The document outlining the responsibilities, qualifications, and skills required for a procurement professional specializing in the aerospace industry details the precise tasks and competencies necessary to effectively acquire components, materials, and services. This specification typically includes requirements like negotiation abilities, understanding of aerospace standards and regulations, and proficiency in supply chain management practices. For example, a company might create a document detailing the need for a candidate with experience in purchasing avionics equipment and managing vendor relationships within FAA guidelines.

Such a document is vital for ensuring a streamlined and compliant supply chain, crucial for safety and efficiency within the aerospace sector. It allows organizations to precisely target recruitment efforts, attract qualified candidates, and establish clear performance expectations. Historically, these descriptions have evolved from general purchasing roles to specialized positions reflecting the increasing complexity and stringent regulatory requirements of aerospace manufacturing and operations. The existence of a well-defined role supports better purchasing decisions, cost control, and adherence to quality standards, all of which contribute to the overall success of aerospace projects.

The elements found within such a description typically include core responsibilities, required education and experience, essential skills, and reporting structure. Further discussion will examine these areas in detail, providing a comprehensive understanding of the multifaceted role and its significance in the aerospace landscape.

Key Considerations for Crafting an Effective Aerospace Buyer Specification

The following points offer guidance in developing a clear and comprehensive role definition for procurement professionals within the aerospace sector, aiding in the attraction of qualified candidates.

Tip 1: Clearly Define Technical Expertise. Outline the specific technical knowledge required, such as familiarity with materials science, FAA regulations, or specific aircraft systems. Example: “Must possess a thorough understanding of AS9100 quality management systems and their application in aerospace component manufacturing.”

Tip 2: Specify Negotiation and Contract Management Skills. Emphasize the importance of effective negotiation and contract management abilities, including experience with various contract types and legal considerations. Example: “Proven ability to negotiate favorable terms and conditions with vendors, ensuring compliance with legal and regulatory requirements.”

Tip 3: Detail Supply Chain Management Responsibilities. Articulate the responsibilities related to supply chain management, including vendor selection, performance monitoring, and risk mitigation strategies. Example: “Responsible for identifying and vetting potential suppliers, evaluating their capabilities, and managing supplier performance to meet quality and delivery targets.”

Tip 4: Highlight Regulatory Compliance Requirements. Clearly state the need for adherence to relevant aerospace regulations and standards, such as FAA, EASA, or military specifications. Example: “Ensures all procurement activities comply with applicable aerospace regulations and standards, including documentation and traceability requirements.”

Tip 5: Emphasize Communication and Collaboration Skills. Underline the significance of effective communication and collaboration with internal stakeholders, such as engineering, quality, and manufacturing teams. Example: “Collaborates effectively with cross-functional teams to define requirements, resolve issues, and ensure timely delivery of materials and components.”

Tip 6: Define Cost Management Expectations. Stipulate the responsibilities related to cost control and optimization, including cost analysis, price negotiation, and value engineering. Example: “Conducts cost analysis and identifies opportunities for cost reduction without compromising quality or performance.”

Tip 7: Include Key Performance Indicators (KPIs). Incorporate measurable KPIs to assess the effectiveness of the role, such as cost savings, on-time delivery rates, and supplier performance scores. Example: “Monitors and reports on key performance indicators related to procurement activities, such as cost savings, on-time delivery, and supplier quality.”

Adherence to these points facilitates the creation of a comprehensive role definition. This aids organizations in attracting qualified candidates and establishing a procurement function that effectively supports the aerospace sector’s demanding requirements.

The careful construction of the document in question directly impacts the quality and efficiency of the aerospace supply chain. Further discussion will now address potential challenges and evolving trends within the field.

1. Responsibilities and duties.

The section outlining responsibilities and duties within an aerospace buyer role definition forms the core of the document, providing clarity on the expectations and functions the individual is expected to perform. It serves as a foundational element, enabling prospective candidates to understand the scope of the position and allowing the hiring organization to define performance metrics. These specific responsibilities directly influence the overall efficiency and effectiveness of the procurement process within the aerospace industry.

- Procurement Execution

This facet encompasses the day-to-day activities of sourcing, negotiating, and purchasing materials, components, and services. It includes generating purchase orders, managing vendor relationships, and ensuring timely delivery of goods. An example would be a buyer responsible for procuring landing gear components, requiring them to identify qualified suppliers, negotiate pricing and lead times, and track shipments to meet production schedules. Failure to execute this duty effectively can lead to production delays and increased costs.

- Supplier Management

This aspect involves identifying, evaluating, and managing suppliers to ensure they meet quality, cost, and delivery requirements. This includes conducting supplier audits, monitoring performance metrics, and resolving any issues that arise. A real-world example is a buyer tasked with managing a supplier providing specialized alloys. They would be responsible for ensuring the supplier maintains required certifications, consistently meets quality standards, and adheres to contractual obligations. Poor supplier management can lead to compromised product quality and supply chain disruptions.

- Contract Negotiation and Management

This duty covers the negotiation of contracts with suppliers, ensuring favorable terms and conditions that protect the organization’s interests. This includes reviewing contract language, negotiating pricing and payment terms, and managing contract compliance. An example is a buyer responsible for negotiating a long-term supply agreement for raw materials. They would need to ensure the contract includes clauses addressing price fluctuations, quality standards, and delivery schedules. Ineffective contract management can expose the organization to financial and legal risks.

- Compliance and Regulatory Adherence

This responsibility involves ensuring all procurement activities comply with relevant aerospace regulations and industry standards, such as FAA requirements, AS9100, and export control regulations. An example is a buyer responsible for procuring components for aircraft engines. They would need to ensure all suppliers comply with FAA regulations regarding traceability and documentation. Failure to adhere to these regulations can result in fines, penalties, and even grounding of aircraft.

These responsibilities and duties, clearly articulated, are critical for defining the specific role within the aerospace sector. Their careful definition ensures compliance, efficiency, and ultimately, the safety and reliability of aerospace products. The explicit delineation of duties directly impacts the qualifications sought in candidates and forms the foundation for performance evaluation, thus highlighting its central role within the overall role definition.

2. Required skills.

The “aerospace buyer job description” invariably includes a section detailing the “required skills,” which directly impacts the effectiveness of the individual fulfilling that role. These skills represent the practical capabilities necessary to perform the defined duties and responsibilities. A lack of alignment between the required skills and the actual demands of the position can lead to inefficiencies, errors, and potential compromises in product quality or regulatory compliance. For instance, a buyer lacking strong negotiation skills might fail to secure favorable pricing terms, negatively affecting the company’s profitability. Similarly, inadequate understanding of aerospace materials could lead to the selection of unsuitable components, potentially jeopardizing the integrity of the final product.

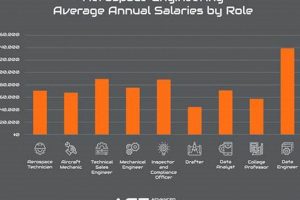

The emphasis on particular skills within a specific role varies based on the specific needs of the organization and the complexity of the products or services being procured. Examples of critical skills often stipulated within this definition include: proficiency in contract negotiation, a detailed understanding of aerospace materials and manufacturing processes, familiarity with relevant regulatory frameworks (e.g., FAA, EASA), the ability to interpret technical drawings and specifications, and robust analytical skills for evaluating supplier proposals. A mastery of ERP systems for purchase order management is often expected, as is the aptitude for forecasting demand and managing inventory levels effectively. An illustration of practical application is a buyer who must leverage their technical expertise to assess the feasibility of a supplier’s proposed alternative material, ensuring it meets all performance and safety requirements stipulated by engineering and regulatory bodies.

Ultimately, the inclusion of precisely defined “required skills” within the “aerospace buyer job description” is not merely a formality, but a necessity for ensuring operational success and regulatory compliance. The challenges lie in accurately identifying and articulating the skills most pertinent to the specific role, and in developing effective methods for assessing these skills during the recruitment process. An aerospace organization’s ability to attract and retain individuals possessing these crucial competencies is fundamental to its long-term competitiveness and ability to meet the stringent demands of the industry.

3. Necessary experience.

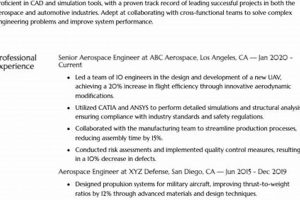

The specification for an aerospace buyer invariably outlines the “necessary experience” as a critical component. It directly impacts an individual’s capability to effectively manage procurement processes within the complex and highly regulated aerospace sector. Prior exposure to supply chain management, contract negotiation, and vendor relations, specifically within the aerospace domain, forms the bedrock of effective performance. For example, a candidate with a proven track record of successfully negotiating long-term contracts for aircraft components exhibits a tangible understanding of market dynamics and risk mitigation strategies. The absence of relevant experience can lead to inefficiencies, errors in judgment, and potential compliance breaches, thus highlighting the critical importance of this criterion.

Furthermore, prior experience provides practical insights into the unique challenges and complexities inherent in aerospace procurement. This includes familiarity with stringent quality standards, regulatory requirements (FAA, EASA), and the critical importance of traceability and documentation. A candidate possessing experience in managing a supplier quality audit, for example, demonstrates a proactive approach to ensuring compliance and mitigating potential risks. Individuals without such experience may struggle to navigate the intricate web of regulations and industry best practices, potentially leading to costly errors or delays. Successful execution of procurement activities within aerospace is intrinsically linked to the depth and breadth of acquired experience.

In summary, the “necessary experience” criterion within the specified role definition serves as a fundamental indicator of a candidate’s readiness and capability to perform effectively within the aerospace procurement environment. It reflects a tangible understanding of industry-specific challenges, regulatory requirements, and best practices. By prioritizing candidates with relevant experience, aerospace organizations can mitigate risks, improve efficiency, and ensure adherence to the stringent standards that define the sector. This emphasis on practical knowledge and proven capabilities ultimately contributes to the safety, reliability, and success of aerospace endeavors.

4. Educational qualifications.

The educational qualifications specified within an aerospace buyer job description represent a crucial factor in determining a candidate’s suitability for the role. The level and type of education deemed necessary reflect the complexity and technical nature of procurement within the aerospace industry. These credentials serve as a baseline indicator of a candidate’s theoretical knowledge and capacity for continuous learning.

- Bachelor’s Degree in a Relevant Field

A bachelor’s degree in supply chain management, business administration, engineering, or a related field is frequently a minimum requirement. This foundational education provides a comprehensive understanding of business principles, analytical techniques, and supply chain methodologies. For instance, a degree in engineering equips a buyer with the technical knowledge to evaluate the feasibility and suitability of materials and components, while a degree in supply chain management offers insights into optimizing logistics and managing inventory effectively. The absence of such a degree may indicate a lack of formal training in critical areas relevant to the position.

- Advanced Certifications

Advanced certifications, such as Certified Professional in Supply Management (CPSM) or Certified Supply Chain Professional (CSCP), often serve as evidence of specialized knowledge and commitment to professional development. These certifications demonstrate mastery of advanced procurement techniques, contract negotiation strategies, and risk management principles. An aerospace buyer holding a CPSM certification, for instance, has demonstrated proficiency in developing and implementing strategic sourcing plans, evaluating supplier performance, and mitigating supply chain disruptions. These certifications enhance a candidate’s credibility and demonstrate a proactive approach to staying abreast of industry best practices.

- Specialized Aerospace Training

Specific training in aerospace-related topics, such as AS9100 quality management systems or FAA regulatory requirements, is highly valuable. This specialized knowledge ensures a thorough understanding of the unique challenges and constraints associated with aerospace procurement. An aerospace buyer with training in AS9100 is equipped to ensure suppliers adhere to stringent quality control standards, while knowledge of FAA regulations ensures compliance with safety and airworthiness requirements. This type of specialized training demonstrates a commitment to the aerospace industry and a capacity to navigate its complex regulatory landscape.

In conclusion, the educational qualifications specified in an aerospace buyer job description reflect the technical demands and regulatory complexities of the role. A combination of a relevant bachelor’s degree, advanced certifications, and specialized aerospace training provides a solid foundation for success in this challenging and critical function. These qualifications serve as a benchmark for assessing a candidate’s theoretical knowledge, analytical skills, and commitment to continuous learning, all of which are essential for ensuring the integrity and efficiency of the aerospace supply chain.

5. Reporting structure.

The delineation of the reporting structure within an aerospace buyer role specification dictates the lines of authority and communication, directly impacting the efficiency and effectiveness of the procurement function. The hierarchical framework establishes who the buyer reports to and who, if anyone, reports to the buyer. This clarity is crucial for accountability, decision-making processes, and the flow of information. For example, a buyer reporting directly to a Supply Chain Manager facilitates seamless integration of procurement strategies with overall supply chain objectives. Conversely, a convoluted or ambiguous reporting structure can lead to confusion, delays, and a diminished sense of responsibility, negatively impacting the entire purchasing process.

The specific reporting structure often reflects the size and organizational model of the aerospace company. In smaller firms, a buyer may report directly to the CEO or a senior operations executive. In larger organizations, the buyer typically reports to a purchasing manager, commodity manager, or a director of supply chain management. Regardless of the specific title, the reporting structure should clearly define the scope of authority and the level of autonomy the buyer possesses. A well-defined structure enables the buyer to navigate internal processes efficiently, secure necessary approvals, and escalate critical issues without ambiguity. For example, a buyer needing expedited approval for a critical component can more effectively navigate the process when the reporting lines are clearly established.

Ultimately, the “reporting structure” component within the role definition is not merely an organizational chart element but a critical determinant of operational effectiveness. A clear and logical reporting structure fosters accountability, streamlines communication, and empowers the aerospace buyer to perform their duties efficiently and effectively. Challenges in establishing a suitable reporting structure may arise from complex organizational matrices or unclear lines of authority. However, prioritizing a well-defined reporting structure is paramount for ensuring a robust and responsive procurement function, thereby contributing to the overall success of aerospace operations.

6. Industry knowledge.

The “aerospace buyer job description” mandates a significant degree of industry knowledge due to the sector’s unique complexities and stringent regulations. A buyer’s familiarity with aerospace materials, manufacturing processes, and quality standards directly impacts the efficiency and effectiveness of procurement activities. Lack of adequate knowledge can result in the selection of unsuitable components, non-compliance with regulatory requirements, and compromised product safety. For example, a buyer unfamiliar with AS9100 quality management standards might inadvertently select a supplier lacking proper certifications, leading to significant quality control issues and potential grounding of aircraft.

Deep understanding of the aerospace landscape allows buyers to effectively assess supplier capabilities, negotiate contracts that mitigate risks specific to the industry, and anticipate potential supply chain disruptions. For instance, a buyer with knowledge of market trends in raw materials used in aircraft construction can strategically time purchases to minimize costs and secure favorable pricing terms. Furthermore, familiarity with FAA regulations ensures that all procurement activities adhere to strict airworthiness requirements, reducing the risk of penalties and legal liabilities. A skilled buyer leverages industry knowledge to proactively identify and address potential challenges, contributing to a more resilient and cost-effective supply chain.

The imperative of industry knowledge within the aerospace buyer role stems from the sector’s focus on safety, reliability, and technological advancement. Continuously evolving regulations and technological innovations necessitate ongoing learning and adaptation. The absence of comprehensive industry knowledge poses substantial risks, potentially leading to compromised product quality, regulatory non-compliance, and increased costs. Therefore, the “aerospace buyer job description” invariably emphasizes the critical importance of this domain expertise, highlighting its direct impact on the success and sustainability of procurement operations within the aerospace industry.

7. Compliance requirements.

Compliance requirements are intrinsically linked to the responsibilities detailed in an aerospace buyer job description, forming a non-negotiable aspect of the role. These requirements dictate adherence to a complex web of regulations, standards, and ethical guidelines governing the procurement of materials, components, and services within the aerospace sector.

- Regulatory Adherence

Aerospace buyers must ensure strict compliance with regulations set by bodies such as the FAA (Federal Aviation Administration), EASA (European Union Aviation Safety Agency), and other relevant authorities. This includes meticulous documentation, traceability of parts, and adherence to airworthiness directives. For example, a buyer procuring engine components must ensure that the supplier possesses the necessary certifications and that all materials meet stringent FAA standards. Failure to comply can result in significant fines, legal repercussions, and grounding of aircraft.

- Quality Management Systems

Compliance with quality management systems, such as AS9100, is paramount in aerospace procurement. Buyers are responsible for ensuring that suppliers adhere to these standards, which encompass rigorous quality control processes, inspection procedures, and documentation requirements. An aerospace buyer might conduct supplier audits to verify compliance with AS9100 standards, ensuring that all parts meet the necessary specifications and performance criteria. Deviation from these standards can compromise product quality and safety.

- Export Control Regulations

Aerospace buyers must navigate complex export control regulations, particularly when dealing with international suppliers or dual-use items. This includes obtaining necessary licenses, verifying end-use declarations, and adhering to restrictions on the export of sensitive technologies. A buyer procuring components for military aircraft, for example, must ensure compliance with ITAR (International Traffic in Arms Regulations) to prevent unauthorized transfer of controlled technologies. Violation of export control regulations can result in severe penalties and reputational damage.

- Ethical Procurement Practices

Compliance also extends to ethical considerations, requiring buyers to maintain transparency, avoid conflicts of interest, and promote fair competition. This includes adhering to codes of conduct, disclosing potential conflicts of interest, and ensuring that all procurement decisions are based on objective criteria. An aerospace buyer, for instance, must avoid accepting gifts or favors from suppliers that could influence procurement decisions. Upholding ethical standards is crucial for maintaining trust and integrity in the procurement process.

These facets of compliance collectively underscore the critical role of the aerospace buyer in safeguarding the integrity and safety of aerospace products. The responsibilities detailed in the job description are inherently intertwined with these compliance imperatives, demanding a meticulous and ethical approach to procurement. The ability to effectively navigate these requirements is paramount for ensuring the long-term success and sustainability of aerospace operations.

Frequently Asked Questions Regarding the Aerospace Buyer Role

This section addresses common inquiries and misconceptions concerning the role of a procurement professional specializing in the aerospace sector. The information provided aims to offer clarity and a comprehensive understanding of the responsibilities and requirements associated with this critical function.

Question 1: What distinguishes an aerospace buyer from a general procurement specialist?

The key differentiator lies in the specialized knowledge and skills required to navigate the stringent regulatory environment, technical complexities, and quality standards inherent in the aerospace industry. A general procurement specialist may lack the necessary expertise in areas such as FAA compliance, AS9100 quality management systems, and aerospace materials science.

Question 2: What are the most critical skills for success in this role?

Essential skills include proficiency in contract negotiation, a thorough understanding of aerospace materials and manufacturing processes, familiarity with relevant regulatory frameworks, the ability to interpret technical drawings and specifications, robust analytical skills for evaluating supplier proposals, and mastery of ERP systems for purchase order management.

Question 3: What educational qualifications are typically required?

A bachelor’s degree in supply chain management, business administration, engineering, or a related field is frequently a minimum requirement. Advanced certifications such as CPSM or CSCP, along with specialized aerospace training, are highly valued.

Question 4: What types of experience are considered most relevant?

Prior experience in supply chain management, contract negotiation, and vendor relations, specifically within the aerospace domain, is highly beneficial. Experience managing supplier quality audits and navigating regulatory compliance requirements is particularly valuable.

Question 5: How significant is compliance with regulations such as FAA and ITAR?

Compliance with regulations such as FAA, EASA, and ITAR is of paramount importance. Failure to adhere to these regulations can result in significant fines, legal repercussions, and potentially the grounding of aircraft. Buyers must possess a comprehensive understanding of these regulations and ensure all procurement activities comply.

Question 6: What are the primary responsibilities of an aerospace buyer?

The core responsibilities encompass procurement execution, supplier management, contract negotiation and management, and ensuring compliance with relevant aerospace regulations and industry standards. This involves sourcing, negotiating, and purchasing materials, components, and services while adhering to stringent quality and regulatory requirements.

In conclusion, the aerospace buyer role demands a specialized skillset and a comprehensive understanding of the unique challenges and requirements of the aerospace industry. Compliance, technical expertise, and strong negotiation skills are essential for success in this critical function.

The complexities in the role often involve adapting quickly. The next section will address adaptability and soft skills.

Aerospace Buyer Job Description

This exploration has highlighted the multifaceted nature of the “aerospace buyer job description,” emphasizing its importance in defining the responsibilities, qualifications, and skills necessary for procurement professionals within the aerospace sector. From stringent regulatory compliance to technical expertise and negotiation prowess, the specified criteria directly impact the safety, reliability, and efficiency of aerospace operations. A well-defined role specification is not merely a recruitment tool but a fundamental element in ensuring a robust and capable supply chain.

The continued evolution of aerospace technology and regulations necessitates a proactive approach to defining and refining the “aerospace buyer job description.” Organizations must prioritize attracting and retaining individuals equipped to navigate the complexities of this dynamic industry. The future demands professionals who not only possess the requisite skills and knowledge but also demonstrate a commitment to ethical conduct and continuous improvement, thereby safeguarding the integrity of the aerospace supply chain and ensuring the continued advancement of the industry.