This field of engineering encompasses the design, development, testing, and production of aircraft, spacecraft, and related systems. It integrates principles from various disciplines, including aerodynamics, propulsion, structures, materials science, and control systems. Examples of applications range from commercial airliners and military jets to satellites and space probes.

The significance of this engineering domain lies in its contribution to advancements in transportation, communication, national security, and scientific exploration. Historically, it has driven innovation, leading to improved fuel efficiency, enhanced safety measures, and expanded access to space. These advancements benefit society through global connectivity, economic growth, and the advancement of knowledge.

The following sections will delve into specific areas within this broad engineering discipline, exploring current research, emerging technologies, and future challenges in greater detail. Focus will be placed on key advancements and the pivotal role engineers play in shaping the future of air and space travel.

Essential Guidance for Aspiring Engineers in Air and Space

The demanding nature of careers related to air and space systems requires thorough preparation and a commitment to continuous learning. The following guidelines are intended to provide critical insight for those considering a path in this challenging field.

Tip 1: Solidify Foundational Knowledge: A strong understanding of mathematics, physics, and computer science is indispensable. Rigorous coursework in these areas is vital for grasping advanced concepts later in the curriculum. For example, mastery of differential equations is crucial for understanding flight dynamics.

Tip 2: Cultivate Interdisciplinary Skills: Success often depends on the ability to integrate knowledge from diverse areas. Gain familiarity with subjects such as thermodynamics, materials science, and control theory to develop a comprehensive perspective on complex engineering problems. The design of a new aircraft wing, for instance, requires understanding both aerodynamic forces and material properties.

Tip 3: Prioritize Practical Experience: Seek opportunities to apply theoretical knowledge through internships, research projects, or participation in engineering competitions. Hands-on experience with wind tunnels, flight simulators, or software tools enhances understanding and develops problem-solving skills. Building and testing a model rocket provides valuable insights into real-world challenges.

Tip 4: Develop Strong Communication Skills: Effective communication is essential for collaborating with colleagues, presenting research findings, and documenting design processes. Practice writing clear and concise technical reports, delivering presentations, and participating in constructive discussions. Communicating the results of a stress test effectively can prevent catastrophic failures.

Tip 5: Stay Abreast of Technological Advancements: This field is constantly evolving, so continuous learning is paramount. Stay informed about new technologies, such as additive manufacturing, advanced composite materials, and artificial intelligence, to maintain a competitive edge. Reading technical journals and attending industry conferences are excellent ways to stay informed.

Tip 6: Embrace Lifelong Learning: Continuing education and professional development are essential for career advancement. Consider pursuing advanced degrees, certifications, or specialized training to enhance expertise and adapt to evolving industry demands. Developing proficiency in new simulation software can greatly enhance an engineer’s capabilities.

These directives emphasize the significance of a robust educational foundation, practical experience, and a commitment to staying current with advancements. Adhering to these recommendations will increase the likelihood of success in this demanding and rewarding career path.

The ensuing discussion will focus on emerging trends and future prospects, offering additional insights into the evolving landscape of this vital engineering sector.

1. Aerodynamics

Aerodynamics forms a fundamental cornerstone within air and space vehicle engineering, representing the study of air’s motion and its interaction with solid objects. Its significance stems from the fact that the aerodynamic forces generated by airflow around an aircraft or spacecraft directly dictate its ability to fly, maneuver, and maintain stability. The principles of aerodynamics are applied to design airfoils, fuselages, and control surfaces to optimize lift, minimize drag, and ensure predictable handling characteristics. Ignoring aerodynamic principles can lead to catastrophic consequences, such as uncontrolled flight or structural failure. A real-world example includes the redesign of the Boeing 737 MAX’s Maneuvering Characteristics Augmentation System (MCAS), which was directly tied to addressing unintended aerodynamic behavior at high angles of attack.

The practical application of aerodynamics extends far beyond the initial design phase. Wind tunnel testing and computational fluid dynamics (CFD) simulations are routinely employed to validate designs, identify potential problems, and refine aerodynamic performance. These simulations allow engineers to model airflow around complex geometries and predict aerodynamic forces with high accuracy. This facilitates informed decision-making regarding aircraft configuration, control surface placement, and other design parameters. Examples can be seen in Formula 1 car designs; each winglet and panel goes through extensive wind tunnel testing and CFD analysis to maximize downforce and minimize drag.

In summary, aerodynamics is inextricably linked to the success of the aerospace and aeronautical industry. A deep understanding of these principles is essential for engineers to design safe, efficient, and effective air and space vehicles. The ongoing evolution of computational methods and experimental techniques continues to drive advancements in aerodynamic design, addressing challenges associated with increased speed, altitude, and maneuverability.

2. Propulsion Systems

Propulsion systems are an indispensable component within the larger domain of air and space vehicle engineering. They provide the necessary thrust to overcome drag and gravity, enabling sustained flight within Earth’s atmosphere and facilitating travel beyond it. The selection and design of a suitable propulsion system are inextricably linked to mission objectives, influencing vehicle performance parameters such as range, speed, payload capacity, and operational ceiling. The causal relationship is evident: without an efficient and reliable propulsion system, the intended flight or space mission becomes unachievable. For example, a commercial airliner relies on turbofan engines to generate thrust for efficient and long-distance travel, while a rocket uses chemical or electric propulsion to escape Earth’s gravity.

The development of diverse propulsion technologies addresses the wide-ranging requirements of air and space vehicles. These include gas turbines, ramjets, scramjets, rocket engines (liquid-propellant, solid-propellant, hybrid), and electric propulsion systems. Each technology leverages different principles of physics and chemistry to generate thrust. For instance, a gas turbine engine compresses air, mixes it with fuel, and ignites the mixture to produce hot exhaust gases that drive a turbine and generate thrust. Electric propulsion, on the other hand, uses electrical energy to accelerate ionized propellant, creating a low but sustained thrust for long-duration space missions. Furthermore, the design process considers factors such as specific impulse, thrust-to-weight ratio, fuel consumption, and environmental impact to optimize system efficiency and performance.

In summary, propulsion systems are foundational to the success of air and space missions. Understanding the principles, design considerations, and technological advancements in this area is crucial for engineers working in the domain. Challenges remain in improving fuel efficiency, reducing emissions, and developing advanced propulsion concepts for future space exploration endeavors. Addressing these challenges demands a concerted effort involving innovation in materials science, combustion technology, and alternative propulsion techniques.

3. Structural Integrity

Structural integrity is a critical facet of air and space vehicle engineering, directly influencing the safety and reliability of aircraft and spacecraft. It refers to the ability of a vehicle’s structure to withstand applied loads and environmental conditions without failure. The design and analysis of aerospace structures inherently necessitates considering the static and dynamic forces encountered during flight or space travel, encompassing aerodynamic pressure, gravitational forces, thermal stresses, and vibrations. Consequently, structural failure can precipitate catastrophic events, underscoring the importance of rigorous analysis and testing procedures. The Comet airliner disasters of the 1950s, attributed to metal fatigue around the square windows, provide a stark example of the consequences of neglecting structural integrity considerations during design and manufacturing.

Ensuring structural integrity involves employing a combination of analytical techniques, experimental validation, and advanced materials. Finite element analysis (FEA) is routinely used to simulate stress distributions within complex structures, predicting potential failure points and optimizing designs. Experimental testing, including fatigue testing, non-destructive testing (NDT), and full-scale structural tests, validates the analytical models and identifies unforeseen weaknesses. Materials selection also plays a pivotal role, with engineers carefully considering factors such as strength-to-weight ratio, fatigue resistance, corrosion resistance, and high-temperature performance. The increasing use of composite materials, such as carbon fiber reinforced polymers, exemplifies the ongoing pursuit of lighter, stronger, and more durable aerospace structures. As example, the structural design of the International Space Station (ISS) required comprehensive FEA to ensure that the modules and connecting structures could withstand the combined stresses of launch, orbital maneuvers, and long-term exposure to the space environment.

In summary, structural integrity is an indispensable element of air and space vehicle engineering, demanding a meticulous and comprehensive approach to design, analysis, testing, and materials selection. Maintaining structural integrity necessitates continuous monitoring and inspection throughout the vehicle’s service life to detect and address any signs of degradation or damage. As vehicles become more complex and operate in increasingly demanding environments, the challenges associated with ensuring structural integrity will continue to grow, necessitating further advancements in analytical methods, testing techniques, and materials science. The ongoing development of structural health monitoring systems, which integrate sensors and data analysis algorithms to detect damage in real-time, represents a significant step toward proactively managing structural integrity and enhancing flight safety.

4. Control Engineering

Control engineering is intrinsically linked to the safe and effective operation of air and space vehicles. This discipline focuses on designing and implementing systems that maintain stability, regulate performance, and automate tasks within aircraft and spacecraft. The fundamental cause-and-effect relationship is clear: disruptions in control systems can lead to deviations from planned trajectories, compromising mission objectives and potentially endangering lives. Consequently, the integration of robust control mechanisms is not merely an enhancement, but a necessity for air and space endeavors. The development of autopilot systems in commercial airliners, for example, reduces pilot workload during routine flights, improving fuel efficiency and maintaining course stability. Similarly, attitude control systems in satellites ensure proper orientation for communication and observation purposes.

The practical applications of control engineering span a wide spectrum within air and space contexts. Flight control systems manage an aircraft’s movement in response to pilot commands or automated instructions, manipulating control surfaces such as ailerons, elevators, and rudders. Guidance, navigation, and control (GNC) systems direct spacecraft along pre-defined paths, utilizing sensors, actuators, and sophisticated algorithms to compensate for external disturbances. Moreover, control engineering principles are applied in propulsion systems to regulate engine thrust and fuel flow, optimizing performance and minimizing fuel consumption. The implementation of fly-by-wire technology, replacing mechanical linkages with electronic signals, exemplifies the increasing reliance on control engineering to enhance aircraft responsiveness and safety.

In summary, control engineering is an indispensable component of air and space vehicle design and operation. Its role in ensuring stability, regulating performance, and automating tasks is paramount to mission success and safety. The ongoing development of advanced control algorithms, sensor technologies, and actuator systems continues to push the boundaries of what is achievable in the realm of air and space travel. Addressing challenges related to system reliability, robustness, and adaptability remains a crucial focus for researchers and engineers in this field. The future of this domain hinges on creating innovative control solutions that can seamlessly integrate with increasingly complex and autonomous aerospace systems.

5. Materials Science

Materials science is fundamentally intertwined with aerospace and aeronautical engineering, acting as a critical enabler for advancements in aircraft and spacecraft performance. The characteristics of the materials used directly influence structural integrity, weight, heat resistance, and overall operational capabilities. The selection process invariably involves balancing often conflicting requirements, such as high strength and low density, to achieve optimal design outcomes. An illustration of this connection is found in the development of titanium alloys, possessing a superior strength-to-weight ratio compared to steel, which are now widely employed in aircraft engine components and airframe structures. In essence, materials science provides the building blocks that dictate the limits of what is aerodynamically and structurally feasible. The use of advanced materials is often the enabling factor for achieving ambitious performance goals, dictating the boundaries of current aerospace capabilities.

The practical applications of this relationship are manifold. The development of composite materials, such as carbon fiber reinforced polymers, has revolutionized aircraft design by enabling the creation of lighter and stronger airframes. These materials contribute to improved fuel efficiency, increased payload capacity, and enhanced aerodynamic performance. High-temperature alloys, such as nickel-based superalloys, are crucial for turbine blades in jet engines, withstanding extreme heat and stress. The advancement of ablative materials is indispensable for spacecraft heat shields, protecting vehicles during atmospheric re-entry by dissipating heat through controlled ablation. These examples exemplify how material properties directly impact the functionality and reliability of aerospace systems. Without continued innovation in materials, progress towards more efficient, durable, and capable aircraft and spacecraft would be significantly hampered.

In summary, materials science is not merely a supporting discipline but a foundational pillar of aerospace and aeronautical engineering. The continual pursuit of novel materials with enhanced properties is essential for meeting the ever-increasing demands of air and space travel. Challenges remain in developing materials that can withstand extreme environments, such as prolonged exposure to radiation in space or ultra-high temperatures in hypersonic flight. Addressing these challenges requires a multidisciplinary approach, combining expertise in materials science, engineering, and physics. Future advancements in this field will undoubtedly shape the next generation of aircraft and spacecraft, driving innovation and expanding the boundaries of aerospace exploration.

Frequently Asked Questions

The following questions and answers address common inquiries and misconceptions regarding the field of aerospace and aeronautical engineering, providing clear and concise information for prospective students and interested parties.

Question 1: What is the fundamental distinction between aerospace and aeronautical engineering?

Aeronautical engineering focuses on the design, development, and analysis of aircraft that operate within Earth’s atmosphere. Aerospace engineering, conversely, encompasses the broader field of designing, building, and testing vehicles and systems intended for operation both within and beyond Earth’s atmosphere, including spacecraft, satellites, and missiles.

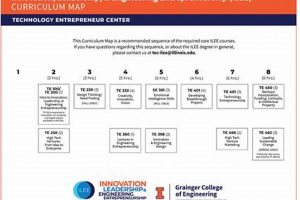

Question 2: What academic qualifications are typically required for a career in this field?

A bachelor’s degree in aerospace engineering or a closely related field is generally considered the minimum requirement for entry-level positions. Advanced degrees, such as a Master’s or Doctorate, are often necessary for research-oriented roles and leadership positions.

Question 3: What are the core skills necessary for success in aerospace and aeronautical engineering?

Success in this field necessitates a strong foundation in mathematics, physics, and computer science. Proficiency in areas such as aerodynamics, structural analysis, propulsion systems, and control theory is also essential. Furthermore, effective problem-solving, critical thinking, and communication skills are crucial for collaborating within multidisciplinary teams.

Question 4: What are some typical career paths for graduates with degrees in this discipline?

Graduates can pursue diverse career paths within the aerospace industry, including roles in aircraft design, spacecraft engineering, propulsion system development, flight testing, and research and development. Opportunities also exist in government agencies, such as NASA and defense contractors.

Question 5: What are the primary challenges currently facing the aerospace and aeronautical engineering industry?

Key challenges include reducing the environmental impact of air travel through the development of more fuel-efficient aircraft, enabling sustainable space exploration through advanced propulsion systems, and ensuring the safety and reliability of increasingly complex aerospace systems. Additionally, addressing cybersecurity threats to aircraft and spacecraft is becoming increasingly critical.

Question 6: How is the field of aerospace and aeronautical engineering evolving to meet future demands?

The field is rapidly evolving through advancements in areas such as additive manufacturing, artificial intelligence, and advanced materials. These innovations are enabling the creation of lighter, stronger, and more efficient aircraft and spacecraft. Furthermore, there is a growing emphasis on autonomous systems, electric propulsion, and the exploration of new frontiers in space.

These questions offer a snapshot of the key aspects associated with aerospace and aeronautical engineering. Further research and exploration are encouraged for a more in-depth understanding.

The following section will explore future trends and emerging technologies within the aerospace sector, highlighting potential areas for innovation and growth.

Conclusion

This exposition has elucidated the multifaceted nature of aerospace and aeronautical engineering, underscoring its pivotal role in advancing air and space travel. From fundamental principles of aerodynamics and propulsion to the complexities of structural integrity and control systems, this engineering discipline demands a comprehensive understanding of diverse scientific and technological domains. The ongoing pursuit of novel materials, efficient propulsion methods, and intelligent control algorithms remains central to pushing the boundaries of what is achievable in flight and space exploration.

Continued investment in research and development, coupled with a commitment to rigorous education and training, is essential to ensuring the sustained progress of aerospace and aeronautical engineering. As society faces evolving challenges in transportation, communication, and exploration, this discipline will undoubtedly play a crucial role in shaping the future. It is incumbent upon engineers, scientists, and policymakers to collaborate in fostering an environment that supports innovation and enables the realization of ambitious aerospace endeavors.