Positions utilizing computational fluid dynamics within the aerospace sector involve the application of numerical methods and algorithms to analyze and predict fluid flow phenomena related to aircraft, spacecraft, and related systems. These roles typically require expertise in fluid mechanics, heat transfer, and computer programming, along with experience using specialized software packages. An example includes simulating airflow over a wing to optimize its aerodynamic performance.

The simulation and analysis of fluid dynamics are crucial for optimizing designs, ensuring safety, and improving the efficiency of flight. This has led to a growing demand for skilled professionals. Historically, physical wind tunnel testing was the primary method for aerodynamic analysis, but advancements in computing power and numerical methods have made simulation an indispensable and often more cost-effective tool in the design process.

The following sections will delve into specific responsibilities, required qualifications, common employers, and future trends within this field.

Guidance for Pursuing Career Opportunities

The following recommendations offer insights into effectively targeting and securing desired roles. These points emphasize proactive skill development and strategic career planning.

Tip 1: Strengthen Foundational Knowledge: A robust understanding of fluid mechanics, thermodynamics, and heat transfer is paramount. These principles underpin effective utilization of simulation software and accurate interpretation of results. Example: Rigorous coursework in compressible and incompressible flows provides a solid base.

Tip 2: Master Industry-Standard Software: Proficiency in programs such as ANSYS Fluent, Star-CCM+, or OpenFOAM is essential. Employers often seek candidates with demonstrable experience using these tools for complex problem-solving. Example: Completing certification courses or contributing to open-source projects can showcase software skills.

Tip 3: Develop Programming Skills: Familiarity with programming languages such as Python or C++ enables customization of simulation processes, development of user-defined functions, and efficient data analysis. Example: Creating scripts to automate repetitive tasks within CFD software enhances productivity.

Tip 4: Seek Relevant Project Experience: Participating in research projects, internships, or academic competitions provides valuable practical experience. This demonstrates an ability to apply theoretical knowledge to real-world engineering challenges. Example: Simulating the performance of a novel airfoil design as part of a university research project.

Tip 5: Network with Professionals: Attending industry conferences, joining professional organizations, and connecting with individuals through online platforms can facilitate valuable connections and provide insights into career opportunities. Example: Engaging with experts at AIAA conferences or participating in online CFD forums.

Tip 6: Tailor Resumes and Cover Letters: Customize application materials to highlight specific skills and experience that align with the requirements of the target. Emphasize relevant project accomplishments and demonstrate a clear understanding of the organization’s objectives. Example: Referencing specific projects or software mentioned in the requirement section.

Tip 7: Prepare for Technical Interviews: Anticipate questions related to fundamental concepts, numerical methods, and practical applications. Practice problem-solving and clearly articulate the rationale behind your approaches. Example: Being able to describe the advantages and disadvantages of different turbulence models.

By focusing on fundamental knowledge, software proficiency, and practical experience, individuals can significantly enhance their prospects. Networking and targeted application strategies are crucial for gaining a competitive edge in the field.

The subsequent sections will offer further insights into compensation expectations and long-term career advancement opportunities.

1. Aerodynamic Simulations

Aerodynamic simulations form a cornerstone of work in the field. This involves employing computational fluid dynamics to model airflow around aerospace vehicles and components. The simulations directly influence design decisions by predicting lift, drag, and stability characteristics. Inaccurate predictions can lead to design flaws, reduced performance, or compromised safety. Therefore, expertise in aerodynamic simulation is often a prerequisite for these roles.

A practical example can be found in the design of aircraft wings. CFD simulations allow engineers to test various airfoil shapes and wing configurations to optimize lift-to-drag ratios. The resulting data informs the selection of the most efficient design, contributing to reduced fuel consumption and improved flight range. Similarly, simulations are used to analyze the aerodynamic effects of control surfaces, such as ailerons and elevators, ensuring effective maneuvering capabilities. Furthermore, for space vehicles, aerodynamic simulations assist in understanding atmospheric re-entry conditions, essential for designing heat shields and controlling trajectory.

Understanding the interplay between aerodynamic simulations and the broader context is vital for professionals to successfully navigate the field. As computational power increases and simulation techniques become more sophisticated, the demand for skilled individuals who can accurately model, interpret, and apply these insights is set to grow. Addressing the challenges associated with computational cost and model validation will be key to maximizing the benefits of aerodynamic simulation in future aerospace endeavors.

2. Thermal Management Analysis

Thermal management analysis within jobs involving computational fluid dynamics for the aerospace sector addresses the critical challenge of maintaining acceptable operating temperatures for various systems and components. Excess heat can severely degrade performance, reduce lifespan, or cause catastrophic failures in aircraft, spacecraft, and related equipment. Therefore, accurate thermal modeling and simulation are integral to ensuring reliability and safety. This involves assessing heat generation, heat transfer mechanisms (conduction, convection, radiation), and the effectiveness of cooling strategies.

For instance, in aircraft engine design, thermal analysis is used to optimize cooling passages within turbine blades, preventing them from melting under extreme operating conditions. Simulations can predict the temperature distribution throughout the blade, identifying hotspots and enabling the design of more efficient cooling solutions. Similarly, for electronics systems onboard satellites, careful thermal management is crucial to dissipate heat generated by sensitive components. CFD simulations can model the flow of air or other coolants through electronic enclosures, ensuring that temperatures remain within specified limits. Failure to adequately manage thermal loads can result in component malfunction and mission failure. These analyses can also support the design of advanced insulation or shielding systems to protect equipment from external sources of heat, such as solar radiation or aerodynamic heating during atmospheric entry.

In summation, thermal management analysis represents a vital component, ensuring the reliable operation of aerospace systems in thermally challenging environments. Challenges remain in accurately representing complex physical phenomena such as two-phase flow or non-equilibrium thermodynamics. As computational capabilities advance, the accuracy and sophistication of these analyses will continue to improve, playing an increasingly crucial role in future aerospace developments. Professionals require a strong foundation in heat transfer principles, numerical methods, and experience with specialized software to effectively contribute to these endeavors.

3. Structural Load Prediction

Structural load prediction is intrinsically linked. It is crucial for ensuring the integrity and safety of aerospace vehicles. Accurately estimating the forces acting on an aircraft or spacecraft during flight is essential for designing structures that can withstand those stresses without failure. Positions involving computational fluid dynamics contribute directly to this process by providing detailed pressure distributions on external surfaces. These pressure distributions are then used as inputs for structural analysis simulations, such as finite element analysis (FEA), to determine stress and strain levels within the structure.

For example, in the design of an aircraft wing, CFD simulations are used to predict the pressure distribution across the wing’s surface at various flight conditions. This pressure data is then applied as a load to a finite element model of the wing structure. The FEA simulation calculates the resulting stresses and deflections within the wing, allowing engineers to identify areas of high stress concentration that may require reinforcement. Similarly, for spacecraft, CFD simulations can predict the aerodynamic loads experienced during launch and atmospheric re-entry, providing critical data for designing robust and reliable structures. Overestimation of those loads leads to the use of unecessary material. Conversely, underestimation can lead to failure.

The ability to accurately predict structural loads is paramount in aerospace engineering. By providing detailed pressure data, these roles are vital in the design and certification process. Continuous advancements in computational power and simulation techniques are further enhancing the accuracy and reliability of load predictions, playing an increasingly important role in ensuring the safety and efficiency of next-generation aerospace vehicles. Addressing challenges in model validation and turbulence modeling remains a focus for future development.

4. Optimization Techniques

The application of optimization techniques is integral to positions leveraging computational fluid dynamics within the aerospace sector. These methodologies seek to enhance the performance characteristics of aircraft, spacecraft, and related systems by iteratively refining designs based on simulation results. This ensures designs meet performance requirements while minimizing factors like weight, drag, or fuel consumption.

- Adjoint Optimization

Adjoint optimization employs adjoint solvers to efficiently compute gradients of objective functions (e.g., drag) with respect to design variables (e.g., airfoil shape). This allows for rapid identification of design modifications that will improve performance. For example, optimizing the shape of a wing to reduce drag at a specific flight condition. Its application reduces the computational cost of design exploration compared to traditional methods, by not re-running simulations for each design tweak.

- Shape Optimization

Shape optimization involves systematically altering the geometry of a component to achieve a desired performance goal. Algorithms are coupled with CFD solvers to iteratively refine the shape of an airfoil, nozzle, or other aerospace component. This approach enables the discovery of non-intuitive designs that outperform conventional geometries. Example: Using a morphing wing to reduce drag during various flight conditions.

- Topology Optimization

Topology optimization focuses on determining the optimal material distribution within a given design space to maximize stiffness, minimize weight, or achieve other performance objectives. CFD can be integrated to account for fluid-structure interaction effects. This can lead to lightweight structural components. Example: Generating a lightweight internal support structure for an aircraft wing that maximizes stiffness while minimizing weight, accounting for aerodynamic loads.

- Multi-Objective Optimization

Multi-objective optimization addresses scenarios where multiple conflicting objectives must be considered simultaneously. Algorithms explore the trade-offs between different performance metrics to identify a set of Pareto-optimal designs that represent the best compromise solutions. Example: Optimizing an aircraft wing to simultaneously minimize drag and maximize lift, while also considering manufacturing constraints.

The implementation of the above-mentioned techniques requires not only an understanding of optimization algorithms, but also proficiency in CFD software and a strong foundation in aerospace engineering principles. These are critical tools. Consequently, the effective application of these capabilities enhances vehicle efficiency, performance, and overall design robustness. These roles support the development of next-generation aerospace technologies.

5. Software Proficiency

Expertise in specific software packages is a non-negotiable element in roles involving computational fluid dynamics within the aerospace sector. Employers seek individuals who can effectively utilize these tools to simulate complex flow phenomena, analyze results, and optimize designs. Without this skill, individuals cannot effectively perform these jobs.

- Pre-processing Software

Software tools such as ANSA or HyperMesh are essential for preparing geometric models for CFD analysis. This involves cleaning up CAD geometry, generating high-quality meshes, and defining boundary conditions. The accuracy and efficiency of the pre-processing stage directly impacts the quality of the simulation results. Example: Generating a well-defined mesh around a complex aircraft wing to accurately capture boundary layer effects.

- CFD Solvers

Proficiency in using CFD solvers such as ANSYS Fluent, Star-CCM+, or OpenFOAM is critical. These solvers employ numerical methods to solve the governing equations of fluid dynamics. Expertise includes selecting appropriate turbulence models, defining solver settings, and monitoring convergence. Example: Using a Reynolds-averaged Navier-Stokes (RANS) solver to simulate airflow over a turbine blade and predicting pressure distribution.

- Post-processing Software

Software tools such as Tecplot or ParaView enable the visualization and analysis of CFD results. This involves creating contour plots, vector fields, and animations to understand flow behavior. Expertise in post-processing includes extracting relevant data, generating reports, and presenting findings effectively. Example: Visualizing the separation of airflow over a wing at high angles of attack to understand stall characteristics.

- Scripting and Automation Tools

Familiarity with scripting languages such as Python or Tcl allows for the automation of repetitive tasks, customization of simulation workflows, and integration of CFD software with other engineering tools. This enhances efficiency and enables more complex analyses. Example: Developing a Python script to automatically run a series of CFD simulations with varying parameters and generate a summary report of the results.

The selection and application of appropriate software tools is a core competency required in positions focused on the intersection of computational fluid dynamics and aerospace engineering. A demonstrated ability to leverage these tools effectively translates directly into the ability to contribute meaningfully to design optimization, performance analysis, and safety assessments. Consequently, individuals with robust software skills are highly sought-after within this sector.

Frequently Asked Questions

The following section addresses common inquiries regarding career paths involving the application of computational fluid dynamics within the aerospace industry. These answers aim to provide clarity on necessary qualifications, job responsibilities, and career prospects.

Question 1: What educational background is typically required?

A bachelor’s degree in aerospace engineering, mechanical engineering, or a related field is generally the minimum requirement. Many positions, particularly those involving research and development, necessitate a master’s degree or doctorate. Coursework should include fluid mechanics, heat transfer, numerical methods, and computer programming.

Question 2: What are the core technical skills needed to succeed?

Proficiency in industry-standard CFD software (e.g., ANSYS Fluent, Star-CCM+, OpenFOAM) is essential. A strong understanding of turbulence modeling, numerical discretization schemes, and mesh generation techniques is also necessary. Additionally, programming skills in languages such as Python or C++ are often required for scripting and data analysis.

Question 3: What are typical job responsibilities?

Responsibilities may include performing aerodynamic simulations of aircraft components, analyzing thermal management systems for spacecraft, predicting structural loads on aerospace vehicles, and optimizing designs using computational techniques. Analyzing data, generating reports, and presenting findings to stakeholders are also common tasks.

Question 4: What types of companies hire professionals with expertise?

Aerospace manufacturers (e.g., Boeing, Airbus, Lockheed Martin), government research laboratories (e.g., NASA, national labs), and engineering consulting firms are primary employers. These organizations utilize CFD to support design, analysis, and research activities.

Question 5: What is the outlook for jobs requiring these skills?

The demand is projected to remain strong due to the increasing reliance on simulation in the aerospace industry. Advancements in computing power and numerical methods are driving the adoption of CFD in various applications. Continued innovation in the aerospace sector will also create new opportunities.

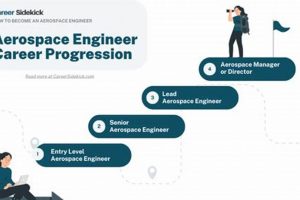

Question 6: What are common career progression paths?

Entry-level positions may involve performing basic simulations and data analysis under the supervision of senior engineers. With experience, individuals can advance to roles with greater responsibilities, such as leading projects, developing new simulation methodologies, or managing teams. Opportunities may also arise in specialized areas such as optimization or uncertainty quantification.

These FAQs highlight the essential aspects of pursuing roles related to computational fluid dynamics in aerospace. A strong educational foundation, coupled with relevant technical skills and a continuous learning mindset, is critical for success.

The next section will delve into case studies illustrating practical applications of CFD in aerospace engineering.

Conclusion

This exploration has elucidated the critical role of computational fluid dynamics within the aerospace domain. Expertise is vital for aerodynamic design, thermal management, and structural integrity. Individuals seeking opportunities within this field must demonstrate proficiency in relevant software, coupled with a strong grasp of underlying engineering principles. Specific examples, from wing optimization to engine thermal analysis, underscore the practical impact and necessity of skills in aerospace cfd jobs.

The aerospace sector’s continued reliance on simulation suggests sustained demand for qualified professionals. Individuals are encouraged to pursue advanced training, maintain awareness of emerging technologies, and cultivate strong problem-solving abilities. The accurate and efficient application of CFD will remain a cornerstone of aerospace innovation and progress.