Positions involved in the design, development, testing, and application of substances used in the construction of aircraft and spacecraft components are critical for the aerospace industry. These roles necessitate specialized knowledge of material properties, manufacturing processes, and performance requirements under extreme conditions. An example would be a materials engineer researching new alloys to improve the strength-to-weight ratio of an aircraft wing.

The availability of professionals skilled in this domain is paramount for advancing aerospace technology. Their expertise directly impacts fuel efficiency, structural integrity, and overall safety of flight vehicles. Historically, advancements in this area have been instrumental in enabling longer flights, heavier payloads, and the exploration of space, contributing significantly to both commercial aviation and space exploration endeavors.

Therefore, this article will further explore the specific skill sets required, common career paths, and the outlook for individuals seeking employment in this vital and continuously evolving area of engineering.

The following advice provides actionable strategies for individuals pursuing or advancing a career focused on the development and application of substances used in aerospace engineering.

Tip 1: Cultivate a Strong Foundation in Materials Science: A robust understanding of material properties, including mechanical, thermal, and chemical behavior, is fundamental. Coursework in metallurgy, polymer science, and composite materials is highly recommended. For example, a deep knowledge of the stress-strain curves of various alloys is essential for selecting the appropriate material for a specific aircraft component.

Tip 2: Develop Expertise in Manufacturing Processes: Familiarity with manufacturing techniques such as casting, forging, welding, additive manufacturing (3D printing), and composite layup is crucial. Understanding the impact of these processes on material properties is equally important. As an illustration, knowledge of the heat-affected zone in welding is essential for ensuring structural integrity.

Tip 3: Gain Proficiency in Relevant Software and Simulation Tools: Proficiency with Finite Element Analysis (FEA) software packages, Computer-Aided Design (CAD) tools, and material modeling software is highly valuable. These tools enable the simulation of material behavior under various conditions, allowing for optimized designs and reduced testing costs. Consider learning ANSYS, ABAQUS, or similar simulation software.

Tip 4: Secure Internships or Co-op Experiences: Practical experience in the aerospace industry is invaluable. Internships or co-op programs provide opportunities to apply theoretical knowledge to real-world problems and gain exposure to industry-standard practices. Seek placements with aerospace manufacturers, research institutions, or testing laboratories.

Tip 5: Pursue Advanced Degrees and Certifications: A Master’s degree or Ph.D. in materials science, aerospace engineering, or a related field can significantly enhance career prospects. Furthermore, professional certifications, such as those offered by ASM International or the Society for the Advancement of Material and Process Engineering (SAMPE), demonstrate a commitment to professional development.

Tip 6: Stay Abreast of Emerging Technologies: The field of aerospace materials is constantly evolving. Actively follow industry publications, attend conferences, and participate in continuing education courses to stay informed about the latest advancements in areas such as nanomaterials, advanced composites, and additive manufacturing.

Tip 7: Network with Industry Professionals: Building a strong professional network can open doors to new opportunities and provide valuable insights into the industry. Attend industry events, join professional organizations, and connect with professionals on platforms such as LinkedIn.

By focusing on these key areas, individuals can enhance their qualifications and significantly improve their prospects for securing a successful and rewarding career in the specialized domain of aerospace material science.

The information presented provides a foundation for career advancement. Future discussions can delve into specific company profiles and emerging trends within the field.

1. Materials Expertise

Materials expertise forms the cornerstone of many roles within the aerospace industry. This specialized knowledge directly influences the performance, safety, and longevity of aircraft and spacecraft, underscoring its critical importance in various engineering and manufacturing functions.

- Material Selection and Design

This facet involves choosing the most appropriate materials for specific components based on their performance requirements, operating environment, and cost-effectiveness. For instance, a materials engineer might select titanium alloys for high-stress airframe components due to their high strength-to-weight ratio and corrosion resistance. Understanding material limitations and advantages is paramount for efficient aerospace design.

- Material Characterization and Testing

Characterization involves determining the physical, chemical, and mechanical properties of materials to ensure they meet stringent aerospace standards. Testing encompasses various methods, such as tensile testing, fatigue testing, and non-destructive evaluation, to validate material performance under simulated flight conditions. For example, composite materials used in aircraft wings undergo rigorous testing to ensure they can withstand the stresses of flight without failing. The rigorous testing ensures the quality of aerospace equipment.

- Materials Processing and Manufacturing

This area focuses on the methods used to transform raw materials into finished aerospace components, including casting, forging, machining, welding, and additive manufacturing. Materials experts must understand how these processes affect material properties and structural integrity. As an illustration, specialized welding techniques are required to join dissimilar metals in aircraft engines to prevent corrosion and maintain structural strength.

- Failure Analysis and Prevention

When materials fail, materials experts analyze the causes to prevent future occurrences. This includes investigating fractures, corrosion, and other forms of degradation to identify design flaws, manufacturing defects, or environmental factors that contributed to the failure. An example is the investigation of fatigue cracks in aircraft landing gear to improve maintenance schedules and prevent catastrophic failures. It enables us to take measures to protect people and property.

In conclusion, expertise in materials is central to many aspects of aerospace manufacturing and engineering. From initial material selection and testing to advanced manufacturing techniques and failure analysis, specialized materials knowledge enables the creation of safer, more efficient, and more durable aircraft and spacecraft. This underscores the significant role of material specialists in the progression of aerospace technology and validates the necessity of such specialized professionals.

2. Engineering Design

Engineering design is intrinsically linked to roles focused on materials in the aerospace sector. The design process relies heavily on a thorough understanding of material properties and behavior under various operational conditions, placing material specialists at the forefront of critical design decisions.

- Structural Analysis and Optimization

Structural analysis is a crucial element in aerospace design. It assesses the ability of aircraft and spacecraft components to withstand applied loads and environmental stresses. Material specialists contribute by providing accurate material property data, which is essential for Finite Element Analysis (FEA) and other simulation techniques. For example, the design of an aircraft wing requires precise knowledge of the fatigue resistance of the aluminum alloys used, ensuring structural integrity throughout the aircraft’s lifespan.

- Component Design and Integration

The design of individual components necessitates careful material selection and integration to ensure compatibility and optimal performance. Material engineers collaborate with design engineers to choose materials that meet specific requirements, such as high-temperature resistance for engine components or low weight for airframe structures. An illustrative case involves designing the interface between carbon fiber composites and metallic fasteners, where material compatibility and corrosion prevention are paramount.

- Thermal Management Design

Managing heat within aerospace systems is critical, especially in high-speed flight and space environments. Material specialists contribute by selecting materials with appropriate thermal conductivity, expansion coefficients, and heat resistance. For instance, the design of a heat shield for a spacecraft re-entering the atmosphere requires materials that can withstand extreme temperatures without degrading, necessitating expertise in ceramics and ablative materials.

- Weight Reduction Strategies

Minimizing weight is a fundamental objective in aerospace design. Material engineers play a vital role by identifying and implementing lightweight materials, such as advanced composites and aluminum-lithium alloys, without compromising structural integrity. An example is the replacement of traditional steel components with titanium alloys in landing gear to reduce weight and improve fuel efficiency.

In summary, the intersection of engineering design and materials expertise is critical for the development of safe, efficient, and high-performing aerospace systems. Material specialists are integral to optimizing structural integrity, managing thermal loads, reducing weight, and ensuring component compatibility, highlighting the indispensable role they play in aerospace engineering.

3. Research and Development

Research and development (R&D) constitutes a critical function for aerospace materials positions. The aerospace industry continually seeks advanced substances to enhance performance, safety, and efficiency of aircraft and spacecraft. Positions in R&D are therefore instrumental in driving innovation within this domain.

- New Material Discovery and Synthesis

This facet involves the identification, creation, and synthesis of novel materials exhibiting superior properties compared to existing options. Examples include the development of high-temperature ceramics for turbine blades and self-healing polymers for composite structures. Individuals in these roles must demonstrate proficiency in chemistry, materials science, and advanced analytical techniques. Discovering a new alloy, for example, that offers higher strength at elevated temperatures directly impacts engine efficiency and durability.

- Material Property Enhancement

Focus is placed on improving specific properties of existing substances through modifications to composition, microstructure, or processing techniques. This could involve increasing the fatigue resistance of aluminum alloys or enhancing the thermal conductivity of composite materials. Such work relies on precise control of manufacturing processes and advanced characterization methods to validate improvements. The optimization of an existing carbon fiber layup to increase tensile strength is a prime example.

- Advanced Manufacturing Techniques

R&D also encompasses the development and refinement of novel manufacturing processes to produce aerospace components with greater precision, efficiency, and cost-effectiveness. This includes exploring additive manufacturing (3D printing), advanced composite layup techniques, and innovative joining methods. The application of electron beam welding to create highly durable, lightweight structures illustrates this aspect.

- Testing and Validation of New Materials

A vital stage in R&D involves rigorous testing and validation of new materials under simulated operational conditions. This includes mechanical testing, thermal analysis, and environmental exposure to assess performance and durability. Data obtained from these tests informs design decisions and ensures compliance with stringent aerospace standards. Performing accelerated aging tests on a new polymer composite to predict its lifespan in space environments showcases the criticality of this facet.

In essence, R&D positions within the aerospace materials field are at the forefront of technological advancement. They require a deep understanding of materials science, engineering principles, and experimental techniques. The work performed by individuals in these roles directly impacts the future of aerospace technology, influencing the development of safer, more efficient, and more capable aircraft and spacecraft. The evolution of lighter, stronger, and more heat-resistant materials is a direct result of the ongoing research efforts in this area.

4. Testing and Validation

Testing and validation are inseparable from roles involving aerospace materials. These processes are essential to guaranteeing materials used in aircraft and spacecraft meet rigorous performance and safety requirements. Materials professionals are intricately involved in planning, executing, and analyzing data from a variety of tests to qualify materials for specific aerospace applications.

- Non-Destructive Evaluation (NDE)

NDE techniques, such as ultrasonic testing, radiography, and eddy current inspection, are used to detect internal flaws and surface defects in materials without damaging them. Materials specialists in this area develop and implement NDE procedures to ensure materials meet quality standards before and during service. For example, NDE is routinely used to inspect composite laminates for delamination or porosity, thereby preventing structural failures in aircraft components. The precision of these tests is directly influenced by the skill of personnel in relevant job roles.

- Mechanical Testing

Mechanical testing encompasses a range of procedures to determine a material’s response to applied forces, including tensile strength, fatigue resistance, and fracture toughness. Materials engineers design and conduct these tests to characterize material behavior under different loading conditions and validate material models used in structural analysis. A common example is the fatigue testing of turbine blades to ensure they can withstand the cyclic stresses of engine operation. Analysis of the resulting data is a key function of many positions.

- Environmental Testing

Aerospace materials must withstand extreme environmental conditions, including high and low temperatures, radiation exposure, and corrosive atmospheres. Environmental testing simulates these conditions to assess the durability and performance of materials over their service life. For instance, materials used in spacecraft are subjected to vacuum and radiation testing to ensure they can survive the harsh conditions of space. Professionals in this field are critical for selecting and implementing the correct tests.

- Material Certification

Material certification involves demonstrating that a material meets all applicable regulatory and industry standards. This process requires comprehensive testing and documentation to verify material properties, manufacturing processes, and quality control procedures. Materials specialists are responsible for compiling and presenting the necessary data to certification authorities, such as the FAA or ESA, to obtain approval for use in aerospace applications. A detailed understanding of certification requirements is a prerequisite for many such positions.

In summation, testing and validation constitute a fundamental aspect of positions concerned with aerospace materials. These processes ensure the safety, reliability, and performance of aircraft and spacecraft by validating material properties and detecting potential flaws. The professionals who conduct these tests, analyze the data, and manage the certification process are crucial for maintaining the integrity of aerospace vehicles.

5. Manufacturing Processes

The proficiency of personnel in positions related to aerospace materials is intrinsically linked to a thorough comprehension of manufacturing processes. The selection, application, and performance of materials are directly influenced by the methods employed to fabricate aerospace components. This understanding is crucial for ensuring structural integrity, optimizing material properties, and achieving cost-effective production.

- Casting and Forging

These processes are used to create near-net-shape components from molten metal or solid billets, respectively. The thermal history and deformation patterns inherent in casting and forging significantly affect the microstructure and mechanical properties of the final product. Individuals involved with aerospace materials must understand how to control these parameters to achieve desired material characteristics. For example, controlling cooling rates during casting of turbine blades is essential to prevent the formation of detrimental phases that could reduce creep resistance. Selecting the right casting parameters can also help control porosity.

- Machining and Joining

Machining operations, such as milling, turning, and grinding, are employed to achieve precise dimensions and surface finishes on aerospace components. Joining processes, including welding, brazing, and adhesive bonding, are used to assemble complex structures from multiple parts. Material specialists must understand the impact of these processes on material properties, such as residual stress and heat-affected zone formation, to ensure structural integrity. For instance, friction stir welding is often used to join aluminum alloys in aircraft fuselages due to its ability to minimize distortion and maintain high joint strength. Proper surface treatment is a part of the job function.

- Composite Manufacturing

Composite manufacturing involves the fabrication of components from fiber-reinforced polymer matrices. Processes such as hand layup, automated fiber placement, and resin transfer molding are used to create complex shapes with high strength-to-weight ratios. Material specialists must possess expertise in composite materials science, processing techniques, and quality control methods to ensure the performance and reliability of composite structures. For example, controlling fiber alignment and resin impregnation during composite wing fabrication is critical to achieving optimal stiffness and strength. Proper management of composite layups is an important part of the job.

- Additive Manufacturing (3D Printing)

Additive manufacturing offers the ability to create complex geometries and customized components directly from digital designs. Processes such as powder bed fusion and directed energy deposition are used to build up parts layer by layer, enabling the creation of lightweight, high-performance structures. Material specialists must understand the relationship between process parameters, material microstructure, and mechanical properties to ensure the quality and consistency of additively manufactured parts. As an illustration, optimizing laser power and scan speed during powder bed fusion of titanium alloys is crucial to minimizing porosity and achieving desired tensile strength. Material selection is key.

In conclusion, positions concerned with aerospace materials require a comprehensive understanding of various manufacturing processes. The properties of materials are affected by these processes. From casting and forging to machining, joining, composite manufacturing, and additive manufacturing, the selection, application, and performance of materials are inextricably linked to the methods used to fabricate aerospace components. A deep comprehension of these manufacturing techniques is essential for ensuring the structural integrity, optimizing material properties, and achieving cost-effective production in the aerospace industry.

6. Regulatory Compliance

The aerospace industry operates under stringent regulatory frameworks designed to ensure safety and reliability. These regulations, established by bodies such as the Federal Aviation Administration (FAA) and the European Aviation Safety Agency (EASA), directly impact positions involving materials. Individuals in these roles must possess a thorough understanding of applicable standards and requirements, as material selection, processing, and testing are all subject to regulatory oversight. Non-compliance can result in significant consequences, including production delays, financial penalties, and, most critically, compromised safety. For example, the use of unapproved materials in aircraft construction can lead to structural failures, highlighting the critical link between material choices and regulatory adherence.

The impact of regulatory compliance extends across various aspects of materials-related positions. Material specifications, manufacturing processes, and quality control procedures must all align with regulatory guidelines. Furthermore, documentation and traceability are paramount; detailed records must be maintained to demonstrate that materials meet specified requirements. An illustrative case is the implementation of a rigorous traceability system for titanium alloys used in aircraft engines, ensuring that each component can be traced back to its origin and manufacturing history. This level of accountability is essential for maintaining airworthiness and preventing potential safety hazards. Regulatory adherence is paramount.

In summary, regulatory compliance is an indispensable component of positions within the aerospace materials sector. A comprehensive understanding of regulations, coupled with meticulous attention to detail, is essential for ensuring the safety, reliability, and airworthiness of aircraft and spacecraft. While navigating the complex regulatory landscape presents challenges, adherence to these guidelines is non-negotiable, safeguarding both the public and the integrity of the aerospace industry. Positions involving materials are responsible for upholding the specified standards.

Frequently Asked Questions Regarding Aerospace Materials Jobs

The following questions and answers address common inquiries and misconceptions related to career opportunities focused on materials within the aerospace sector.

Question 1: What specific educational background is typically required to secure positions involved with aerospace materials?

A bachelor’s degree in materials science, aerospace engineering, mechanical engineering, or a closely related field is generally the minimum requirement. Advanced degrees, such as a Master’s or Ph.D., are often preferred for research and development-oriented roles.

Question 2: Are there specific certifications that can enhance an individual’s prospects for positions involving aerospace materials?

Professional certifications offered by organizations such as ASM International and the Society for the Advancement of Material and Process Engineering (SAMPE) can demonstrate specialized knowledge and commitment to professional development, thereby enhancing career prospects.

Question 3: What are the primary skill sets that employers seek in candidates for positions involving aerospace materials?

Employers typically seek candidates with a strong foundation in materials science, proficiency in manufacturing processes, experience with relevant software tools (e.g., FEA, CAD), and a demonstrated ability to solve complex engineering problems.

Question 4: What types of tasks might an individual in a materials-focused position in the aerospace industry be expected to perform on a daily basis?

Daily tasks can vary depending on the specific role, but may include material selection, testing, failure analysis, process optimization, design collaboration, and regulatory compliance activities.

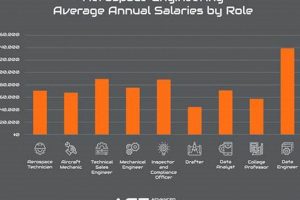

Question 5: What is the typical career progression for individuals working in the field of aerospace materials?

Career progression often begins with entry-level engineering positions and can advance to roles such as senior materials engineer, project manager, research scientist, or technical specialist, depending on individual expertise and career goals.

Question 6: What is the general outlook for positions related to aerospace materials in the coming years?

The outlook for these positions is generally positive, driven by ongoing advancements in aerospace technology, increasing demand for fuel-efficient aircraft, and growing investment in space exploration. Expertise in advanced composites, additive manufacturing, and sustainable materials is particularly valuable.

This FAQ section provides clarity on key aspects relevant to professionals and aspiring candidates in the specialized field of aerospace material science.

The discussion transitions now to a consideration of the future of aerospace materials and the emerging trends shaping the industry.

Aerospace Materials Jobs

This article has explored various facets of “aerospace materials jobs,” emphasizing the essential role these positions play in advancing the aerospace industry. From material selection and testing to manufacturing processes and regulatory compliance, expertise in this domain is crucial for ensuring the safety, performance, and reliability of aircraft and spacecraft. The discussion highlighted the diverse skill sets required, potential career paths, and the generally positive outlook for professionals in this field.

The ongoing pursuit of lighter, stronger, and more sustainable substances will continue to drive demand for qualified individuals capable of addressing the challenges and opportunities presented by emerging technologies. Aspiring professionals are encouraged to cultivate a robust foundation in materials science, actively seek practical experience, and remain abreast of the latest advancements to make a significant contribution to this vital and evolving sector. The progress of aerospace technology hinges on the dedicated efforts of those in “aerospace materials jobs”.