Institutions that consistently demonstrate exceptional educational programs, research opportunities, and career placement rates within the field of flight vehicle design and construction, both atmospheric and beyond, are crucial for aspiring engineers. These institutions typically possess a combination of highly qualified faculty, cutting-edge facilities, and strong industry connections. For example, a university recognized for its pioneering research in hypersonics and its graduates’ prominent positions at leading aerospace companies would be considered a strong contender.

Selecting a superior academic environment dedicated to aeronautical and astronautical advancements provides numerous advantages. Graduates often experience enhanced career prospects, access to advanced research projects, and opportunities for networking with influential figures in the industry. Historically, these institutions have played a pivotal role in driving technological innovation, contributing significantly to space exploration, national defense, and commercial aviation. Their alumni frequently lead groundbreaking projects and companies, shaping the future of aerospace.

This article will delve into the factors that contribute to the excellence of educational programs in this technical field, examine specific examples of institutions recognized for their contributions, and offer guidance to prospective students navigating the complex process of choosing the right academic path for a successful career in air and space technologies.

Guidance for Aspiring Aerospace Engineers

The pursuit of higher education in aeronautical and astronautical engineering requires careful consideration. The following recommendations are designed to assist prospective students in making informed decisions about their academic pathways.

Tip 1: Rigorously Evaluate Curriculum Content: Prospective students should carefully scrutinize the course offerings of each program. A strong curriculum will encompass fundamental principles of aerodynamics, propulsion, structures, and control systems, as well as more advanced topics such as space mission design, composite materials, and computational fluid dynamics. Prioritize programs that integrate hands-on experience through laboratory work and design projects.

Tip 2: Assess Faculty Expertise and Research Opportunities: The quality of the faculty directly influences the educational experience. Investigate the research interests and publications of faculty members to ensure alignment with personal academic goals. Institutions with robust research programs provide invaluable opportunities for undergraduate and graduate students to participate in cutting-edge projects, gaining practical experience and contributing to the advancement of knowledge.

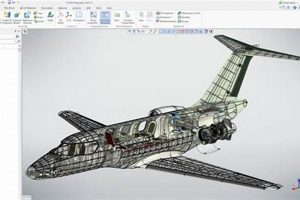

Tip 3: Analyze Available Resources and Facilities: State-of-the-art facilities are essential for effective aerospace engineering education. Look for institutions with well-equipped laboratories, wind tunnels, flight simulators, and computer-aided design (CAD) software. Access to such resources enables students to apply theoretical concepts in practical settings and develop the skills necessary for success in the industry.

Tip 4: Examine Industry Connections and Internship Programs: Strong relationships with aerospace companies and government agencies are critical for career advancement. Investigate the availability of internship programs, co-op opportunities, and industry-sponsored research projects. These experiences provide invaluable exposure to real-world engineering challenges and facilitate networking with potential employers.

Tip 5: Consider Accreditation and Rankings: Accreditation by recognized organizations, such as ABET (Accreditation Board for Engineering and Technology), ensures that a program meets established quality standards. While rankings should not be the sole determinant, they can provide a general indication of a program’s reputation and resources. Consult multiple sources and consider factors beyond rankings, such as program focus and faculty expertise.

Tip 6: Investigate Capstone Project Opportunities: A culminating capstone project is a crucial component of an aerospace engineering education. Evaluate the scope and complexity of capstone projects offered by different programs. Opportunities to design, build, and test aerospace systems provide invaluable hands-on experience and prepare students for the demands of professional practice.

These guidelines provide a framework for discerning the most suitable academic environments for aerospace engineering studies, thereby increasing the likelihood of achieving a rewarding and impactful career in the field.

The next section will elaborate on the various specializations available within aerospace engineering and how to align academic choices with specific career aspirations.

1. Reputation

The reputation of an academic institution constitutes a critical determinant in evaluating its standing as one of the premier settings for aerospace engineering education globally. A strong reputation, built over decades or even centuries, directly reflects the consistent quality of its educational programs, the groundbreaking nature of its research endeavors, and the professional achievements of its alumni. It serves as a tangible indicator of past performance and a predictor of future success, influencing perceptions among prospective students, faculty, and industry employers.

A positive reputation acts as a powerful magnet, attracting highly qualified students who seek rigorous academic challenges and unparalleled learning opportunities. These individuals are often motivated to excel and contribute significantly to the field of aerospace engineering. Concurrently, a strong reputation facilitates the recruitment of distinguished faculty members who possess expertise in diverse areas of aerospace research and practice. These educators, in turn, enhance the quality of instruction and mentorship available to students. For example, the Massachusetts Institute of Technology (MIT) maintains an enduring reputation for excellence in aerospace engineering, drawing exceptional students and faculty due to its long history of innovation and leadership in the field. Employers specifically target graduates from reputable programs because they are perceived to possess a superior skill set, a strong work ethic, and a deep understanding of aerospace principles.

Conversely, an institution lacking a solid reputation in aerospace engineering may struggle to attract top-tier students and faculty, limiting its capacity to deliver high-quality education and conduct impactful research. Therefore, reputation is not merely a superficial attribute; it is an intrinsic component of what defines an institution as one of the leading providers of aerospace engineering education worldwide, impacting its ability to educate future leaders and advance technological frontiers.

2. Research

Research represents a cornerstone of institutions recognized as leading providers of aerospace engineering education. The quality and volume of research activities directly influence the educational experience, contributing significantly to the development of both fundamental knowledge and advanced technologies in the field. Institutions that prioritize research provide unparalleled opportunities for students to engage in cutting-edge projects, collaborate with faculty experts, and contribute to innovations shaping the future of aerospace. For example, Stanford University’s propulsion research laboratory focuses on advanced propulsion systems which allows students to participate in real-world problems and learn about advancements and new innovations.

The connection between robust research programs and superior educational outcomes is evident in several ways. Active research environments foster a culture of inquiry and innovation, stimulating critical thinking and problem-solving skills among students. Moreover, faculty members engaged in research are at the forefront of their respective fields, bringing the latest advancements and real-world challenges into the classroom. Research-intensive institutions also tend to attract funding from government agencies, industry partners, and private donors, enabling them to invest in state-of-the-art facilities, equipment, and resources that further enhance the research and educational experience. California Institute of Technology (Caltech) receives considerable funding to do research on propulsion systems. This allows students to work hands-on and come up with solutions for real-world problems.

In conclusion, research is not merely an ancillary activity but rather a defining characteristic of institutions recognized for excellence in aerospace engineering. The commitment to research fosters innovation, enhances the educational experience, and prepares graduates to be leaders and problem-solvers in a rapidly evolving industry. Recognizing the significance of research is crucial for students seeking a comprehensive and impactful aerospace engineering education.

3. Faculty

The quality of faculty constitutes a primary determinant when evaluating academic institutions within the field of aerospace engineering. Institutions recognized as leading within the realm invariably possess a cadre of professors who not only demonstrate exceptional academic credentials but also maintain active involvement in relevant industry research and practice. Their expertise directly impacts the curriculum, research opportunities, and the overall educational experience provided to students. For example, a university with several faculty members who are fellows of the American Institute of Aeronautics and Astronautics (AIAA) suggests a high level of expertise and influence within the field.

Faculty members at superior aerospace engineering programs serve multiple roles. They are instructors, mentors, and researchers. Their ability to effectively communicate complex concepts, guide students through challenging projects, and provide personalized career advice significantly contributes to student success. Furthermore, faculty engaged in cutting-edge research often incorporate their findings into their teaching, ensuring that the curriculum remains current and relevant to industry needs. The presence of faculty who are actively consulting with or conducting research for aerospace companies further strengthens the connection between academia and industry, providing students with valuable insights into real-world engineering challenges. For instance, having professors who’ve designed components for NASA missions brings practical, current application to the student body.

Ultimately, the caliber of the faculty directly correlates with the quality of education and the long-term success of graduates. Institutions that prioritize the recruitment and retention of highly qualified faculty are better positioned to provide students with the knowledge, skills, and professional connections necessary to excel in the competitive aerospace industry. Selecting an institution with faculty whose interests align with a student’s academic and career goals is a critical step in pursuing a fulfilling and impactful career in aerospace engineering.

4. Resources

The availability and quality of resources at an academic institution correlate directly with its standing among the best colleges for aerospace engineering education. These resources encompass a wide range of physical and intellectual assets crucial for effective teaching, advanced research, and comprehensive student development. Insufficient resources impede the institution’s capacity to offer a competitive learning environment, while abundant, high-quality resources enable students and faculty to thrive, fostering innovation and driving progress in the field. For example, access to advanced computational facilities allows students to conduct complex simulations essential for designing and analyzing aerospace systems. The existence of specialized laboratories equipped with industry-standard equipment provides practical experience in manufacturing, testing, and experimentation.

Specific resources critical to aerospace engineering programs include wind tunnels for aerodynamic testing, propulsion laboratories for engine development, and composite materials fabrication facilities. Furthermore, access to comprehensive libraries, both physical and digital, provides students and faculty with the information needed to conduct research and stay abreast of the latest advancements in the field. Funding for research projects is also a vital resource, enabling faculty to pursue groundbreaking investigations and provide students with opportunities to participate in cutting-edge research. For instance, a university with robust funding for satellite design and development can provide its students with hands-on experience in building and testing spacecraft components.

In summary, the availability of adequate resources is not merely a desirable attribute but rather a fundamental prerequisite for an institution to be considered among the foremost providers of aerospace engineering education globally. These resources empower students and faculty to push the boundaries of knowledge and innovation, preparing graduates to meet the challenges of a dynamic and rapidly evolving industry. Limited resources can hinder an institution’s ability to maintain a leading position. Therefore, evaluating the resources available is crucial when assessing the quality and potential of an aerospace engineering program.

5. Industry

A robust connection with industry is a defining characteristic of leading aerospace engineering programs. This interaction provides students with practical experience, exposes them to real-world challenges, and enhances their career prospects post-graduation. The strength and depth of these industry relationships are significant factors in determining an institution’s standing within the field.

- Internship and Co-op Opportunities

Internships and cooperative education programs are critical components of an aerospace engineering education. They offer students the opportunity to apply classroom knowledge in professional settings, working alongside experienced engineers on real projects. For example, a leading institution might have partnerships with major aerospace companies such as Boeing, Airbus, or SpaceX, providing students with invaluable experience in design, manufacturing, or testing. The availability and quality of these opportunities directly impact a graduate’s readiness for the workforce.

- Industry-Sponsored Research

Collaborative research projects between universities and aerospace companies foster innovation and provide students with access to cutting-edge technology. These partnerships allow students to contribute to solutions for real-world problems faced by the industry, gaining valuable research experience and building relationships with potential employers. An example includes a university working with a defense contractor on developing new materials for aircraft, allowing students to participate in materials testing and analysis. Such projects are often funded by industry, resulting in improved resources, equipment, and opportunities for students.

- Advisory Boards and Guest Lectures

Many top aerospace engineering programs maintain advisory boards comprised of industry leaders. These boards provide guidance on curriculum development, ensuring that the program remains relevant to the current needs of the industry. Additionally, guest lectures from industry professionals expose students to different career paths, emerging technologies, and practical insights. This interaction provides students with a broader understanding of the industry landscape and helps them make informed career decisions.

- Recruitment and Placement

Leading aerospace engineering programs often have strong recruitment relationships with major companies and government agencies. These institutions host career fairs and on-campus recruitment events, providing students with direct access to potential employers. The placement rates of graduates into relevant positions within the industry are indicative of the program’s success in preparing students for professional careers. High placement rates and starting salaries are strong indicators of industry recognition and the value placed on graduates from these institutions.

The multifaceted relationship with industry is integral to shaping successful aerospace engineers. By providing hands-on experience, fostering innovation, and facilitating career opportunities, strong industry connections enhance the value and reputation of the leading academic institutions in the field, solidifying their position as the best colleges for aerospace engineering education worldwide.

6. Alumni

The accomplishments and trajectories of an institution’s alumni constitute a crucial metric in assessing its standing among the leading establishments for aerospace engineering education. A program’s alumni network serves as tangible evidence of its ability to prepare graduates for successful careers and contributions to the field.

- Career Trajectories and Leadership Positions

The career paths and leadership roles attained by alumni provide valuable insight into the effectiveness of an aerospace engineering program. A high proportion of graduates holding prominent positions in aerospace companies, government agencies like NASA, or leading research institutions indicates the program’s success in equipping individuals with the skills and knowledge necessary to excel. For example, institutions with alumni serving as chief engineers, program managers, or CEOs within the aerospace sector demonstrate a proven track record of developing industry leaders.

- Contributions to Technological Advancements

The contributions of alumni to aerospace technology and innovation are a significant indicator of a program’s impact. Graduates who have made substantial contributions to areas such as aircraft design, propulsion systems, space exploration, or satellite technology reflect the quality of education and research opportunities provided by the institution. Publications, patents, and industry awards received by alumni serve as tangible evidence of their contributions and the program’s influence on technological progress.

- Industry Recognition and Awards

The recognition and accolades received by alumni within the aerospace industry contribute to an institution’s reputation and prestige. Graduates who have been honored with prestigious awards, such as those presented by professional organizations like AIAA (American Institute of Aeronautics and Astronautics) or IEEE (Institute of Electrical and Electronics Engineers), signify their exceptional achievements and the program’s ability to cultivate talent. These awards can also provide networking opportunities and further career advancement.

- Philanthropic Contributions and Institutional Support

The extent to which alumni support their alma mater through philanthropic contributions and active involvement in institutional activities demonstrates their satisfaction with their educational experience and their commitment to the program’s continued success. Alumni donations can fund scholarships, research initiatives, and facility upgrades, further enhancing the quality of education and research opportunities available to current students. Active participation in alumni networks and mentorship programs also provides valuable support and guidance to aspiring aerospace engineers.

In conclusion, the successes and contributions of alumni are a powerful testament to the quality and impact of an aerospace engineering program. Their achievements reflect the effectiveness of the institution’s curriculum, research opportunities, and overall educational environment, reinforcing its position among the foremost providers of aerospace engineering education worldwide.

Frequently Asked Questions (FAQs)

This section addresses common inquiries regarding leading institutions in aerospace engineering. The information provided aims to offer clarity and direction for prospective students, parents, and educators navigating the complexities of higher education within this specialized field.

Question 1: What factors are considered when determining which institutions are recognized as the “best colleges for aerospace engineering in the world”?

Recognition stems from a confluence of factors. These encompass academic reputation, research output, faculty expertise, available resources, industry connections, and alumni achievements. Each element contributes to a holistic assessment of an institution’s ability to deliver a high-quality aerospace engineering education.

Question 2: Is there a definitive ranking of the “best colleges for aerospace engineering in the world”?

Various ranking systems exist, but they should be interpreted with caution. Rankings often emphasize different metrics, and their methodologies are subject to debate. A comprehensive evaluation should consider multiple sources of information and prioritize personal academic and career goals.

Question 3: How important is accreditation in assessing the quality of “best colleges for aerospace engineering in the world?”

Accreditation by recognized organizations, such as ABET (Accreditation Board for Engineering and Technology), is a critical indicator of program quality. Accreditation ensures that a program meets established standards for curriculum, faculty, and resources, providing assurance of a baseline level of competence.

Question 4: What are the typical career paths for graduates from the “best colleges for aerospace engineering in the world?”

Graduates pursue diverse career paths within the aerospace industry. These include roles in aircraft design, propulsion systems, space exploration, satellite technology, and defense. Career opportunities are also available in research institutions, government agencies, and related engineering fields.

Question 5: How can prospective students increase their chances of acceptance into the “best colleges for aerospace engineering in the world?”

A strong academic record, particularly in mathematics and science, is essential. Participation in extracurricular activities related to STEM (science, technology, engineering, and mathematics), such as robotics clubs or science competitions, can demonstrate a passion for the field. Letters of recommendation from teachers and mentors are also valuable.

Question 6: Do “best colleges for aerospace engineering in the world” offer financial aid and scholarship opportunities?

Many institutions offer financial aid and scholarship programs to assist students with tuition and other expenses. Eligibility criteria vary, and prospective students should research the specific offerings of each institution. Merit-based scholarships recognize academic achievement, while need-based aid is awarded based on financial circumstances.

The information provided within this FAQ section should serve as a starting point for further investigation and inquiry. Seeking personalized advice from academic advisors and current students is recommended for making informed decisions about higher education in aerospace engineering.

The subsequent segment will focus on key takeaway points, summarizing the core principles outlined throughout this discourse.

Conclusion

The preceding analysis has dissected the attributes that define institutions recognized as leading providers of aerospace engineering education globally. These elements encompass academic reputation, research prowess, faculty expertise, resource availability, industry collaboration, and the accomplishments of their alumni. Institutions excelling in these domains equip graduates with the requisite knowledge and skills to contribute meaningfully to the advancement of aerospace technology and innovation.

Selection of a suitable academic program represents a critical decision for aspiring aerospace engineers. A thorough assessment of institutional strengths, coupled with a clear understanding of individual career aspirations, will maximize the likelihood of achieving professional success within this demanding and dynamic field. Continued investment in aerospace education remains paramount to addressing the complex challenges facing the industry and ensuring future technological leadership.