Individuals in this profession are responsible for ensuring the airworthiness and operational readiness of aircraft and related systems. These professionals perform scheduled inspections, diagnose mechanical and electrical malfunctions, and conduct repairs and overhauls in compliance with strict regulatory standards. For example, they might inspect a jet engine for wear and tear, troubleshoot an avionics issue, or oversee the replacement of landing gear components.

The role is critical to the safety and efficiency of air travel and defense operations. Their expertise directly contributes to preventing accidents and minimizing downtime, thereby reducing operational costs and ensuring public safety. Historically, the discipline has evolved alongside advancements in aviation technology, demanding continuous learning and adaptation to new aircraft designs and maintenance procedures.

The following sections will delve deeper into the specific responsibilities, required skills, educational pathways, and career prospects associated with this vital field. This will provide a comprehensive overview of what it entails to work in this technically demanding and safety-critical occupation.

Essential Guidance for Aspiring Professionals

The subsequent recommendations provide crucial insights for individuals seeking a career maintaining the complex machinery of aviation. Adhering to these guidelines can significantly enhance one’s prospects for success in this demanding field.

Tip 1: Prioritize Foundational Knowledge: A strong grasp of mathematics, physics, and electrical engineering principles is indispensable. These subjects form the bedrock upon which further specialized aerospace engineering knowledge is built. Consider supplemental coursework if deficiencies exist.

Tip 2: Seek Reputable Certification: Attaining an FAA Airframe and Powerplant (A&P) license is frequently a prerequisite for employment. Thoroughly research and select an accredited training program known for its rigor and comprehensive curriculum.

Tip 3: Embrace Continuous Learning: Aviation technology is constantly evolving. Participate in continuing education courses and workshops to stay abreast of the latest advancements in aircraft systems and maintenance procedures.

Tip 4: Develop Strong Troubleshooting Skills: Effective diagnosis of mechanical and electrical issues is paramount. Practice utilizing diagnostic tools, interpreting technical manuals, and systematically eliminating potential causes of malfunctions.

Tip 5: Cultivate Meticulous Documentation Practices: Accurate and detailed record-keeping is essential for compliance with regulatory requirements and maintaining a comprehensive maintenance history. Develop proficiency in documenting inspections, repairs, and modifications.

Tip 6: Focus on Safety Protocols: Adherence to safety regulations is non-negotiable in this profession. Rigorously follow established procedures and prioritize safety at all times to mitigate the risk of accidents and injuries.

Tip 7: Network with Industry Professionals: Attend industry events, join professional organizations, and connect with experienced personnel. Networking can provide valuable insights, mentorship opportunities, and potential job prospects.

Following these recommendations diligently will enhance both the technical competence and professional standing of any individual aiming to succeed in the field. The commitment to these principles promotes excellence in aircraft maintenance and ensures the highest standards of aviation safety.

The following sections will build upon these guidelines, further exploring the specific roles and challenges encountered in this crucial career path.

1. Airworthiness Regulations Compliance

Adherence to airworthiness regulations forms the cornerstone of responsibilities within the aviation maintenance sector. These regulations, mandated by governing bodies, dictate the standards for aircraft maintenance and operation. The proficiency in understanding and implementing these regulations defines a significant portion of the duties of those responsible for maintaining the operational readiness of aviation assets.

- Ensuring Aircraft Safety

Airworthiness regulations exist to ensure aircraft operate within established safety parameters. Professionals in this area are tasked with verifying that all maintenance actions, from routine inspections to complex repairs, meet these safety standards. An example includes meticulously following procedures outlined in the aircraft’s maintenance manual when replacing a critical component, ensuring it is correctly installed and functions as intended to prevent in-flight failures.

- Documentation and Record-Keeping

Comprehensive and accurate documentation is a central tenet of compliance. Maintenance personnel are required to maintain detailed records of all maintenance activities performed, including parts used, inspections conducted, and any deviations from standard procedures. These records serve as evidence of compliance and are essential for tracking the maintenance history of an aircraft, which can be audited by regulatory authorities at any time. Failure to maintain adequate records can lead to significant penalties.

- Inspections and Audits

Airworthiness regulations mandate regular inspections and audits of maintenance facilities and practices. These inspections, conducted by regulatory agencies, assess whether the facility is adhering to established standards and following proper procedures. They are also responsible for conducting these inspections according to schedule and protocol. Successfully passing these audits is vital for maintaining operational certifications and avoiding costly fines or operational disruptions.

- Continuous Improvement and Training

Compliance requires a commitment to continuous improvement and ongoing training. As regulations evolve and new technologies emerge, maintenance personnel must stay abreast of the latest changes and best practices. This necessitates regular training programs and a culture of continuous learning within maintenance organizations, ensuring that all personnel are equipped with the knowledge and skills necessary to maintain aircraft in accordance with the latest standards.

Ultimately, compliance with airworthiness regulations is not merely a procedural requirement; it is a fundamental responsibility that underpins the safety and reliability of air travel. Professionals who demonstrate a commitment to upholding these standards play a critical role in safeguarding the lives of passengers and crew, and ensuring the continued integrity of the aviation industry. It underscores the significance of having a fully-trained, skilled, and committed team to oversee all aspects of air transportation maintenance operations.

2. Precision Troubleshooting Skills

The efficacy of an aviation maintenance professional is intrinsically linked to the application of precision troubleshooting skills. These skills represent the systematic and analytical approach necessary to diagnose and rectify complex malfunctions within aircraft systems. A deficiency in this area directly impacts the safety and operational readiness of aircraft. The consequences of inaccurate or incomplete troubleshooting range from costly delays to potentially catastrophic failures. For instance, correctly diagnosing an intermittent fault in an aircraft’s hydraulic system requires a meticulous process of isolating the faulty component using specialized equipment and a deep understanding of system schematics. Failure to identify the root cause can lead to repeated malfunctions and compromised safety.

The practical application of these abilities extends across various maintenance scenarios. These professionals frequently employ diagnostic tools, such as multimeters, oscilloscopes, and specialized software, to analyze electrical circuits, hydraulic systems, and engine performance. A clear instance of this involves identifying the source of an avionics system failure. Accurate interpretation of diagnostic data, coupled with a thorough understanding of the aircraft’s technical manuals, allows for the precise location and repair of the problem. Furthermore, these troubleshooting aptitudes contribute significantly to preventative maintenance programs. By recognizing subtle deviations from normal operating parameters, maintenance personnel can proactively address potential issues before they escalate into more significant problems, thereby increasing aircraft reliability and reducing maintenance costs.

In summary, precision troubleshooting skills constitute an indispensable element of the aviation maintenance engineer’s skillset. These competencies are not merely theoretical knowledge; they are actively deployed in real-world scenarios, demanding a blend of technical expertise, analytical thinking, and systematic methodology. The commitment to developing and refining these capabilities is crucial for ensuring the safe and efficient operation of aircraft, making precision troubleshooting an essential attribute for any professional in this field.

3. Safety protocol adherence

Adherence to safety protocols forms a non-negotiable component of the responsibilities shouldered by an aerospace maintenance professional. The consequences of neglecting established safety measures in this high-stakes field are potentially catastrophic, ranging from equipment damage and personnel injury to loss of life. Consequently, a thorough understanding and unwavering commitment to safety protocols is not merely a desirable trait but a fundamental requirement for any individual involved in aircraft maintenance. These protocols are designed to mitigate risks inherent in the complex tasks performed, encompassing everything from working with hazardous materials to operating heavy machinery around aircraft. For instance, the improper handling of flammable aviation fuel can result in explosions or fires, while neglecting lock-out/tag-out procedures during maintenance on electrical systems can lead to electrocution.

The specific protocols that must be followed are often dictated by regulatory bodies, such as the Federal Aviation Administration (FAA), and are meticulously documented in maintenance manuals and operating procedures. These documents outline the precise steps to be taken when performing various tasks, including pre-flight inspections, component replacements, and system overhauls. The professional in this sector bears the responsibility of not only understanding these protocols but also ensuring that they are consistently and rigorously applied in all maintenance activities. Regular safety training, drills, and audits are essential for reinforcing safety consciousness and identifying potential areas for improvement. This proactive approach helps to prevent accidents and ensures that all personnel are equipped to respond effectively in the event of an emergency. For example, emergency preparedness drills, conducted with a focus on fuel spills or aircraft fires, simulate real-world scenarios, and improve response effectiveness.

In summary, safety protocol adherence is inextricably linked to the competency and ethical conduct of an aerospace maintenance engineer. It is not simply a matter of complying with regulations but a fundamental responsibility to protect the lives of passengers, crew, and fellow maintenance personnel. By prioritizing safety above all else, professionals in this field contribute to the overall safety and reliability of air travel, upholding the highest standards of excellence in the aviation industry. The ongoing challenge lies in maintaining a constant state of vigilance and continuously reinforcing safety awareness among all members of the maintenance team, thereby fostering a culture of safety that permeates every aspect of their work.

4. Continuous Technical Learning

The rapidly evolving landscape of aviation technology mandates continuous technical learning as an indispensable element of the aerospace maintenance engineer’s professional development. Stagnation in knowledge and skills can lead to compromised safety, inefficient maintenance practices, and an inability to effectively service modern aircraft systems. Therefore, a commitment to ongoing education and skill enhancement is not merely beneficial but essential for remaining competent and effective in this field.

- Adaptation to New Aircraft Technologies

Aircraft manufacturers consistently introduce new technologies, materials, and systems designed to improve performance, efficiency, and safety. Aerospace maintenance engineers must actively pursue training and education to acquire the knowledge and skills needed to maintain these advanced systems. For example, the introduction of composite materials in aircraft construction necessitates specialized training in repair techniques different from traditional aluminum structures. Without this training, engineers risk damaging these materials, compromising the aircraft’s structural integrity.

- Understanding Evolving Regulations and Standards

Aviation regulations and industry standards are subject to frequent updates and revisions. These changes often reflect lessons learned from accidents, technological advancements, or evolving safety concerns. Aerospace maintenance engineers must stay informed about these changes and adapt their practices accordingly. Failure to comply with the latest regulations can result in fines, operational restrictions, or even the revocation of maintenance certifications. Continuous learning ensures compliance and promotes adherence to the highest safety standards.

- Mastering Advanced Diagnostic Techniques

Modern aircraft rely on complex electronic systems for navigation, communication, and flight control. Diagnosing malfunctions in these systems requires proficiency in using advanced diagnostic tools and techniques. Continuous learning allows aerospace maintenance engineers to stay current with the latest diagnostic technologies, such as advanced oscilloscopes, spectrum analyzers, and specialized software. This expertise enables them to quickly and accurately identify the root causes of problems, minimizing downtime and ensuring the reliable operation of critical aircraft systems.

- Enhancing Problem-Solving and Critical-Thinking Skills

Continuous technical learning extends beyond simply acquiring new knowledge; it also fosters the development of problem-solving and critical-thinking skills. Exposure to new concepts and techniques encourages engineers to think creatively and analytically when addressing complex maintenance challenges. These skills are essential for troubleshooting unfamiliar problems, adapting to unforeseen circumstances, and developing innovative solutions to improve maintenance efficiency and effectiveness. The combination of technical expertise and strong problem-solving abilities allows aerospace maintenance engineers to excel in their roles and contribute to the continuous improvement of aviation safety and reliability.

In conclusion, continuous technical learning is not a passive undertaking but an active and ongoing process that defines the career of a proficient aerospace maintenance engineer. It is the cornerstone of their ability to maintain aircraft safely, efficiently, and in compliance with evolving regulations. By embracing a lifelong commitment to learning, these professionals ensure that they remain at the forefront of their field, contributing to the continued advancement and safety of the aviation industry.

5. Component Failure Analysis

Component failure analysis is intrinsically linked to the responsibilities of an aerospace maintenance engineer, representing a critical function in maintaining aircraft safety and operational efficiency. This process involves a systematic investigation to determine the root cause of a component malfunction or breakdown. The results of these analyses directly inform maintenance procedures, design improvements, and preventative strategies. For example, an engineer might investigate a turbine blade failure in a jet engine. The analysis would involve examining the blade’s material composition, microstructure, and fracture surface to identify factors such as fatigue, corrosion, or manufacturing defects. This understanding then informs the development of improved blade designs or more frequent inspections to prevent similar failures in the future.

The ability to conduct effective component failure analysis has practical implications that extend beyond individual repairs. Data collected from these investigations contributes to broader reliability engineering efforts, which aim to improve the overall lifespan and performance of aircraft components. Another example is the study of landing gear failures. By analyzing the causes of such failures, engineers can identify weaknesses in the design or maintenance protocols and implement changes to reduce the likelihood of future incidents. This includes modifications to inspection intervals, the use of more durable materials, or the implementation of enhanced maintenance procedures. This analytical process ensures that aircraft components consistently perform to design specifications, minimizing the risk of in-flight malfunctions.

In conclusion, component failure analysis serves as a vital feedback loop in the aerospace industry. It transforms incidents of component malfunction into opportunities for learning and improvement. While challenges exist in accurately determining the root cause of failures, particularly in complex systems, the effective implementation of component failure analysis methodologies is paramount. This process not only enhances the safety and reliability of aircraft but also contributes to the overall advancement of aerospace engineering practices, underlining its significance in the broader operational context.

6. Preventative Maintenance Scheduling

Preventative maintenance scheduling is a cornerstone of aviation safety and operational efficiency, directly impacting the role and responsibilities of professionals in the field. A well-structured schedule mitigates the risk of component failure, extends the lifespan of aircraft, and ensures compliance with stringent regulatory requirements. The expertise and diligence of the personnel responsible for maintaining aircraft dictate the effectiveness of these schedules, influencing the overall safety and cost-effectiveness of aviation operations.

- Optimizing Aircraft Availability

A carefully crafted preventative maintenance schedule minimizes aircraft downtime by strategically planning maintenance activities during periods of low operational demand. This ensures that aircraft are available when needed, supporting flight schedules and reducing disruptions. The scheduling often involves a balance between time-based inspections (e.g., every 100 flight hours) and condition-based maintenance (e.g., monitoring engine performance parameters to detect potential issues). Effective scheduling ensures that maintenance is performed proactively, preventing minor issues from escalating into major problems that could ground an aircraft unexpectedly.

- Ensuring Regulatory Compliance

Aviation authorities, such as the FAA and EASA, mandate specific maintenance requirements that must be adhered to by all aircraft operators. Preventative maintenance schedules are designed to incorporate these regulatory requirements, ensuring that all necessary inspections and maintenance tasks are completed within the specified intervals. Aerospace maintenance engineers play a critical role in ensuring compliance by meticulously tracking maintenance activities and maintaining accurate records. Failure to adhere to these schedules can result in significant penalties and potentially compromise the airworthiness of the aircraft.

- Extending Component Lifespan

Regular preventative maintenance helps to extend the lifespan of aircraft components by identifying and addressing potential issues before they lead to catastrophic failures. The practice often involves routine inspections, lubrication, and component replacements based on predefined schedules or condition monitoring data. This proactive approach reduces the likelihood of costly repairs and extends the overall operational life of the aircraft. For instance, regularly inspecting and servicing landing gear components can prevent corrosion and fatigue, extending their service life and reducing the risk of landing gear failure.

- Enhancing Safety and Reliability

Ultimately, the goal of preventative maintenance scheduling is to enhance the safety and reliability of aircraft operations. By systematically inspecting, maintaining, and replacing components, maintenance personnel reduce the risk of in-flight failures and ensure that aircraft operate within established safety parameters. This contributes to a safer and more reliable aviation system, protecting passengers, crew, and the general public. Effective preventative maintenance scheduling is, therefore, not merely a procedural requirement but a fundamental commitment to aviation safety.

The successful implementation of preventative maintenance scheduling hinges on the expertise, diligence, and commitment of aerospace maintenance engineers. Their ability to plan, execute, and document maintenance activities effectively is critical for ensuring the safety, reliability, and efficiency of aircraft operations. The intricate interplay between scheduling, compliance, and proactive maintenance highlights the vital role these professionals play in the aviation industry.

Frequently Asked Questions Regarding Aerospace Maintenance Engineering

This section addresses common inquiries pertaining to the role, responsibilities, and requirements associated with aerospace maintenance engineering. The information provided aims to offer clarity and informed perspectives on this critical profession.

Question 1: What specific qualifications are required to pursue a career as an aerospace maintenance engineer?

Generally, a recognized certification, such as an FAA Airframe and Powerplant (A&P) license, is required. Furthermore, a strong foundation in mathematics, physics, and engineering principles is essential. Many employers also prefer candidates with an associate’s or bachelor’s degree in a related field.

Question 2: What are the typical daily tasks performed by individuals in this profession?

Daily tasks vary depending on the specific work environment and the type of aircraft being maintained. However, typical duties include conducting routine inspections, troubleshooting mechanical and electrical malfunctions, performing repairs and component replacements, and documenting all maintenance activities meticulously.

Question 3: What are the most common challenges encountered in maintaining modern aircraft?

Modern aircraft increasingly rely on complex electronic systems and composite materials, which present unique maintenance challenges. Troubleshooting avionics issues, repairing composite structures, and staying current with evolving technologies are among the common difficulties.

Question 4: How important is continuous training in this field?

Continuous training is paramount due to the rapid advancements in aviation technology and regulatory changes. Maintenance personnel must actively pursue ongoing education to stay abreast of new aircraft systems, diagnostic techniques, and safety protocols.

Question 5: What safety protocols are critical for maintaining aircraft?

Adherence to stringent safety protocols is non-negotiable. These protocols encompass the proper handling of hazardous materials, the use of personal protective equipment, adherence to lock-out/tag-out procedures, and the meticulous following of maintenance manuals and safety directives.

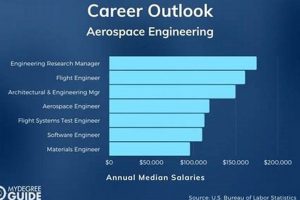

Question 6: What career advancement opportunities are available within aerospace maintenance engineering?

Career advancement opportunities include specialization in specific aircraft systems, progression into supervisory or management roles, and transitioning into quality assurance or engineering positions. Continued education and certifications can enhance career prospects.

In summary, aerospace maintenance engineering demands a blend of technical expertise, analytical skills, and a strong commitment to safety. Continuous learning and professional development are essential for success in this evolving field.

The subsequent sections will explore the future trends and evolving demands shaping the profession.

Concluding Remarks on the Profession

This exploration has illuminated the multifaceted responsibilities and critical importance of the aerospace maintenance engineer. The role encompasses rigorous adherence to safety protocols, continuous technical learning, and the application of precise troubleshooting skills. The effective execution of preventative maintenance scheduling and thorough component failure analysis are also paramount to ensuring airworthiness and operational efficiency.

The aviation sector demands professionals committed to upholding the highest standards of safety and technical competence. Continued diligence and adaptation to evolving technologies will be critical for those serving as an aerospace maintenance engineer, thereby contributing to the sustained integrity and advancement of air travel.