The field concerned with the design, development, testing, and production of aircraft and spacecraft represents a significant branch of engineering. It encompasses a broad spectrum of disciplines, from aerodynamics and propulsion to materials science and structural analysis. A crucial subset involves the principles and practices associated with the creation and operation of missiles and space vehicles, focusing on their flight dynamics, control systems, and payload integration. An example of this is the development of advanced propulsion systems for interplanetary travel.

This area of expertise plays a vital role in national security, space exploration, and technological advancement. Its historical roots can be traced back to early experiments with rockets, but it has since evolved into a sophisticated and complex discipline. Advancements in this domain have led to the creation of satellite communication networks, weather forecasting systems, and the ability to study the universe beyond Earth. The benefits derived from these endeavors extend to various aspects of daily life, impacting communication, navigation, and scientific knowledge.

The following sections will delve deeper into the specific aspects of vehicle design, propulsion mechanisms, orbital mechanics, and the challenges associated with operating in extreme environments. Furthermore, the discussion will address the ethical considerations and future trends shaping the trajectory of this constantly evolving area of applied science and engineering.

Key Considerations in Vehicle and Propulsion Development

The following provides actionable considerations for those involved in the conception, design, and implementation of projects within this specialized field. These points emphasize critical areas requiring meticulous attention and rigorous analysis.

Tip 1: Prioritize System-Level Integration: The interplay between vehicle structure, propulsion, avionics, and payload systems is paramount. Modifications to one subsystem inevitably impact others. Robust system engineering processes and comprehensive interface control documents are essential.

Tip 2: Emphasize Rigorous Testing and Verification: Simulation alone is insufficient. Prototypes must undergo comprehensive testing under relevant environmental conditions (vacuum, extreme temperatures, vibration). Failures must be thoroughly investigated and corrective actions implemented before flight.

Tip 3: Account for Orbital Mechanics and Trajectory Optimization: Efficient mission planning necessitates a deep understanding of celestial mechanics. Optimization of launch windows, trajectory profiles, and orbital maneuvers is crucial for maximizing payload delivery and minimizing fuel consumption.

Tip 4: Implement Robust Redundancy and Fault Tolerance: Systems must be designed to withstand component failures without compromising mission objectives or safety. Redundant sensors, actuators, and control algorithms enhance reliability and survivability.

Tip 5: Adhere to Stringent Safety Protocols: Given the inherent risks associated with high-energy propulsion systems and hazardous environments, strict adherence to safety regulations and protocols is non-negotiable. Thorough hazard analyses and comprehensive emergency response plans are mandatory.

Tip 6: Invest in Advanced Materials Research: Optimizing vehicle performance necessitates the utilization of lightweight, high-strength materials capable of withstanding extreme temperatures and pressures. Continuous research and development in materials science are essential for achieving performance breakthroughs.

Tip 7: Foster Collaboration Across Disciplines: Success requires effective communication and collaboration among engineers from diverse specializations. Cross-functional teams that share knowledge and expertise are more likely to overcome complex challenges.

Adhering to these points can significantly improve the efficiency, reliability, and safety of related projects, ultimately contributing to greater success in the field.

The succeeding section will examine the challenges and possibilities awaiting the future of this continually expanding branch of applied science.

1. Propulsion Systems

Propulsion systems are a fundamental component of aerospace engineering and rocket science. Their design, operation, and performance are critical determinants of mission success, impacting everything from payload capacity to mission duration and achievable orbits.

- Chemical Rockets: The Workhorse of Spaceflight

Chemical rockets, employing the combustion of propellants such as liquid oxygen and kerosene or solid propellants, remain the most widely used propulsion method. They provide high thrust levels necessary for overcoming Earth’s gravity and achieving initial orbital velocities. However, their efficiency is limited by the energy density of the propellants, restricting their use in long-duration, deep-space missions. Examples include the Saturn V rocket used in the Apollo program and the Space Shuttle’s Solid Rocket Boosters.

- Electric Propulsion: Efficiency for Long-Duration Missions

Electric propulsion systems, such as ion thrusters and Hall-effect thrusters, utilize electric fields to accelerate ionized propellant, typically xenon. Although generating significantly lower thrust compared to chemical rockets, they exhibit substantially higher specific impulse (a measure of fuel efficiency). This makes them well-suited for long-duration missions, such as interplanetary travel and station-keeping for satellites. The Dawn spacecraft, which explored the asteroid belt, utilized ion propulsion.

- Advanced Propulsion Concepts: The Future of Space Exploration

Numerous advanced propulsion concepts are under development, aiming to overcome the limitations of current technologies. These include nuclear thermal propulsion, which heats a propellant using a nuclear reactor, and fusion propulsion, which harnesses the energy released by nuclear fusion reactions. These technologies promise significantly higher thrust and specific impulse, potentially enabling faster and more ambitious space missions, such as manned missions to Mars.

- Propellant Management and Storage: A Critical Subsystem

Efficient propellant management and storage are crucial for ensuring the reliable operation of propulsion systems. This involves minimizing propellant boil-off (evaporation) during long-duration missions, maintaining propellant at the required temperature and pressure, and accurately measuring propellant levels. Cryogenic propellants, such as liquid hydrogen and liquid oxygen, pose significant challenges due to their extremely low boiling points, requiring sophisticated insulation and storage techniques.

The choice of propulsion system depends on the specific mission requirements, considering factors such as payload mass, mission duration, and desired trajectory. Continual advancements in propulsion technology are driving innovation in aerospace engineering and rocket science, enabling increasingly complex and ambitious space exploration endeavors. The interplay between these developments and other technological areas, such as materials science and control systems, is essential for future progress.

2. Orbital Mechanics

Orbital mechanics, a cornerstone of aerospace engineering and rocket science, provides the theoretical framework for understanding and predicting the motion of artificial satellites and spacecraft. Its application is indispensable for mission planning, spacecraft navigation, and the overall success of space-related endeavors.

- Keplerian Elements: Describing Orbits

Six parameters known as Keplerian elementssemi-major axis, eccentricity, inclination, longitude of the ascending node, argument of periapsis, and true anomalyuniquely define an orbit. These elements are used to mathematically represent the size, shape, orientation, and position of an orbiting body at a specific time. For instance, knowing the Keplerian elements of a communications satellite allows ground stations to accurately point their antennas. Variations in these elements over time, due to perturbations like atmospheric drag or gravitational influences from other celestial bodies, must be modeled and accounted for in precise orbit determination.

- Trajectory Optimization: Efficient Mission Planning

Trajectory optimization involves finding the most fuel-efficient or time-optimal path for a spacecraft to follow between two points in space. This is a complex problem that often requires sophisticated numerical methods and algorithms. For example, planning a mission to Mars involves considering various trajectory options, including Hohmann transfer orbits, gravity assists, and low-thrust trajectories, each with its own trade-offs in terms of travel time and propellant consumption. Precise trajectory optimization is crucial for minimizing mission costs and maximizing payload delivery.

- Orbital Maneuvers: Altering Spacecraft Orbits

Orbital maneuvers are changes in a spacecraft’s orbit achieved through the application of thrust. These maneuvers can include changes in altitude, inclination, or orbital phase. The Hohmann transfer, a common orbital maneuver, involves two engine burns to transfer a spacecraft between two circular orbits. More complex maneuvers, such as plane changes, require significantly more propellant. Understanding the principles of orbital mechanics is essential for designing efficient and precise orbital maneuvers, allowing spacecraft to perform a variety of tasks, such as rendezvous and docking, satellite deployment, and deorbiting.

- Perturbation Analysis: Accounting for Deviations

Real-world orbits deviate from the idealized Keplerian model due to various perturbations, including atmospheric drag, gravitational influences from the Sun, Moon, and other planets, and solar radiation pressure. Accurate modeling of these perturbations is critical for predicting the long-term behavior of spacecraft orbits. For example, atmospheric drag, which is most significant for low-Earth orbit satellites, gradually reduces a satellite’s altitude over time. Perturbation analysis techniques are used to predict these orbital decay rates and plan for necessary orbit maintenance maneuvers to extend the satellite’s operational lifetime.

These facets of orbital mechanics are integral to the successful execution of aerospace engineering and rocket science projects. From the initial design of a spacecraft’s trajectory to the ongoing maintenance of its orbit, a thorough understanding of these principles is paramount. As space exploration advances, demanding more complex and ambitious missions, the importance of orbital mechanics will only continue to grow, driving further innovation and refinement in related analytical and computational techniques.

3. Materials Science

Materials science constitutes a critical discipline intertwined with aerospace engineering and rocket science. The selection, development, and application of materials directly impact the performance, safety, and longevity of aerospace vehicles and their components. Meeting the stringent demands of spaceflight requires materials that can withstand extreme temperatures, pressures, radiation exposure, and mechanical stresses.

- High-Temperature Alloys and Ceramics

In propulsion systems, materials capable of withstanding extreme temperatures are essential. High-temperature alloys, such as nickel-based superalloys, are used in turbine blades and combustion chambers of rocket engines. Ceramic matrix composites (CMCs) are increasingly employed due to their high strength-to-weight ratio and ability to maintain structural integrity at elevated temperatures. The Space Shuttle’s thermal protection system relied heavily on ceramic tiles to shield the vehicle from the intense heat generated during re-entry into Earth’s atmosphere. The development and refinement of these materials enable more efficient and durable propulsion systems.

- Lightweight Structural Materials

Minimizing weight is paramount in aerospace engineering and rocket science. Lightweight materials, such as aluminum alloys, titanium alloys, and composite materials, are used extensively in airframes, rocket bodies, and payload structures. Carbon fiber reinforced polymers (CFRPs) offer exceptional strength-to-weight ratios and are employed in aircraft wings, fuselage panels, and rocket motor casings. The use of lightweight materials reduces the overall mass of the vehicle, increasing payload capacity and improving fuel efficiency. The design and manufacturing processes for these materials are continuously refined to optimize their structural properties and minimize defects.

- Radiation-Resistant Materials

Spacecraft operating in orbit or beyond are exposed to high levels of ionizing radiation, which can degrade electronic components and structural materials. Radiation-resistant materials, such as certain polymers and shielding materials, are employed to protect sensitive equipment and ensure the long-term reliability of spacecraft. The International Space Station (ISS) incorporates shielding to reduce radiation exposure to astronauts. Research into new radiation-resistant materials is ongoing to enable longer duration space missions and protect against the hazards of space radiation.

- Ablative Materials for Re-entry

During atmospheric re-entry, spacecraft experience extreme heat due to atmospheric friction. Ablative materials are designed to protect the vehicle by gradually vaporizing, carrying away heat through convection and radiation. These materials typically consist of a resin matrix reinforced with fibers, such as carbon or silica. As the material heats up, it undergoes a phase change, forming a char layer that insulates the underlying structure. The design and performance of ablative materials are critical for ensuring the survival of spacecraft during re-entry, as demonstrated by the heat shields used on the Apollo command module and the Orion spacecraft.

The advancement of materials science is a driving force in aerospace engineering and rocket science, enabling the development of more efficient, reliable, and capable space vehicles. The continuous pursuit of new materials and improved manufacturing techniques is essential for pushing the boundaries of space exploration and expanding humanity’s reach into the cosmos.

4. Aerodynamics Expertise

Aerodynamics expertise is fundamental to the success of aerospace engineering and rocket science endeavors. It represents the body of knowledge concerning the interaction of air or other gases with moving objects. This interaction generates forces and moments that profoundly influence the performance, stability, and control of both aircraft and spacecraft throughout their flight regimes. In the context of rocket science, understanding aerodynamic principles is crucial during atmospheric ascent and re-entry phases where the vehicle encounters significant air resistance.

The shape of a rocket, for instance, directly impacts the aerodynamic drag it experiences as it ascends through the atmosphere. Optimizing this shape, informed by aerodynamic expertise, can reduce drag, leading to improved fuel efficiency and increased payload capacity. Similarly, during re-entry, the design of a spacecraft’s heat shield relies heavily on aerodynamic principles to manage the intense heat generated by atmospheric friction. Improper aerodynamic design can lead to catastrophic failure, highlighting the practical significance of this knowledge base. Examples include the design of hypersonic vehicles like the X-15 or the Space Shuttle, both of which required extensive aerodynamic analysis to achieve stable and controlled flight.

Aerodynamics expertise plays a pivotal role in ensuring efficient and safe passage through the atmosphere, and even in low-density atmospheric environments where subtle forces can impact trajectories. Challenges in this area often involve dealing with complex flow phenomena such as turbulence, shock waves, and flow separation, requiring advanced computational fluid dynamics (CFD) simulations and wind tunnel testing. The application of aerodynamics expertise within aerospace engineering and rocket science is therefore essential, bridging theoretical understanding with practical application to enable successful space missions and advancements in aviation technology.

5. Control Systems

Control systems form an indispensable element of aerospace engineering and rocket science, ensuring the stability, maneuverability, and precision necessary for successful mission execution. These systems govern the orientation and trajectory of vehicles, responding in real-time to disturbances and commands to maintain desired flight paths or orbital positions. Without effective control systems, rockets and spacecraft would be rendered uncontrollable, unable to achieve their intended objectives or, more critically, posing significant safety risks. The development of a rocket’s guidance, navigation, and control (GNC) system, for example, dictates its ability to accurately place a satellite into a specific orbit. Failures in this system can lead to mission failure, as demonstrated by past launch vehicle anomalies attributed to faulty sensors or control algorithms. The cause-and-effect relationship is evident: robust control systems directly enable successful space missions, while deficiencies lead to detrimental outcomes.

The practical applications of control systems within this field are vast. They encompass a range of functions, including attitude control, which maintains a spacecraft’s orientation in space; trajectory control, which guides a vehicle along its planned path; and propulsion control, which regulates the thrust and direction of rocket engines. Moreover, advanced control techniques are increasingly employed to compensate for uncertainties in vehicle dynamics and environmental conditions. Adaptive control algorithms, for instance, adjust system parameters in response to changing atmospheric conditions during launch or variations in spacecraft mass due to fuel consumption. The development of autonomous landing systems for reusable rockets, such as those employed by SpaceX, relies heavily on sophisticated control systems that integrate sensor data, trajectory planning, and real-time adjustments to ensure a precise landing on a designated target.

In summary, control systems are not merely components within aerospace engineering and rocket science; they are integral to the operational viability of these disciplines. The challenges associated with designing and implementing these systems, particularly in the face of stringent performance requirements and demanding operational environments, necessitate continuous innovation and refinement. As space missions become more complex and ambitious, the role of advanced control systems will only intensify, serving as a critical enabler for future advancements in space exploration and utilization.

6. Structural Integrity

Structural integrity is a paramount consideration within aerospace engineering and rocket science. It refers to the ability of an aerospace vehicle to withstand the loads and stresses encountered during all phases of its mission, from manufacturing and ground handling to launch, flight, and landing or impact. Maintaining structural integrity is not merely a design goal; it is a fundamental requirement for mission success and safety.

- Load Analysis and Design

Aerospace structures are subjected to a complex array of loads, including static loads due to gravity and inertia, dynamic loads from engine vibrations and aerodynamic forces, and thermal loads from aerodynamic heating and solar radiation. Accurate load analysis is essential for determining the magnitude and distribution of these forces. Design practices must account for worst-case load scenarios and incorporate safety factors to ensure structural integrity under unforeseen conditions. The design of a rocket’s launch vehicle, for instance, must withstand extreme axial compression and bending moments during ascent, while the wings of a high-speed aircraft must resist significant aerodynamic lift and drag forces. The consequences of inadequate load analysis can be catastrophic, as seen in past structural failures during flight testing.

- Material Selection and Testing

The choice of materials is critical to achieving structural integrity. Materials used in aerospace structures must possess high strength-to-weight ratios, resistance to fatigue and corrosion, and the ability to withstand extreme temperatures. Aluminum alloys, titanium alloys, composite materials, and high-temperature alloys are commonly employed, each with its own set of advantages and limitations. Rigorous material testing is essential to verify that the selected materials meet the required performance characteristics. This testing includes tensile tests, fatigue tests, and creep tests to assess the material’s response to various loading conditions. The selection of appropriate materials, coupled with thorough testing, is a cornerstone of structural integrity in aerospace engineering and rocket science.

- Structural Analysis and Modeling

Structural analysis and modeling techniques are used to predict the behavior of aerospace structures under load. Finite element analysis (FEA) is a widely used computational method for simulating the stress and strain distribution within a structure. FEA models can be used to identify areas of high stress concentration and to optimize the structural design. For example, FEA can be used to analyze the stress distribution in a rocket engine nozzle during firing, helping engineers to identify potential failure points and to optimize the nozzle design for maximum performance and durability. The accuracy of structural analysis models is crucial for ensuring that the structure can withstand the anticipated loads without failure.

- Damage Tolerance and Inspection

Even with careful design and manufacturing, aerospace structures can develop flaws or damage during their service life. Damage tolerance is the ability of a structure to withstand a certain amount of damage without catastrophic failure. This is achieved through the use of redundant structural elements and the implementation of inspection programs to detect and repair damage before it becomes critical. Non-destructive testing (NDT) techniques, such as ultrasonic testing, radiographic testing, and eddy current testing, are used to inspect aerospace structures for cracks, corrosion, and other defects. Damage tolerance design and regular inspections are essential for maintaining the structural integrity of aging aircraft and spacecraft.

The facets of structural integrity outlined above highlight its multifaceted nature and the critical role it plays in ensuring the safety and success of aerospace and rocket science endeavors. From meticulous load analysis to advanced material selection, sophisticated modeling techniques, and robust damage tolerance strategies, structural integrity remains a non-negotiable aspect of the design, manufacturing, and operation of all aerospace vehicles. As future space missions become more ambitious and demanding, the importance of structural integrity will continue to grow, driving further innovation and refinement in related engineering practices.

Frequently Asked Questions

The following addresses common inquiries regarding the complex and specialized field of aerospace engineering rocket science, providing clarification on key concepts and dispelling potential misconceptions.

Question 1: What distinguishes aerospace engineering from general engineering disciplines?

Aerospace engineering focuses specifically on the design, development, and testing of aircraft and spacecraft. This involves a deep understanding of aerodynamics, propulsion, materials science, and control systems tailored to the unique challenges of flight within Earth’s atmosphere and in outer space. General engineering disciplines, while providing foundational knowledge, do not typically delve into the specific requirements of aerospace vehicles.

Question 2: What are the fundamental principles underlying rocket propulsion?

Rocket propulsion relies on Newton’s Third Law of Motion: For every action, there is an equal and opposite reaction. Rockets expel mass in the form of hot gases, generating thrust in the opposite direction. Key factors influencing propulsion efficiency include propellant energy density, nozzle design, and combustion chamber pressure.

Question 3: Why is materials science so critical in aerospace engineering and rocket science?

Aerospace vehicles operate in extreme environments, subjecting materials to high temperatures, pressures, radiation exposure, and mechanical stresses. Materials science provides the knowledge to select and develop materials that can withstand these conditions while minimizing weight, ensuring structural integrity and prolonged operational life.

Question 4: How does orbital mechanics influence mission planning for space exploration?

Orbital mechanics dictates the trajectories and energy requirements for spacecraft to travel between points in space. Understanding orbital mechanics allows mission planners to optimize launch windows, calculate fuel consumption, and design efficient orbital maneuvers, ultimately determining the feasibility and cost-effectiveness of space missions.

Question 5: What role do control systems play in ensuring the stability and maneuverability of aerospace vehicles?

Control systems are essential for maintaining stability and guiding aerospace vehicles along their intended trajectories. These systems utilize sensors, actuators, and control algorithms to respond to disturbances and commands, ensuring precise control of the vehicle’s orientation and position in flight or in orbit.

Question 6: What are the ethical considerations associated with aerospace engineering rocket science?

Ethical considerations include the responsible development and deployment of aerospace technologies, particularly in areas such as national security and space debris mitigation. Ensuring the peaceful and sustainable use of space requires careful consideration of the potential environmental and societal impacts of aerospace activities.

The aforementioned points underscore the complexity and significance of aerospace engineering and rocket science. A firm grasp of these concepts is essential for anyone involved in the field.

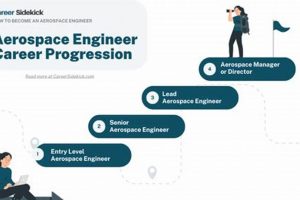

The next section will explore career paths and educational opportunities available to those interested in pursuing a career in aerospace engineering rocket science.

Concluding Remarks

This exploration has illuminated the multifaceted nature of aerospace engineering rocket science, underscoring its pivotal role in advancing both atmospheric and spacefaring capabilities. Key elements, including propulsion systems, orbital mechanics, materials science, aerodynamics expertise, control systems, and structural integrity, are integral to the successful design, development, and operation of aerospace vehicles. Understanding the intricacies of these disciplines is essential for addressing the complex challenges inherent in this field.

As technological advancements continue to reshape the landscape of aerospace engineering rocket science, a commitment to rigorous research, ethical considerations, and collaborative innovation remains paramount. The future of space exploration and aviation rests on the continued pursuit of knowledge and the responsible application of these specialized skills, paving the way for groundbreaking discoveries and transformative achievements in the years to come.