One field concentrates on the design, development, testing, and production of aircraft and spacecraft. The other addresses the study and application of electricity, electronics, and electromagnetism. While seemingly disparate, both are crucial to technological advancement and share a foundation in mathematics and physics. An example of the first might be designing a new type of commercial airliner, while the second could involve developing more efficient power grids or microchips.

The importance of these domains is undeniable. The first has facilitated global travel and exploration, pushing the boundaries of what is physically possible in the skies and beyond. The second is fundamental to modern communication, computing, and energy distribution, underpinning virtually every aspect of contemporary life. Historically, advancements in these areas have driven economic growth, improved living standards, and shaped geopolitical landscapes.

The remainder of this article will delve into the specific disciplines within each of these two major fields, exploring their current challenges, potential future directions, and the interdisciplinary nature of innovation at their respective frontiers. A comparison of career paths, educational requirements, and emerging technologies will be highlighted to provide a comprehensive overview.

Guidance for Aspiring Professionals

The following outlines several key considerations for individuals contemplating a career in either design, development, and manufacturing of systems operating within Earth’s atmosphere or beyond or the harnessing and application of electrical phenomena. Careful planning and strategic development are paramount for success in these demanding, yet rewarding, fields.

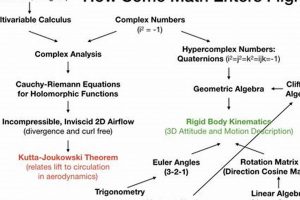

Tip 1: Solidify Foundational Knowledge: A strong understanding of mathematics and physics is indispensable. Rigorous coursework in calculus, differential equations, linear algebra, mechanics, electromagnetism, and thermodynamics will provide the necessary analytical tools.

Tip 2: Cultivate Programming Proficiency: Expertise in programming languages such as Python, MATLAB, or C++ is highly valued. These skills are essential for simulation, data analysis, and the development of automated systems.

Tip 3: Seek Practical Experience: Internships and research opportunities offer invaluable real-world experience. Active participation in projects involving design, testing, or analysis can significantly enhance one’s skillset.

Tip 4: Specialize Strategically: Given the breadth of each field, it is advisable to focus on a specific area of interest. This might include propulsion systems, avionics, power electronics, or control systems. Deeper expertise in one area provides more specialized and valuable skill sets.

Tip 5: Develop Strong Communication Skills: Effective written and oral communication is crucial for collaboration, presentation, and documentation. Clear and concise communication can aid and make the work effectively.

Tip 6: Embrace Lifelong Learning: Technological advancements are rapid. Continuous professional development through conferences, workshops, and independent study is essential to remain competitive. Staying updated to industry trends by learning new materials, and skills.

Tip 7: Understand Regulatory Frameworks: Familiarity with relevant industry standards and regulations, such as those from the FAA or IEEE, is critical for ensuring safety and compliance. Understanding this will ensure safety and compliance.

These considerations represent a starting point for navigating the complex landscape of these fields. By prioritizing fundamental knowledge, practical experience, and continuous learning, aspiring professionals can position themselves for successful and impactful careers. Adhering to these guidelines can greatly assist individuals in these specialized sectors.

The subsequent sections will explore the current research frontiers and future trends shaping these critical engineering disciplines.

1. Innovation

Innovation serves as the cornerstone of progress within both aerospace and electrical engineering. It is the driving force behind advancements in aircraft design, satellite technology, power generation, and electronic devices. The constant pursuit of novel solutions, improved materials, and more efficient systems defines the trajectory of these fields. Without innovation, development stagnates, and societal benefits derived from technological progress diminish. Consider the evolution of aircraft wings: iterative innovations in airfoil design, materials science, and manufacturing processes have resulted in more efficient and safer air travel. Similarly, in electrical engineering, the transition from vacuum tubes to transistors to integrated circuits represents a series of transformative innovations that have revolutionized computing and electronics.

The effects of innovation extend beyond mere technological improvements. It fosters economic growth, creates new industries, and enhances national security. The development of new aerospace technologies, such as reusable rockets, has lowered the cost of space access, opening up new opportunities for commercial spaceflight and scientific research. In electrical engineering, advancements in renewable energy technologies, such as solar panels and wind turbines, are mitigating climate change and promoting energy independence. Furthermore, innovation drives competition, forcing companies to continually improve their products and services. The development of advanced radar systems, for instance, has led to improved air traffic control and weather forecasting, enhancing public safety. Practical applications are numerous and far-reaching, impacting nearly every facet of modern life.

In summary, innovation is not merely a desirable attribute but an absolute necessity for continued advancement in aerospace and electrical engineering. The pursuit of new knowledge, coupled with the application of creative problem-solving techniques, is essential for addressing the complex challenges facing society. While challenges such as funding limitations, regulatory hurdles, and ethical considerations exist, the potential benefits of innovation far outweigh the risks. Continued investment in research and development, coupled with a supportive regulatory environment, is crucial for fostering a culture of innovation and ensuring that these fields continue to drive progress and improve the quality of life for all.

2. Efficiency

Efficiency is a critical performance parameter in both aerospace and electrical engineering, directly impacting operational costs, environmental footprint, and overall system viability. Optimizing for efficiency necessitates a deep understanding of fundamental physical principles and the application of advanced engineering techniques.

- Aerodynamic Efficiency in Aircraft Design

In aerospace, aerodynamic efficiency directly correlates to fuel consumption and range. Designing aircraft with minimal drag, using advanced airfoil shapes, and implementing boundary layer control techniques are essential for maximizing lift-to-drag ratios. For example, the use of winglets reduces induced drag, improving fuel efficiency on long-haul flights. In practical terms, small gains in aerodynamic efficiency translate to significant cost savings and reduced emissions over an aircraft’s operational lifespan.

- Energy Conversion Efficiency in Power Systems

In electrical engineering, the efficiency of energy conversion processes is paramount. Power plants, transformers, and electric motors all contribute to the overall efficiency of the electrical grid. Losses due to heat generation, resistance, and magnetic hysteresis must be minimized. High-efficiency transformers and advanced motor designs, such as permanent magnet synchronous motors, reduce energy waste and improve system performance. For instance, upgrading an old power plant with more efficient turbines can significantly decrease fuel consumption per kilowatt-hour produced.

- Propulsion System Efficiency

The propulsive efficiency of an aircraft or spacecraft dictates the amount of thrust generated per unit of fuel consumed. Advanced engine designs, such as high-bypass turbofans and scramjets, aim to maximize thrust while minimizing fuel burn. Similarly, in electric propulsion systems for spacecraft, efficient ion thrusters and plasma propulsion technologies are crucial for long-duration missions. Improving propulsive efficiency directly translates to increased payload capacity or extended mission duration.

- Power Electronics Efficiency

Power electronics devices, such as inverters and converters, are used to efficiently transform and control electrical power. High-efficiency power electronics are essential for applications ranging from electric vehicle charging to renewable energy integration. Minimizing switching losses, conduction losses, and core losses is critical for maximizing overall system efficiency. Silicon carbide (SiC) and gallium nitride (GaN) based power devices offer improved performance compared to traditional silicon devices, enabling higher switching frequencies and reduced power losses.

The pursuit of efficiency is an ongoing endeavor in both aerospace and electrical engineering, driven by economic, environmental, and performance considerations. Advancements in materials science, computational modeling, and control systems are continuously pushing the boundaries of what is achievable. Continued research and development in these areas are essential for developing sustainable and cost-effective solutions for the future.

3. Safety

Safety is a paramount concern, functioning as an indispensable element within both aerospace and electrical engineering. It is not merely an added feature, but rather a fundamental design constraint that dictates material selection, system architecture, operational procedures, and regulatory oversight. Within aerospace, catastrophic failures can result in significant loss of life and substantial economic consequences. Electrical engineering mishaps, such as power grid failures or malfunctioning medical devices, can equally result in widespread disruption and potential harm. The connection between design and safety is not abstract; flaws in engineering decisions directly translate to tangible risks.

The importance of safety is demonstrated by numerous real-world examples. The Challenger and Columbia space shuttle disasters, both traced to engineering flaws and insufficient safety protocols, underscore the devastating consequences of neglecting safety in aerospace. Similarly, electrical system failures, such as the Northeast Blackout of 2003, highlight the vulnerability of critical infrastructure and the need for robust safety measures in electrical engineering. These events serve as stark reminders of the potential for even minor design flaws or procedural oversights to escalate into large-scale disasters. Consequently, rigorous testing, extensive simulations, and adherence to stringent safety standards are essential components of both disciplines. For example, fail-safe mechanisms, redundant systems, and robust error detection capabilities are routinely incorporated into aerospace and electrical designs to mitigate potential risks.

Understanding the practical significance of safety is critical for all engineers working in these fields. It necessitates a thorough comprehension of potential hazards, risk assessment methodologies, and applicable safety regulations. It also requires a commitment to ethical engineering practices and a willingness to prioritize safety above all other considerations. Challenges remain, including the increasing complexity of systems, the need for continuous innovation, and the potential for human error. Overcoming these challenges demands ongoing research, education, and collaboration among engineers, regulators, and other stakeholders to develop and implement effective safety strategies. Prioritizing safety ultimately protects lives, safeguards infrastructure, and fosters public trust in engineering endeavors.

4. Integration

The confluence of diverse subsystems into cohesive, functional units defines the effectiveness of both aerospace and electrical engineering endeavors. System-level integration is paramount, ensuring that individual components operate harmoniously to achieve overarching objectives. Without effective integration, the performance and reliability of complex systems are significantly compromised.

- Avionics Systems Integration

In aerospace, avionics systems represent a prime example of complex integration. Navigation, communication, flight control, and sensor systems must seamlessly interact to provide pilots with accurate information and reliable control over the aircraft. Integrating these disparate systems requires careful consideration of data interfaces, processing speeds, and redundancy architectures. Failure to properly integrate avionics systems can lead to navigational errors, communication failures, and potentially catastrophic loss of control. Modern commercial airliners rely on highly integrated avionics suites to ensure safe and efficient operation.

- Power Grid Integration

Electrical grids exemplify the challenges of integrating diverse energy sources and distribution networks. Integrating renewable energy sources, such as solar and wind power, requires sophisticated control systems and energy storage solutions to manage intermittent generation patterns. Simultaneously, grid operators must maintain stable voltage and frequency levels while accommodating varying load demands across vast geographical areas. Effective grid integration is essential for ensuring reliable and affordable electricity supply.

- Control Systems Integration

Both aerospace and electrical systems rely heavily on integrated control systems. In aerospace, flight control systems integrate data from multiple sensors to automatically stabilize the aircraft and execute pilot commands. Similarly, in electrical engineering, industrial control systems integrate sensors, actuators, and programmable logic controllers to automate manufacturing processes and optimize energy consumption. The effectiveness of these control systems depends on the accurate and timely integration of data from diverse sources.

- Sensor Fusion and Data Integration

The ability to fuse data from multiple sensors and integrate it into a unified representation is critical for many aerospace and electrical engineering applications. For example, autonomous vehicles rely on sensor fusion to combine data from cameras, lidar, and radar to create a comprehensive understanding of their surroundings. Similarly, in electrical grids, sensor data from various points in the network is integrated to monitor grid health and detect potential faults. Effective sensor fusion and data integration enhance situational awareness and enable more informed decision-making.

These examples underscore the centrality of integration in aerospace and electrical engineering. Whether it’s orchestrating complex avionics systems or managing the flow of electricity across vast networks, effective integration is essential for realizing the full potential of these technologies. The challenges associated with integration are considerable, but the rewards enhanced performance, improved reliability, and greater efficiency make it a critical area of focus for engineers in both fields.

5. Reliability

Reliability stands as a cornerstone in both aerospace and electrical engineering, directly affecting operational safety, mission success, and economic viability. Its importance stems from the complex and often critical nature of the systems developed within these fields. Unreliable aerospace components can lead to catastrophic failures, resulting in loss of life and equipment. Similarly, unreliable electrical systems can cause widespread power outages, disrupt vital services, and jeopardize public safety. Consequently, rigorous design, testing, and maintenance procedures are essential to ensure the dependability of systems and components.

Within aerospace, reliability considerations influence every aspect of design, from material selection to redundancy implementation. For example, aircraft engines are subjected to extensive testing to ensure they can withstand extreme temperatures, pressures, and vibrations. Redundant systems, such as multiple flight control computers or backup power supplies, are incorporated to mitigate the risk of single-point failures. In electrical engineering, reliability is a key factor in the design of power grids, telecommunications networks, and electronic devices. Power grids, for instance, rely on redundant transmission lines and automatic switching systems to maintain service during equipment failures. Similarly, electronic devices incorporate error correction codes and fault-tolerant architectures to improve data integrity and system uptime. The practical applications of reliability engineering are diverse and far-reaching, impacting everything from the safety of air travel to the availability of electricity.

Ensuring reliability presents ongoing challenges, particularly as systems become more complex and operate in increasingly demanding environments. Aging infrastructure, cyber threats, and the integration of new technologies all pose potential risks to system dependability. Overcoming these challenges requires a multidisciplinary approach, combining advanced engineering techniques with proactive maintenance strategies and robust security measures. By prioritizing reliability, engineers can minimize the risk of failures, enhance system performance, and contribute to a safer and more sustainable future. The commitment to reliability is not just a technical imperative but also an ethical obligation.

6. Control

The implementation of control systems is integral to the functionality and performance of aerospace and electrical engineering systems. Control engineering principles ensure stability, accuracy, and efficiency in the operation of dynamic systems, enabling precise management of complex processes and equipment across both domains.

- Flight Control Systems

In aerospace, flight control systems are responsible for maintaining aircraft stability and enabling pilots to maneuver the aircraft safely and effectively. These systems utilize sensors to measure aircraft attitude, velocity, and acceleration, and then employ feedback control algorithms to adjust control surfaces, such as ailerons, elevators, and rudders. Autopilots, a subset of flight control, automate certain aspects of flight, reducing pilot workload and improving fuel efficiency. The precision and reliability of flight control systems are paramount for ensuring aviation safety.

- Power Grid Control Systems

Electrical power grids rely on sophisticated control systems to maintain stable voltage and frequency levels, balance supply and demand, and prevent cascading failures. These systems employ Supervisory Control and Data Acquisition (SCADA) technology to monitor grid conditions in real-time and automatically adjust generator output, transmission line configurations, and load shedding strategies. The integration of renewable energy sources, such as solar and wind power, poses new challenges for grid control, requiring advanced forecasting algorithms and dynamic voltage regulation techniques.

- Robotics and Automation

Control systems are fundamental to the operation of robots and automated machinery in both aerospace and electrical engineering applications. Robots used in aerospace manufacturing, for instance, require precise control over their movements to perform tasks such as drilling, welding, and composite layup. Similarly, automated assembly lines in electronics manufacturing plants rely on feedback control systems to ensure accurate component placement and reliable soldering. Advanced control algorithms, such as model predictive control and adaptive control, enable robots to adapt to changing conditions and perform complex tasks with high precision.

- Embedded Control Systems

Embedded control systems, which integrate microprocessors and control algorithms directly into physical devices, are ubiquitous in both aerospace and electrical engineering. Aircraft engines, for example, utilize embedded control systems to manage fuel injection, ignition timing, and turbine blade cooling. Similarly, electric vehicles rely on embedded control systems to regulate motor torque, battery charging, and regenerative braking. The design and implementation of embedded control systems require a deep understanding of both hardware and software, as well as careful attention to real-time performance and reliability.

These facets highlight the critical role of control systems in ensuring the safe, efficient, and reliable operation of aerospace and electrical engineering systems. The development of advanced control algorithms, coupled with the integration of increasingly sophisticated sensors and actuators, continues to drive innovation and improve performance across both fields.

Frequently Asked Questions

This section addresses common inquiries and dispels misconceptions regarding career paths and foundational knowledge relevant to design, development, and manufacturing of systems operating within Earth’s atmosphere or beyond or the harnessing and application of electrical phenomena.

Question 1: Is a background in both physics and mathematics equally crucial for success in aerospace or electrical engineering?

Both disciplines demand a strong foundation in physics and mathematics; however, the specific emphasis may vary. Mathematics provides the analytical tools, while physics offers the fundamental principles. A deep understanding of both is essential for tackling complex problems.

Question 2: What are the primary differences in day-to-day work between an engineer focused on flight systems and one specializing in power grid management?

Flight systems engineers often engage in design, testing, and simulation of aircraft components or systems, requiring meticulous attention to detail and strict adherence to safety standards. Power grid management engineers focus on optimizing energy distribution, ensuring grid stability, and integrating renewable energy sources. The former emphasizes mechanical and aerodynamic considerations, while the latter focuses on electrical and electromagnetic phenomena.

Question 3: How does one choose between concentrating on hardware versus software aspects within each of these respective fields?

The choice depends on individual aptitude and interests. Hardware-focused engineers work with physical components and systems, requiring hands-on skills and a strong understanding of materials and manufacturing processes. Software-focused engineers develop algorithms, control systems, and simulations, necessitating proficiency in programming languages and software development methodologies. Both paths offer rewarding career opportunities.

Question 4: What role does computer programming play in the advancement of these engineering areas?

Computer programming is integral to the advancement of both fields. It is used for simulation, modeling, data analysis, and the development of control systems. Proficiency in programming languages is essential for engineers seeking to innovate and solve complex problems.

Question 5: Are there specific personality traits that typically align well with professionals in design, development, and manufacturing of systems operating within Earth’s atmosphere or beyond or the harnessing and application of electrical phenomena?

Successful engineers in these fields often possess strong analytical skills, problem-solving abilities, and attention to detail. They are typically curious, persistent, and adaptable. The ability to work collaboratively and communicate effectively is also essential.

Question 6: How significant is the impact of government regulations on the practice of designing, developing, and manufacturing of systems operating within Earth’s atmosphere or beyond or the harnessing and application of electrical phenomena?

Government regulations play a significant role in both fields, particularly in areas related to safety, environmental impact, and security. Compliance with regulations is essential for ensuring that products and systems meet established standards and do not pose undue risks to the public or the environment.

The inquiries addressed above provides a foundational overview. Individual exploration and continued learning are highly encouraged for complete comprehension.

The following sections explores the future perspectives of these critical disciplines.

Conclusion

This article has provided a comprehensive overview of aerospace or electrical engineering, encompassing essential facets from foundational principles to contemporary challenges. Key aspects such as innovation, efficiency, safety, integration, reliability, and control have been examined to illustrate the multifaceted nature of these critical domains. Furthermore, it has addressed frequently asked questions and dispelled common misconceptions regarding career paths and foundational knowledge.

Continued advancement in aerospace or electrical engineering is imperative for societal progress and technological innovation. The pursuit of novel solutions, the adherence to rigorous safety standards, and the integration of emerging technologies will shape the future of these fields. Further research, education, and collaboration are essential to ensure that design, development, and manufacturing of systems operating within Earth’s atmosphere or beyond or the harnessing and application of electrical phenomena continue to serve humanity effectively and responsibly. These fields will persistently redefine the boundaries of what is feasible and influence the trajectory of technological development.

![Best Alabama Aerospace Engineering Ranking [2024 Guide] Innovating the Future of Flight with Reliable Aviation Solutions Best Alabama Aerospace Engineering Ranking [2024 Guide] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/03/th-111-300x200.jpg)

![Top Aerospace Engineering Programs in Canada [Rankings] Innovating the Future of Flight with Reliable Aviation Solutions Top Aerospace Engineering Programs in Canada [Rankings] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/03/th-99-300x200.jpg)