The phrase’s core component, denoting a professional occupation, signifies an individual trained in the design, development, testing, and production of aircraft, spacecraft, and related systems. The qualification necessitates a strong foundation in mathematics, physics, and engineering principles. For example, individuals in this field might work on improving fuel efficiency in commercial airliners or designing propulsion systems for interplanetary spacecraft.

This professional role is vital to advancements in aviation, space exploration, and national defense. The continuous pursuit of innovation within this sector has historically yielded significant technological breakthroughs, impacting numerous fields beyond aerospace, including materials science, computing, and telecommunications. This influence extends to job creation, economic growth, and the advancement of scientific knowledge.

Given the pivotal role of expertise in this area, articles often explore specific aspects of the profession, such as advancements in particular technologies, career paths within the field, educational requirements, or the impact of regulatory changes. The analysis of these varied topics helps to understand the nuanced challenges and opportunities faced by professionals in this dynamic environment.

Guidance from Experienced Professionals

The following insights are intended to provide pragmatic advice drawn from seasoned professionals in the field of aerospace engineering, focusing on strategies for career development and technical expertise.

Tip 1: Prioritize Fundamental Knowledge: A comprehensive understanding of core principles in mathematics, physics, and thermodynamics is crucial. These foundational elements underpin all advanced concepts and applications within the field. For example, proficiency in fluid dynamics is essential for aerodynamic design.

Tip 2: Cultivate Strong Analytical Skills: The ability to analyze complex systems and identify critical parameters is paramount. This skill involves meticulous data interpretation and the application of rigorous problem-solving methodologies. Effective analysis can prevent costly design flaws and improve system performance.

Tip 3: Seek Opportunities for Hands-On Experience: Practical experience gained through internships, research projects, or personal engineering endeavors provides invaluable context for theoretical knowledge. Building and testing physical models, for example, allows to validate simulation results and identify unexpected real-world behaviors.

Tip 4: Develop Proficiency in Simulation Software: Familiarity with industry-standard simulation software, such as computational fluid dynamics (CFD) or finite element analysis (FEA) tools, is essential for modern engineering practice. Mastering these tools enables engineers to simulate and optimize designs before physical prototyping, saving time and resources.

Tip 5: Embrace Continuous Learning: The aerospace industry is characterized by rapid technological advancements. Staying abreast of emerging technologies, novel materials, and innovative design techniques through continuous professional development is essential for maintaining competitiveness.

Tip 6: Enhance Communication Skills: The ability to effectively communicate technical information, both verbally and in writing, is crucial for collaboration and project management. Clearly conveying complex ideas to diverse audiences ensures alignment and avoids misunderstandings.

Tip 7: Specialize Strategically: While a broad understanding of aerospace engineering principles is important, focusing on a specific area of expertise, such as propulsion systems, structural design, or avionics, can significantly enhance career prospects. Deep expertise in a niche area makes one a valuable asset to any engineering team.

Adopting these strategies can significantly enhance one’s professional trajectory and technical proficiency in the challenging yet rewarding field.

Further sections of this article delve into specific areas of application, recent advancements, and the future outlook for professionals in this dynamic domain.

1. Aerodynamic Principles Application

The application of aerodynamic principles forms a cornerstone of the skill set inherent to an aerospace engineer’s training and subsequent professional activity. This application is not merely a theoretical exercise but rather a fundamental requirement for the design, analysis, and optimization of aircraft and spacecraft. Understanding how air flows around a body, generates lift, and creates drag directly impacts the performance, stability, and safety of any aerial vehicle. Consequently, the mastery of these principles dictates the effectiveness of an individual within the field. For example, the design of an aircraft wing relies heavily on the precise application of aerodynamic principles to achieve optimal lift-to-drag ratios, ensuring efficient flight.

Practical application extends beyond wing design to encompass a wide range of engineering challenges. Computational fluid dynamics (CFD) simulations, wind tunnel testing, and flight tests are routinely employed to validate designs based on theoretical models. Consider the design of supersonic aircraft, where accurately predicting and managing shock waves is crucial for minimizing drag and preventing structural damage. Aerospace engineers must skillfully apply advanced aerodynamic concepts to mitigate the detrimental effects of supersonic flow, often relying on specialized airfoil designs and control surfaces. The development of efficient and reliable vertical takeoff and landing (VTOL) aircraft provides another instance, where complex interactions between rotors, airframe, and the surrounding air necessitate a nuanced understanding of aerodynamic phenomena.

The ability to translate theoretical knowledge of aerodynamics into practical engineering solutions distinguishes competent practitioners in the field. A solid grasp of these principles facilitates innovation, enabling engineers to develop novel designs and improve existing technologies. Challenges remain in predicting and controlling turbulent flows and in accurately modeling complex flow phenomena at extreme flight conditions. However, continuous research and development efforts are pushing the boundaries of aerodynamic understanding, thereby enhancing the capabilities of aerospace engineers and enabling advancements in aircraft and spacecraft design.

2. Propulsion System Design

Propulsion system design constitutes a critical specialization within the broader scope of professional practice. It directly influences aircraft and spacecraft performance, dictating factors such as speed, range, payload capacity, and operational efficiency. Consequently, competence in this area is paramount for those actively engaged in the design and development of aerial and space-faring vehicles. Indeed, the effectiveness of a vehicle’s propulsion mechanism directly affects its mission capabilities. For instance, a more efficient jet engine design leads to reduced fuel consumption and extended flight range for commercial airliners, whereas innovative rocket engine designs enable deeper space exploration missions. The inextricable link highlights the significance of this domain within the field.

The practical implications of propulsion system expertise extend to various sectors, including commercial aviation, space exploration, and national defense. In commercial aviation, efforts are concentrated on improving fuel efficiency and reducing emissions, driving the development of advanced engine technologies such as geared turbofans and hybrid-electric propulsion systems. Space exploration necessitates robust and reliable rocket engines capable of generating the high thrust required to escape Earth’s gravity and navigate interplanetary space. The design of solid rocket boosters for the Space Shuttle and the development of liquid-fueled engines for the Saturn V rocket exemplify successful propulsion systems that have enabled significant advancements in space exploration. Military applications frequently demand high-performance engines capable of providing superior maneuverability and speed, requiring sophisticated designs and advanced materials.

In summary, competence in propulsion system design is not merely a desirable attribute but a fundamental requirement for many professional roles. The advancement and innovation within this area has been a major contributor to overall advancement and capability within aeronautics and space exploration. Challenges remain in achieving higher efficiencies, reducing emissions, and developing propulsion systems suitable for hypersonic flight and deep-space missions. Yet these challenges also provide opportunities for continued research and development, ensuring that propulsion system design will remain a critical focus area for professionals in this vital profession.

3. Materials Science Expertise

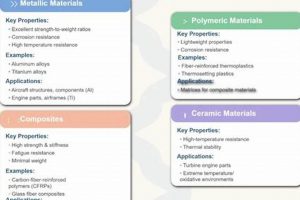

Materials science expertise is an indispensable component of proficiently performing the duties of professionals in aeronautics and astronautics. The cause-and-effect relationship is clear: inadequate knowledge of materials properties leads to suboptimal designs and potentially catastrophic failures. The performance and safety of aircraft and spacecraft are intrinsically linked to the materials from which they are constructed. Structural integrity, resistance to extreme temperatures and pressures, weight minimization, and long-term durability are all predicated on the effective selection and application of appropriate materials. For example, the transition from aluminum alloys to carbon fiber composites in aircraft construction has led to significant weight reductions, enhancing fuel efficiency and performance.

Practical applications of materials science knowledge permeate all aspects of the field. Turbine blades in jet engines, exposed to extreme temperatures and stresses, require advanced nickel-based superalloys or ceramic matrix composites to withstand the harsh operating conditions. The heat shields on spacecraft, critical for protecting the vehicle during atmospheric re-entry, utilize specialized ceramic materials with high thermal resistance. Furthermore, the development of lightweight, high-strength materials is crucial for constructing efficient and reliable spacecraft structures. Consider the development of advanced aluminum-lithium alloys, which offer improved strength-to-weight ratios compared to conventional aluminum alloys, enabling the construction of lighter and more efficient aircraft and spacecraft.

In conclusion, materials science expertise is not merely an ancillary skill but a fundamental requirement for anyone engaged in aeronautics and astronautics. A thorough understanding of material properties, behavior, and processing techniques is essential for designing safe, efficient, and reliable aircraft and spacecraft. Challenges remain in developing materials that can withstand increasingly demanding operating conditions and in predicting long-term material behavior under extreme environments. Continued research and development in materials science is, therefore, critical for advancing the state of aeronautics and astronautics and addressing the challenges of future aerospace missions.

4. Simulation Software Proficiency

The effective utilization of simulation software is an integral competency for professionals. Proficiency in these tools enables the design, analysis, and validation of aerospace systems with a level of precision and efficiency unattainable through traditional methods. This proficiency is critical for minimizing risks, reducing development costs, and accelerating the innovation cycle in this complex domain.

- Computational Fluid Dynamics (CFD) Mastery

CFD software facilitates the simulation of fluid flow around aircraft and spacecraft, allowing engineers to analyze aerodynamic performance, predict lift and drag characteristics, and optimize designs for enhanced efficiency and stability. For instance, CFD simulations are routinely employed in the design of airfoil shapes to minimize drag at various flight speeds. This capability is essential for ensuring the aerodynamic integrity of aerospace vehicles.

- Finite Element Analysis (FEA) Expertise

FEA software enables the simulation of structural behavior under various loading conditions, allowing engineers to analyze stress distributions, predict deformation, and optimize designs for structural integrity and weight reduction. Consider the use of FEA in designing aircraft wings to withstand aerodynamic loads during flight. Such simulations ensure the structural reliability of aerospace components.

- Systems Modeling and Simulation Capabilities

Systems modeling and simulation tools allow for the analysis of complex interactions between different subsystems within an aerospace vehicle. These tools enable engineers to evaluate overall system performance, identify potential bottlenecks, and optimize system integration. As an example, modeling and simulation can be used to analyze the interactions between the propulsion, control, and navigation systems of an aircraft, ensuring seamless operation and optimal performance.

- Real-Time Simulation and Hardware-in-the-Loop (HIL) Testing

Real-time simulation and HIL testing environments permit the integration of physical hardware components with simulated systems, enabling engineers to evaluate system performance under realistic operating conditions. For example, HIL testing can be used to evaluate the performance of an aircraft’s flight control system by connecting the physical flight control hardware to a simulated flight environment. This approach facilitates rigorous testing and validation of aerospace systems before actual flight.

The confluence of these skills and expertise is fundamentally necessary for success in this role. It enables informed decision-making, minimizes reliance on costly physical prototypes, and facilitates the development of innovative and high-performance aerospace vehicles.

5. Regulatory Compliance Adherence

Regulatory compliance adherence represents a non-negotiable element within the multifaceted responsibilities of professionals in the aerospace field. The aerospace industry, characterized by intricate technologies and high-stakes operational environments, is subject to stringent regulations imposed by governmental agencies and international organizations. Failure to comply with these regulations can result in severe consequences, including financial penalties, operational restrictions, and, most critically, compromised safety. Therefore, comprehensive understanding and meticulous application of relevant regulatory frameworks are intrinsic to the skill set and ethical conduct expected of individuals working in this profession.

Consider, for example, the design and certification of a new aircraft engine. Professionals involved in this process must adhere to regulations set forth by aviation authorities, such as the Federal Aviation Administration (FAA) in the United States or the European Aviation Safety Agency (EASA) in Europe. These regulations cover a wide range of aspects, including engine performance, emissions, noise levels, and structural integrity. Compliance is demonstrated through rigorous testing, detailed documentation, and adherence to established engineering standards. The inability to meet these regulatory requirements would prevent the engine from being certified for commercial use, significantly impacting the manufacturer’s operations and financial viability. Similarly, adherence to safety standards in the design and operation of spacecraft is governed by agencies like NASA, which emphasizes rigorous testing, risk assessment, and adherence to established protocols to ensure mission success and astronaut safety. These examples highlight the practical significance of regulatory compliance in ensuring the safety and reliability of aerospace operations.

In conclusion, regulatory compliance adherence constitutes an essential, non-detachable aspect of a professional’s role in aerospace. Challenges persist in keeping pace with evolving regulations and interpreting complex compliance requirements. However, the potential consequences of non-compliance necessitate a proactive and diligent approach to regulatory matters, thereby safeguarding the safety, reliability, and integrity of aerospace activities.

Frequently Asked Questions

The following questions address common inquiries and misconceptions regarding the profession, providing objective answers based on established facts.

Question 1: What is the typical educational pathway to becoming an aerospace engineer?

The standard educational path involves obtaining a bachelor’s degree in aerospace engineering or a closely related field, such as mechanical engineering with an aerospace specialization. Advanced positions often require a master’s degree or doctorate.

Question 2: Are there specific skills essential for success in this profession?

Core competencies include a strong foundation in mathematics, physics, and engineering principles. Analytical problem-solving, proficiency in computer-aided design (CAD) and simulation software, and effective communication skills are also critical.

Question 3: What are the common career paths available after completing an aerospace engineering degree?

Potential career paths include design engineering, research and development, testing and analysis, manufacturing, and project management. Specific roles may involve working on aircraft, spacecraft, propulsion systems, or avionics.

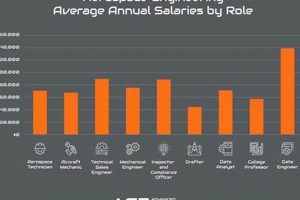

Question 4: What is the expected salary range for an aerospace engineer?

Salary varies depending on experience, education, and location. Entry-level positions typically offer a competitive starting salary, with potential for significant increases with experience and advanced degrees. Industry statistics provide detailed salary ranges.

Question 5: What are the most significant challenges currently facing the aerospace engineering field?

Key challenges include developing more fuel-efficient and environmentally friendly aircraft, reducing the cost of space access, ensuring the safety and reliability of autonomous systems, and addressing cybersecurity threats in aviation.

Question 6: How does regulatory compliance impact the work of an aerospace engineer?

Regulatory compliance is paramount, dictating design standards, testing procedures, and operational requirements. Engineers must adhere to regulations imposed by agencies such as the FAA or EASA to ensure the safety and airworthiness of aircraft and spacecraft.

This FAQ section provides a concise overview of key aspects of the aerospace engineering profession. It aims to clarify common questions and provide accurate information for those considering or already pursuing a career in this field.

Subsequent sections delve into advanced topics and future trends within the aerospace industry.

The Aerospace Engineer

This examination has underscored the multi-faceted nature of the domain. From mastering core scientific principles to navigating complex regulatory frameworks, the role demands a synthesis of analytical rigor, technical expertise, and unwavering commitment to safety and innovation. Aerodynamic design, propulsion system development, materials selection, simulation software proficiency, and regulatory compliance are but a few of the essential areas of competence.

The ongoing evolution of aerospace technology presents both opportunities and challenges for individuals in this field. The pursuit of sustainable aviation practices, the expansion of space exploration endeavors, and the integration of autonomous systems will necessitate continued adaptation and innovation. Therefore, the future requires a commitment to lifelong learning, ensuring that professionals remain equipped to address the increasingly complex demands of the twenty-first century and beyond. The responsibility for advancing aerospace technology rests squarely upon the shoulders of skilled and dedicated professionals.