A rigorous examination of a specific problem or project within the realm of flight vehicle design, construction, and operation, it provides a focused analysis of engineering principles in action. For example, a detailed report on the development of a new composite wing structure for a commercial airliner, encompassing design considerations, material selection, testing procedures, and performance analysis, would exemplify this type of focused analysis.

This approach is vital for the advancement of the field. By meticulously documenting and analyzing real-world challenges and solutions, engineers gain invaluable insights into the efficacy of various methodologies and technologies. Historically, the examination of past projects, such as the development of the Saturn V rocket or the Space Shuttle, has served as a cornerstone for future innovation, fostering a culture of learning and improvement. These analyses contribute to better designs, safer operations, and more efficient systems.

The following sections will delve into various aspects of these focused analyses, exploring specific applications, methodologies for conducting effective investigations, and the utilization of these findings to enhance future projects.

Conducting Effective Analyses

The following guidelines are designed to enhance the quality and impact of such focused explorations within the aerospace domain.

Tip 1: Define a Clear Scope. Establish specific boundaries for the project under investigation. A clearly defined scope prevents unfocused exploration and ensures relevant data collection. For instance, if the project involves the failure analysis of a turbine blade, the scope should specify the operating conditions, material composition, and environmental factors to be considered.

Tip 2: Employ Rigorous Data Collection Methods. Utilize precise and reliable data sources. This may involve experimental testing, computational simulations, and historical records. Ensure that all data is accurately recorded and properly calibrated. For example, strain gauge measurements on a composite structure should be accompanied by calibration certificates and uncertainty analyses.

Tip 3: Apply Appropriate Analytical Techniques. Select the most suitable analytical tools for the problem at hand. This might involve finite element analysis, computational fluid dynamics, statistical analysis, or a combination thereof. Justify the choice of analytical techniques based on their suitability for the specific problem and the available data.

Tip 4: Maintain Objectivity and Transparency. Present findings in an unbiased and transparent manner. Clearly state assumptions, limitations, and uncertainties. Acknowledge potential sources of error and bias. This fosters credibility and allows for critical evaluation by other engineers.

Tip 5: Document the Entire Process. Meticulously document every stage of the investigation, from initial problem definition to final conclusions. This includes data collection procedures, analytical methods, results, and interpretations. Proper documentation facilitates reproducibility and allows for future reference.

Tip 6: Focus on Practical Implications. Emphasize the practical implications of the findings. Identify lessons learned and recommendations for future designs, operations, or maintenance procedures. Translate the results into actionable insights that can improve engineering practice.

Tip 7: Consider Regulatory and Ethical Factors. Integrate relevant regulatory requirements and ethical considerations into the analysis. This ensures that the findings are aligned with industry standards and promote responsible engineering practices. For example, compliance with FAA regulations should be considered when analyzing aircraft safety incidents.

By adhering to these guidelines, engineers can ensure that these focused analyses are thorough, reliable, and impactful, contributing to the advancement of aerospace technology and the enhancement of safety and efficiency.

The subsequent sections will examine the application of these tips in specific aerospace domains.

1. Problem Identification

Within the context of focused aerospace analyses, the initial and arguably most critical phase revolves around the precise delineation of the problem. This initial step dictates the subsequent trajectory of the analysis, influencing data acquisition strategies, analytical methodologies employed, and ultimately, the validity and applicability of derived conclusions.

- Defining the Scope of the Anomaly

This entails establishing clear boundaries for the issue under scrutiny. A poorly defined problem leads to unfocused investigations and irrelevant data collection. For example, when investigating engine failure, specifying parameters such as engine type, operating conditions at the time of failure, and maintenance history becomes imperative. Failure to do so might result in a diffused and inconclusive analysis.

- Establishing Failure Criteria

The criteria by which a component or system is deemed to have failed must be explicitly defined. This definition dictates the parameters that are monitored and analyzed. For example, in a structural analysis, failure might be defined by exceeding a specific stress threshold, experiencing excessive deformation, or exhibiting crack propagation beyond acceptable limits. These criteria directly influence the selection of appropriate analysis techniques.

- Identifying Potential Root Causes

This involves generating a preliminary list of potential factors contributing to the observed anomaly. This process typically involves brainstorming, reviewing historical data, and consulting with subject matter experts. For example, if a satellite experiences a power loss, potential root causes might include solar panel degradation, battery malfunction, software errors, or external interference. A comprehensive list of potential causes ensures that all relevant avenues are explored.

- Prioritizing Investigative Efforts

Given the complexity of aerospace systems, resources for investigation are often limited. Therefore, it is necessary to prioritize potential root causes based on their likelihood and potential impact. This prioritization guides the allocation of resources and focuses investigative efforts on the most promising avenues. For instance, if a component exhibits signs of corrosion, investigative efforts might prioritize examining the effectiveness of corrosion protection measures before exploring other, less likely causes.

The thorough execution of these facets within the Problem Identification stage ensures that the subsequent stages of a focused aerospace analysis are properly aligned, leading to more efficient and effective resolution of complex engineering challenges. The rigor applied at this initial step directly impacts the quality and reliability of the conclusions drawn and the effectiveness of any resulting design modifications or operational adjustments.

2. Data Acquisition

Data acquisition constitutes a critical pillar within the framework of aerospace engineering analyses, serving as the foundation upon which accurate assessments and informed decisions are built. The integrity and relevance of the data directly influence the reliability of subsequent analyses and the validity of derived conclusions.

- Sensor Selection and Calibration

The appropriate selection and meticulous calibration of sensors are paramount. Sensors must be chosen to accurately measure relevant parameters such as temperature, pressure, strain, acceleration, and flow rate. Calibration procedures must be rigorously followed to ensure the accuracy and reliability of sensor readings. For instance, when analyzing aerodynamic performance in a wind tunnel, properly calibrated pressure sensors and force balances are essential for obtaining accurate measurements of lift, drag, and pitching moment.

- Instrumentation Placement and Installation

Strategic placement and secure installation of instrumentation are crucial for capturing representative data. The location of sensors must be carefully considered to ensure that they are measuring the parameters of interest at the appropriate locations. Installation procedures must be followed precisely to minimize measurement errors and ensure the long-term stability of the instrumentation. For example, when monitoring the structural integrity of an aircraft wing, strain gauges must be strategically placed at locations of high stress concentration and securely bonded to the wing surface.

- Data Logging and Storage

Efficient data logging and secure storage are essential for preserving the integrity of acquired data. Data logging systems must be capable of capturing data at the required sampling rates and storing it in a reliable and accessible format. Data storage protocols must be implemented to protect against data loss or corruption. For instance, during flight testing, data logging systems must be capable of capturing thousands of data points per second and storing them in a format that can be easily analyzed.

- Signal Processing and Noise Reduction

Signal processing techniques and noise reduction methods are often necessary to improve the quality of acquired data. Raw sensor signals may be contaminated by noise from various sources, such as electrical interference or vibration. Signal processing techniques, such as filtering and averaging, can be used to reduce noise and extract the underlying signal of interest. For example, when analyzing vibration data from a rocket engine, signal processing techniques can be used to filter out unwanted noise and identify resonant frequencies.

These facets of data acquisition are intrinsically linked within an aerospace analysis. The quality of the data obtained significantly dictates the credibility and usefulness of the analysis itself. For example, if the problem is premature engine failure, the process begins with obtaining accurate data from sensors, recording the data, and making the data relevant. It then uses signal processing to reduce data noise for analysis. A rigorous data acquisition process is therefore not simply a preliminary step but an integral component influencing the entire analytical outcome.

3. Analytical Methods

The selection and application of appropriate analytical methods are central to any aerospace engineering case study. These methods provide the framework for transforming raw data into meaningful insights, enabling engineers to understand complex phenomena and develop effective solutions. The cause-and-effect relationship is evident: the accuracy and relevance of the analytical methods directly impact the validity and utility of the conclusions drawn from the case study. Analytical methods are not merely tools; they are integral components that determine the depth and reliability of the investigation.

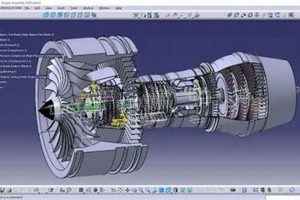

For instance, in a case study examining the failure of a composite aircraft component, finite element analysis (FEA) might be employed to simulate stress concentrations and predict failure modes. Computational fluid dynamics (CFD) could be used to analyze aerodynamic forces and thermal loads. Statistical analysis might be applied to assess the reliability of the component based on historical data. The judicious selection of these methods, coupled with rigorous validation, is crucial for accurately identifying the root cause of the failure and developing effective mitigation strategies. Without appropriate analytical rigor, such a case study would lack credibility and practical significance.

Ultimately, the effective integration of analytical methods transforms a collection of observations into a structured and insightful analysis. Challenges exist in selecting the most appropriate methods, ensuring the accuracy of inputs, and interpreting the results correctly. However, the ability to apply these methods skillfully is indispensable for advancing the field of aerospace engineering, fostering innovation, and ensuring the safety and reliability of aerospace systems. The analytical foundation is thus critical for the overall success of this form of research.

4. Results Interpretation

Within the context of aerospace engineering analyses, results interpretation forms the crucial bridge between raw data and actionable insights. It represents the process of critically evaluating analytical outputs, extracting pertinent information, and drawing reasoned conclusions that address the initial problem definition. The effectiveness of results interpretation directly governs the value and applicability of an aerospace study, as even the most meticulous data collection and sophisticated analytical methods are rendered inconsequential if the findings are not properly understood and translated into practical implications. The absence of thorough interpretation transforms a potentially insightful analysis into a mere collection of data points.

A representative instance of the importance of results interpretation arises in the analysis of flight test data. Consider a case where airspeed sensors during flight testing indicate unexpected fluctuations. While the raw data may reveal the magnitude and frequency of these fluctuations, proper interpretation necessitates correlating these data with other parameters, such as angle of attack, control surface deflections, and atmospheric conditions. This interpretation could lead to the identification of previously unmodeled aerodynamic phenomena or uncover inconsistencies in the flight control system. Similarly, in the realm of structural analysis, Finite Element Analysis (FEA) results may depict stress concentrations in a component. However, interpretation requires assessing the magnitude and location of these stresses in relation to material properties, safety factors, and operational loads to determine whether they pose a significant risk of failure. This careful analysis informs decisions regarding design modifications or operational limitations.

In summary, the interpretation of results constitutes an indispensable element of aerospace engineering studies. It moves beyond the mere presentation of data to the critical assessment of its implications, informing decisions regarding design, operation, and maintenance. The value of an engineering study lies not simply in the quantity of data generated, but in the insights derived through astute interpretation. Addressing inherent challenges in results interpretation, such as distinguishing between genuine phenomena and data artifacts, is crucial for maximizing the efficacy of this process and advancing the broader goals of aerospace engineering.

5. Design Improvement

Design improvement is intrinsically linked to focused engineering analyses within the aerospace sector. These analyses serve as critical feedback loops, providing data-driven insights that inform and guide subsequent iterations of the design process. Analyses dissect the performance of existing designs under diverse operating conditions, uncovering vulnerabilities, inefficiencies, and potential failure modes. This understanding then becomes the catalyst for targeted design refinements, aimed at enhancing performance, improving reliability, and ensuring safety. For example, a detailed investigation into the structural failure of a composite wing component might reveal a previously unacknowledged stress concentration point. This finding would directly inform design improvements, such as modifying the laminate layup or introducing a reinforcement feature, to mitigate the identified weakness.

The significance of design improvement as a component of these analyses cannot be overstated. It elevates the process from a purely diagnostic exercise to a proactive strategy for advancing aerospace technology. By meticulously documenting the iterative design process, encompassing the initial design, subsequent analysis, and resulting improvements, engineers create a valuable knowledge base for future projects. Moreover, design improvements informed by real-world data are more likely to yield tangible benefits. Consider the redesign of the Boeing 737 MAX’s Maneuvering Characteristics Augmentation System (MCAS). The analyses following the tragic accidents highlighted critical design flaws, leading to a comprehensive system redesign aimed at preventing future incidents. This represents a stark illustration of the practical significance of incorporating design improvement as a core element of aerospace analyses.

In conclusion, design improvement is not merely an adjunct to these analyses but a fundamental driver of progress in the field. By leveraging the insights gained from focused investigations, aerospace engineers can iteratively refine designs, pushing the boundaries of performance while upholding the highest standards of safety and reliability. The continuous cycle of analysis and improvement is essential for ensuring the continued advancement and dependability of aerospace systems. The incorporation of this process ensures that the findings are translated into tangible improvements in future designs.

Frequently Asked Questions Regarding Focused Aerospace Analyses

This section addresses common inquiries and misconceptions surrounding focused investigations within the aerospace engineering domain.

Question 1: What distinguishes a focused investigation from a general aerospace engineering project?

A focused investigation centers on the detailed examination of a specific problem, component, or system within aerospace engineering. Unlike broader projects encompassing design or development, the primary aim is to understand root causes, assess performance, or evaluate specific design features in depth.

Question 2: What are the primary benefits of conducting detailed analyses?

These detailed analyses provide critical insights into system behavior, performance limitations, and potential failure modes. They facilitate the identification of areas for improvement in design, manufacturing, and operational procedures, ultimately enhancing safety, reliability, and efficiency.

Question 3: What types of data are typically gathered in these investigations?

The data collected varies depending on the specific objective of the study. Common data types include experimental measurements (e.g., strain, temperature, pressure), simulation results (e.g., finite element analysis, computational fluid dynamics), historical operational data, and manufacturing records. The selection of data must align with the problem under investigation.

Question 4: What analytical methods are commonly employed?

The analytical methods used depend on the nature of the problem and the available data. Common methods include finite element analysis, computational fluid dynamics, statistical analysis, system identification techniques, and failure mode and effects analysis. The selection of analytical methods must be justified based on their suitability for the specific problem and the characteristics of the available data.

Question 5: How are the results of these investigations used to improve aerospace systems?

The findings are used to inform design modifications, optimize operational procedures, and enhance maintenance practices. They provide evidence-based insights for improving system performance, mitigating risks, and ensuring compliance with regulatory requirements. The implementation of these insights requires careful consideration of trade-offs between performance, cost, and safety.

Question 6: What are the challenges associated with conducting rigorous investigations?

Challenges include obtaining high-quality data, selecting appropriate analytical methods, accurately interpreting results, and effectively communicating findings. Resource constraints, time limitations, and the complexity of aerospace systems can also pose significant challenges. Addressing these challenges requires a combination of technical expertise, project management skills, and effective communication.

Thorough implementation ensures an accurate and comprehensive analysis, contributing to the improvement of aerospace engineering.

The next section will further clarify the challenges of undertaking focused investigations and propose methods for mitigating them.

Conclusion

This exploration of aerospace engineering case studies has highlighted their crucial role in advancing the field. From problem identification to design improvement, these detailed analyses provide essential insights that drive innovation and enhance safety. The implementation of rigorous methodologies and careful interpretation of results are paramount to their success.

Continued dedication to the principles outlined herein will undoubtedly yield significant advancements in aerospace technology. The commitment to thorough, evidence-based investigation remains indispensable for ensuring the continued progress and integrity of the industry. Future practitioners must embrace these principles, ensuring the reliability and safety of aerospace systems for generations to come.