The field concerned with the design, development, testing, and production of aircraft and spacecraft faces a unique set of difficulties and accompanying resolutions. These challenges span numerous domains, from fundamental aerodynamic principles to the complexities of propulsion systems and the ever-present demands of structural integrity. Finding effective answers is crucial for advancing air and space travel.

Addressing the complexities within this sector is paramount for national security, economic growth, and scientific discovery. Historically, breakthroughs in related fields have spurred innovation, leading to more efficient and safer air travel, the exploration of space, and the development of advanced materials. The pursuit of optimized performance and reliability has consistently driven technological progress.

Therefore, the following sections will delve into specific technical hurdles related to aerodynamics, propulsion, materials science, and control systems, while outlining the methodologies and technologies employed to overcome them. Subsequent discussions will cover the influence of regulatory environments and the continuous drive for improvement, ensuring the sustainability and viability of future endeavors.

Aerospace endeavors are characterized by intricate technical demands and rigorous safety requirements. Effective problem-solving necessitates a methodical approach and a thorough understanding of underlying principles. The following strategies offer guidance for addressing common difficulties encountered in this field.

Tip 1: Emphasize Robust Simulation and Modeling: Utilize advanced simulation tools throughout the design process to predict performance and identify potential weaknesses early on. Finite element analysis, computational fluid dynamics, and system-level simulations are crucial for optimizing designs and mitigating risks before physical prototyping.

Tip 2: Adopt a Systems Engineering Perspective: Consider the entire system, including interactions between subsystems, when addressing specific issues. A change in one area can have unforeseen consequences elsewhere. Systems engineering ensures a holistic approach to problem resolution and integration.

Tip 3: Prioritize Rigorous Testing and Validation: Subject designs to thorough testing under realistic conditions. This includes wind tunnel tests, structural load tests, and flight tests. Data obtained from testing should be used to validate models, refine designs, and identify areas for improvement.

Tip 4: Implement Advanced Materials and Manufacturing Techniques: Exploit the properties of composite materials, additive manufacturing, and other advanced techniques to achieve lighter, stronger, and more efficient structures. These materials and processes offer design flexibility and performance enhancements that are not attainable with traditional methods.

Tip 5: Leverage Data Analytics and Machine Learning: Employ data analytics and machine learning to extract insights from operational data, identify patterns, and predict failures. Predictive maintenance and performance optimization are just two of the many applications where data-driven approaches can significantly improve efficiency and reliability.

Tip 6: Foster Collaboration and Knowledge Sharing: Encourage communication and knowledge sharing among engineers, scientists, and other stakeholders. Cross-functional teams can bring diverse perspectives and expertise to bear on challenging problems. Furthermore, access to past project data and lessons learned can prevent the repetition of mistakes.

Tip 7: Adhere to Strict Regulatory Compliance: Understand and comply with all applicable regulations and standards. These regulations are designed to ensure safety, reliability, and environmental protection. Compliance requires meticulous documentation, rigorous testing, and ongoing monitoring.

These strategies underscore the importance of a comprehensive and meticulous approach to navigating the technical complexities and safety-critical requirements of aerospace projects. By focusing on simulation, systems thinking, rigorous testing, advanced materials, data analytics, collaboration, and regulatory compliance, engineers can effectively address current challenges and pave the way for future innovations.

The application of these principles fosters a culture of continuous improvement, ensuring that aerospace endeavors remain at the forefront of technological advancement.

1. Aerodynamics

Aerodynamics, the study of air in motion and its interaction with solid objects, forms a cornerstone in addressing many critical aerospace engineering problems. Deficiencies in aerodynamic design directly impact aircraft performance, stability, and fuel efficiency. For instance, inadequate wing design can result in increased drag, reduced lift, and ultimately, compromised flight capabilities. Therefore, effective aerodynamic solutions are indispensable for overcoming these limitations.

The relationship between aerodynamics and successful outcomes in aerospace engineering is evident in countless applications. The development of supercritical airfoils, which minimize drag at transonic speeds, enabled faster and more fuel-efficient commercial airliners. Similarly, winglets, small vertical extensions at the wingtips, reduce induced drag by disrupting the formation of wingtip vortices, leading to improved fuel economy. Furthermore, advanced computational fluid dynamics (CFD) techniques allow engineers to simulate airflow around complex shapes, enabling the optimization of designs for maximum performance before physical prototypes are even built.

Ultimately, the application of sound aerodynamic principles is essential for ensuring the safety, efficiency, and viability of aerospace vehicles. Continuous advancements in aerodynamic theory and computational tools are vital for tackling the evolving challenges in aircraft and spacecraft design, contributing significantly to the broader goals of aerospace engineering. Poor aerodynamic design presents significant challenges that can affect aircraft performance, stability, and overall efficiency, underscoring the critical role of continuous improvements in aerodynamic knowledge and application.

2. Propulsion Systems

Propulsion systems represent a critical intersection point within aerospace engineering, directly influencing the resolution of numerous challenges. The efficiency, power output, and reliability of these systems are fundamental determinants of an aircraft’s range, payload capacity, and overall performance. Consequently, improvements or deficiencies in propulsion technology translate directly into enhanced or diminished aerospace capabilities. For instance, the development of high-bypass turbofan engines significantly improved the fuel efficiency of commercial airliners, addressing a critical economic and environmental concern. Conversely, limitations in rocket engine technology can constrain the scope and duration of space exploration missions.

The development and refinement of propulsion systems involve addressing several complex issues. Engineers must contend with the limitations of current materials to withstand extreme temperatures and pressures. Combustion stability is paramount for ensuring smooth and efficient engine operation, while also minimizing harmful emissions. Furthermore, integrating advanced control systems is essential for optimizing performance across a wide range of flight conditions. The evolution of scramjet technology exemplifies the pursuit of high-speed propulsion, potentially enabling hypersonic flight. Moreover, ongoing research into electric propulsion systems, including ion drives and plasma thrusters, offers solutions for extended space missions with reduced propellant consumption.

In summary, propulsion systems are integral to resolving fundamental challenges in aerospace engineering. Advancements in this area drive improvements in aircraft performance, reduce environmental impact, and enable more ambitious space exploration endeavors. Addressing the multifaceted technical complexities of propulsion technology remains a central focus in the field, ensuring continued progress in air and space travel.

3. Material Science

The discipline of material science plays a pivotal role in the resolution of aerospace engineering problems. Material properties directly influence structural integrity, weight, performance, and longevity of aircraft and spacecraft. Inadequate materials can lead to catastrophic failures, decreased efficiency, and increased operational costs. Therefore, advancements in materials are frequently the enablers for breakthroughs in aerospace design and capabilities. For example, the transition from aluminum to composite materials in aircraft structures has resulted in significant weight reductions, leading to improved fuel efficiency and increased payload capacity.

The demands placed on aerospace materials are exceptionally stringent. They must withstand extreme temperatures, high stresses, corrosive environments, and radiation exposure, depending on the specific application. Titanium alloys, for instance, are widely used in jet engines due to their high strength-to-weight ratio and ability to maintain structural integrity at elevated temperatures. Similarly, ceramic matrix composites are being developed for hypersonic vehicles to withstand the intense heat generated during atmospheric reentry. Moreover, the development of self-healing materials and advanced coatings offers the potential to extend the lifespan of aerospace components, reducing maintenance requirements and improving overall reliability.

In conclusion, material science is inextricably linked to the success of aerospace engineering endeavors. Continuous advancements in material properties, processing techniques, and testing methodologies are essential for addressing existing challenges and enabling future innovations in the field. The ongoing pursuit of lighter, stronger, more durable, and more heat-resistant materials remains a critical driver of progress in aerospace technology, ensuring safer, more efficient, and more capable air and space vehicles.

4. Structural Integrity

Structural integrity, the ability of an aerospace vehicle to withstand applied loads without failure, is a paramount concern within aerospace engineering. It fundamentally dictates the safety, reliability, and performance of aircraft and spacecraft. Compromised structural integrity presents significant threats, potentially leading to catastrophic incidents. Addressing the complexities related to structural health is thus a core focus within aerospace engineering problem-solving.

- Load Analysis and Prediction

Accurate assessment of loads experienced during flight or space travel is crucial. This includes static loads, dynamic loads (e.g., turbulence, vibrations), and thermal loads. Predicting these loads requires sophisticated modeling and simulation techniques. An underestimation of loads can result in structural failure, while overestimation can lead to unnecessary weight penalties, negatively impacting performance. The challenge lies in developing robust models that accurately reflect real-world operating conditions. For example, predicting the stresses on a wing during a high-G maneuver requires precise knowledge of aerodynamic forces and material properties.

- Material Selection and Characterization

The choice of materials is directly linked to structural integrity. Materials must possess adequate strength, stiffness, fatigue resistance, and damage tolerance for the intended application. Accurate characterization of material properties, including variations due to manufacturing processes and environmental factors, is essential for reliable structural design. The selection process involves trade-offs between performance requirements, cost, and manufacturability. The use of composite materials in modern aircraft exemplifies this, offering high strength-to-weight ratios but also requiring careful consideration of delamination and impact resistance.

- Damage Detection and Monitoring

Even with careful design and material selection, damage can occur during service. This includes cracks, corrosion, and impact damage. Early detection of damage is crucial for preventing catastrophic failures. Non-destructive testing (NDT) techniques, such as ultrasonic testing, radiography, and eddy current testing, are employed to inspect structures for defects. Furthermore, structural health monitoring (SHM) systems, which integrate sensors directly into the structure, can provide real-time information about structural condition. An example of SHM is the use of fiber optic sensors to detect strain changes indicative of crack growth.

- Design for Durability and Damage Tolerance

Aerospace structures are designed to withstand repeated loading and environmental exposure over their service life. Durability focuses on preventing the initiation of cracks, while damage tolerance focuses on ensuring that cracks, once initiated, grow slowly and predictably, allowing for detection and repair before failure. Design for damage tolerance involves incorporating features that arrest crack growth, such as crack stoppers and tear straps. The “fail-safe” design philosophy, where redundant structural elements are used to carry the load in case of a failure of a primary element, is a key aspect of ensuring structural integrity.

These facets of structural integrity load analysis, material selection, damage detection, and durability design are intertwined and critical for ensuring the safety and performance of aerospace vehicles. Addressing these challenges necessitates a multidisciplinary approach, involving expertise in mechanics, materials science, sensing technologies, and computational modeling. Continuous research and development efforts are focused on improving the accuracy of predictive models, developing new materials with enhanced properties, and implementing more effective damage detection and monitoring systems, all contributing to the broader goal of enhancing structural integrity in aerospace applications.

5. Control Systems

Control systems are fundamental to resolving a multitude of aerospace engineering problems. These systems govern the stability, maneuverability, and overall performance of aircraft, spacecraft, and related technologies. Deficiencies or failures within control systems can result in catastrophic consequences, emphasizing the criticality of their design and implementation. The development of effective flight control systems, for example, directly addresses challenges related to atmospheric turbulence, aerodynamic instability, and pilot workload. Similarly, attitude control systems for satellites ensure precise orientation, enabling accurate data collection and communication. The sophistication of these systems is directly proportional to the operational capabilities of modern aerospace vehicles.

The importance of control systems stems from their ability to regulate complex and often unpredictable environments. In aircraft, fly-by-wire systems, which replace traditional mechanical linkages with electronic signals, provide enhanced stability and maneuverability, particularly in challenging flight conditions. Autopilots reduce pilot fatigue on long flights and improve fuel efficiency by maintaining optimal flight paths. In spacecraft, reaction wheels and thrusters are used to control attitude and trajectory, enabling precise orbital maneuvers and scientific observations. The integration of advanced sensors, such as accelerometers, gyroscopes, and GPS receivers, provides the necessary feedback for closed-loop control, allowing systems to adapt to changing conditions and correct for disturbances.

The continuous evolution of control system technology is essential for addressing emerging challenges in aerospace engineering. The development of autonomous flight control systems for unmanned aerial vehicles (UAVs) enables a wide range of applications, from surveillance and reconnaissance to package delivery and infrastructure inspection. Adaptive control algorithms, which adjust system parameters in real-time to compensate for uncertainties and variations in operating conditions, are crucial for ensuring robust performance in unpredictable environments. Model predictive control (MPC) techniques allow for optimal control strategies to be computed based on predicted future states, enabling improved fuel efficiency and trajectory optimization. Therefore, control systems remain an indispensable element of aerospace engineering, driving innovation and enabling increasingly complex and demanding missions.

6. Sustainability

The intersection of sustainability and aerospace engineering presents a complex set of challenges and demands innovative solutions. The aerospace industry, historically reliant on fossil fuels and resource-intensive manufacturing processes, faces increasing pressure to mitigate its environmental impact. The pursuit of sustainable aerospace practices necessitates a re-evaluation of traditional approaches, considering the full lifecycle impact of aircraft and spacecraft, from design and production to operation and disposal. The effect of greenhouse gas emissions from aircraft is a primary concern, contributing to climate change and necessitating the development of alternative propulsion systems and fuel-efficient designs. Similarly, the production of aerospace components generates significant waste and consumes substantial energy, prompting a search for more sustainable manufacturing techniques.

The importance of sustainability as a core component of aerospace engineering problem-solving is evident in several key areas. Firstly, the development of sustainable aviation fuels (SAF), derived from renewable sources such as algae, biomass, or waste products, offers a promising pathway to reducing carbon emissions. Secondly, electric and hybrid-electric propulsion systems are gaining traction, particularly for regional aircraft, offering the potential for near-zero emissions. Furthermore, lightweight materials, such as carbon fiber composites and advanced alloys, can reduce aircraft weight, leading to improved fuel efficiency. Airframe design innovations, such as blended wing bodies and improved aerodynamic profiles, also contribute to reduced fuel consumption. The operational aspect of sustainability encompasses optimized flight paths, reduced idling times, and efficient air traffic management systems.

Realizing a sustainable aerospace sector requires a concerted effort from engineers, policymakers, and industry stakeholders. Challenges include the high cost of SAF production, the limited availability of suitable materials, and the regulatory hurdles associated with new technologies. However, the potential benefits reduced environmental impact, enhanced energy security, and increased economic competitiveness make the pursuit of sustainable aerospace engineering a critical imperative. Further research and development are needed to accelerate the transition to more sustainable practices, ensuring that future generations can continue to benefit from air and space travel without compromising the health of the planet. Addressing sustainability will fundamentally change how aircraft and spacecraft are designed, manufactured, and operated, ensuring that the industry aligns with global environmental goals.

Frequently Asked Questions

This section addresses common inquiries related to the technical difficulties and their respective resolutions within the field of aerospace engineering. The information provided aims to offer clarity and insight into key areas of concern and innovation.

Question 1: What are the most significant challenges facing aerospace engineers today?

Current challenges span several domains, including the reduction of carbon emissions from aircraft, the development of hypersonic flight capabilities, the creation of more durable and lightweight materials, and the enhancement of autonomous flight systems.

Question 2: How does computational fluid dynamics (CFD) contribute to solving aerodynamic problems?

CFD provides a virtual environment for simulating airflow around complex shapes, allowing engineers to optimize designs for maximum performance, minimize drag, and ensure stability before physical prototypes are constructed. This reduces the need for extensive wind tunnel testing and accelerates the design process.

Question 3: What advancements are being made in sustainable aviation fuels (SAF)?

Research is focused on developing SAF from renewable sources, such as algae, biomass, and waste products. These fuels offer a pathway to significantly reducing the carbon footprint of air travel. However, challenges remain in scaling up production and reducing costs to make SAF commercially viable.

Question 4: How are engineers addressing the challenges of extreme temperatures in hypersonic flight?

The development of high-temperature materials, such as ceramic matrix composites and advanced alloys, is crucial for withstanding the intense heat generated during hypersonic flight. Active cooling systems and thermal barrier coatings are also employed to protect critical components.

Question 5: What role does artificial intelligence (AI) play in solving aerospace engineering problems?

AI is used in a variety of applications, including flight control optimization, predictive maintenance, and autonomous navigation. Machine learning algorithms can analyze vast amounts of data to identify patterns and improve performance in real-time.

Question 6: How is structural health monitoring (SHM) used to ensure the safety of aircraft?

SHM systems integrate sensors into aircraft structures to detect damage, such as cracks and corrosion, early on. This allows for timely repairs and prevents catastrophic failures, enhancing the overall safety and reliability of air travel.

The pursuit of advanced solutions within aerospace engineering is a continuous endeavor, driven by the need for safer, more efficient, and more sustainable air and space travel. Addressing the challenges outlined above requires innovation, collaboration, and a commitment to pushing the boundaries of what is possible.

The next section will explore the ethical considerations that guide decisions and innovations of aerospace engineers.

Conclusion

This exploration has detailed diverse challenges in aerospace engineering and the solutions devised to address them. These issues span aerodynamics, propulsion, materials science, structural integrity, control systems, and sustainability. Advances within each area contribute to safer, more efficient, and environmentally conscious aerospace endeavors.

The continuous pursuit of innovative solutions to these engineering problems is essential for advancing air and space travel. Sustained research, development, and a commitment to collaboration are crucial for overcoming existing limitations and ensuring the continued progress of the aerospace sector.

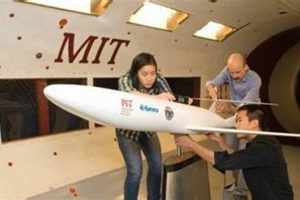

![Free MIT Aerospace Engineering Courses [Online & Self-Paced] Innovating the Future of Flight with Reliable Aviation Solutions Free MIT Aerospace Engineering Courses [Online & Self-Paced] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-184-300x200.jpg)