Positions within this sector involve contributing to the design, manufacturing, maintenance, and operation of aircraft and spacecraft. These roles span a wide array of disciplines, from engineering and technical specialties to administrative and management functions, all focused on advancing the capabilities and safety of flight. For instance, an engineer might design a new aircraft wing, while a technician might perform routine maintenance on an engine.

Engaging in this field offers opportunities for professional growth, involvement in cutting-edge technological advancements, and the satisfaction of contributing to a critical industry. Historically, this area has driven innovation in materials science, aerodynamics, and communications, leading to advancements that extend beyond aviation. The constant demand for skilled professionals ensures a stable career path for qualified individuals.

The subsequent sections will delve into specific career paths, required qualifications, and the overall employment landscape within this dynamic domain, providing insights into how one can pursue and succeed in this competitive yet rewarding industry. This will cover education requirements, typical job duties, and emerging trends shaping future opportunities.

Career Advancement Guidance

The following points provide potential candidates with relevant advice on increasing their prospects within this specialized employment area.

Tip 1: Obtain Relevant Certifications: Completing industry-recognized certifications, such as FAA Airframe and Powerplant licenses, can significantly enhance a candidate’s appeal. These credentials demonstrate a commitment to professional standards and a validated skill set.

Tip 2: Focus on Specialized Training: Seek out focused training programs aligned with specific areas of interest, such as avionics systems, composite materials, or propulsion technologies. This specialization can lead to opportunities in high-demand roles.

Tip 3: Develop Strong Problem-Solving Skills: Employers value individuals who can effectively troubleshoot complex technical issues. Cultivating analytical and critical-thinking abilities is crucial for success in this field.

Tip 4: Emphasize Safety Consciousness: A demonstrated commitment to safety protocols and regulatory compliance is paramount. Highlight any experience with safety management systems or hazard analysis techniques.

Tip 5: Build a Professional Network: Attend industry events, join professional organizations, and connect with individuals working in relevant positions. Networking can provide valuable insights and potential job leads.

Tip 6: Tailor Resumes and Cover Letters: Customize application materials to align with the specific requirements and responsibilities outlined in each job posting. Emphasize relevant skills and experiences that directly address employer needs.

Tip 7: Gain Practical Experience: Seek internships, apprenticeships, or entry-level positions to acquire hands-on experience. Even seemingly minor roles can provide valuable exposure to the industry and its operational aspects.

Adherence to these guidelines can improve a candidate’s ability to stand out in a competitive job market, ultimately increasing their chances of securing a desirable position. Proactive skill development and strategic career planning are vital for long-term success.

The subsequent sections will explore the future outlook for this sector, highlighting emerging technologies and the evolving demands of employers. This forward-looking perspective can assist individuals in aligning their skills with future career opportunities.

1. Engineering Expertise

Engineering expertise forms a cornerstone of roles within the aerospace sector. Positions ranging from design engineers to systems analysts rely heavily on a profound understanding of engineering principles. A deficiency in this expertise directly impacts the ability to develop, test, and maintain aircraft and spacecraft safely and effectively. For example, the structural integrity of an aircraft wing is contingent on accurate calculations and material selection, a direct result of engineering analysis. Consequently, inadequate engineering knowledge can lead to catastrophic failures, underscoring its critical importance.

The application of engineering principles within this industry extends to various specialized domains, including aerodynamics, propulsion, and avionics. Aerodynamics engineers optimize aircraft shapes to reduce drag and improve lift; propulsion engineers focus on engine design and performance; avionics engineers develop and integrate electronic systems for navigation and control. Each of these areas demands a deep understanding of underlying scientific and mathematical principles. Without skilled engineers in these areas, the advancement of aerospace technology would be severely hampered. Consider the development of fuel-efficient jet engines; this advancement relies on iterative design improvements driven by engineering expertise.

In summary, engineering expertise is not merely a desirable skill but a fundamental requirement for many careers. Its presence dictates the safety, efficiency, and innovation within the industry. Challenges remain in attracting and retaining qualified engineers, requiring ongoing investment in education and training programs. Recognizing the practical significance of this relationship is essential for stakeholders aiming to foster a robust and sustainable aerospace workforce.

2. Technical Skills

Proficiency in a range of technical skills is indispensable for individuals pursuing careers in the aerospace sector. These competencies are not merely supplementary but rather foundational to the safe and effective execution of tasks related to aircraft design, manufacturing, maintenance, and operation. The demand for specialized expertise necessitates a highly skilled workforce capable of addressing complex technical challenges.

- Aircraft Maintenance and Repair

This facet encompasses the ability to diagnose, troubleshoot, and repair aircraft systems and components. Technicians must possess a comprehensive understanding of aircraft structures, engines, hydraulics, and electrical systems. For instance, the ability to accurately diagnose a malfunctioning turbine engine or repair structural damage to an aircraft fuselage directly impacts flight safety. The implications of inadequate maintenance skills can lead to catastrophic failures and compromise the integrity of aircraft operations.

- Avionics Systems Integration

The integration and maintenance of avionics systems, including navigation, communication, and flight control systems, are critical technical skills. Professionals in this area must be adept at working with complex electronic equipment, interpreting technical schematics, and conducting system testing. A real-world example involves calibrating an aircraft’s inertial navigation system to ensure accurate positioning during flight. Errors in avionics integration can lead to navigation errors and compromised flight safety.

- Computer-Aided Design (CAD) and Manufacturing (CAM)

The utilization of CAD and CAM software is essential for designing and manufacturing aircraft components. Engineers and technicians must be proficient in creating detailed 3D models, generating manufacturing instructions, and operating computer-controlled machinery. The design of a new aircraft wing, for example, relies heavily on CAD software to optimize its aerodynamic performance. The accuracy and efficiency of the manufacturing process are directly influenced by the skills of CAD/CAM operators.

- Materials Science and Testing

A solid understanding of materials science and testing methodologies is crucial for selecting and evaluating materials used in aircraft construction. Technicians must be capable of conducting non-destructive testing (NDT) procedures to detect flaws in aircraft structures without causing damage. For example, ultrasonic testing can be used to identify cracks in an aircraft’s fuselage. The selection of appropriate materials and the implementation of rigorous testing protocols are paramount to ensuring the structural integrity and durability of aircraft.

The technical skills described above represent a subset of the diverse competencies required for success in this field. These skills, coupled with a strong foundation in mathematics, science, and engineering principles, enable professionals to contribute meaningfully to the advancement of aerospace technology. The ongoing development and refinement of these skills are essential for maintaining a competitive edge and ensuring the continued safety and reliability of aircraft operations.

3. Quality Assurance

Quality assurance serves as a cornerstone within the realm of aerospace employment. It represents a systematic approach to ensuring that products and services meet specified requirements and maintain consistently high standards. In the context of aerospace roles, quality assurance is not merely a procedural formality but a critical component safeguarding human lives and operational efficiency.

- Inspection and Testing Protocols

Rigorous inspection and testing protocols are integral to quality assurance in aerospace. These protocols involve the meticulous examination of materials, components, and assembled systems to identify defects or deviations from established standards. For example, non-destructive testing methods, such as ultrasonic or radiographic inspections, are employed to detect hidden flaws in aircraft structures. The failure to adhere to these protocols can result in catastrophic consequences, emphasizing the importance of meticulous attention to detail.

- Compliance with Regulatory Standards

Aerospace operations are governed by stringent regulatory standards established by agencies such as the Federal Aviation Administration (FAA) and the European Aviation Safety Agency (EASA). Quality assurance professionals must ensure that all processes and products comply with these regulations. This includes maintaining detailed documentation, conducting audits, and implementing corrective actions to address any non-compliance issues. Non-compliance can lead to significant penalties, including fines, operational restrictions, and reputational damage.

- Process Control and Improvement

Quality assurance involves the implementation of process control measures to monitor and optimize manufacturing and maintenance activities. This includes statistical process control (SPC) techniques to track key performance indicators and identify trends that may indicate potential problems. Continuous improvement initiatives, such as Six Sigma or Lean methodologies, are often employed to enhance efficiency and reduce defects. For instance, implementing statistical process control in the manufacturing of turbine blades can improve dimensional accuracy and reduce scrap rates.

- Documentation and Traceability

Comprehensive documentation and traceability systems are essential for maintaining quality control throughout the aerospace supply chain. This includes tracking the origin of materials, the manufacturing processes used, and the results of inspections and tests. This level of traceability allows for the rapid identification and containment of any issues that may arise. For example, in the event of a component failure, the traceability system can be used to identify other aircraft that may be affected and implement appropriate corrective actions.

The aforementioned facets underscore the vital role of quality assurance in maintaining safety, reliability, and compliance within the aerospace industry. Individuals pursuing careers in this sector must possess a deep understanding of quality assurance principles and a commitment to upholding the highest standards. The effective implementation of quality assurance measures is essential for mitigating risks and ensuring the continued success of aerospace operations. The dedication of personnel to these aspects ensures that those in positions related to aviation benefit from the stringent guidelines implemented.

4. Safety Compliance

Adherence to rigorous safety protocols forms a non-negotiable cornerstone of operations within the aerospace industry. The intersection of “safety compliance” and employment necessitates that individuals in these roles demonstrate an unwavering commitment to maintaining and enforcing safety standards. This commitment permeates all levels of the organizational hierarchy, from design engineers to maintenance technicians, each of whom plays a critical role in upholding the integrity of aircraft and spacecraft systems. The direct consequence of neglecting safety compliance can range from minor equipment malfunctions to catastrophic accidents involving significant loss of life and financial resources.

The importance of “safety compliance” within specific aerospace roles is further underscored by examples such as adherence to FAA regulations in aircraft maintenance, rigorous testing of components before installation, and comprehensive risk assessments prior to flight operations. Consider the role of a quality control inspector; their primary responsibility is to verify that all manufactured parts meet stringent quality standards. A failure to identify a critical defect in a turbine blade, for instance, could lead to engine failure during flight. Similarly, pilots must meticulously adhere to pre-flight checklists and emergency procedures to mitigate potential hazards. These practical applications highlight how a robust safety culture directly contributes to the reliability and security of aerospace operations.

In conclusion, understanding the practical significance of “safety compliance” in relation to the industry is paramount for ensuring the sustained operational integrity and protection of human life. Challenges remain in continually adapting safety protocols to accommodate technological advancements and emerging threats. However, a steadfast commitment to robust safety measures, coupled with comprehensive training programs and proactive risk management strategies, is essential for fostering a safety-conscious culture and mitigating potential hazards within the ever-evolving aerospace domain. The continued emphasis on safety, as a core value, will ensure the ongoing success and sustainability of roles within this critical sector.

5. Project Management

Effective project management is an indispensable function within the aerospace sector. Roles in this area involve overseeing complex projects from inception to completion, ensuring that they are delivered on time, within budget, and to the required specifications. The successful execution of aerospace projects necessitates a high degree of organization, communication, and problem-solving skills.

- Planning and Scheduling

Project managers are responsible for developing detailed project plans, including timelines, resource allocation, and risk assessments. This involves breaking down complex tasks into manageable components and assigning responsibilities to team members. For example, the development of a new satellite requires a detailed schedule that coordinates the efforts of engineers, technicians, and subcontractors. Effective planning and scheduling are critical to minimizing delays and cost overruns.

- Resource Management

Managing resources, including personnel, equipment, and funding, is a key aspect of project management. This involves allocating resources efficiently to ensure that tasks are completed on time and within budget. A real-world example would be coordinating the use of wind tunnels for aircraft testing, ensuring that they are available when needed and that the results are accurately analyzed. Inefficient resource management can lead to delays and increased costs.

- Risk Management

Identifying and mitigating risks is a critical responsibility of project managers. This involves assessing potential threats to project success and developing contingency plans to address them. For instance, the development of a new rocket engine carries the risk of technical failures or delays in component delivery. Project managers must develop strategies to minimize these risks and ensure that the project stays on track. Proactive risk management can prevent costly setbacks and ensure project success.

- Communication and Coordination

Effective communication and coordination are essential for ensuring that all stakeholders are informed and aligned. This involves facilitating communication between team members, subcontractors, and clients. A project manager might hold regular meetings to discuss progress, address issues, and coordinate activities. Clear and consistent communication is critical to avoiding misunderstandings and ensuring that everyone is working towards the same goals. This skill ensures fluid operation between all related parties.

These facets illustrate the diverse and critical role of project management within the aerospace industry. The successful completion of aerospace projects, whether it’s developing a new aircraft, launching a satellite, or designing a space station, relies heavily on the skills and expertise of project managers. The ongoing demand for skilled project managers ensures that individuals with the necessary qualifications and experience have ample opportunities in this sector. It also helps to keep things on task.

6. Continuous Learning

Continuous learning is not merely an option but a prerequisite for sustained success. The rapid pace of technological advancement within aviation necessitates that professionals consistently update their knowledge and skills to remain effective and competitive. This dedication to ongoing education ensures they are conversant with emerging technologies and best practices.

- Technological Adaptation

The introduction of new materials, software, and aerospace systems requires ongoing education to ensure employees possess the skills to work with them effectively. For example, a technician trained only on traditional aluminum aircraft may require additional training to maintain aircraft constructed with composite materials. Failing to adapt to these changes limits career progression and operational capabilities.

- Regulatory Compliance

Aerospace regulations are subject to frequent revisions and updates. Professionals must engage in continuous learning to stay abreast of these changes and ensure compliance with the latest safety standards. Consider the frequent updates to FAA regulations; personnel must actively participate in training programs to remain compliant. Non-compliance can lead to penalties and jeopardize operational licenses.

- Skill Enhancement

Continuous learning provides opportunities to enhance existing skills and acquire new competencies, leading to increased job performance and career advancement. For instance, an engineer may pursue advanced training in computational fluid dynamics (CFD) to improve their ability to design more efficient aircraft. Investing in skills enhancement provides a competitive edge and fosters innovation.

- Safety Improvement

Ongoing training in safety procedures and risk management techniques is essential for minimizing accidents and ensuring the well-being of personnel and passengers. Flight crews, maintenance personnel, and air traffic controllers all require regular safety training to reinforce best practices and address emerging threats. Regular drills and simulations help embed safety protocols into everyday operations.

These facets illustrate that continuous learning is integral to the success of individuals and organizations. By embracing a culture of lifelong learning, professionals can remain at the forefront of technological innovation, maintain regulatory compliance, enhance their skills, and improve safety outcomes. The commitment to ongoing education is not merely an advantage but a strategic imperative for those seeking sustained career success in the dynamic aerospace sector.

Frequently Asked Questions

The following addresses common inquiries concerning positions within this advanced industry, clarifying requirements, expectations, and overall employment conditions.

Question 1: What educational qualifications are typically required to secure employment?

Educational requirements vary according to the specific role. Engineering positions generally necessitate a bachelor’s or master’s degree in aerospace, mechanical, or electrical engineering. Technical roles may require an associate’s degree or certification from a vocational training program.

Question 2: What are the most in-demand skills currently sought by employers?

Employers frequently seek candidates with expertise in areas such as CAD/CAM software, composite materials, avionics systems, and project management. Strong analytical and problem-solving skills are also highly valued.

Question 3: How does one gain relevant experience to enter the field?

Gaining experience through internships, apprenticeships, or entry-level positions is crucial. Participating in industry-related projects or research can also enhance a candidate’s qualifications.

Question 4: What are some common career progression paths within this sector?

Career progression paths depend on the specific role. Engineers may advance to senior engineering positions or project management roles. Technicians may become lead technicians or supervisors. Continuous professional development can facilitate career advancement.

Question 5: What is the work environment typically like?

The work environment can vary depending on the employer and role. Some positions may involve working in manufacturing facilities, while others may be office-based. Safety protocols are strictly enforced across all work environments.

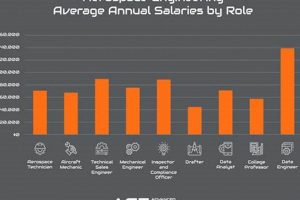

Question 6: What are the typical salary expectations for entry-level positions?

Salary expectations vary based on education, experience, and location. Entry-level engineering positions may offer salaries in the range of \$60,000 to \$80,000 per year, while technical positions may offer salaries in the range of \$40,000 to \$60,000 per year.

Key takeaways emphasize that preparation, skill development, and continuous learning are essential for thriving in this challenging yet rewarding domain. Staying informed about industry trends and employer expectations is crucial for career success.

The subsequent section will provide information regarding resources and career development tools available to assist individuals pursuing roles within the aviation sector.

The preceding exploration has detailed key facets of roles within the aerospace sector, encompassing required skills, responsibilities, and advancement prospects. These details serve to inform potential applicants of the conditions and requirements, emphasizing the high standards and demands inherent in this highly regulated industry.

Recognizing the significance of “king aerospace jobs,” and the potential for contributing to advancements in aviation, individuals are encouraged to pursue further education and training. The future of flight depends on the dedication and expertise of those who commit to these challenging but essential roles, thus strengthening the capabilities for continuous innovations and future developments.