Aerospace engineering encompasses the design, development, testing, and production of aircraft, spacecraft, and related systems. It integrates principles of aerodynamics, propulsion, structures, control, and materials science to create vehicles capable of operating within Earth’s atmosphere and in the vacuum of space. One could examine the principles involved in the design of a commercial airliner as an instance of this discipline, considering factors such as lift, drag, and structural integrity.

The field plays a crucial role in national defense, space exploration, and commercial aviation. Advancements in the field contribute to more efficient air travel, the development of satellite technologies for communication and observation, and the pursuit of scientific discoveries through space missions. Its historical trajectory reveals a constant drive for innovation, from the early days of flight to the current endeavors in reusable launch systems and hypersonic aircraft.

The following sections will delve into the core areas of specialization within this field, including aerodynamics, propulsion systems, structural analysis, and control systems, providing a detailed understanding of the key principles and technologies involved.

Guidance in Aerospace Engineering

The subsequent points serve as guidance for individuals interested in pursuing or advancing within the aerospace engineering discipline. They highlight crucial areas to consider for academic pursuits and professional development.

Tip 1: Master Fundamental Principles: A thorough understanding of mathematics, physics, and chemistry forms the bedrock of aerospace engineering. This includes calculus, differential equations, linear algebra, thermodynamics, and fluid dynamics. A strong foundation in these areas is essential for tackling complex engineering problems.

Tip 2: Specialize Strategically: The field is vast. Consider specializing in a specific area such as aerodynamics, propulsion, structures, or control systems. Specialization allows for in-depth knowledge and expertise, increasing career prospects and contribution potential.

Tip 3: Cultivate Software Proficiency: Familiarity with industry-standard software tools is indispensable. This includes CAD software (e.g., AutoCAD, CATIA), simulation software (e.g., ANSYS, MATLAB), and programming languages (e.g., Python, C++). Practical experience with these tools enhances employability.

Tip 4: Prioritize Practical Experience: Seek internships, co-op programs, or research opportunities to gain hands-on experience. These experiences provide valuable insights into real-world engineering challenges and enhance problem-solving skills.

Tip 5: Embrace Continuous Learning: The aerospace field is continuously evolving. Stay abreast of the latest advancements in materials, technologies, and design methodologies through journals, conferences, and professional development courses. Lifelong learning is crucial for staying competitive.

Tip 6: Develop Strong Communication Skills: Aerospace engineers must effectively communicate complex technical information to both technical and non-technical audiences. Honing written and oral communication skills is vital for collaboration and project success.

Tip 7: Emphasize Systems Thinking: Understand that aerospace systems are highly integrated. Develop the ability to analyze and understand the interactions between different components and subsystems. This holistic approach is essential for designing robust and reliable systems.

Adhering to these guidelines enhances the likelihood of success in an academic career path and professional work within the aerospace engineering sector. A dedication to fundamental principles, strategic specialization, and continuous learning are paramount.

The next section will explore the current trends and future directions of aerospace engineering, highlighting areas of ongoing research and development that are shaping the future of flight and space exploration.

1. Aerodynamics

Aerodynamics, a cornerstone of aerospace engineering, dictates how air interacts with moving objects, influencing design and performance. It is integral to comprehending lift, drag, and stability, and significantly impacts the efficiency and safety of aircraft and spacecraft.

- Airfoil Design and Performance

Airfoil design, rooted in aerodynamic principles, determines lift generation and drag reduction. For example, the shape of an aircraft wing is meticulously engineered to maximize lift at cruising speeds while minimizing drag to conserve fuel. Understanding airfoil behavior across various flight conditions is crucial for optimizing aerodynamic efficiency.

- Boundary Layer Effects

The boundary layer, a thin layer of air adjacent to an aircraft’s surface, significantly affects drag and heat transfer. Laminar flow minimizes drag, while turbulent flow increases it. Control of the boundary layer through techniques like suction or blowing is employed to improve aerodynamic performance, especially at high speeds.

- Compressible Flow and Shock Waves

At supersonic speeds, air becomes compressible, leading to the formation of shock waves. These waves increase drag and can cause significant heating. Aerodynamic design must mitigate these effects through specialized shapes like swept wings and sharp leading edges, seen in supersonic aircraft and spacecraft re-entry vehicles.

- Wind Tunnel Testing and CFD Simulation

Wind tunnel testing and Computational Fluid Dynamics (CFD) simulation are essential tools for analyzing aerodynamic performance. Wind tunnels provide empirical data on lift, drag, and stability, while CFD simulations allow for detailed analysis of airflow around complex geometries. These methods validate designs before prototyping and flight testing.

These facets of aerodynamics are indispensable in aerospace engineering, influencing design choices and performance characteristics. The continuous refinement of aerodynamic principles through research and testing ensures advancements in aircraft and spacecraft design, improving efficiency, safety, and capabilities for both atmospheric and space environments.

2. Propulsion Systems

Propulsion systems represent a critical aspect of aerospace engineering, enabling both atmospheric flight and space travel. Their design and functionality are fundamental to the successful operation of aircraft and spacecraft, directly impacting performance, efficiency, and mission capabilities.

- Jet Engines and Turbine Technology

Jet engines, a primary propulsion method for aircraft, rely on the thermodynamic principles of air compression, combustion, and expansion to generate thrust. Turbine technology, integral to jet engines, involves complex designs that must withstand extreme temperatures and stresses. For example, the design of turbine blades in a modern jet engine requires advanced materials and cooling techniques to maintain structural integrity and optimize performance. This is crucial for achieving efficient and reliable air travel.

- Rocket Propulsion and Chemical Rockets

Rocket propulsion enables space travel by generating thrust through the expulsion of high-velocity exhaust. Chemical rockets, the most common type, use the combustion of propellants to create this exhaust. The selection of propellants, such as liquid oxygen and liquid hydrogen, is based on their energy content and exhaust velocity. This selection is essential for maximizing the performance of a rocket and achieving the necessary velocity for orbital maneuvers or interplanetary travel.

- Electric Propulsion and Ion Thrusters

Electric propulsion systems, including ion thrusters, use electrical energy to accelerate propellant ions, generating thrust. While producing lower thrust levels compared to chemical rockets, electric propulsion offers significantly higher efficiency, making them suitable for long-duration space missions. For instance, ion thrusters are employed in spacecraft for station keeping and deep-space exploration, demonstrating the advantages of low propellant consumption over extended periods.

- Propellant Management and Storage

Efficient propellant management and storage are vital for the performance and reliability of propulsion systems. This includes managing propellant boil-off, preventing propellant sloshing, and ensuring stable propellant delivery to the engine. Cryogenic propellants, such as liquid hydrogen and liquid oxygen, require specialized storage tanks and insulation to minimize heat transfer and maintain their liquid state. Proper propellant management is essential for mission success, especially in long-duration space missions.

These aspects of propulsion systems highlight their significance in aerospace engineering. The continuous development of advanced propulsion technologies, coupled with improvements in propellant management, is crucial for enabling more efficient air travel, expanding space exploration capabilities, and reducing the cost of access to space. These advancements directly influence the design, performance, and operational feasibility of aerospace vehicles.

3. Structural Integrity

Structural integrity represents a critical and non-negotiable facet within the realm of aerospace engineering. It defines the ability of an aerospace vehicle whether an aircraft, spacecraft, or missile to withstand the stresses and strains imposed upon it during operation without catastrophic failure. In the context of aerospace engineering, this encompasses design considerations from material selection to manufacturing processes, all aimed at ensuring a robust and reliable structure. The consequences of compromised structural integrity range from minor performance degradation to complete loss of the vehicle and its occupants, emphasizing its paramount importance. For example, the Comet airliner disasters of the 1950s were attributed to metal fatigue around the square windows, a direct failure of structural integrity due to design flaws.

The pursuit of structural integrity necessitates a multi-faceted approach. Advanced materials like composites, aluminum alloys, and titanium are selected based on their strength-to-weight ratios, fatigue resistance, and thermal properties. Finite element analysis (FEA) and other simulation tools are used extensively to predict stress distributions and identify potential failure points before physical prototypes are even constructed. Furthermore, rigorous testing protocols, including static load tests, fatigue tests, and non-destructive inspection methods, are implemented to validate the structural design and identify any manufacturing defects. The Space Shuttle Challenger disaster in 1986, caused by the failure of an O-ring seal due to low temperatures, serves as a stark reminder of the need for meticulous attention to detail in all aspects of structural design and testing.

In conclusion, structural integrity is not merely a component of aerospace engineering; it is an overarching principle that guides the entire design and development process. Maintaining structural integrity is challenged by the harsh environments that aircraft and spacecraft operate within. From the intense aerodynamic forces and temperature extremes experienced during flight to the radiation exposure and vacuum conditions of space, engineers must continuously innovate and refine their methods to ensure the safety and reliability of aerospace vehicles. The advancements in materials science, computational analysis, and testing techniques are essential for pushing the boundaries of aerospace technology while simultaneously upholding the highest standards of structural integrity.

4. Control Mechanisms

Control mechanisms are fundamental to aerospace engineering, ensuring the stable, predictable, and efficient operation of aircraft, spacecraft, and missiles. These systems manage the vehicle’s orientation, trajectory, and velocity, and provide necessary adjustments for atmospheric conditions, propulsion variations, and mission objectives. Without effective control mechanisms, aerospace vehicles would be inherently unstable and unable to perform their intended functions.

- Flight Control Surfaces and Aerodynamic Control

Aircraft flight control surfaces, such as ailerons, elevators, and rudders, are essential components of aerodynamic control. These surfaces alter the airflow around the aircraft, generating aerodynamic forces that enable the pilot or autopilot system to maneuver the aircraft in three-dimensional space. The design and positioning of these surfaces are critical for achieving desired handling characteristics and stability margins. For example, the control surfaces on a commercial airliner must allow for smooth and precise control during takeoff, landing, and cruise, while also providing sufficient authority to counteract atmospheric disturbances.

- Attitude Control Systems in Spacecraft

Spacecraft attitude control systems maintain the desired orientation of a spacecraft in the absence of aerodynamic forces. These systems utilize a variety of actuators, including reaction wheels, control moment gyroscopes, and thrusters, to apply torques that counteract external disturbances and maintain the spacecraft’s pointing direction. Precise attitude control is crucial for many space missions, such as Earth observation, satellite communication, and space telescope operations. The pointing accuracy of the James Webb Space Telescope, for example, is maintained through a complex attitude control system that compensates for solar pressure and other disturbances.

- Guidance, Navigation, and Control (GNC) Systems

Guidance, navigation, and control (GNC) systems integrate sensors, computers, and actuators to guide aerospace vehicles along a desired trajectory. The guidance system determines the optimal path to the target, the navigation system estimates the vehicle’s position and velocity, and the control system executes the necessary commands to follow the planned trajectory. GNC systems are essential for autonomous operations, such as missile guidance, spacecraft rendezvous, and drone navigation. The precision landing capabilities of SpaceX’s Falcon 9 rockets are a testament to the effectiveness of modern GNC systems.

- Stability Augmentation Systems

Stability augmentation systems enhance the inherent stability of aerospace vehicles by automatically compensating for undesirable dynamics. These systems utilize sensors to detect deviations from the desired flight condition and apply corrective control inputs to maintain stability. Stability augmentation systems are particularly important for aircraft with inherently unstable designs, such as some military aircraft and high-performance drones. Fly-by-wire systems, which replace mechanical linkages with electronic controls, often incorporate stability augmentation features to improve handling qualities and reduce pilot workload.

These control mechanisms are indispensable in aerospace engineering, facilitating the safe and efficient operation of vehicles across diverse environments. The continuous evolution of control systems, driven by advancements in sensor technology, computing power, and control algorithms, enables increasingly sophisticated and autonomous aerospace missions, pushing the boundaries of what is possible in flight and space exploration.

5. Materials Science

Materials science is fundamental to aerospace engineering. The selection, characterization, and application of materials directly influence the performance, safety, and longevity of aerospace vehicles. A deep understanding of material properties and behavior under extreme conditions is essential for engineers seeking to design reliable and efficient aircraft and spacecraft.

- High Strength-to-Weight Ratio Materials

Materials with high strength-to-weight ratios, such as aluminum alloys, titanium alloys, and composite materials, are critical for minimizing the weight of aerospace structures while maintaining structural integrity. Reducing weight improves fuel efficiency, increases payload capacity, and enhances maneuverability. For example, the extensive use of carbon fiber reinforced polymers (CFRP) in modern aircraft, like the Boeing 787 Dreamliner, significantly reduces weight compared to traditional aluminum designs, improving fuel economy and range.

- High-Temperature Materials

Components exposed to extreme temperatures, such as those in propulsion systems and hypersonic vehicles, require materials capable of withstanding these harsh conditions without significant degradation. Superalloys, ceramics, and high-temperature composites are employed in these applications. Turbine blades in jet engines, for instance, are often made from nickel-based superalloys that can maintain their strength and creep resistance at temperatures exceeding 1000C, ensuring efficient engine operation.

- Corrosion-Resistant Materials

Aerospace vehicles operating in atmospheric environments are susceptible to corrosion, which can compromise structural integrity. Corrosion-resistant materials, such as stainless steel, anodized aluminum, and specialized coatings, are used to mitigate this issue. The external surfaces of aircraft are often coated with protective paints and sealants to prevent corrosion from moisture, salt, and pollutants, extending the lifespan of the aircraft and reducing maintenance costs.

- Radiation-Shielding Materials

Spacecraft and satellites operating in space are exposed to high levels of radiation, which can damage sensitive electronic components and pose risks to astronauts. Radiation-shielding materials, such as high-density polymers, aluminum, and lead, are used to protect these components. Satellites often incorporate shielding to protect against radiation-induced single event upsets (SEUs) in electronic circuits, ensuring reliable operation in the harsh space environment.

The connection between materials science and aerospace engineering is undeniable. Continuous advancements in materials science drive innovation in aerospace vehicle design, enabling improved performance, increased durability, and enhanced mission capabilities. The ongoing research and development of new materials will continue to shape the future of aerospace technology.

6. System Integration

System integration, within the scope of aerospace engineering, addresses the complex process of combining individual components and subsystems into a cohesive, functioning whole. The success of any aerospace project hinges upon effective system integration, as the failure of even a seemingly minor interface can propagate throughout the entire vehicle, leading to compromised performance or catastrophic failure. This process encompasses not only the physical connection of parts but also the seamless interaction of software, electronics, and mechanical systems. Cause and effect are paramount; for example, an improperly integrated navigation system (cause) can lead to a mission failure due to incorrect trajectory calculations (effect). Understanding the interplay of systems becomes crucial to design robust and functional aerospace systems. The importance of system integration cannot be overstated; it represents the culmination of all engineering disciplines involved in a project, from aerodynamics and propulsion to structures and control. The International Space Station (ISS) exemplifies successful system integration, bringing together modules and systems from multiple countries and agencies into a single, operational research platform. The ISSs power supply, communication network, life support, and control systems must operate in sync to sustain the crew and enable scientific experiments. The development of new generations of autonomous drones or electrical air vehicles also demands highly integrative system design, and advanced software is often called to manage the operation.

Practical applications of a robust system integration process are evident in the development of modern aircraft. For example, the flight control system, avionics, and engine management system must communicate and coordinate seamlessly to ensure safe and efficient flight. Any discrepancies or conflicts in the data exchanged between these systems can result in instability or loss of control. Similarly, in spacecraft design, the integration of the propulsion system, power generation, thermal control, and communication systems is crucial for mission success. Consider the Mars rovers; their scientific instruments, mobility system, power generation, and communication systems are integrated to enable autonomous exploration of the Martian surface. The operation is highly dependent on its data collection, processing and storing.

In summary, system integration is the linchpin of successful aerospace engineering endeavors. It requires a holistic approach that considers the interactions between all components and subsystems. Challenges arise from the increasing complexity of aerospace systems, the need for interoperability between different vendors and technologies, and the stringent reliability and safety requirements. As aerospace systems become more autonomous and interconnected, the importance of effective system integration will only continue to grow, demanding advanced tools, methodologies, and expertise. This area ensures the future of innovative aerospace technologies and continues to be the focus of innovation.

Frequently Asked Questions

The following addresses common inquiries and misconceptions regarding the discipline of aerospace engineering, providing detailed and informative responses to enhance understanding.

Question 1: What distinguishes aerospace engineering from other engineering fields?

Aerospace engineering specializes in the design, development, and testing of vehicles and systems operating within Earth’s atmosphere (aeronautical engineering) and in space (astronautical engineering). This contrasts with other engineering fields like mechanical or electrical engineering, which have broader applications.

Question 2: What academic background is essential for pursuing a career in aerospace engineering?

A strong foundation in mathematics, physics, and computer science is indispensable. Coursework should include calculus, differential equations, linear algebra, thermodynamics, fluid dynamics, and materials science. A bachelor’s degree in aerospace engineering, or a closely related field, is typically required.

Question 3: What are the primary areas of specialization within aerospace engineering?

Specialization areas include aerodynamics, propulsion systems, structural analysis, control systems, avionics, and space systems engineering. Focusing on one area allows for in-depth expertise and tailored career development.

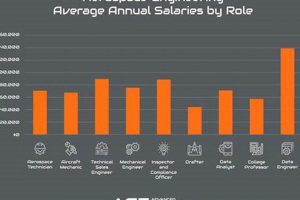

Question 4: What are some common career paths for aerospace engineers?

Aerospace engineers find employment in various sectors, including aircraft manufacturing, spacecraft development, government research agencies, and private space exploration companies. Roles may include design engineering, research and development, testing and evaluation, and project management.

Question 5: What are the major challenges currently facing the aerospace engineering field?

Challenges include developing more fuel-efficient aircraft, creating sustainable propulsion systems, reducing the cost of space access, and mitigating the environmental impact of air travel. Advancements in materials science, artificial intelligence, and advanced manufacturing are critical for addressing these challenges.

Question 6: How does one stay current with advancements in aerospace engineering?

Continuous learning is essential. This includes reading technical journals, attending conferences, participating in professional development courses, and engaging with industry experts. Membership in professional organizations, such as the American Institute of Aeronautics and Astronautics (AIAA), provides access to valuable resources and networking opportunities.

This FAQ section provides insight into the core principles, academic requirements, and career prospects within the aerospace engineering discipline. A solid educational background, continuous learning, and specialized expertise are essential for success.

The subsequent segment will analyze current technological trends shaping the trajectory of aerospace engineering, spotlighting pivotal fields of ongoing research and development.

Conclusion

This exploration has illuminated the multifaceted nature of aerospace engineering, dissecting its core disciplines, essential principles, and future trajectory. From the foundational understanding of aerodynamics and propulsion to the critical importance of structural integrity and system integration, this field demands rigorous expertise and continuous innovation. The FAQ section has addressed common inquiries, underscoring the academic prerequisites, career prospects, and persistent challenges inherent in this complex domain.

Aerospace engineering remains a vital and evolving field, driving advancements in air travel, space exploration, and national security. Continued progress hinges on a commitment to fundamental research, technological innovation, and the cultivation of a highly skilled workforce. The pursuit of more efficient, sustainable, and capable aerospace systems necessitates sustained investment and a dedication to pushing the boundaries of what is possible.

![Why Australian Aerospace Engineering Matters - [Year] Trends Innovating the Future of Flight with Reliable Aviation Solutions Why Australian Aerospace Engineering Matters - [Year] Trends | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/01/th-836-300x200.jpg)

![Alabama Aerospace Engineering: [Your Suffix Here] Innovating the Future of Flight with Reliable Aviation Solutions Alabama Aerospace Engineering: [Your Suffix Here] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/01/th-828-300x200.jpg)