Positions in this field involve the skilled operation of Computer Numerical Control (CNC) machinery to fabricate precision components utilized within the aeronautics and space industries. These roles require a deep understanding of machining principles, blueprint reading, and material properties to produce parts that meet stringent quality standards and dimensional tolerances. As an example, an individual in this occupation might be tasked with machining a turbine blade for a jet engine or creating structural elements for a satellite.

The demand for qualified professionals in this area is driven by the continued growth of the aviation sector, space exploration initiatives, and the increasing complexity of aircraft and spacecraft designs. Possessing the necessary expertise translates into opportunities for career advancement, competitive salaries, and the satisfaction of contributing to technologically advanced projects. Historically, the evolution of CNC technology has revolutionized manufacturing processes, enabling the production of intricate parts with greater accuracy and efficiency, thereby fueling the need for skilled operators.

The subsequent sections will delve into the specific skills and qualifications sought by employers, detail the common responsibilities associated with these roles, and provide insights into career pathways and potential earning potential.

Essential Guidance for Aspiring Professionals

The following represents crucial advice for individuals seeking to establish or advance their careers in the field of precision manufacturing for the aeronautics and space sectors.

Tip 1: Develop a Robust Understanding of CNC Programming Languages: Proficiency in G-code and other programming languages is paramount. Candidates should demonstrate the ability to write, interpret, and modify CNC programs to optimize machining processes. For instance, mastering parametric programming can significantly improve efficiency when machining families of parts with slight variations.

Tip 2: Prioritize Blueprint Reading and Geometric Dimensioning & Tolerancing (GD&T): An expert understanding of engineering drawings and GD&T principles is essential for accurately interpreting design specifications and ensuring parts meet critical tolerances. Inability to properly interpret GD&T can result in parts that are rejected, costing time and resources.

Tip 3: Gain Experience with a Variety of CNC Machines: Exposure to different types of CNC machines, such as milling machines, lathes, and multi-axis machines, will broaden skill sets and increase employability. Experience with specific machine models commonly used in aerospace manufacturing is highly advantageous.

Tip 4: Emphasize Material Science Knowledge: The aerospace industry utilizes a wide range of materials, including aluminum alloys, titanium, and composites. Understanding the properties and machining characteristics of these materials is critical for selecting appropriate cutting tools and optimizing machining parameters.

Tip 5: Seek Certifications from Recognized Organizations: Obtaining certifications from organizations such as the National Institute for Metalworking Skills (NIMS) demonstrates competency and commitment to professional development. Certification validates skill sets and can improve career prospects.

Tip 6: Prioritize Precision and Attention to Detail: Given the stringent quality requirements in the aerospace industry, meticulousness and a commitment to accuracy are crucial. A single error can have significant consequences; therefore, adherence to established procedures and a focus on precision are paramount.

Tip 7: Pursue Continuous Learning and Professional Development: CNC technology is constantly evolving. Staying abreast of the latest advancements through ongoing training, workshops, and industry publications is essential for maintaining a competitive edge.

By diligently adhering to this advice, individuals can significantly enhance their prospects within this specialized and demanding field, positioning themselves for long-term success.

The subsequent discourse will explore the specific responsibilities and tasks typically associated with roles in this domain.

1. Precision Machining

Precision machining serves as the cornerstone of manufacturing processes integral to the aerospace industry. The ability to create components with exacting dimensional accuracy and surface finish characteristics is not merely desirable but absolutely mandatory. This requirement directly impacts the skill set and responsibilities inherent in roles related to these machining operations.

- Dimensional Accuracy and Tolerance Control

Achieving exceptionally tight tolerances, often measured in microns, is fundamental. Parts must conform precisely to design specifications to ensure proper fit and function within complex assemblies. An example includes the machining of turbine blades for jet engines, where even slight deviations can drastically reduce efficiency and lifespan.

- Surface Finish Quality

The surface finish of machined components impacts their performance and longevity. Smoother surfaces reduce friction, improve wear resistance, and can enhance the aerodynamic properties of certain parts. Machining wing components to meet specific roughness averages (Ra) is a common example where surface integrity is paramount.

- Material Removal Techniques and Tooling Selection

The efficient and precise removal of material is crucial. Selecting appropriate cutting tools, speeds, and feeds is vital for achieving desired tolerances and surface finishes while minimizing tool wear. Machining hardened alloys used in landing gear requires specialized tooling and techniques to maintain accuracy and avoid premature tool failure.

- Adherence to Regulatory Standards

Aerospace manufacturing is heavily regulated, with stringent quality control processes in place. Machinists must adhere to these standards, ensuring that all parts meet specified requirements and are properly documented. Compliance with AS9100 standards is a common requirement.

The convergence of these facets underscores the critical relationship between precision machining capabilities and the performance and safety of aircraft and spacecraft. Roles requiring proficiency in these areas are thus highly valued, reflecting the demanding nature of these positions and their direct impact on the reliability of aerospace systems.

2. Material Expertise

Material expertise is intrinsically linked to the effectiveness of CNC machining within the aeronautics and space sectors. The performance and safety of aircraft and spacecraft are directly dependent on the properties and characteristics of the materials employed in their construction. Therefore, individuals in these roles must possess comprehensive knowledge of material science and its application to machining processes.

- Material Selection for Specific Applications

Aerospace components are manufactured from a diverse range of materials, each possessing unique properties suited to specific applications. Aluminum alloys, titanium, nickel-based superalloys, composites, and ceramics are commonly used, each with its own set of advantages and disadvantages. For instance, titanium alloys are favored for their high strength-to-weight ratio in structural components, while nickel-based superalloys are used in high-temperature environments such as jet engines. CNC machinists must understand these distinctions to select appropriate materials and machining parameters.

- Machining Characteristics and Challenges

Different materials exhibit varying machining characteristics, influencing tool wear, surface finish, and the risk of defects. Some materials, such as titanium, are prone to work hardening, requiring specific cutting strategies to prevent tool damage and maintain dimensional accuracy. Composites, on the other hand, can be abrasive and delaminate during machining, necessitating specialized tools and techniques. A qualified CNC machinist possesses the expertise to mitigate these challenges.

- Heat Treatment and Surface Modification

Many aerospace materials undergo heat treatment or surface modification processes to enhance their mechanical properties and corrosion resistance. CNC machinists need to understand how these processes affect material properties and how to compensate for any dimensional changes that may occur. For example, stress relieving after rough machining can improve dimensional stability during subsequent finishing operations.

- Material Identification and Traceability

Maintaining material traceability is crucial in aerospace manufacturing to ensure quality control and regulatory compliance. CNC machinists must be able to accurately identify materials and track their provenance throughout the manufacturing process. This includes verifying material certifications, documenting machining parameters, and implementing proper handling and storage procedures.

In summary, material expertise is not merely a supplementary skill but rather a fundamental requirement for roles within the realm of aerospace CNC machining. It ensures that components are manufactured to the highest standards of quality, performance, and reliability, directly contributing to the safety and efficiency of aircraft and spacecraft.

3. Quality Assurance

Quality assurance constitutes a critical component of manufacturing processes in the aeronautics and space sectors. Given the inherent safety-critical nature of aircraft and spacecraft components, stringent quality control measures are indispensable. The role of individuals involved in machining operations is directly intertwined with upholding these rigorous standards.

- Dimensional Verification and Inspection

Ensuring that machined parts adhere precisely to engineering drawings and specifications is paramount. This involves utilizing precision measuring instruments, such as coordinate measuring machines (CMMs), micrometers, and calipers, to verify dimensional accuracy. For example, the diameter of a bolt hole on an aircraft wing spar must fall within a specified tolerance range to ensure proper fit and structural integrity. Failure to meet these requirements can compromise the performance and safety of the aircraft.

- Non-Destructive Testing (NDT)

NDT methods are employed to detect internal flaws or defects in machined components without compromising their structural integrity. Techniques such as ultrasonic testing, radiographic testing, and dye penetrant inspection are used to identify cracks, voids, or inclusions that may not be visible to the naked eye. For instance, NDT may be used to inspect turbine blades for fatigue cracks, which can lead to catastrophic engine failure if left undetected. These inspections contribute significantly to ensuring the long-term reliability of aerospace components.

- Material Certification and Traceability

Maintaining complete traceability of materials used in aerospace manufacturing is essential for quality control and regulatory compliance. This involves verifying that materials meet specified requirements and tracking their provenance throughout the manufacturing process. Material certifications, such as those issued by NADCAP-accredited suppliers, provide assurance that materials have been tested and conform to industry standards. This traceability helps to identify and mitigate potential risks associated with material defects or inconsistencies.

- Process Control and Statistical Analysis

Implementing robust process control measures is crucial for minimizing variations in machining processes and ensuring consistent product quality. Statistical process control (SPC) techniques are used to monitor key process parameters, such as cutting tool wear, machine vibration, and temperature fluctuations, to identify and address potential issues before they result in defects. By analyzing process data, machinists can optimize machining parameters, reduce scrap rates, and improve overall efficiency. This proactive approach to quality control helps to maintain high standards of product quality and consistency.

- AS9100 Compliance and Documentation

Aerospace manufacturers are typically certified to AS9100, a quality management standard specific to the aerospace industry. Individuals are expected to understand and adhere to AS9100 requirements, which encompass all aspects of the manufacturing process, from design and planning to production and inspection. Proper documentation of processes, inspections, and corrective actions is essential for demonstrating compliance and maintaining certification. Understanding and application of these principles are a core part of the role.

These facets of quality assurance, when integrated effectively within machining operations, collectively ensure that aerospace components meet the stringent requirements necessary for safe and reliable operation. The proficiency of personnel in applying these principles directly impacts the quality, performance, and longevity of aircraft and spacecraft.

4. Programming Skills

Proficiency in CNC programming is paramount within the sphere of precision manufacturing for the aeronautics and space sectors. The creation of complex geometries, optimization of machining parameters, and assurance of dimensional accuracy are all fundamentally dependent on robust programming capabilities.

- G-Code Proficiency

G-code serves as the foundational programming language for CNC machines. A comprehensive understanding of G-code syntax and commands is essential for creating efficient and accurate machining programs. Mastery includes the ability to program complex toolpaths, control spindle speeds and feed rates, and execute coordinate transformations. Without proficiency in G-code, machinists cannot effectively translate design specifications into machine-executable instructions.

- CAD/CAM Software Utilization

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software are integral tools for generating CNC programs. CAD software is used to create 3D models of parts, while CAM software is used to generate toolpaths and machine code from those models. The ability to seamlessly integrate CAD models into CAM software and optimize toolpaths for efficient machining is a critical skill. Expertise in software such as Mastercam, Siemens NX, or similar platforms is highly valued.

- Parametric Programming

Parametric programming involves the use of variables and mathematical expressions to create flexible and adaptable CNC programs. This technique enables machinists to easily modify program parameters to accommodate variations in part geometry or material properties. For instance, a parametric program can be used to machine a family of similar parts with slightly different dimensions, significantly reducing programming time and increasing efficiency. Such expertise is critical for handling variations encountered in aerospace manufacturing.

- Simulation and Verification

Prior to executing a CNC program on a machine, simulation and verification are crucial steps to prevent errors and potential damage. Simulation software allows machinists to visualize the toolpath and identify any collisions or other issues. Verification software analyzes the program code to detect syntax errors or other potential problems. By thoroughly simulating and verifying programs, machinists can minimize the risk of costly mistakes and ensure the safe and efficient operation of CNC machines.

In conclusion, programming skills represent a cornerstone of proficiency in aerospace CNC machining. A synergistic blend of G-code expertise, CAD/CAM software proficiency, parametric programming capabilities, and rigorous simulation practices enables machinists to produce high-precision components essential for the performance and reliability of aircraft and spacecraft.

5. Blueprint Interpretation

Blueprint interpretation stands as a foundational skill within the precision manufacturing landscape, particularly crucial in roles related to aerospace CNC machining. The ability to accurately decipher and apply the information contained within engineering drawings directly impacts the quality, safety, and functionality of aerospace components. Without this competency, the manufacturing process is inherently compromised, leading to potential errors and non-conforming parts.

- Understanding Orthographic Projections

Aerospace blueprints typically employ orthographic projections to represent three-dimensional objects in two dimensions. The machinist must be able to visualize the part from multiple viewpoints (front, top, side) and accurately interpret the relationships between these views. For example, correctly interpreting a hidden line indicating a bore feature is critical for ensuring that the machining operation is performed to the specified depth and diameter. Failure to do so could render the part unusable.

- Decoding Geometric Dimensioning and Tolerancing (GD&T)

GD&T provides a standardized system for defining dimensional tolerances and geometric controls on engineering drawings. The machinist must be fluent in GD&T principles to understand the permissible variations in size, form, orientation, and location of part features. Accurately interpreting a feature control frame specifying a positional tolerance, for instance, ensures that the machined feature is located within the acceptable range relative to a datum reference frame. Incorrect interpretation can result in parts that fail to meet critical performance requirements.

- Interpreting Material Specifications and Surface Finish Requirements

Aerospace blueprints specify the materials to be used in manufacturing, along with any required heat treatments or surface finishes. The machinist must understand these specifications to select appropriate cutting tools and machining parameters. For example, knowing the specific alloy of aluminum to be used, as well as the required surface roughness average (Ra) for a bearing surface, enables the machinist to select the correct cutting speed and feed rate to achieve the desired outcome. This directly affects the part’s longevity and functionality.

- Applying Revision Control and Configuration Management

Aerospace blueprints are subject to revision control to manage changes and updates to the design. The machinist must ensure that they are working with the correct revision level of the drawing to avoid manufacturing parts to outdated specifications. Understanding the configuration management system and being able to identify the latest revision status is essential for maintaining product integrity. Manufacturing a component to an obsolete revision level can lead to costly rework or scrap, highlighting the importance of proper document control.

The accurate interpretation of engineering drawings is not merely a technical skill, but a critical competency that directly influences the success of aerospace CNC machining operations. The examples illustrate the importance of meticulous attention to detail and a comprehensive understanding of engineering documentation in ensuring that components meet stringent requirements for safety, performance, and reliability. Furthermore, the adherence to documented processes and specifications, derived from blueprint interpretation, directly correlates to maintaining airworthiness and operational efficiency in the aerospace sector.

6. Safety Protocols

Adherence to stringent safety protocols is non-negotiable within aerospace CNC machining. The environment involves high-speed machinery, hazardous materials, and the potential for serious injury. A comprehensive understanding and rigorous implementation of safety procedures are paramount to ensure the well-being of personnel and the integrity of equipment.

- Machine Guarding and Interlock Systems

Properly functioning machine guards and interlock systems are essential to prevent accidental contact with moving parts. Guards must be in place at all times during machine operation, and interlocks must be functional to immediately shut down the machine if a guard is opened or bypassed. For instance, a lathe should not operate with the chuck guard open, and a milling machine’s enclosure should be properly secured. Failure to maintain these safety features can lead to severe injuries, including amputations.

- Personal Protective Equipment (PPE)

The use of appropriate PPE is mandatory in aerospace CNC machining environments. This includes safety glasses with side shields, hearing protection, steel-toed boots, and appropriate gloves. Safety glasses protect against flying debris and swarf, hearing protection mitigates noise exposure, and steel-toed boots prevent foot injuries from dropped objects. Gloves protect against cuts, abrasions, and chemical exposure. Neglecting to wear the required PPE can result in eye injuries, hearing loss, foot injuries, and skin irritation.

- Hazardous Material Handling and Disposal

Aerospace CNC machining often involves the use of hazardous materials, such as coolants, cutting fluids, and cleaning solvents. Proper handling, storage, and disposal procedures must be followed to prevent exposure and environmental contamination. For example, coolants should be stored in designated containers, and used cutting fluids must be disposed of according to environmental regulations. Improper handling of these materials can lead to respiratory problems, skin irritation, and environmental damage.

- Emergency Procedures and First Aid

A clear understanding of emergency procedures and basic first aid is crucial for responding effectively to accidents or injuries. Employees must be trained in how to shut down machinery in an emergency, evacuate the area, and provide basic first aid to injured colleagues. Readily accessible first aid kits and emergency contact information are essential. In the event of a severe laceration from a machining accident, prompt and appropriate first aid can minimize blood loss and prevent infection.

The integration of these safety protocols directly contributes to minimizing risks and ensuring a safe working environment for those in these machining-related occupations. The effective implementation and consistent enforcement of these measures are fundamental for maintaining the well-being of personnel, safeguarding equipment, and upholding the integrity of the manufacturing process in the aerospace sector.

Frequently Asked Questions Regarding Careers in Aerospace CNC Machining

The following addresses common inquiries concerning roles involving Computer Numerical Control (CNC) machining within the aeronautics and space industries. These questions aim to provide clarity on the qualifications, responsibilities, and career prospects associated with these positions.

Question 1: What specific certifications are most beneficial for seeking opportunities?

Certifications from recognized organizations, such as the National Institute for Metalworking Skills (NIMS), hold significant value. These credentials demonstrate a validated level of competency in specific machining skills and programming techniques, enhancing a candidate’s credibility.

Question 2: What are the most commonly used software programs in this field?

CAD/CAM software proficiency is essential. Common programs include Mastercam, Siemens NX, and SolidWorks. Experience with these platforms allows for efficient design translation into machine-executable code.

Question 3: How critical is knowledge of specific aerospace materials?

A comprehensive understanding of aerospace-grade materials, such as aluminum alloys, titanium, composites, and superalloys, is highly important. Knowledge of their machining characteristics, thermal properties, and applications is crucial for optimal part production.

Question 4: What level of precision is typically required in these roles?

Aerospace machining demands extremely tight tolerances, often measured in microns. This necessitates meticulous attention to detail and proficiency in using precision measuring instruments.

Question 5: How important is adherence to safety regulations?

Compliance with safety protocols is paramount. The environment presents potential hazards; therefore, adherence to established safety procedures is non-negotiable for personal well-being and equipment integrity.

Question 6: Is continuous learning necessary in this profession?

Continuous professional development is critical due to the evolving nature of CNC technology. Staying abreast of new techniques, software updates, and material advancements is vital for maintaining a competitive edge.

In summary, a combination of technical expertise, industry-specific knowledge, and unwavering commitment to quality and safety is essential for success in this field.

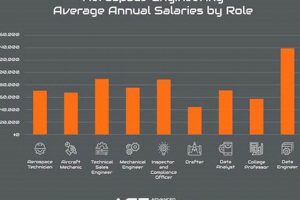

The next section will provide insights into potential career pathways and earning potential within aerospace CNC machining.

Aerospace CNC Machinist Positions

This exposition has detailed the critical competencies, responsibilities, and qualifications intrinsic to opportunities in aerospace CNC machining. The discussion encompassed essential skills such as blueprint interpretation, programming proficiency, material expertise, and unwavering adherence to quality assurance protocols and safety regulations. A robust understanding of these elements is paramount for individuals aspiring to contribute to the precision manufacturing demands of the aviation and space industries.

Given the continued advancements within aerospace technology and the consistent demand for high-precision components, careers in this field offer significant potential for professional growth and contribution. It is imperative for aspiring individuals to pursue continuous learning and skill development to meet the evolving challenges and uphold the stringent standards inherent in aerospace manufacturing. The exacting nature of this work underscores its importance in ensuring the safety and reliability of aircraft and spacecraft.