Positions in the design, development, testing, and production of aircraft, spacecraft, and related systems located within the Commonwealth of Pennsylvania constitute a segment of the engineering sector. This encompasses roles ranging from research and development to manufacturing and quality control, all contributing to the advancement of flight technology and related applications within the state.

The availability of these technical positions contributes significantly to Pennsylvania’s economy by fostering innovation and technological advancement. Historically, the state has played a role in the broader aerospace industry, and the continuation of these career paths supports the ongoing development of expertise and infrastructure related to aeronautics and astronautics. The presence of these opportunities attracts skilled professionals and contributes to the overall competitiveness of the state’s technological landscape.

This overview will delve into the sectors and companies within Pennsylvania that offer these specialized roles, examine the required qualifications and skills necessary for securing such employment, and provide insights into the future outlook for this field within the state. Furthermore, it will explore the educational pathways available to those aspiring to enter this engineering domain within Pennsylvania.

The following insights aim to guide individuals seeking technical employment within the aeronautics field in Pennsylvania, focusing on strategies to enhance their competitiveness and navigate the employment landscape effectively.

Tip 1: Focus on Relevant Education: Pursue degrees in aerospace, mechanical, or electrical engineering from accredited institutions. Coursework should emphasize aerodynamics, propulsion, structural analysis, and control systems. A strong academic foundation is fundamental.

Tip 2: Acquire Specialized Skills: Develop expertise in software used in the industry, such as CAD/CAM, MATLAB, or finite element analysis tools. Proficiency in these programs demonstrates a practical understanding of engineering principles.

Tip 3: Gain Practical Experience: Seek internships or co-op positions with aerospace companies, research institutions, or government agencies. Hands-on experience applying theoretical knowledge to real-world problems is highly valued.

Tip 4: Network Actively: Attend industry conferences, workshops, and career fairs. Networking provides opportunities to connect with potential employers, learn about job openings, and gain insights into industry trends.

Tip 5: Tailor Resumes and Cover Letters: Customize application materials to match the specific requirements of each position. Highlight relevant skills, experiences, and accomplishments that demonstrate a strong fit for the role.

Tip 6: Research Pennsylvania’s Aerospace Sector: Identify key companies and organizations operating within the state. Understanding the local market helps focus job search efforts and identify potential employers.

Tip 7: Consider Advanced Degrees: A master’s or doctoral degree can enhance career prospects, particularly for research and development positions. Advanced studies demonstrate a commitment to in-depth knowledge and expertise.

Adherence to these recommendations can significantly improve the likelihood of securing a fulfilling and impactful technical role within Pennsylvania. By prioritizing education, skill development, and networking, individuals can position themselves for success in this competitive sector.

The subsequent sections will delve into the specific employers and areas of specialization present within Pennsylvania, providing a more detailed understanding of the available opportunities.

1. Design opportunities

Design opportunities represent a critical segment within the broader scope of aerospace engineering employment in Pennsylvania. These opportunities encompass a spectrum of activities ranging from conceptualizing new aircraft and spacecraft to refining existing designs for improved performance, efficiency, or safety. The presence of design-focused roles signifies the existence of a robust engineering ecosystem within the state, one capable of not only manufacturing established products but also innovating and developing novel solutions for the aerospace sector. For example, companies specializing in composite materials might offer design positions focused on integrating these materials into aircraft structures to reduce weight and improve fuel efficiency. This illustrates a direct link between design capabilities and the overall competitiveness of aerospace engineering firms in Pennsylvania.

The impact of design capabilities on the aerospace engineering landscape within Pennsylvania is substantial. Effective design leads to increased operational efficiency, reduced environmental impact, and enhanced safety standards in the aviation industry. Moreover, the presence of strong design teams within Pennsylvania-based companies can attract further investment and partnerships, leading to the creation of more employment opportunities in related fields such as manufacturing, testing, and software development. Consider, for instance, the design of more fuel-efficient engines by Pennsylvania-based aerospace component manufacturers. Successful designs translate to increased sales, leading to an expansion of the manufacturing workforce and associated support staff.

In summary, design opportunities are not merely a subset of aerospace engineering positions in Pennsylvania but a fundamental driver of innovation, economic growth, and competitiveness within the sector. A deeper understanding of the specific design specializations in demand, the skills required for these roles, and the companies actively seeking design engineers is essential for both job seekers and those seeking to promote the growth of aerospace engineering within the state.

2. Manufacturing positions

Manufacturing positions are integral to the aerospace engineering sector in Pennsylvania, representing the practical application of design and engineering principles. These roles are critical in translating theoretical concepts into tangible products and systems.

- Precision Machining and Fabrication

This facet involves the use of advanced machinery and techniques to create precise components for aircraft and spacecraft. Examples include Computer Numerical Control (CNC) machining of engine parts and the fabrication of lightweight structures. The implication is a need for skilled machinists and technicians capable of operating sophisticated equipment and adhering to strict tolerances.

- Assembly and Integration

Assembly positions focus on the physical integration of various components into larger subassemblies and finished products. This includes tasks such as wiring harnesses, installing avionics, and integrating propulsion systems. Aerospace companies in Pennsylvania require personnel with meticulous attention to detail and proficiency in following complex assembly procedures.

- Quality Assurance and Control

Quality assurance roles ensure that all manufactured parts and assemblies meet stringent quality standards and specifications. This involves conducting inspections, performing tests, and implementing corrective actions to address any defects or deviations. This aspect is vital for maintaining safety and reliability and demands professionals with expertise in quality management systems.

- Materials Processing and Composites Manufacturing

The use of advanced materials, such as carbon fiber composites and titanium alloys, is prevalent in modern aircraft and spacecraft. Manufacturing roles in this area involve processes like composite layup, heat treatment, and surface finishing. A specialized understanding of materials science and processing techniques is essential for these positions.

These manufacturing facets underscore the significance of a skilled workforce capable of translating engineering designs into tangible products. The prevalence of these roles is indicative of the state’s manufacturing capabilities and its contribution to the aerospace industry. Pennsylvanias economic and technological landscape benefits from these skilled professionals, contributing to its competitiveness in the broader aerospace sector.

3. Research roles

Research roles form a crucial component of aerospace engineering employment within Pennsylvania. These positions, often located at universities, research institutions, and within the research and development arms of aerospace companies, drive innovation and technological advancement within the sector, directly impacting the capabilities and competitiveness of Pennsylvania’s aerospace industry.

- Aerodynamics Research

Aerodynamics research focuses on studying the motion of air and its interaction with aircraft and spacecraft. This can involve computational fluid dynamics (CFD) simulations, wind tunnel testing, and flight testing. Examples include researching novel wing designs to improve fuel efficiency or developing control systems for hypersonic vehicles. This research is vital for enhancing aircraft performance and enabling the development of advanced aerospace technologies within Pennsylvania.

- Materials Science Research

Materials science research is concerned with the development and characterization of new materials for use in aerospace applications. This includes research into lightweight composites, high-temperature alloys, and smart materials. For example, researchers may investigate new methods for creating stronger, lighter composite materials to reduce aircraft weight and improve performance. This research directly supports the development of more efficient and durable aircraft and spacecraft manufactured in Pennsylvania.

- Propulsion Systems Research

Propulsion systems research focuses on improving the efficiency, performance, and reliability of aircraft and spacecraft engines. This can include research into advanced combustion techniques, novel engine designs, and alternative fuels. For example, researchers may investigate the use of biofuels or hydrogen as sustainable aviation fuels. This research is essential for reducing the environmental impact of air travel and enabling the development of more sustainable propulsion systems.

- Avionics and Control Systems Research

Avionics and control systems research focuses on developing advanced electronic systems for aircraft and spacecraft. This can include research into autonomous flight control, sensor fusion, and artificial intelligence. For example, researchers may develop algorithms for autonomous navigation or develop new sensor technologies for detecting structural damage. This research is critical for enhancing the safety, efficiency, and autonomy of aircraft and spacecraft operating within and developed in Pennsylvania.

These research areas collectively contribute to the advancement of aerospace engineering, driving innovation within Pennsylvania’s aerospace industry. By fostering research and development, Pennsylvania can maintain its competitiveness in this sector and attract and retain skilled aerospace engineers.

4. Testing facilities

The presence of testing facilities within Pennsylvania directly influences the availability and nature of opportunities in this engineering domain. These facilities provide essential services for validating designs, assessing performance, and ensuring the safety and reliability of aerospace components and systems. Without robust testing capabilities, the entire aerospace engineering lifecycle within the state would be severely constrained. For example, a company designing a new aircraft wing component would rely on local testing facilities to perform structural integrity tests under simulated flight conditions, a process critical for certification and market entry.

Testing positions often require specialized skills in instrumentation, data acquisition, and analysis. These specialized opportunities range from technicians who conduct routine tests to engineers who design and oversee complex testing protocols. Furthermore, the presence of testing facilities supports the development of research and development capabilities, as data collected during testing provides valuable insights for improving existing designs and developing new technologies. For instance, the test data from a materials testing laboratory might inform the development of new composite materials that are lighter and stronger than existing options, thereby improving aircraft fuel efficiency.

In summary, these specialized facilities are a cornerstone of aerospace engineering activity in Pennsylvania. Their presence not only creates employment opportunities directly related to testing but also supports a broader ecosystem of design, manufacturing, and research activities. The continued investment in and maintenance of testing infrastructure are essential for sustaining the growth and competitiveness of the aerospace sector within the state, enhancing the availability of associated career paths.

5. Systems engineering

Systems engineering plays a pivotal role within aerospace engineering in Pennsylvania, ensuring the seamless integration and optimal performance of complex aerospace systems. This discipline focuses on the holistic view of projects, encompassing all lifecycle phases from conceptual design to deployment and maintenance. The availability of systems engineering positions directly reflects the maturity and sophistication of aerospace activities within the state.

- Requirements Management

This facet involves defining, documenting, and managing all system requirements, ensuring that the final product meets all specified needs. In Pennsylvania, systems engineers might be responsible for translating customer requirements for a new satellite payload into detailed technical specifications, ensuring that the satellite performs as intended in orbit. Effective requirements management reduces the risk of costly design errors and delays.

- Architecture and Design

Systems engineers develop the overall architecture and design of aerospace systems, defining the interfaces and interactions between different components. For example, a systems engineer working on a new aircraft flight control system in Pennsylvania would be responsible for designing the system architecture, ensuring that the sensors, computers, and actuators work together effectively. This ensures that the system functions safely and reliably under all flight conditions.

- Integration and Testing

This phase involves integrating the various components of an aerospace system and conducting rigorous testing to ensure that the system meets all requirements. Systems engineers oversee this process, identifying and resolving any integration issues. In Pennsylvania, this might involve integrating a new radar system into an existing aircraft and conducting flight tests to verify its performance. Thorough integration and testing are essential for ensuring system reliability and safety.

- Risk Management

Systems engineers identify and assess potential risks throughout the lifecycle of an aerospace project and develop mitigation strategies. For example, a systems engineer working on a new spacecraft in Pennsylvania might identify the risk of radiation damage to electronic components and implement shielding measures to protect the system. Effective risk management minimizes the likelihood of project delays, cost overruns, and system failures.

These interconnected facets demonstrate the breadth and depth of systems engineering expertise required within the aerospace sector in Pennsylvania. The demand for skilled systems engineers directly reflects the complexity and ambition of aerospace projects undertaken within the state, further solidifying its position as a key player in the national aerospace industry. Continued investment in systems engineering education and training will be crucial for sustaining Pennsylvania’s competitive advantage.

6. Quality control

Quality control constitutes a critical element within the aerospace engineering landscape in Pennsylvania. The stringent demands for safety, reliability, and performance in aerospace applications necessitate rigorous quality control processes at every stage of design, manufacturing, and testing. The availability of quality control positions is, therefore, directly proportional to the overall level of aerospace activity within the state, reflecting both the presence of established aerospace manufacturers and the growth of related support industries.

- Inspection and Testing Protocols

This facet encompasses the development and implementation of standardized inspection and testing procedures to verify that aerospace components and systems meet specified requirements. For instance, non-destructive testing (NDT) methods, such as ultrasonic and radiographic inspection, are employed to detect defects in aircraft structures without causing damage. In Pennsylvania, aerospace quality control professionals are responsible for ensuring that these inspection protocols are rigorously followed, thus contributing to the safety and airworthiness of aircraft and spacecraft.

- Adherence to Regulatory Standards

The aerospace industry is heavily regulated, with organizations such as the Federal Aviation Administration (FAA) setting stringent standards for quality and safety. Quality control personnel in Pennsylvania must ensure compliance with these regulatory requirements, documenting all processes and procedures to demonstrate adherence. For example, quality control engineers might oversee the implementation of AS9100, a widely recognized quality management standard for the aerospace industry. Compliance with these standards is essential for maintaining the state’s reputation as a reliable source of aerospace products and services.

- Statistical Process Control (SPC)

SPC techniques are used to monitor manufacturing processes and identify sources of variation that could lead to defects. Quality control professionals in Pennsylvania employ SPC charts and other statistical tools to track key process parameters and ensure that manufacturing processes remain within acceptable limits. For example, SPC might be used to monitor the dimensional accuracy of machined aircraft components, allowing manufacturers to identify and correct any deviations before they result in defective parts.

- Root Cause Analysis and Corrective Action

When defects or non-conformities are identified, quality control personnel are responsible for conducting root cause analysis to determine the underlying cause of the problem. This involves systematically investigating the factors that contributed to the defect and implementing corrective actions to prevent recurrence. In Pennsylvania, quality control teams might investigate the cause of a failure in a composite material used in aircraft construction, identifying factors such as improper curing procedures or contamination. Implementing corrective actions ensures continuous improvement in manufacturing processes and enhances the overall quality and reliability of aerospace products.

The multifaceted nature of quality control underscores its importance within the aerospace engineering sector in Pennsylvania. From ensuring compliance with regulatory standards to implementing statistical process control and conducting root cause analysis, quality control professionals play a critical role in maintaining the safety, reliability, and performance of aerospace products and systems. Their expertise is essential for sustaining the state’s competitiveness in the global aerospace market and for attracting and retaining aerospace engineering businesses.

7. Software development

Software development is an increasingly vital component of aerospace engineering, and its influence on job opportunities within Pennsylvania is significant. The complexity of modern aircraft, spacecraft, and associated systems demands sophisticated software solutions, driving the demand for skilled software developers within the state’s aerospace sector.

- Flight Control Systems

Flight control systems rely heavily on software to maintain stability, execute maneuvers, and ensure safe operation. Developers in Pennsylvania contribute to coding, testing, and verifying these systems, which are critical for both manned and unmanned aircraft. The demand for expertise in real-time operating systems, control algorithms, and safety-critical software development practices is particularly high.

- Simulation and Modeling

Software development is essential for creating realistic simulations used in the design, testing, and training phases of aerospace engineering. Pennsylvania-based companies employ software developers to build high-fidelity models of aircraft performance, aerodynamic characteristics, and environmental conditions. These simulations allow engineers to evaluate designs, identify potential problems, and train pilots in a virtual environment, reducing the costs and risks associated with physical testing.

- Data Analysis and Processing

Aerospace systems generate vast amounts of data, which must be processed and analyzed to extract meaningful insights. Software developers in Pennsylvania create applications for analyzing flight data, monitoring system performance, and predicting maintenance needs. These data analysis tools help engineers optimize aircraft operations, improve safety, and reduce costs.

- Embedded Systems

Embedded systems are used to control various functions within aircraft and spacecraft, such as engine management, navigation, and communication. Software developers in Pennsylvania work on developing and integrating embedded software for these systems, ensuring that they operate reliably and efficiently. This requires expertise in programming languages such as C and C++, as well as knowledge of embedded hardware platforms and real-time operating systems.

The integration of software development across these diverse facets of aerospace engineering highlights its importance for technical employment in Pennsylvania. The demand for skilled software developers is likely to continue growing as aerospace systems become increasingly complex and reliant on software-based solutions.

Frequently Asked Questions

The following provides responses to commonly asked questions regarding employment opportunities within the aerospace engineering sector in Pennsylvania.

Question 1: What educational qualifications are generally required for positions?

A bachelor’s degree in aerospace engineering, mechanical engineering, or a closely related field is typically the minimum requirement. Certain research-oriented roles or advanced engineering positions may necessitate a master’s or doctoral degree.

Question 2: What types of companies offer employment in this sector within Pennsylvania?

Opportunities exist within established aerospace manufacturers, component suppliers, research institutions, and government agencies operating within the state. Specific companies will vary depending on current market conditions and project needs.

Question 3: Are internships and co-op programs readily available?

Many Pennsylvania-based companies and universities offer internship and cooperative education programs. These programs provide valuable practical experience and can enhance the competitiveness of job applicants.

Question 4: What specific technical skills are most in demand?

Proficiency in CAD/CAM software, finite element analysis tools, and programming languages relevant to aerospace engineering, such as MATLAB or Python, is generally highly valued. Specific skill requirements will vary depending on the particular position.

Question 5: What is the typical salary range for entry-level positions?

Salary ranges are dependent upon factors such as education, experience, and the specific employer. Researching industry salary benchmarks for similar positions in Pennsylvania is advisable.

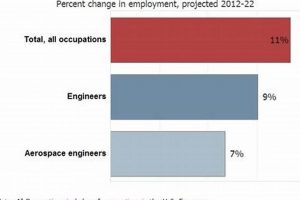

Question 6: What is the long-term outlook for aerospace engineering employment in Pennsylvania?

The long-term outlook is generally positive, driven by ongoing advancements in aviation technology, increasing demand for air travel, and the continued presence of aerospace-related industries within the state. However, economic fluctuations and changes in government spending can influence the overall job market.

In summary, securing a fulfilling career requires a combination of relevant education, specialized skills, and proactive networking. Continuous professional development is recommended to stay abreast of advancements in the field.

The subsequent section will present resources and links to assist individuals in their search for these career paths.

Concluding Remarks

This exploration of employment opportunities within Pennsylvania’s aeronautics sector has highlighted the diverse range of positions available, from design and manufacturing to research and quality control. The presence of these roles signifies the state’s contribution to the broader aerospace industry and underscores the importance of a skilled workforce in driving innovation and economic growth. Aspiring engineers and professionals seeking to advance their careers can leverage the insights provided herein to navigate the employment landscape effectively.

Continued investment in education, skill development, and infrastructure will be essential for sustaining Pennsylvania’s competitiveness in the national and global aerospace market. A proactive approach to career planning, combined with a commitment to continuous learning, will position individuals for success in this demanding yet rewarding field. The future of Pennsylvania’s aerospace sector depends on the talent and dedication of those who pursue these challenging and vital opportunities.

![Guide to Aerospace Welder Job Description [+Skills] Innovating the Future of Flight with Reliable Aviation Solutions Guide to Aerospace Welder Job Description [+Skills] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-692-300x200.jpg)