The study and practice related to designing, developing, and testing aircraft and spacecraft within the state of Wisconsin encompass a range of activities. These activities include research, manufacturing, and education, contributing to advancements in flight technology and space exploration. For example, specific programs at Wisconsin universities offer specialized training in areas like aerodynamics, propulsion, and aerospace structures.

This field contributes significantly to the state’s economy, fostering innovation and technological development. The historical context reveals a consistent presence of aerospace-related industries and academic research within Wisconsin. Benefits extend to workforce development, technological breakthroughs, and contributions to national defense and scientific exploration efforts.

The following sections will further detail specific academic programs, research initiatives, and industrial activities related to this important technical sector within the state.

Guidance for Aspiring Professionals

The following recommendations are directed toward individuals pursuing a career path related to the design, development, and application of flight and space vehicle technology, particularly within the context of Wisconsin’s educational and industrial landscape.

Tip 1: Emphasize Foundational Knowledge: A strong grasp of fundamental sciences, including mathematics, physics, and chemistry, is paramount. Coursework in these areas provides the necessary theoretical underpinnings for advanced studies in aerospace-specific disciplines.

Tip 2: Pursue Relevant Academic Specialization: Select a degree program with a focus on aeronautical or astronautical engineering. Within those programs, consider concentrating on areas such as aerodynamics, propulsion systems, control systems, or structural mechanics, depending on individual interests and career goals.

Tip 3: Gain Practical Experience Through Internships: Seek internship opportunities at aerospace companies, research institutions, or government agencies. Practical experience complements academic learning and provides valuable insights into real-world engineering challenges.

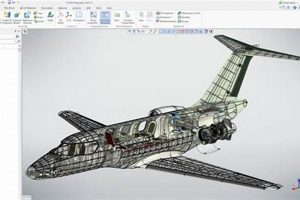

Tip 4: Develop Proficiency in Simulation and Modeling Software: Familiarity with industry-standard software tools for computer-aided design (CAD), computational fluid dynamics (CFD), and finite element analysis (FEA) is essential for modern aerospace engineering practice.

Tip 5: Cultivate Strong Communication and Teamwork Skills: Aerospace projects are inherently collaborative, requiring effective communication and teamwork. Develop the ability to articulate technical concepts clearly and work effectively in multidisciplinary teams.

Tip 6: Stay Informed on Emerging Technologies: The field is rapidly evolving. Maintain awareness of emerging technologies such as additive manufacturing, advanced materials, and autonomous systems through professional journals, conferences, and continuing education.

Tip 7: Consider Advanced Studies: For specialized roles or research-oriented careers, consider pursuing a master’s degree or doctorate in a relevant area. Advanced degrees provide in-depth knowledge and research experience.

Following these guidelines can significantly enhance an individual’s prospects for success within a complex and demanding technical field. This preparation will prove beneficial as the exploration of this topic continues.

The subsequent sections will delve deeper into specific opportunities and resources available within Wisconsin.

1. Education

Educational institutions within Wisconsin are foundational to the state’s contribution to aeronautics and astronautics. These institutions serve as the primary source for developing the skilled workforce necessary to sustain and advance the field. The curriculum focuses on core engineering principles, coupled with specialized topics such as aerodynamics, propulsion, and materials science. The availability of robust, technically focused education is a direct cause of the state’s capacity to participate in aerospace research, development, and manufacturing. For example, universities with established engineering programs offer advanced degrees that allow students to specialize in areas directly applicable to the aerospace sector.

The impact of education extends beyond the academic realm. Graduates enter various sectors, including private companies involved in aircraft component manufacturing, research laboratories focused on advanced aerospace technologies, and government agencies responsible for oversight and regulation. Furthermore, educational outreach programs, such as those designed to inspire students at the primary and secondary levels, play a critical role in fostering interest and building the pipeline of future aerospace professionals. The strength of these educational programs directly correlates with the ability to attract and retain talent within the state.

In summary, education is an indispensable component of the aerospace sector in Wisconsin. It provides the knowledge, skills, and innovation necessary for sustained growth and competitiveness. Challenges remain in ensuring that curricula remain current with rapidly evolving technologies and that programs are accessible to a diverse student population. However, continued investment in education is crucial to securing Wisconsin’s position within the broader aerospace ecosystem.

2. Research

Research is a crucial element driving advancements in flight and space vehicle technologies within Wisconsin. Its influence is multifaceted, impacting areas from fundamental materials science to the development of sophisticated control systems. This investigation, both theoretical and experimental, directly causes progress in performance, safety, and efficiency of aerospace systems. Without robust research programs, the field in Wisconsin would stagnate, relying on external innovation rather than fostering local expertise. For instance, university-led projects focusing on advanced composite materials have led to lighter and stronger aircraft components, enhancing fuel efficiency and payload capacity. Such activities demonstrate the practical significance of research in translating theoretical concepts into tangible improvements with direct industrial applications.

Further research efforts focus on areas such as autonomous flight control, advanced propulsion systems, and the integration of artificial intelligence into aerospace applications. These initiatives often involve collaboration between academic institutions, private sector companies, and government agencies, creating a synergistic environment for innovation. A practical application of this is seen in the development of unmanned aerial vehicles (UAVs) for various purposes, ranging from agricultural monitoring to infrastructure inspection. The research conducted in Wisconsin contributes to the refinement of these technologies, enhancing their capabilities and expanding their range of applications. This directly affects the competitiveness of Wisconsin-based aerospace firms.

In conclusion, research forms the cornerstone of the aerospace sector in Wisconsin. It fuels innovation, drives technological progress, and strengthens the state’s position within the global aerospace landscape. Challenges remain in securing consistent funding for research initiatives and attracting top talent to the state. However, continued investment in research is essential to maintaining a vibrant and competitive aerospace sector within Wisconsin, ensuring its long-term growth and contribution to both the state and the nation.

3. Manufacturing

Manufacturing forms a critical pillar in the framework of aeronautics and astronautics within Wisconsin. It translates theoretical designs and research findings into tangible products, enabling the practical application of aerospace technology. The success of manufacturing directly influences Wisconsin’s ability to participate in and benefit from the global aerospace market.

- Component Manufacturing

Wisconsin-based companies often specialize in the production of specific components for aircraft and spacecraft. These components can range from structural elements and propulsion system parts to electronic control systems and specialized sensors. An example includes the manufacturing of high-precision engine components for jet aircraft. The quality and reliability of these components are paramount, directly impacting the safety and performance of aerospace vehicles.

- Materials Processing

The aerospace sector demands advanced materials with unique properties, such as high strength-to-weight ratios, resistance to extreme temperatures, and corrosion resistance. Wisconsin’s manufacturing capabilities include the processing of these materials, which encompass composites, alloys, and ceramics. For example, facilities in the state may specialize in fabricating composite structures for aircraft wings or fuselages. The precision and control of these processes are critical for achieving the required material properties and dimensional accuracy.

- Precision Machining

Many aerospace components require intricate designs and tight tolerances, necessitating advanced machining techniques. Wisconsin manufacturers often employ computer numerical control (CNC) machining and other precision manufacturing methods to produce these parts. An example is the production of complex turbine blades for jet engines, where dimensional accuracy and surface finish are critical for efficient operation. The ability to achieve these high levels of precision is essential for meeting the stringent requirements of the aerospace industry.

- Quality Control and Testing

Stringent quality control and testing procedures are integral to aerospace manufacturing. These procedures ensure that components and systems meet the required specifications and performance standards. Wisconsin facilities implement rigorous inspection processes, non-destructive testing methods, and functional testing to verify product quality. For instance, manufacturers may use ultrasonic testing to detect flaws in composite structures or perform vibration testing to simulate in-flight conditions. These measures are indispensable for ensuring the safety and reliability of aerospace products.

The facets outlined above are interconnected and contribute to the overall strength of aeronautics and astronautics within Wisconsin. The ability to manufacture high-quality components, process advanced materials, perform precision machining, and implement rigorous quality control measures enables Wisconsin companies to compete effectively in the global aerospace market. Continued investment in manufacturing technology and workforce development is essential for sustaining and expanding Wisconsin’s role in the aerospace sector.

4. Innovation

Innovation serves as a core catalyst for progress within aeronautics and astronautics in Wisconsin. It drives the development of new technologies, processes, and solutions that enhance the performance, safety, and efficiency of aerospace systems. Without a continuous focus on innovation, the sector risks becoming stagnant and losing its competitive edge. Wisconsin’s role in aeronautics and astronautics depends on fostering an environment that encourages and supports innovative thinking.

Examples of innovation within Wisconsin’s aerospace landscape include advancements in composite materials for aircraft structures, the development of novel propulsion systems, and the integration of artificial intelligence into flight control systems. Academic institutions, research laboratories, and private companies all contribute to this innovation ecosystem. The practical application of these innovations leads to improved fuel efficiency, reduced emissions, enhanced safety features, and increased payload capacity. Furthermore, it generates economic benefits through the creation of new businesses, high-skilled jobs, and intellectual property.

In summary, innovation is indispensable to Wisconsin’s participation in the aeronautics and astronautics field. It necessitates ongoing investment in research and development, collaboration between diverse stakeholders, and a culture that embraces experimentation and risk-taking. Addressing the challenges of securing funding for innovative projects and attracting top talent to the state are crucial for maintaining a vibrant and competitive aerospace sector within Wisconsin, contributing to both state and national progress.

5. Regulation

The aeronautics and astronautics activities within Wisconsin are subject to a comprehensive regulatory framework designed to ensure safety, security, and environmental responsibility. These regulations, enforced by federal and state agencies, govern the design, manufacturing, operation, and maintenance of aircraft and related systems.

- Federal Aviation Administration (FAA) Oversight

The FAA is the primary regulatory body overseeing civil aviation in the United States, including activities within Wisconsin. The FAA establishes and enforces standards for aircraft design, manufacturing, and operation. Wisconsin-based aerospace companies and operators must comply with FAA regulations to ensure the airworthiness of their products and the safety of their operations. This includes obtaining certifications, adhering to maintenance schedules, and following operational procedures. FAA oversight is crucial for maintaining the integrity of Wisconsin’s civil aviation sector.

- Environmental Regulations

Aerospace activities can have environmental impacts, including noise pollution, air emissions, and waste generation. Wisconsin’s Department of Natural Resources (DNR), along with federal agencies like the Environmental Protection Agency (EPA), enforces regulations to mitigate these impacts. These regulations may include restrictions on aircraft noise levels, limits on emissions from manufacturing facilities, and requirements for proper waste disposal. Compliance with environmental regulations is essential for minimizing the environmental footprint of the aerospace sector in Wisconsin.

- Export Control Regulations

Aerospace technology is often subject to export control regulations due to its potential military applications. The U.S. Department of Commerce and the U.S. Department of State administer these regulations, which restrict the export of certain technologies and components to foreign countries. Wisconsin-based aerospace companies that export their products or technologies must comply with export control regulations, which involves obtaining licenses and adhering to restrictions on the transfer of sensitive information. Compliance is critical for ensuring national security and preventing the proliferation of advanced technologies.

- State-Specific Regulations

In addition to federal regulations, Wisconsin may have state-specific regulations that affect the aerospace sector. These regulations may pertain to airport zoning, air traffic control, or the licensing of aviation professionals. Wisconsin’s Department of Transportation (WisDOT) may play a role in administering these regulations. Compliance with state-specific regulations is necessary for operating legally within Wisconsin’s airspace and aviation infrastructure.

The various regulations outlined above are essential for ensuring the safe, secure, and environmentally responsible operation of the aerospace sector within Wisconsin. Compliance with these regulations is a legal and ethical imperative for all stakeholders involved in aeronautics and astronautics activities within the state.

6. Workforce

The skill and availability of personnel constitute a critical element influencing the capabilities and competitiveness of the aeronautics and astronautics sector within Wisconsin. A highly qualified workforce drives innovation, ensures efficient manufacturing, and supports the safe operation of aerospace systems. The following outlines key facets of the workforce in relation to this field.

- Engineering Talent

Aeronautical, mechanical, electrical, and software engineers are fundamental to the design, development, and testing of aircraft and spacecraft. Universities and technical colleges within Wisconsin play a vital role in producing graduates with the requisite knowledge and skills. For example, graduates of these institutions are employed in roles that involve designing aircraft structures, developing propulsion systems, and creating flight control software. The availability of skilled engineers is a primary determinant of the sector’s ability to innovate and compete.

- Skilled Technicians

Beyond engineers, skilled technicians are essential for the manufacturing, maintenance, and repair of aerospace systems. These technicians possess expertise in areas such as machining, welding, electronics, and avionics. Technical colleges and apprenticeship programs provide training for these critical roles. For example, certified aircraft mechanics maintain the airworthiness of aircraft fleets. The presence of a skilled technical workforce is critical for ensuring the reliability and safety of aerospace operations.

- Management and Support Staff

The aerospace sector requires qualified management and support staff to oversee operations, manage finances, and ensure regulatory compliance. This includes professionals in areas such as project management, supply chain management, quality control, and human resources. These individuals are responsible for coordinating and supporting the activities of engineers and technicians. For example, project managers oversee the development and production of aircraft components. The effective management and support staff are essential for the efficient operation of aerospace organizations.

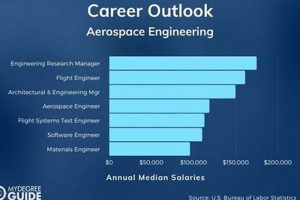

- Attracting and Retaining Talent

Attracting and retaining skilled professionals is a persistent challenge for the aerospace sector. Competition for talent is intense, and companies must offer competitive salaries, benefits, and career development opportunities to attract and retain qualified individuals. Wisconsin’s quality of life, educational opportunities, and research infrastructure can be leveraged to attract talent from other states and countries. Retention efforts should focus on providing employees with opportunities for professional growth, recognition, and a positive work environment. Success in attracting and retaining talent is crucial for the long-term health of the sector.

In summation, a well-trained and available workforce directly influences the strength and potential of aeronautics and astronautics in Wisconsin. Addressing the challenges of talent acquisition and retention, and continued investment in education and training programs will be essential for sustained growth.

Frequently Asked Questions

The following questions address common inquiries regarding the study and practice of design, development, and application of flight and space vehicle technology within Wisconsin. The information is intended to provide clarity and insight into this technical field.

Question 1: What specific academic programs in Wisconsin offer specialized training in aeronautics or astronautics?

Several universities across Wisconsin provide programs in mechanical engineering, electrical engineering, and related disciplines with opportunities for specialization in areas relevant to aeronautics and astronautics. Specific course offerings may include aerodynamics, propulsion, control systems, and aerospace structures. Prospective students should consult individual university websites for detailed program information.

Question 2: What types of companies in Wisconsin are involved in the manufacturing of aerospace components?

Wisconsin hosts a range of companies engaged in aerospace component manufacturing. These companies produce parts for aircraft engines, structural elements, avionics systems, and other critical components. The manufacturing processes often involve advanced materials, precision machining, and rigorous quality control procedures.

Question 3: What research initiatives are currently underway in Wisconsin that contribute to advancements in flight and space technology?

Ongoing research initiatives within Wisconsin encompass areas such as advanced materials, autonomous flight control, and propulsion systems. These projects often involve collaboration between universities, private companies, and government agencies. The research aims to improve the performance, safety, and efficiency of aerospace systems.

Question 4: What are the primary regulatory bodies governing aerospace activities within Wisconsin?

The Federal Aviation Administration (FAA) is the primary regulatory body overseeing civil aviation in Wisconsin. The FAA establishes and enforces standards for aircraft design, manufacturing, operation, and maintenance. Other regulatory bodies, such as the Environmental Protection Agency (EPA) and the Wisconsin Department of Natural Resources (DNR), may also have jurisdiction over specific aspects of aerospace activities.

Question 5: What are the key skills and qualifications that employers seek in candidates for aerospace engineering positions in Wisconsin?

Employers typically seek candidates with a strong foundation in engineering principles, specialized knowledge in aeronautics or astronautics, proficiency in relevant software tools, and excellent communication and teamwork skills. Practical experience gained through internships or research projects is also highly valued.

Question 6: How does Wisconsin’s geographical location and resources influence its role in the aerospace sector?

Wisconsin’s location within the Midwestern industrial corridor and its access to skilled labor and research infrastructure contribute to its role in the aerospace sector. The state’s proximity to major aerospace companies and its established manufacturing base provide opportunities for collaboration and growth.

The information presented aims to address common questions and provide a foundational understanding of the field within Wisconsin. Further research and exploration are encouraged for those seeking more detailed information.

The following sections will explore future trends and challenges in the field within Wisconsin.

Conclusion

This exploration of Wisconsin aerospace engineering has highlighted the multifaceted nature of this sector within the state. The intersection of education, research, manufacturing, innovation, regulation, and workforce development shapes its current state and future potential. Each of these components is essential to maintain Wisconsin’s participation in the broader national and global landscape.

Sustained investment in education, research, and infrastructure remains critical for Wisconsin to maintain a competitive position in this technologically advanced sector. Proactive engagement with evolving technologies and adapting to changing global demands will define the state’s aerospace trajectory in the years to come. Continued collaboration among academic institutions, private enterprises, and government agencies can ensure future growth and innovation.