Positions within the aeronautics and space sector located in a specific city in Washington state constitute a significant portion of the local employment landscape. These roles encompass a wide array of disciplines, including engineering, manufacturing, quality control, and administrative support, all contributing to the design, production, and maintenance of aircraft and related technologies. For instance, an individual might be employed as a structural engineer, a composite technician, or a program manager, all focused on supporting aerospace operations in this area.

The presence of a major aircraft manufacturer and its associated supply chain creates a substantial economic impact within the region. The concentration of these specialized careers not only offers opportunities for local residents but also attracts talent from across the nation and internationally. Historically, the region has benefited from its legacy as a hub for aircraft production, fostering a skilled workforce and a supportive infrastructure that continues to drive innovation and growth in the industry.

The following sections will delve into the specific types of roles available, the necessary qualifications to pursue them, and the overall outlook for the industry in this geographic location. Understanding these aspects is crucial for individuals seeking employment or those interested in the broader economic impact of this industrial sector.

Successful entry into the aeronautics and space sector requires strategic planning and a focused approach. The following tips are designed to assist prospective employees in maximizing their opportunities within the competitive job market.

Tip 1: Targeted Education and Training: Emphasize education and training aligned with high-demand skills within the aeronautics industry. Degrees in aerospace engineering, mechanical engineering, electrical engineering, and materials science provide a strong foundation. Certifications related to specific manufacturing processes, such as composite fabrication or welding, can also enhance employability.

Tip 2: Specialized Skill Development: Cultivate skills directly applicable to aerospace manufacturing and engineering roles. Proficiency in CAD software (e.g., CATIA, SolidWorks), finite element analysis (FEA), and computational fluid dynamics (CFD) is highly valued. Familiarity with aerospace standards and regulations, such as those set by the FAA, is also crucial.

Tip 3: Networking and Industry Events: Actively participate in networking events, industry conferences, and career fairs specific to the aeronautics and space sector. These events provide opportunities to connect with potential employers, learn about industry trends, and gain insights into available positions. Professional organizations like the American Institute of Aeronautics and Astronautics (AIAA) can offer valuable networking resources.

Tip 4: Strategic Resume and Cover Letter Construction: Tailor resumes and cover letters to highlight relevant experience and skills directly applicable to the target roles. Quantify achievements whenever possible, using metrics to demonstrate the impact of contributions. Emphasize projects, internships, and academic work that showcase technical capabilities.

Tip 5: Internship and Co-op Opportunities: Seek out internship and co-op opportunities with aerospace companies. These experiences provide practical, hands-on training and valuable industry exposure. Internships can serve as a pathway to full-time employment upon graduation.

Tip 6: Online Presence and Portfolio Development: Establish a professional online presence through platforms like LinkedIn. Showcase relevant projects, skills, and accomplishments in an online portfolio. This allows potential employers to easily assess qualifications and experience.

Tip 7: Understanding Company Culture: Research the culture of prospective employers. Understanding the values and working environment can improve the likelihood of a successful job search and long-term career satisfaction. Company websites, industry news, and employee reviews can provide valuable insights.

Adhering to these guidelines enhances the prospects for securing a fulfilling and impactful career within the aeronautics and space field. Diligence, preparation, and a proactive approach are essential for success in this competitive industry.

The subsequent sections will explore specific companies in the area and their potential openings, providing further context for the aforementioned strategies.

1. Engineering Design

Engineering design serves as a foundational pillar for numerous roles within the aeronautics and space sector concentrated in a specific city in Washington State. It is the genesis of aircraft and spacecraft development, directly impacting the types of careers available and the skills demanded. The design phase dictates the subsequent manufacturing processes, material selection, and quality control procedures, thereby influencing the job functions of engineers, technicians, and manufacturing specialists. A flawed or inefficient design can cascade into costly manufacturing challenges, delays, and potential safety risks, underscoring the critical importance of competent engineering design teams. For instance, the design of a new wing structure requires stress analysis, aerodynamic modeling, and material considerations, tasks performed by specialized engineers. This drives the need for roles such as structural analysts, aerodynamicists, and materials engineers.

The practical significance of understanding the connection lies in recognizing the skillset required to thrive in the industry. Candidates aspiring to secure such positions must possess a strong understanding of engineering principles, computer-aided design (CAD) software, and relevant industry standards. Furthermore, the complexity of modern aircraft necessitates collaboration across various engineering disciplines, making teamwork and communication skills essential. A design change in the fuselage, for example, may impact the electrical wiring and hydraulic systems, requiring coordinated efforts between different engineering teams. The ability to integrate these diverse elements is vital for efficient aircraft development.

In conclusion, engineering design is not merely one aspect of the aeronautics and space industry; it is the driving force that shapes the demand for specific engineering skills, influences manufacturing processes, and ultimately dictates the success of aircraft development. Addressing the challenges within this discipline, such as optimizing for fuel efficiency or reducing noise pollution, requires continuous innovation and a highly skilled workforce. Understanding this interconnectedness is essential for individuals seeking to contribute to this dynamic sector.

2. Manufacturing Processes

Manufacturing processes are intrinsically linked to the availability and nature of aeronautics and space sector positions within a particular city in Washington state. These processes, encompassing the fabrication, assembly, and testing of aircraft components and systems, directly create demand for skilled labor in various specialized roles. The complexity of modern aircraft necessitates a wide range of manufacturing techniques, from traditional machining and welding to advanced composite fabrication and additive manufacturing. Each process requires individuals with specific training and expertise. For example, the construction of aircraft wings involves composite lay-up, curing, and inspection, generating positions for composite technicians, quality control inspectors, and manufacturing engineers. Without established and efficient manufacturing processes, the sector in this location would be unable to sustain its operations and employment levels.

The practical implication of this connection lies in the industrys dependence on a skilled workforce capable of executing these complex procedures. Educational institutions and training programs in the region must align their curricula with the specific manufacturing demands of the sector. Furthermore, ongoing investment in technology and process improvement is essential to maintain competitiveness and ensure the availability of high-paying manufacturing positions. The integration of automation and robotics, for instance, requires skilled technicians to operate and maintain the equipment, as well as engineers to design and optimize the automated processes. A real-world example is the implementation of automated drilling systems for fuselage assembly, which necessitates skilled operators and maintenance personnel, changing the nature of manufacturing jobs rather than simply eliminating them. The efficiency and effectiveness of the sectors manufacturing processes directly influence its capacity to attract and retain aerospace manufacturing.

In summary, manufacturing processes are a core determinant of the composition and availability of aeronautics and space jobs within the identified locale. A robust and innovative manufacturing ecosystem fosters a skilled workforce and attracts investment, contributing to the long-term sustainability and growth of the sector. Addressing challenges such as workforce development, technology adoption, and supply chain optimization is critical for ensuring that the region remains a competitive hub for aeronautics and space manufacturing, providing stable and fulfilling career opportunities.

3. Quality Assurance

Quality assurance forms a critical, non-negotiable component of the aeronautics and space industry. Its role is to prevent defects, ensure compliance with stringent regulatory standards, and ultimately guarantee the safety and reliability of aircraft. Given the concentration of aeronautical activity in a specific Washington city, quality assurance directly influences the types of roles available, the skill sets demanded, and the overall integrity of the local aerospace sector. The direct connection is the presence of highly-skilled individuals, performing quality control, is a requirement of air safety that influences the entire area.

- Regulatory Compliance and Inspection

A significant portion of quality assurance involves adhering to regulations established by aviation authorities, such as the Federal Aviation Administration (FAA). This requires rigorous inspection processes at every stage of aircraft production, from raw materials to finished components. For instance, inspectors must verify that welds meet specific strength requirements, that composite materials are properly cured, and that electrical systems function according to design specifications. In the context of the area’s aerospace sector, this translates into a continuous demand for certified inspectors, quality engineers with expertise in regulatory standards, and compliance specialists who can navigate the complex web of aviation regulations.

- Testing and Validation

Aircraft components and systems undergo extensive testing to validate their performance under various operating conditions. This may involve simulated flight tests, environmental testing (e.g., exposure to extreme temperatures and pressures), and destructive testing to determine the limits of structural integrity. In the geographic location, this creates opportunities for test engineers, validation specialists, and data analysts who can interpret test results and identify potential weaknesses in aircraft design or manufacturing. The testing phase is crucial for identifying and addressing potential flaws before aircraft enter service.

- Process Control and Improvement

Quality assurance extends beyond inspection and testing to encompass the implementation of process control measures aimed at preventing defects from occurring in the first place. This involves statistical process control, root cause analysis, and continuous improvement initiatives. A relevant instance would be a team implementing Six Sigma methodologies to reduce the number of defects in a specific manufacturing process, improving efficiency and quality simultaneously. In the mentioned area, this need translates into a demand for quality engineers with expertise in statistical analysis, process optimization, and lean manufacturing principles.

- Documentation and Traceability

Maintaining meticulous records is an essential aspect of quality assurance. Every component and process must be documented and traceable to ensure accountability and facilitate troubleshooting in case of problems. The records must contain data on material certifications, test results, inspection reports, and repair history. A practical application of the function would be a detailed record of the materials used in a new wing and the assembly process. This necessitates roles such as quality documentation specialists, configuration management specialists, and database administrators who can manage and maintain the extensive documentation required by the aerospace industry.

These facets highlight the multifaceted nature of quality assurance and its direct relevance to the availability and types of aerospace positions in the Washington city. The emphasis on regulatory compliance, rigorous testing, process control, and detailed documentation creates a constant demand for skilled professionals who can uphold the highest standards of quality and safety in aircraft manufacturing. The absence of a robust quality assurance program would severely jeopardize the area’s aerospace sector, undermining its reputation, competitiveness, and ultimately, its ability to generate employment.

4. Supply Chain

The aeronautics and space sector’s operational efficiency is deeply rooted in the effectiveness of its supply chain. This intricate network, encompassing the sourcing, manufacturing, and delivery of components and materials, plays a decisive role in the availability and characteristics of related positions in a major aircraft manufacturing hub.

- Raw Material Procurement and Logistics

The procurement of raw materials, such as aluminum, titanium, carbon fiber, and specialized alloys, forms the foundation of the supply chain. Efficient logistics are essential to ensure timely delivery of these materials to manufacturing facilities. In a hub, this necessitates roles in procurement management, logistics coordination, and materials handling. For example, a supply chain specialist might be responsible for negotiating contracts with raw material suppliers, optimizing transportation routes, and managing inventory levels to minimize disruptions.

- Component Manufacturing and Subassembly

Numerous specialized companies contribute to the manufacturing of aircraft components, ranging from small fasteners to complex electronic systems. The subassembly of these components into larger modules requires skilled technicians and engineers. In a region with aircraft assembly, this translates into opportunities for machinists, welders, electronics technicians, and manufacturing engineers who specialize in the production and integration of aircraft parts. For instance, a manufacturing technician might be responsible for assembling hydraulic actuators, wiring harnesses, or structural components according to strict specifications.

- Inventory Management and Warehousing

Effective inventory management and warehousing are crucial for maintaining a steady flow of materials and components throughout the manufacturing process. This involves tracking inventory levels, managing storage facilities, and coordinating deliveries to ensure that materials are available when needed. In a major manufacturing area, this need creates opportunities for inventory control specialists, warehouse managers, and supply chain analysts who optimize inventory levels and storage layouts. For example, an inventory control specialist might use software to track the location and quantity of parts, predict demand, and prevent stockouts.

- Quality Control and Supplier Management

Maintaining the quality of components and materials throughout the supply chain is paramount. This requires rigorous quality control procedures and effective supplier management practices. A prominent manufacturing area necessitates roles for quality control inspectors, supplier auditors, and supply chain managers who assess supplier capabilities, conduct audits, and ensure that materials meet stringent quality standards. A quality control inspector might be responsible for inspecting incoming components, verifying compliance with specifications, and identifying potential defects.

These interconnected facets highlight the significant influence the supply chain exerts on the employment landscape in a major aircraft manufacturing hub. A well-functioning supply chain not only ensures the efficient production of aircraft but also supports a wide range of specialized positions requiring diverse skill sets. Any disruption or inefficiency in the supply chain can have cascading effects, leading to production delays, increased costs, and potential job losses, emphasizing the sector’s dependence on a robust and well-managed supply network.

5. Economic Impact

The economic impact associated with the aeronautics and space sector in the identified Washington city extends far beyond the direct employment figures. The industry’s presence generates a ripple effect, stimulating growth in various supporting sectors and contributing significantly to the regional economy.

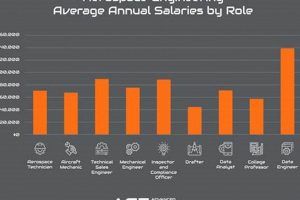

- Direct Employment and Wage Generation

The most immediate effect stems from the direct employment opportunities within aircraft manufacturing and related industries. These positions, often requiring specialized skills and training, tend to offer competitive wages and benefits, contributing to increased household incomes and consumer spending within the local economy. For instance, a substantial number of engineers, technicians, and manufacturing specialists directly employed in the area contribute significantly to the region’s tax base and overall economic activity. The higher-than-average salaries also attract talent from outside the region, further boosting the local economy.

- Supplier Network and Indirect Employment

The manufacturing of aircraft requires a vast network of suppliers providing components, materials, and services. This supplier network, often located within the same region, creates indirect employment opportunities in sectors such as metal fabrication, electronics manufacturing, and logistics. These indirect jobs, while not directly associated with the aircraft manufacturer, are nonetheless dependent on its operations. The presence of a major aerospace company, therefore, fosters the growth of a diverse ecosystem of businesses, contributing to a more resilient and diversified local economy.

- Induced Economic Activity and Consumer Spending

The increased income generated by direct and indirect employment leads to increased consumer spending in the local economy. Employees spend their earnings on housing, food, transportation, and other goods and services, supporting businesses such as restaurants, retail stores, and service providers. This induced economic activity further amplifies the economic impact of the aeronautics and space sector. The restaurants and gas stations near the factory do most of their business during the morning, lunch, and end of day shifts. This boost supports the local schools, safety organizations, and other businesses from sales and property tax funds.

- Innovation and Technological Spillover

The aeronautics and space sector is a driver of innovation, pushing the boundaries of technology in areas such as materials science, aerodynamics, and propulsion systems. These technological advancements often spill over into other sectors, creating new opportunities for innovation and economic growth. For example, the development of lightweight composite materials for aircraft has led to their adoption in the automotive and sporting goods industries. The concentration of aerospace companies in the specific region, therefore, fosters a culture of innovation, attracting talented engineers and scientists and generating new business opportunities.

The points discussed illustrate that the economic impact of the aeronautics sector in this area goes beyond simple job creation. It is a multifaceted phenomenon that stimulates growth in various sectors, fosters innovation, and contributes to the overall prosperity of the region. While this holds true the industry is cyclical in nature. Therefore, the region must have a well diversified economy.

6. Technological Innovation

Technological innovation is a driving force shaping the skillsets demanded and the types of roles available within the aeronautics and space sector in a major aircraft manufacturing center. Advancements in materials, manufacturing processes, and digital technologies directly impact the employment landscape.

- Advanced Materials and Composites

The increasing use of lightweight composites and advanced alloys in aircraft construction necessitates engineers and technicians skilled in materials science, composite fabrication, and non-destructive testing. For example, the development and implementation of carbon fiber-reinforced polymers in aircraft wings require specialized knowledge of composite lay-up techniques, curing processes, and inspection methods. This translates into demand for materials engineers, composite technicians, and quality control specialists with expertise in advanced materials.

- Automation and Robotics in Manufacturing

The integration of automation and robotics in aircraft manufacturing processes, such as drilling, fastening, and painting, requires a workforce proficient in robotics programming, automation control systems, and advanced manufacturing techniques. The implementation of automated drilling systems for fuselage assembly, for example, necessitates skilled technicians who can operate and maintain the robotic equipment, as well as engineers who can design and optimize the automated processes. This creates demand for robotics engineers, automation technicians, and manufacturing engineers with expertise in automation and robotics.

- Digitalization and Data Analytics

The increasing digitalization of aircraft design, manufacturing, and maintenance processes generates vast amounts of data that can be analyzed to improve efficiency, reduce costs, and enhance safety. This requires data scientists, data engineers, and software developers with expertise in data mining, machine learning, and data visualization. For example, the analysis of sensor data from aircraft engines can be used to predict maintenance needs and prevent equipment failures. This creates demand for data scientists who can develop predictive models, data engineers who can manage and process large datasets, and software developers who can create data visualization tools.

- Aerospace Software Development

Modern aircraft rely on complex software systems for flight control, navigation, and communication. The development, testing, and maintenance of these software systems require skilled software engineers with expertise in aerospace software standards, real-time operating systems, and software validation techniques. A relevant example would be the development of flight control software that ensures the stability and maneuverability of an aircraft. This creates demand for software engineers who can develop, test, and maintain safety-critical software systems for aerospace applications.

These technological advancements are reshaping the aeronautics and space sector in specific locales, creating new opportunities for skilled professionals and driving demand for specialized training and education. The ability to adapt to these technological changes is essential for individuals seeking to pursue a career in the aerospace sector and for the region to maintain its competitiveness as a hub for aerospace manufacturing.

Frequently Asked Questions

The following section addresses common inquiries regarding career opportunities within the aeronautics and space sector in a specific city in Washington State. These questions aim to provide clarity and informed insights into the industry’s complexities.

Question 1: What are the primary skill sets in demand within the aeronautics and space sector in this area?

The industry necessitates professionals with expertise in engineering (aerospace, mechanical, electrical, and materials), manufacturing (composite fabrication, machining, and assembly), quality assurance (inspection, testing, and compliance), and data analytics. Strong problem-solving, communication, and teamwork skills are also essential.

Question 2: What educational qualifications are typically required for entry-level aeronautics positions?

A bachelor’s degree in a relevant engineering discipline is generally required for engineering roles. Technical positions may require an associate’s degree or vocational training in a specialized field. Certifications in areas such as composite fabrication, welding, or non-destructive testing can also enhance employability.

Question 3: How can one effectively navigate the application process for positions within the aeronautics sector?

Tailor resumes and cover letters to highlight relevant experience and skills, emphasizing projects, internships, and academic achievements. Utilize online job boards, attend industry-specific career fairs, and network with professionals in the field. Demonstrating a strong understanding of the industry and its specific challenges is crucial.

Question 4: What is the general outlook for employment within the aeronautics and space sector?

The long-term outlook remains positive, driven by increasing demand for commercial aircraft, defense spending, and space exploration. However, the industry is subject to cyclical fluctuations, influenced by factors such as global economic conditions, airline profitability, and geopolitical events. Continuous skills development is essential to maintain competitiveness.

Question 5: Are there opportunities for career advancement within the aeronautics and space sector?

The industry offers pathways for career advancement across various disciplines. Engineers can progress into project management, technical leadership, or specialized research roles. Manufacturing professionals can advance into supervisory or process improvement positions. Continuous professional development, certifications, and advanced degrees can facilitate career progression.

Question 6: What are some common misconceptions about working in the aerospace industry?

One misconception is that all positions require advanced degrees. While engineering roles necessitate a bachelor’s degree or higher, technical and manufacturing positions often require vocational training or associate’s degrees. Another misconception is that the industry is solely focused on engineering. Diverse roles exist in areas such as finance, human resources, and supply chain management.

These answers provide a foundational understanding of the aeronautics and space sector and serve as a starting point for further exploration of the industry.

The following section will provide links to the local job boards.

Aerospace Jobs Everett WA

The preceding analysis has illuminated the multifaceted nature of aeronautics and space sector positions within Everett, Washington. The region’s reliance on a robust supply chain, constant quality assurance, state of the art manufacturing process, innovative engineering design, coupled with significant economic impacts and technological advancements, necessitates a skilled workforce. This ecosystem fosters diverse employment opportunities that span engineering, manufacturing, quality control, and administrative functions.

The sustainability of the aerospace sector in Everett depends on continued investment in education, workforce development, and technological innovation. Recognizing the industry’s cyclical nature, proactive planning and diversification efforts are crucial for long-term economic stability. Individuals seeking careers within this sector should focus on acquiring specialized skills, pursuing relevant certifications, and cultivating a deep understanding of the industry’s challenges and opportunities. The future of aeronautics and space sector positions in Everett rests on the collective ability to adapt, innovate, and maintain a commitment to excellence.