Positions within the aeronautics and space industry located in the city of Tacoma, Washington constitute a specific employment sector. These roles encompass a range of technical and administrative functions necessary for the design, manufacture, maintenance, and operation of aircraft and related systems. Examples include aircraft mechanics, aerospace engineers, quality control inspectors, and supply chain managers working for companies with operations in or near Tacoma.

This sector plays a significant role in the local economy, providing skilled employment opportunities and contributing to regional economic growth. Historically, the Puget Sound region, including Tacoma, has been a hub for aerospace activity, benefiting from the presence of major manufacturers and a skilled workforce. The proximity to key transportation infrastructure and a supportive business environment have further fostered its development.

The following sections will explore the types of roles available, the skills and education required, the companies that operate in the area, and the resources available to individuals seeking careers in this field. This information aims to provide a comprehensive overview of career prospects for those interested in pursuing opportunities in this dynamic and technologically advanced industry.

The pursuit of opportunities in the aeronautics and space sector within the Tacoma, WA region requires a strategic approach. Consider these points to enhance career prospects.

Tip 1: Targeted Skill Development: Focus on acquiring skills that align with industry demand. This includes proficiency in CAD software, materials science, and specific manufacturing processes relevant to aircraft production.

Tip 2: Education and Certification: Obtain relevant degrees and certifications. An engineering degree, FAA certifications for aircraft maintenance, or specialized training in aerospace technology are highly valued.

Tip 3: Networking: Actively participate in industry events and professional organizations. Networking can provide valuable insights into unadvertised positions and connect individuals with potential employers.

Tip 4: Company Research: Thoroughly research companies operating in the Tacoma area. Understand their specific needs, projects, and corporate culture to tailor applications effectively.

Tip 5: Tailored Resume and Cover Letter: Customize resumes and cover letters to highlight relevant experience and skills. Emphasize accomplishments and quantify achievements whenever possible.

Tip 6: Internship Opportunities: Seek internships with aerospace companies. Internships provide practical experience and can lead to full-time employment after graduation.

Tip 7: Continuous Learning: Commit to continuous learning and professional development. The aerospace industry is constantly evolving, so staying up-to-date with the latest technologies and trends is essential.

Adhering to these guidelines will position individuals favorably in the competitive environment. Proactive planning and preparation are crucial for maximizing career potential.

The subsequent sections will delve into specific companies located in Tacoma and the resources available for career advancement in this field.

1. Engineering Design Roles

Engineering Design Roles are a cornerstone of the aeronautics and space sector, particularly impacting the availability and nature of opportunities within Tacoma, WA. These roles encompass the conceptualization, development, and refinement of aircraft, spacecraft, and related systems, driving innovation and technical advancement.

- Aerodynamic Analysis and Simulation

This facet involves using computational fluid dynamics (CFD) software and wind tunnel testing to analyze the aerodynamic performance of aircraft designs. Engineers optimize wing shapes, control surfaces, and overall aircraft configurations to minimize drag, maximize lift, and ensure stable flight characteristics. In Tacoma, this could apply to the design of components for commercial aircraft or specialized modifications for military applications, impacting fuel efficiency and performance.

- Structural Design and Analysis

This aspect focuses on ensuring the structural integrity of aircraft components under various load conditions. Engineers use finite element analysis (FEA) software to model stress and strain distributions, optimizing designs for strength and weight efficiency. Examples in Tacoma may involve designing lightweight composite structures for aircraft fuselages or developing robust landing gear systems to withstand repeated impacts. This has a direct correlation with safety and longevity of components manufactured.

- Systems Integration and Testing

This area involves integrating various subsystems, such as avionics, propulsion, and hydraulic systems, into a cohesive and functional aircraft design. Engineers develop integration plans, conduct system-level testing, and troubleshoot issues to ensure seamless operation. In Tacoma, this could involve integrating new sensor technologies into existing aircraft platforms or developing advanced control systems for unmanned aerial vehicles (UAVs). Proper testing is essential to maintaining compliance and quality assurance.

- Design for Manufacturing (DFM)

This facet focuses on optimizing designs for efficient and cost-effective manufacturing processes. Engineers consider factors such as material selection, tooling requirements, and assembly procedures to reduce production costs and improve manufacturability. This ensures that theoretical designs can be realistically translated into physical components at scale. DFM consideration ensures profitability and scalability of operations within the Tacoma area.

These facets of Engineering Design Roles collectively shape the landscape of aeronautics and space opportunities in Tacoma. The demand for skilled engineers with expertise in these areas directly impacts the growth and competitiveness of the local industry, driving innovation and creating high-value employment opportunities. Further development of skilled labor is a crucial factor to support growth in the region.

2. Manufacturing Technician Positions

Manufacturing Technician Positions form a critical segment within the aeronautics and space sector in Tacoma, WA. These roles are directly involved in the fabrication, assembly, and testing of aircraft components and systems, contributing substantially to the production process and the overall quality of finished products.

- Precision Assembly and Fabrication

Technicians perform intricate assembly tasks requiring a high degree of accuracy and attention to detail. This includes assembling structural components, wiring harnesses, and hydraulic systems according to engineering specifications. Examples include assembling wing structures or installing avionics equipment in aircraft. Such activities directly impact the safety and reliability of the finished aircraft.

- Operation of Specialized Machinery

These positions involve operating and maintaining advanced manufacturing equipment, such as CNC machines, laser cutters, and robotic assembly systems. Technicians program machines, monitor performance, and troubleshoot issues to ensure efficient production. In Tacoma, this might entail operating equipment used to manufacture composite materials for aircraft fuselages or machining precision components for engine systems. Proper operation ensures efficiency and quality.

- Quality Control and Inspection

Technicians inspect components and assemblies to ensure they meet quality standards and specifications. This involves using precision measuring instruments, visual inspection techniques, and non-destructive testing methods. Examples include inspecting welds for structural integrity or verifying the dimensions of machined parts. Rigorous inspection processes are vital for maintaining compliance and minimizing defects.

- Process Improvement and Troubleshooting

Technicians contribute to process improvement initiatives by identifying and addressing inefficiencies in manufacturing processes. This involves troubleshooting problems, implementing corrective actions, and developing solutions to optimize production flow. In Tacoma, this could involve optimizing assembly line layouts or developing new tooling to improve production efficiency. Continual process enhancement drives greater productivity.

These facets of Manufacturing Technician Positions are essential to the health and growth of the aeronautics and space industry in Tacoma. The demand for skilled technicians directly influences the region’s ability to produce high-quality aircraft components and systems, supporting local economic development and employment opportunities. Continued training and investment in skilled labor will further enhance this sector.

3. Quality Control Assurance

Quality Control Assurance constitutes a fundamental aspect of aeronautics and space operations, particularly within the context of “aerospace jobs in tacoma wa.” This discipline focuses on systematically minimizing errors and defects throughout the manufacturing and assembly processes to ensure the reliability and safety of aircraft components and systems.

- Non-Destructive Testing (NDT) Expertise

NDT techniques, such as ultrasonic testing, radiography, and dye penetrant inspection, are employed to detect internal flaws and surface defects in materials without compromising their structural integrity. NDT technicians in Tacoma’s aerospace sector meticulously inspect critical components like wing spars and engine mounts, ensuring they meet stringent quality standards. These procedures directly impact the safety and longevity of aircraft, making this expertise vital.

- Metrology and Precision Measurement

Metrology specialists utilize advanced measurement tools, including coordinate measuring machines (CMMs) and laser trackers, to verify the dimensional accuracy of manufactured parts. In Tacoma, this role is critical for ensuring that components produced by local aerospace suppliers conform precisely to engineering blueprints. Accurate measurements minimize assembly errors and contribute to the overall performance and safety of aircraft.

- Statistical Process Control (SPC) Implementation

SPC involves using statistical methods to monitor and control manufacturing processes, identifying and addressing variations that could lead to defects. Quality control engineers in Tacoma implement SPC charts and perform data analysis to track key process parameters, such as machining tolerances and material properties. This proactive approach helps maintain consistent quality and reduces the risk of defective products reaching the market.

- Compliance and Regulatory Oversight

Quality control personnel ensure that all manufacturing processes and products adhere to relevant industry standards and regulatory requirements, such as those established by the FAA (Federal Aviation Administration). This involves maintaining detailed documentation, conducting audits, and implementing corrective actions to address any non-compliance issues. Strict adherence to these regulations is paramount for maintaining the safety and airworthiness of aircraft manufactured or maintained in the Tacoma area.

These facets of Quality Control Assurance are essential for maintaining the integrity and reliability of aerospace products in Tacoma. The demand for skilled professionals in these areas underscores the commitment to safety and quality within the local industry. Continuous improvement and rigorous adherence to standards are critical for ensuring that aerospace jobs in Tacoma, WA, contribute to the overall safety and success of the global aviation sector.

4. Supply Chain Management

Supply Chain Management is a critical function within the aeronautics and space industry. Its effectiveness directly influences the operational efficiency, cost management, and overall competitiveness of organizations in this sector, including those offering aerospace jobs in Tacoma, WA. Efficient handling of materials, components, and information from suppliers to end-users is paramount.

- Procurement and Sourcing Strategies

Procurement involves identifying, evaluating, and selecting suppliers capable of providing the necessary raw materials, components, and sub-assemblies for aircraft manufacturing. Strategic sourcing aims to optimize costs, minimize risks, and ensure a consistent supply of high-quality materials. For example, Boeing’s supply chain in the Puget Sound region, which includes Tacoma, relies on a network of suppliers for everything from aluminum alloys to specialized avionics equipment. Effective procurement directly impacts the availability and pricing of materials, influencing project timelines and budgets for aerospace firms in the region.

- Logistics and Transportation Optimization

Logistics focuses on the efficient movement and storage of materials throughout the supply chain. Optimization involves selecting the most cost-effective and timely transportation methods, managing inventory levels, and coordinating deliveries to minimize disruptions. Companies with aerospace jobs in Tacoma, WA, must manage complex logistics networks to transport large aircraft components, such as wings and fuselage sections, from various manufacturing sites to final assembly locations. Efficient logistics are crucial for minimizing lead times and maintaining production schedules.

- Inventory Management and Warehousing

Inventory management involves maintaining optimal levels of raw materials, work-in-process, and finished goods to meet production demands while minimizing storage costs and the risk of obsolescence. Warehousing provides secure storage facilities for these materials, ensuring they are readily available when needed. Aerospace companies in Tacoma must carefully manage inventory levels of critical components, such as engines and landing gear, to avoid production delays or excessive holding costs. Effective inventory management requires sophisticated forecasting and planning tools.

- Supplier Relationship Management (SRM)

SRM involves building and maintaining strong relationships with key suppliers to ensure collaboration, communication, and mutual benefit. Effective SRM enables aerospace companies to proactively address supply chain risks, improve quality, and drive innovation. For example, Boeing works closely with its suppliers to develop new materials and manufacturing processes, fostering a collaborative environment that benefits both parties. Strong SRM relationships are essential for maintaining a reliable and responsive supply chain.

These facets of Supply Chain Management are integral to the success of organizations offering aerospace jobs in Tacoma, WA. Efficient supply chain operations not only reduce costs and improve productivity but also contribute to the overall competitiveness of the local aerospace industry, ensuring the availability of high-quality components and systems needed for aircraft manufacturing and maintenance. Skilled professionals in this field are essential for maintaining a robust and resilient supply chain, supporting the growth and stability of aerospace employment in the region.

5. Aircraft Maintenance Expertise

Aircraft maintenance expertise is a critical component underpinning a significant portion of aerospace jobs in Tacoma, WA. The demand for skilled professionals capable of ensuring the airworthiness and safety of aircraft directly fuels employment opportunities within the region. This expertise encompasses a broad range of technical skills, including inspection, repair, overhaul, and modification of aircraft structures, engines, and avionics systems. The presence of major maintenance, repair, and overhaul (MRO) facilities and the proximity to Boeing, a primary manufacturer, amplify the need for qualified aircraft mechanics, technicians, and engineers in the Tacoma area. For example, the ongoing maintenance requirements of commercial airlines operating out of Seattle-Tacoma International Airport (SeaTac) create a consistent stream of work for MRO providers, consequently bolstering the local job market in this specialized domain.

The influence of aircraft maintenance extends beyond routine servicing. It also includes preventative maintenance, which is essential for preventing equipment failures and ensuring optimal performance. Professionals possessing expertise in predictive maintenance techniques, such as condition monitoring and data analysis, are increasingly sought after. The ability to proactively identify potential issues before they escalate into major problems is invaluable for minimizing downtime, reducing costs, and enhancing safety. Furthermore, the increasing complexity of modern aircraft, with advanced avionics and sophisticated control systems, necessitates specialized training and certifications. Technicians with expertise in specific aircraft types or systems are particularly in demand, commanding higher salaries and enjoying greater job security.

In summary, aircraft maintenance expertise is inextricably linked to the availability and quality of aerospace jobs in Tacoma, WA. The continuous need for aircraft servicing, combined with the increasing complexity of modern aircraft, ensures a sustained demand for skilled maintenance professionals. Continued investment in training programs and certifications is essential for meeting this demand and maintaining the region’s competitive edge in the aerospace industry. The ability to provide comprehensive maintenance services not only supports the operational efficiency of airlines but also contributes significantly to the economic vitality of the Tacoma area.

6. Regulatory Compliance

Regulatory compliance is a linchpin in the aeronautics and space sector; its influence on aerospace jobs in Tacoma, WA, is both pervasive and profound. Strict adherence to federal and international regulations, primarily those mandated by the Federal Aviation Administration (FAA), dictates nearly every aspect of aircraft design, manufacturing, maintenance, and operation. This necessity directly creates demand for specialized roles focusing on ensuring compliance, from quality control inspectors verifying adherence to manufacturing standards to regulatory affairs specialists interpreting and implementing evolving guidelines. Non-compliance can lead to substantial penalties, production delays, and reputational damage, underscoring the critical importance of these roles and the value placed on expertise in this area.

Practical examples of this connection abound in Tacoma’s aerospace industry. Aircraft component manufacturers must demonstrate adherence to stringent material specifications and production processes to receive FAA approval. This requirement generates demand for quality assurance engineers and technicians familiar with FAA regulations and capable of implementing effective quality control systems. Similarly, maintenance, repair, and overhaul (MRO) facilities must maintain detailed records of all maintenance activities and ensure that mechanics and technicians possess the necessary certifications and training to perform their duties. This focus on regulatory compliance drives demand for experienced maintenance supervisors and training personnel who can ensure adherence to FAA guidelines and maintain a safe and compliant operation.

Ultimately, a thorough understanding of regulatory compliance is not merely a desirable attribute but a fundamental requirement for many aerospace jobs in Tacoma, WA. The stringent regulatory environment of the aeronautics and space sector necessitates a workforce skilled in interpreting and implementing complex regulations, ensuring the safety and airworthiness of aircraft, and maintaining the industry’s reputation for excellence. The ongoing evolution of regulations presents a continual challenge, requiring professionals to stay abreast of the latest changes and adapt their practices accordingly. This dynamic environment reinforces the importance of continuous learning and professional development for those seeking careers in the aerospace industry.

7. Economic Impact Locally

The presence of aerospace jobs in Tacoma, WA, generates a significant economic impact within the local community. These positions, encompassing a wide range of skill sets and expertise, contribute directly to the city’s tax base through income and property taxes. Increased tax revenue supports essential public services, including education, infrastructure development, and public safety initiatives. The concentration of highly skilled aerospace workers also attracts related industries and businesses, fostering a more diverse and robust economic ecosystem. For example, suppliers of specialized materials, engineering services, and testing equipment often locate near aerospace manufacturing facilities to better serve their clients, further amplifying the economic benefits.

Furthermore, the economic benefits extend beyond direct employment. Aerospace jobs in Tacoma, WA, support a network of indirect employment opportunities in sectors such as retail, housing, transportation, and hospitality. The increased purchasing power of aerospace employees stimulates local businesses, creating a multiplier effect that boosts overall economic activity. The presence of a thriving aerospace sector also enhances the city’s reputation as a center for innovation and technology, attracting further investment and talent from around the world. This leads to increased property values, improved quality of life, and a more vibrant cultural scene.

In summary, the economic impact locally of aerospace jobs in Tacoma, WA, is substantial and multifaceted. These positions not only provide direct employment opportunities but also stimulate economic growth across various sectors, enhance the city’s reputation, and contribute to the overall well-being of the community. Maintaining and expanding the aerospace sector in Tacoma requires continued investment in workforce development, infrastructure improvements, and a supportive business environment. Ensuring the long-term sustainability of this critical industry is essential for securing the economic prosperity of the region.

Frequently Asked Questions

This section addresses common inquiries regarding career opportunities within the aeronautics and space sector in the Tacoma, Washington, area. The information provided aims to offer clarity and guidance for individuals seeking employment in this industry.

Question 1: What types of qualifications are typically required for entry-level positions?

Entry-level roles often require a minimum of an associate’s degree or vocational training in a relevant field, such as aerospace technology, manufacturing, or engineering technology. Specific certifications, such as FAA Airframe and Powerplant licenses, may be necessary for certain positions. Prior experience through internships or apprenticeships is highly advantageous.

Question 2: Which companies are the primary employers in the Tacoma aerospace sector?

While specific company information is subject to change, key employers in the Tacoma area often include aerospace manufacturers, component suppliers, and maintenance, repair, and overhaul (MRO) facilities. Researching companies with a significant presence in the Puget Sound region is advisable for identifying potential opportunities.

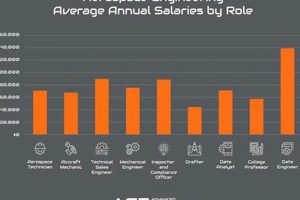

Question 3: What is the typical salary range for aerospace professionals in Tacoma?

Salary ranges vary significantly based on factors such as experience, education, job title, and employer. Researching industry-specific salary surveys and consulting with professional organizations can provide a more accurate estimate for specific roles.

Question 4: Are there specific skills that are particularly in demand in the Tacoma aerospace market?

Skills in high demand often include proficiency in CAD/CAM software, knowledge of composite materials, experience with CNC machining, expertise in quality control procedures, and familiarity with aerospace regulations. Continuous professional development is crucial for maintaining competitiveness.

Question 5: What resources are available for individuals seeking aerospace jobs in Tacoma?

Resources include online job boards, professional organizations, industry-specific conferences and career fairs, and local workforce development agencies. Networking with industry professionals and seeking mentorship opportunities can also be beneficial.

Question 6: How does the cost of living in Tacoma compare to other aerospace hubs?

The cost of living in Tacoma is generally lower than in larger metropolitan areas such as Seattle. Housing costs, in particular, may be more affordable. However, factors such as transportation expenses and taxes should be considered when evaluating overall affordability.

This information serves as a general guide. Thorough research and preparation are essential for navigating the aerospace job market successfully.

The subsequent sections will explore additional strategies for career advancement and provide insights into emerging trends within the sector.

Conclusion

This analysis has explored the multifaceted landscape of “aerospace jobs in tacoma wa,” detailing the roles, skills, companies, and economic factors that define this sector. The examination encompassed engineering design, manufacturing techniques, quality assurance, supply chain management, and regulatory adherence, each contributing uniquely to the vitality of Tacoma’s aerospace industry. A clear understanding of these elements is crucial for navigating the opportunities and challenges within this employment market.

The sustained growth of “aerospace jobs in tacoma wa” depends on continued investment in workforce development, technological innovation, and a supportive business environment. As the aerospace sector evolves, proactive adaptation and strategic planning are essential for both job seekers and industry stakeholders to maintain competitiveness and ensure long-term success.

![Is Aerospace Engineer Job Availability Rising? [2024 Trends] Innovating the Future of Flight with Reliable Aviation Solutions Is Aerospace Engineer Job Availability Rising? [2024 Trends] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-520-300x200.jpg)