The designation signifies an organization engaged in the design, development, testing, and production of aircraft, spacecraft, and related systems. The inclusion of “private limited” indicates a specific business structure, denoting a privately held company with limited liability for its shareholders. This structure impacts its regulatory obligations, financial reporting requirements, and ownership dynamics.

Such entities play a critical role in technological advancement and economic growth, fostering innovation and driving progress in both civilian and military applications. Historically, these organizations have been pivotal in pushing the boundaries of flight and space exploration, contributing significantly to scientific knowledge and national security. Their privately held status often allows for greater agility and focused strategic direction compared to publicly traded counterparts.

The following sections will delve into various aspects related to the operational landscape, technological challenges, and market dynamics faced by businesses functioning within this specific sector. These include a consideration of supply chain management, regulatory compliance, and the evolving competitive environment that characterizes this specialized industry.

Strategic Considerations for Aerospace Ventures

This section outlines crucial strategic considerations for entities operating within the aerospace sector, particularly those structured as private limited companies. These tips aim to enhance operational efficiency, technological competitiveness, and long-term sustainability.

Tip 1: Prioritize Research and Development Investment: Sustained investment in research and development is paramount. Dedicate a significant portion of revenue to exploring new technologies, improving existing designs, and developing innovative solutions. For example, explore advancements in composite materials for lighter, more fuel-efficient aircraft components.

Tip 2: Cultivate a Robust Supply Chain: Develop a diversified and resilient supply chain to mitigate risks associated with component shortages and geopolitical instability. Establish strong relationships with multiple suppliers, ensuring redundancy and competitive pricing. Consider vertical integration in strategically important areas.

Tip 3: Maintain Rigorous Quality Control: Adherence to the highest quality control standards is non-negotiable. Implement comprehensive testing and inspection protocols throughout the manufacturing process. Document all procedures meticulously to comply with stringent regulatory requirements.

Tip 4: Foster a Culture of Innovation: Encourage employees to contribute ideas and explore novel approaches to problem-solving. Implement internal programs that reward innovation and facilitate knowledge sharing across departments. This can lead to breakthroughs in efficiency and performance.

Tip 5: Ensure Regulatory Compliance: Aerospace is a heavily regulated industry. Maintain a dedicated team responsible for ensuring compliance with all applicable regulations, including safety standards, environmental regulations, and export controls. Proactive compliance minimizes legal risks and reputational damage.

Tip 6: Develop Strategic Partnerships: Collaborate with universities, research institutions, and other companies to access specialized expertise and resources. Strategic partnerships can accelerate innovation and reduce development costs.

Tip 7: Focus on Cybersecurity: Aerospace systems are increasingly vulnerable to cyberattacks. Implement robust cybersecurity measures to protect sensitive data and critical infrastructure. Regularly conduct vulnerability assessments and penetration testing.

These strategic considerations are essential for maintaining a competitive edge, ensuring long-term viability, and navigating the complexities of the aerospace industry. By focusing on innovation, quality, and compliance, organizations can position themselves for sustained success.

The subsequent sections will expand upon these strategic considerations, providing a more detailed analysis of the challenges and opportunities facing the industry.

1. Design Innovation

Design innovation is a cornerstone of any successful aerospace engineering firm. For a privately held company, this emphasis on novel and effective design solutions is not merely an aspirational goal but a critical driver of competitive advantage and long-term sustainability.

- Performance Optimization

Design innovation in aerospace frequently centers on enhancing performance metrics. This includes improvements in fuel efficiency through advanced aerodynamic designs, increased payload capacity via structural optimization, and enhanced speed and maneuverability achieved through novel control systems. For example, the development of blended wing body aircraft designs represents a significant innovation aimed at reducing drag and improving fuel economy. Such advancements are essential for firms seeking to offer superior solutions in a demanding market.

- Material Science Integration

The effective application of advanced materials is integral to design innovation. This facet involves incorporating lightweight composites, high-temperature alloys, and smart materials into aircraft and spacecraft designs. The use of carbon fiber reinforced polymers in airframes, for instance, significantly reduces weight compared to traditional aluminum alloys, improving performance and reducing fuel consumption. Privately held aerospace firms that excel in material science integration can create lighter, stronger, and more durable products.

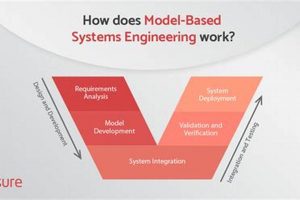

- Systems Engineering Approach

Design innovation requires a holistic systems engineering perspective. This involves considering the interplay between various subsystems, such as propulsion, avionics, and structural components, to optimize overall performance. Developing autonomous flight control systems, for instance, requires integrating sensors, algorithms, and actuators into a seamless and reliable system. Private limited companies that adopt a systems engineering approach are better equipped to tackle complex design challenges and develop integrated solutions.

- Sustainability Considerations

Increasingly, design innovation in aerospace incorporates sustainability considerations. This includes developing more fuel-efficient engines, designing for recyclability, and reducing noise pollution. The development of electric propulsion systems for aircraft, for example, represents a significant innovation aimed at reducing carbon emissions. Privately held companies that prioritize sustainability can gain a competitive advantage by appealing to environmentally conscious customers and complying with increasingly stringent regulations.

These interconnected facets of design innovation demonstrate its vital role in shaping the capabilities and competitiveness of aerospace engineering firms, especially those operating as private limited companies. By prioritizing performance optimization, material science integration, systems engineering, and sustainability, these companies can create advanced solutions that drive progress in the aerospace industry.

2. Manufacturing Precision

Manufacturing precision is not merely a desirable attribute but a fundamental requirement for aerospace engineering firms structured as private limited companies. This is due to the inherent safety-critical nature of aerospace components and the stringent performance demands placed upon them. The financial success and long-term viability of these organizations are inextricably linked to their ability to consistently produce parts and systems that meet or exceed exacting specifications.

- Dimensional Accuracy and Tolerances

Adherence to extremely tight dimensional tolerances is paramount in aerospace manufacturing. Components must conform precisely to design specifications to ensure proper fit, function, and structural integrity. Failure to meet these tolerances can result in assembly problems, performance degradation, and, in severe cases, catastrophic failure. Examples include the precise machining of turbine blades for jet engines or the accurate forming of airframe panels. These processes require advanced machine tools, skilled operators, and rigorous quality control measures.

- Material Integrity and Traceability

Maintaining the integrity of materials used in aerospace manufacturing is crucial. This involves selecting appropriate materials for each application, ensuring they meet specified performance characteristics (e.g., tensile strength, fatigue resistance), and implementing traceability systems to track materials throughout the manufacturing process. For example, specialized alloys used in engine components undergo stringent testing to verify their composition and properties. Traceability systems ensure that any defects or inconsistencies can be traced back to the source, enabling corrective action.

- Process Control and Standardization

Aerospace manufacturing requires meticulous control over all production processes, from raw material processing to final assembly. Standardized procedures and documented processes are essential for ensuring consistency and repeatability. This includes controlling parameters such as temperature, pressure, and cutting speeds during machining operations. Statistical process control (SPC) techniques are often employed to monitor process performance and identify potential deviations from acceptable limits. Standardized processes minimize variability and reduce the risk of defects.

- Non-Destructive Testing (NDT) and Inspection

Non-destructive testing methods are extensively used to detect internal flaws or surface defects in aerospace components without damaging them. Techniques such as ultrasonic testing, radiographic inspection, and dye penetrant testing are employed to identify cracks, voids, and other anomalies. Stringent inspection procedures are implemented at various stages of the manufacturing process to verify conformance to specifications. NDT and inspection are critical for ensuring the safety and reliability of aerospace products.

In summary, manufacturing precision is a non-negotiable aspect of the aerospace industry, particularly for privately held engineering companies. The combined rigor of dimensional accuracy, material integrity, process control, and NDT ensures the creation of safe, efficient, and reliable aerospace components, impacting the company’s reputation, competitive standing, and ultimately, its long-term success within this demanding market.

3. Regulatory Compliance

Regulatory compliance serves as a foundational pillar for any aerospace engineering private limited. The stringent regulations governing the design, manufacturing, testing, and maintenance of aircraft and spacecraft components are not merely suggestions but legally binding mandates. Failure to adhere to these regulations can result in severe penalties, including fines, operational restrictions, and reputational damage, ultimately threatening the company’s viability. Regulatory frameworks such as those established by the Federal Aviation Administration (FAA) in the United States, the European Aviation Safety Agency (EASA) in Europe, and similar bodies worldwide dictate every aspect of aerospace operations. This compliance ensures safety, security, and environmental responsibility within the industry.

Consider the example of a private limited company involved in the production of aircraft engines. This entity must demonstrate strict adherence to FAA regulations pertaining to engine design, materials selection, manufacturing processes, and testing protocols. This includes rigorous testing to ensure the engine’s performance under various conditions, adherence to specific quality control measures throughout the production line, and the maintenance of detailed records to document compliance. Any deviation from these standards, even a seemingly minor one, can lead to the grounding of aircraft and significant financial repercussions for the company. Furthermore, non-compliance can trigger extensive investigations and potential legal action, undermining investor confidence and hindering future business opportunities. Regular audits and certifications are vital for confirming ongoing adherence to these complex rules.

In conclusion, regulatory compliance is not merely a procedural formality but an integral aspect of the operational integrity and long-term sustainability of any aerospace engineering private limited. It impacts every facet of the business, from product development to ongoing maintenance. Challenges stem from the continuously evolving regulatory landscape, demanding a proactive and adaptive approach. Mastery of this critical component distinguishes responsible and successful firms, upholding safety and fostering trust in the aerospace sector.

4. Project Management

Project management is central to the success of aerospace engineering private limited companies. These firms undertake complex, multi-faceted projects requiring precise coordination, rigorous oversight, and adherence to strict deadlines and budgets. Effective project management is not merely a best practice but a critical necessity for navigating the intricate challenges inherent in this industry.

- Scope Definition and Requirements Management

Clearly defining project scope and managing evolving requirements are paramount. Aerospace projects often involve numerous stakeholders, including customers, regulatory agencies, and subcontractors. Effective scope definition ensures that all parties have a shared understanding of project objectives, deliverables, and constraints. Robust requirements management processes are necessary to capture, prioritize, and track changes to requirements throughout the project lifecycle. Mismanagement of scope and requirements can lead to cost overruns, schedule delays, and ultimately, project failure. For example, a private limited company tasked with developing a new satellite must meticulously define the satellite’s capabilities, performance characteristics, and operational parameters, while simultaneously managing changes requested by the customer or mandated by regulatory bodies.

- Risk Assessment and Mitigation

Aerospace projects are inherently risky due to their technological complexity, regulatory scrutiny, and high capital investment. Comprehensive risk assessment is crucial for identifying potential threats and developing mitigation strategies. This includes assessing technical risks (e.g., component failures, design flaws), programmatic risks (e.g., funding shortfalls, schedule delays), and external risks (e.g., geopolitical instability, supply chain disruptions). Mitigation strategies may involve redundancy, contingency planning, and proactive monitoring. Failure to adequately assess and mitigate risks can have severe consequences, ranging from project delays to complete project cancellation. For example, a firm developing a new aircraft engine would need to identify potential risks associated with the engine’s performance, reliability, and certification process, and implement measures to minimize those risks.

- Resource Allocation and Scheduling

Efficient allocation of resources, including personnel, equipment, and funding, is essential for project success. Aerospace projects often require specialized expertise and access to advanced facilities. Effective scheduling involves creating realistic timelines, identifying critical path activities, and monitoring progress against milestones. Improper resource allocation or unrealistic scheduling can lead to bottlenecks, delays, and increased costs. For instance, a company manufacturing composite airframe components must ensure that it has sufficient skilled technicians, specialized tooling, and raw materials available to meet production targets, while also adhering to strict manufacturing schedules.

- Configuration Management and Change Control

Aerospace projects involve complex configurations with numerous interconnected components and subsystems. Robust configuration management is necessary to track and control changes to these configurations throughout the project lifecycle. This includes maintaining accurate records of all design documents, specifications, and modifications. Change control processes ensure that all proposed changes are thoroughly evaluated, approved, and documented before implementation. Poor configuration management can lead to integration problems, performance issues, and safety hazards. As an illustration, a private limited company upgrading the avionics system of an existing aircraft must meticulously track all changes to the aircraft’s wiring diagrams, software code, and hardware configurations to ensure compatibility and functionality.

Effective project management, encompassing these facets, is not merely a supplementary function but an integral element for the successful execution and operation of any aerospace engineering private limited firm. Through meticulous planning, risk mitigation, and resource management, these companies can effectively navigate challenges, uphold safety standards, and achieve desired outcomes, thus securing their standing in this demanding industry.

5. Technological Advancement

Technological advancement constitutes a driving force in the evolution and competitive landscape of aerospace engineering private limited companies. These organizations are predicated on the development and deployment of cutting-edge technologies to achieve superior performance, efficiency, and safety within the aerospace domain. Sustained technological innovation is not merely a strategic advantage but a fundamental requirement for survival and growth in this highly competitive sector.

- Advanced Materials and Manufacturing Processes

The development and application of advanced materials, coupled with innovative manufacturing processes, are critical facets of technological advancement. Aerospace engineering private limited firms continually seek to incorporate lighter, stronger, and more heat-resistant materials into their designs. Examples include the use of carbon fiber reinforced polymers, titanium alloys, and ceramic matrix composites. Advanced manufacturing processes, such as additive manufacturing (3D printing) and automated fiber placement, enable the creation of complex geometries and the reduction of manufacturing lead times. The adoption of these technologies enhances aircraft performance, reduces fuel consumption, and lowers manufacturing costs. These advancements are vital for producing more efficient and cost-effective aerospace solutions.

- Artificial Intelligence and Autonomous Systems

Artificial intelligence (AI) and autonomous systems are transforming the aerospace industry. Aerospace engineering private limited companies are leveraging AI to develop autonomous flight control systems, predictive maintenance capabilities, and enhanced air traffic management solutions. AI-powered systems can analyze vast amounts of data to optimize flight paths, detect potential maintenance issues before they occur, and improve the overall efficiency of air transportation. Autonomous drones and unmanned aerial vehicles (UAVs) are also finding increasing applications in areas such as surveillance, inspection, and cargo delivery. AI and autonomous systems are enabling safer, more efficient, and more cost-effective aerospace operations.

- Hypersonic Technologies and Space Exploration

The pursuit of hypersonic technologies and advancements in space exploration represent key frontiers of technological advancement. Aerospace engineering private limited firms are investing in the development of hypersonic aircraft and spacecraft capable of traveling at speeds exceeding Mach 5. These technologies have potential applications in high-speed transportation, military reconnaissance, and space access. Furthermore, advancements in propulsion systems, robotics, and life support technologies are enabling more ambitious space exploration missions, including lunar and Martian colonization. These efforts require significant investment in research and development and push the boundaries of engineering capabilities.

- Sustainable Aviation Technologies

The growing emphasis on environmental sustainability is driving the development of sustainable aviation technologies. Aerospace engineering private limited companies are actively pursuing solutions to reduce carbon emissions and minimize the environmental impact of air travel. This includes the development of more fuel-efficient engines, the exploration of alternative fuels (e.g., biofuels, hydrogen), and the design of electric and hybrid-electric aircraft. Innovations in aerodynamics, lightweight materials, and propulsion systems are contributing to the realization of more sustainable aviation practices. The adoption of these technologies is essential for mitigating climate change and ensuring the long-term viability of the aerospace industry.

In conclusion, technological advancement is inextricably linked to the success and evolution of aerospace engineering private limited companies. These entities must continuously innovate and adopt new technologies to remain competitive, meet regulatory requirements, and address the evolving needs of the aerospace market. The convergence of advanced materials, AI, hypersonic technologies, and sustainable aviation practices is shaping the future of the industry, driving progress and creating new opportunities for innovation.

Frequently Asked Questions

This section addresses common inquiries concerning the nature, operations, and scope of aerospace engineering private limited companies. The information aims to provide clarity and dispel potential misconceptions about this specialized sector.

Question 1: What core activities define an aerospace engineering private limited?

These entities focus on designing, developing, manufacturing, and testing aircraft, spacecraft, and related systems. Activities encompass research and development, engineering design, prototyping, component manufacturing, system integration, and performance testing.

Question 2: How does the “private limited” structure impact its operations?

The “private limited” designation denotes a specific business structure characterized by private ownership and limited liability. This structure influences access to capital markets, reporting requirements, and governance structures compared to publicly traded corporations.

Question 3: What regulatory oversight governs its activities?

Aerospace engineering private limited companies are subject to rigorous regulatory oversight from national and international aviation authorities, such as the FAA and EASA. These regulations cover design, manufacturing, operations, and maintenance to ensure safety and compliance with industry standards.

Question 4: What are the primary technological challenges faced by such companies?

Technological challenges include developing advanced materials, improving fuel efficiency, reducing emissions, enhancing safety systems, and integrating artificial intelligence and autonomous systems. These challenges necessitate continuous investment in research and development and collaboration with research institutions.

Question 5: How does competition impact these businesses?

Competition is intense within the aerospace sector. Companies must demonstrate technological superiority, cost-effectiveness, and responsiveness to market demands to maintain a competitive advantage. Differentiation through innovation and strategic partnerships is critical for success.

Question 6: What career opportunities are typically available within these organizations?

Career opportunities span a wide range of disciplines, including aerospace engineering, mechanical engineering, electrical engineering, computer science, materials science, and project management. These companies seek highly skilled professionals with expertise in design, analysis, manufacturing, and testing.

In summary, aerospace engineering private limited companies represent a critical segment of the aerospace industry, driving innovation, fostering economic growth, and contributing to advancements in aviation and space exploration. Their success depends on technological prowess, regulatory compliance, and effective management of complex projects.

The next section will delve into the future trends and emerging technologies shaping the aerospace landscape.

Conclusion

The preceding discussion has explored critical facets of aerospace engineering private limited entities, underscoring their operational characteristics, strategic imperatives, and technological drivers. The importance of design innovation, manufacturing precision, regulatory compliance, and effective project management for these organizations has been emphasized. Their dependence on relentless technological advancement for competitiveness and long-term viability also merits noting.

The future landscape for aerospace engineering private limited companies promises both challenges and opportunities. Sustained commitment to innovation, proactive adaptation to evolving regulatory environments, and adept navigation of competitive pressures will determine their ultimate success. Stakeholders must recognize the pivotal role of these enterprises in shaping the future of aviation and space exploration, warranting continued support and strategic investment.

![Top Aerospace Engineering Masters Programs [Ranked] Innovating the Future of Flight with Reliable Aviation Solutions Top Aerospace Engineering Masters Programs [Ranked] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-459-300x200.jpg)