the engine that drives adaptation to change, ensures regulatory compliance, facilitates career advancement, and preserves critical skills, thereby underpinning the safety, reliability, and innovation that define the aerospace industry. The pursuit of ongoing education and skill enhancement is a hallmark of a competent and dedicated aerospace technician.

7. Specialized Knowledge

The attainment of expertise within specific domains of aerospace engineering is a defining characteristic of an aerospace engineering technician qualification. This focused knowledge base enables graduates to effectively contribute to specialized tasks within the broader aerospace sector. Proficiency in these areas facilitates innovation, precision, and adherence to rigorous industry standards.

- Aerodynamics and Fluid Mechanics

A thorough understanding of aerodynamics and fluid mechanics is essential for technicians involved in aircraft design, testing, and performance analysis. This knowledge base encompasses the principles of lift, drag, propulsion, and stability, and it allows technicians to interpret wind tunnel data, analyze flight test results, and identify opportunities for aerodynamic optimization. For example, a technician might use computational fluid dynamics (CFD) software to model airflow around an aircraft wing and identify areas where drag can be reduced. Application of these concepts enables the creation of more efficient and higher-performing aerospace vehicles.

- Aerospace Materials and Structures

Specialized knowledge of aerospace materials and structures encompasses the properties, behavior, and manufacturing techniques associated with materials used in aircraft and spacecraft construction. Technicians learn about the characteristics of aluminum alloys, titanium alloys, composite materials, and other advanced materials, as well as the methods used to fabricate and assemble structural components. This knowledge allows technicians to identify potential material defects, perform non-destructive testing, and implement appropriate repair procedures. For example, a technician might use ultrasonic testing to detect cracks in a composite aircraft skin. Such knowledge ensures the structural integrity and safety of aerospace vehicles.

- Avionics and Electrical Systems

A deep understanding of avionics and electrical systems is critical for technicians involved in the maintenance, repair, and troubleshooting of aircraft electrical and electronic equipment. This knowledge base encompasses the principles of electrical circuits, digital electronics, communication systems, navigation systems, and flight control systems. Technicians learn how to use diagnostic tools to identify malfunctions, repair or replace faulty components, and calibrate avionics systems. For example, a technician might troubleshoot a malfunctioning autopilot system using a logic analyzer and circuit diagrams. Expertise in this area guarantees the reliability and safety of aircraft electronic systems.

- Propulsion Systems and Rocketry

Specialized knowledge of propulsion systems and rocketry encompasses the principles of combustion, thermodynamics, and fluid dynamics as they relate to aircraft engines and rocket propulsion systems. Technicians learn about the design, operation, and maintenance of gas turbine engines, ramjets, and rocket engines, as well as the properties of various types of rocket propellants. This knowledge allows technicians to perform engine inspections, troubleshoot performance issues, and implement maintenance procedures to ensure the safe and efficient operation of propulsion systems. For example, a technician might inspect a jet engine for signs of blade damage or corrosion. Competence in this domain supports the development and maintenance of effective propulsion systems.

These specialized areas represent critical competencies fostered by an aerospace engineering technician qualification. Proficiency in these domains allows graduates to function effectively in niche roles within the industry, contributing directly to advancements in aerospace technology and ensuring the safety and reliability of aircraft and spacecraft. Focused expertise is a cornerstone of the qualification’s value.

Frequently Asked Questions About the Aerospace Engineering Technician Qualification

This section addresses common inquiries regarding this specific academic credential. It provides factual responses to clarify its scope and potential career pathways.

Question 1: What is the typical duration of an aerospace engineering technician program?

Program length varies. An associate’s degree program typically requires two years of full-time study. A bachelor’s degree program requires four years.

Question 2: Are there any prerequisites for enrolling in this degree program?

Most programs require a high school diploma or equivalent. A strong background in mathematics and science is advantageous. Some programs may require placement tests.

Question 3: What is the difference between an aerospace engineer and an aerospace engineering technician?

Aerospace engineers typically focus on design and theoretical aspects. Aerospace engineering technicians apply engineering principles to manufacturing, testing, and maintenance.

Question 4: What are the typical job duties of a graduate with this qualification?

Job duties include assisting engineers in design, conducting tests, maintaining equipment, and ensuring compliance with safety regulations.

Question 5: What is the average salary one can expect to earn with this credential?

Salary expectations fluctuate. Factors such as experience, location, and specific employer affect earning potential. Resources such as the Bureau of Labor Statistics can provide current salary data.

Question 6: Are there opportunities for advancement with this degree?

Advancement opportunities exist. Gaining experience and pursuing additional certifications or education enhances career trajectory.

In conclusion, the Aerospace Engineering Technician qualification provides a pathway to a hands-on career in a dynamic industry. Thorough research and careful planning are vital for individuals considering this career path.

The following analysis will delve into real-world examples of how this academic background directly impacts aerospace projects and technologies.

Conclusion

This exploration has detailed the multi-faceted nature of the aerospace engineering technician degree. From foundational technical proficiency to strict adherence to industry standards and the crucial emphasis on continuous learning, the core tenets of this qualification have been thoroughly examined. The importance of practical application, rigorous safety protocols, and advanced problem-solving skills has been underlined, along with the necessity for specialized knowledge in diverse areas such as aerodynamics, materials, avionics, and propulsion systems.

The aerospace engineering technician degree represents a significant investment in a career path that is vital to the advancement and safety of aerospace technology. As the industry continues to evolve, the demand for skilled technicians equipped with this qualification will remain strong. The commitment to excellence inherent in the pursuit of this degree ensures that graduates are well-prepared to contribute meaningfully to the challenges and opportunities that lie ahead. Prospective students are encouraged to carefully consider the rigorous demands and substantial rewards associated with this field.