These two disciplines represent cornerstones of modern technology and innovation. One concentrates on the design, development, and testing of aircraft and spacecraft, while the other focuses on the design, manufacturing, and operation of mechanical systems. Professionals in these fields apply principles of physics, mathematics, and materials science to create solutions for a wide range of applications.

The impact of these engineering specializations is significant. From advancements in air travel and space exploration to improvements in manufacturing processes and energy systems, their contributions have shaped society. Historically, they have driven technological progress, fostering economic growth and enhancing the quality of life.

The following sections will delve into the specific areas of study, career opportunities, and emerging trends associated with these vital areas of engineering, providing a comprehensive understanding of their scope and potential.

Essential Guidance for Aspiring Professionals

This section offers crucial guidance for individuals considering a career in either aerospace or mechanical engineering. Adhering to these recommendations can enhance academic success and professional preparedness.

Tip 1: Develop a Strong Foundation in Mathematics and Physics: A robust understanding of calculus, differential equations, linear algebra, and classical mechanics is fundamental. These principles underpin the analysis and design processes in both fields.

Tip 2: Cultivate Proficiency in Computer-Aided Design (CAD) Software: Familiarity with industry-standard CAD software is essential for creating and modifying engineering designs. Examples include SolidWorks, CATIA, and AutoCAD.

Tip 3: Pursue Relevant Internships and Research Opportunities: Gaining practical experience through internships or research projects provides invaluable insights into real-world engineering challenges and industry practices. Actively seek out opportunities at aerospace companies, research institutions, or manufacturing firms.

Tip 4: Hone Problem-Solving and Analytical Skills: These disciplines require the ability to identify, analyze, and solve complex engineering problems. Practice applying theoretical knowledge to practical scenarios and develop critical thinking skills.

Tip 5: Enhance Communication Skills: Engineers must effectively communicate technical information to colleagues, clients, and stakeholders. Practice writing technical reports, giving presentations, and participating in team discussions.

Tip 6: Stay Current with Emerging Technologies: Both fields are constantly evolving with advancements in materials science, artificial intelligence, and advanced manufacturing techniques. Continuously seek opportunities to learn about and adapt to these developments.

Tip 7: Consider Specialization: As careers progress, specializing in a specific area, such as propulsion systems, structural analysis, or robotics, can enhance expertise and career prospects.

Implementing these tips can significantly increase the likelihood of success in these challenging but rewarding engineering domains.

The subsequent sections will provide a detailed overview of potential career paths and future trends within these dynamic industries.

1. Thermodynamics

Thermodynamics is an indispensable foundation within both aerospace and mechanical engineering. It governs the behavior of energy and its transformations, influencing the design and optimization of numerous systems. Understanding thermodynamic principles is crucial for engineers seeking to improve efficiency, reduce waste, and ensure the reliable operation of complex machinery.

- Power Generation and Propulsion

Thermodynamics directly impacts power generation, including internal combustion engines, gas turbines, and steam power plants. In aerospace, it is fundamental to the design and analysis of jet engines and rocket propulsion systems. Mechanical engineers apply these principles to improve the efficiency of power plants and explore alternative energy sources, while aerospace engineers optimize engine cycles for greater thrust and fuel efficiency.

- Heat Transfer

The study of heat transfer is essential for managing thermal loads in aerospace vehicles and mechanical systems. Thermodynamics dictates how heat is generated, transferred, and dissipated. In aerospace, this includes managing heat generated during atmospheric reentry. For mechanical engineering, this is relevant in designing heat exchangers, cooling systems for electronic devices, and optimizing insulation for buildings.

- Fluid Mechanics and Compressible Flow

Thermodynamic principles govern the behavior of fluids, especially gases, under varying pressure and temperature conditions. This is crucial for analyzing aerodynamic forces on aircraft (aerospace) and designing efficient pipelines and pumps (mechanical). The study of compressible flow, involving high-speed gases, is particularly important in aerospace engineering for designing supersonic and hypersonic vehicles.

- Refrigeration and Air Conditioning

Thermodynamics provides the theoretical framework for refrigeration and air conditioning systems. Mechanical engineers design and optimize these systems for residential, commercial, and industrial applications, ensuring efficient cooling and heating. While less direct, aerospace applications benefit from this knowledge through the design of climate control systems within aircraft cabins and the cooling of sensitive electronic equipment.

The effective application of thermodynamics enables advancements across a wide spectrum of engineering challenges. From optimizing combustion cycles for cleaner emissions to developing advanced cooling technologies for extreme environments, these principles remain integral to the continued innovation within both aerospace and mechanical engineering.

2. Fluid Dynamics

Fluid dynamics is a fundamental discipline underpinning many aspects of both aerospace and mechanical engineering. It governs the behavior of liquids and gases in motion, providing the theoretical framework for analyzing and designing systems that interact with or are influenced by fluids. The accurate prediction and control of fluid flow are critical for ensuring the performance, efficiency, and safety of numerous engineering applications. For instance, the lift and drag characteristics of an aircraft wing, designed by an aerospace engineer, are directly determined by fluid dynamics principles. Similarly, a mechanical engineer relies on fluid dynamics to design efficient pumps and turbines for power generation or to optimize the flow of coolant through a heat exchanger.

The practical applications of fluid dynamics extend to diverse fields. In aerospace engineering, understanding fluid dynamics is essential for designing aerodynamic surfaces, optimizing engine intakes and exhausts, and predicting the trajectory of projectiles. Computational Fluid Dynamics (CFD) simulations, based on fluid dynamics equations, allow engineers to model complex flow phenomena and evaluate the performance of designs before physical prototypes are even built. Within mechanical engineering, fluid dynamics plays a critical role in designing pipelines for transporting oil and gas, analyzing the flow of air within ventilation systems, and optimizing the performance of hydraulic machinery. The behavior of wind turbines, crucial for renewable energy generation, is also heavily reliant on fluid dynamic principles.

Challenges in fluid dynamics often arise from the complexity of turbulent flows, which are difficult to model accurately. The advancement of computational methods and experimental techniques continues to push the boundaries of understanding, allowing engineers to tackle increasingly complex problems. In conclusion, a thorough grasp of fluid dynamics is indispensable for engineers in both aerospace and mechanical domains, enabling them to design and optimize systems that harness or interact with the power of moving fluids. These disciplines intertwine to deliver functional and effective products.

3. Materials Science

Materials science forms a crucial link within both aerospace and mechanical engineering. The selection, processing, and characterization of materials directly impact the performance, safety, and longevity of engineering designs. In aerospace, where weight is a critical factor, advanced materials such as titanium alloys, composites, and high-temperature ceramics are essential for constructing aircraft and spacecraft. These materials enable engineers to achieve high strength-to-weight ratios, withstand extreme temperatures, and resist corrosion. For example, the development of carbon fiber reinforced polymers has revolutionized aircraft design, allowing for lighter and more fuel-efficient planes. Similarly, in mechanical engineering, materials science dictates the choice of metals, polymers, and ceramics for components ranging from engine blocks to gears and bearings. The durability and reliability of these components depend on the appropriate selection of materials that can withstand specific loads, temperatures, and environmental conditions. The effectiveness of these choices reflects the knowledge of the engineer.

The impact of materials science extends beyond simply selecting existing materials; it also encompasses the development of new materials with tailored properties. Researchers in materials science collaborate with engineers to create alloys with enhanced strength and corrosion resistance, develop new composite materials with improved toughness and stiffness, and synthesize ceramics with superior thermal properties. These advancements often lead to breakthrough innovations in both aerospace and mechanical engineering. For instance, the development of nickel-based superalloys has enabled the design of more efficient and powerful jet engines, while the creation of shape memory alloys has led to innovative actuators and sensors for various mechanical systems. Material selection reflects the need for components to resist various environmental factors that could impact overall safety and durability.

In conclusion, materials science is an integral component of both aerospace and mechanical engineering. Its influence spans from the selection of existing materials to the development of novel compounds with tailored properties. The understanding of material behavior under different conditions is paramount to achieving optimal performance, reliability, and safety in engineering designs. Challenges remain in developing materials that can withstand increasingly demanding environments, such as extreme temperatures, high pressures, and corrosive atmospheres. Continued research and collaboration between materials scientists and engineers will be essential for pushing the boundaries of innovation and shaping the future of both these critical fields. The connection between materials science, aerospace and mechanical engineering is therefore vital.

4. Control Systems

Control systems are integral to the functionality and performance of both aerospace and mechanical engineering applications. These systems, often incorporating feedback loops and automated decision-making, manage and regulate the behavior of dynamic systems to achieve desired outcomes. In aerospace engineering, control systems are essential for flight stability, navigation, and the autonomous operation of aircraft and spacecraft. An autopilot system in an airplane, for example, uses sensors to monitor altitude, heading, and airspeed, and then automatically adjusts control surfaces to maintain a predetermined flight path. Similarly, satellite attitude control systems employ sensors and actuators to maintain the correct orientation of the spacecraft in orbit. The effectiveness of these systems is directly tied to the overall safety and mission success.

Within mechanical engineering, control systems are widely used in robotics, manufacturing, and process control. Industrial robots rely on sophisticated control systems to execute precise movements and perform complex tasks, contributing to increased productivity and efficiency. In manufacturing plants, control systems regulate temperature, pressure, and flow rates in production lines, ensuring consistent product quality and minimizing waste. Furthermore, advanced vehicle systems, such as anti-lock braking (ABS) and electronic stability control (ESC), employ control algorithms to enhance safety and prevent accidents. Each of these systems illustrates a direct impact of control systems on critical functions.

The continued development and refinement of control systems are essential for advancing both aerospace and mechanical engineering. Challenges remain in designing robust and adaptive control systems that can handle uncertainties, disturbances, and changing operating conditions. The integration of artificial intelligence and machine learning techniques into control systems is enabling the development of more intelligent and autonomous systems. Future innovations in control systems will likely play a pivotal role in enabling the next generation of aircraft, spacecraft, robots, and automated manufacturing processes, leading to enhanced performance, efficiency, and reliability in both fields. The reliability and performance of the end product depend highly on the Control system in place.

5. Design Innovation

Design innovation serves as the driving force behind advancements in both aerospace and mechanical engineering. It entails the application of creative and systematic methodologies to develop novel solutions, improve existing technologies, and address emerging challenges within these fields. The ability to conceive, prototype, and implement innovative designs is paramount for maintaining competitiveness and pushing the boundaries of engineering capabilities. The pursuit of efficiency, safety, and sustainability heavily relies on design innovation.

- Conceptualization and Ideation

This facet encompasses the initial stages of design, involving the generation and evaluation of ideas. Engineers explore diverse concepts, considering feasibility, performance, and cost-effectiveness. For example, the development of a new wing design for an aircraft may involve numerous iterations of conceptual sketches, simulations, and wind tunnel testing. In mechanical engineering, conceptualization could involve brainstorming novel solutions for energy storage or developing more efficient combustion engines. The process requires both creative thinking and a thorough understanding of fundamental engineering principles.

- Prototyping and Testing

Once a design concept is selected, engineers create prototypes to validate its functionality and performance. Prototyping may involve physical models, computer simulations, or virtual reality environments. Extensive testing is conducted to identify potential flaws, optimize performance, and ensure compliance with safety standards. For example, aerospace engineers may build a scaled-down model of a new aircraft design and subject it to rigorous wind tunnel tests to measure lift, drag, and stability. Mechanical engineers might prototype a new engine component and subject it to endurance tests to evaluate its reliability under extreme conditions. These steps reflect the core of innovative design.

- Materials and Manufacturing Processes

Design innovation often necessitates the exploration and utilization of advanced materials and manufacturing processes. Engineers may investigate new alloys, composites, or nanomaterials to achieve specific performance characteristics. Furthermore, innovative manufacturing techniques, such as additive manufacturing (3D printing), can enable the creation of complex geometries and customized designs. For example, aerospace engineers are exploring the use of lightweight composites in aircraft structures to reduce weight and improve fuel efficiency. Mechanical engineers are employing 3D printing to create customized tooling and prototypes with intricate designs.

- Integration and Optimization

Design innovation culminates in the integration of various components and subsystems into a cohesive and optimized system. Engineers must carefully consider the interactions between different parts and ensure that they work together seamlessly. Optimization techniques, such as finite element analysis and computational fluid dynamics, are used to refine the design and maximize performance. For example, aerospace engineers may use these tools to optimize the aerodynamic shape of an aircraft to minimize drag and improve fuel efficiency. Mechanical engineers may optimize the design of a heat exchanger to maximize heat transfer and minimize energy consumption. Integration and overall optimization are at the center of design innovation.

The facets of design innovation highlight the iterative and interdisciplinary nature of engineering. From conceptualization to integration, engineers must continuously refine their designs to meet stringent performance, safety, and cost requirements. The successful implementation of design innovation leads to advancements in both aerospace and mechanical engineering, driving progress across a wide range of industries. The link between design innovation and overall efficiency in both engineering fields is unmistakable.

Frequently Asked Questions

The following questions address common inquiries regarding aerospace or mechanical engineering as career paths and areas of study. These answers aim to provide factual and objective information to prospective students and professionals.

Question 1: What distinguishes aerospace engineering from mechanical engineering?

Aerospace engineering focuses on the design, development, and testing of aircraft and spacecraft, encompassing aerodynamics, propulsion, and structural analysis specific to flight vehicles. Mechanical engineering addresses the design, manufacturing, and operation of mechanical systems, including engines, machines, and thermal systems across diverse industries.

Question 2: Which degree offers broader career opportunities?

Mechanical engineering generally provides a broader range of career options due to its applicability across numerous industries, including manufacturing, energy, automotive, and robotics. Aerospace engineering, while specialized, offers focused opportunities within the aerospace industry, government agencies, and research institutions.

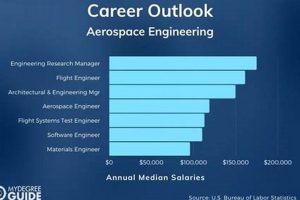

Question 3: What are the typical salary expectations for graduates?

Entry-level salaries vary based on location, employer, and specialization. However, both aerospace and mechanical engineering graduates typically command competitive starting salaries, often exceeding the national average for all bachelor’s degrees. Compensation tends to increase with experience, advanced degrees, and specialized skills.

Question 4: Is advanced mathematics a prerequisite for success in these fields?

A strong foundation in mathematics, including calculus, differential equations, and linear algebra, is essential for both aerospace and mechanical engineering. These mathematical principles underpin the analysis, modeling, and design processes used in these disciplines. Proficiency in mathematical software and tools is also highly valued.

Question 5: Are internships crucial for career advancement?

Internships are highly recommended for gaining practical experience, networking with industry professionals, and enhancing career prospects. Employers often prioritize candidates with relevant internship experience, as it demonstrates applied knowledge and workplace skills.

Question 6: What are the emerging trends influencing these fields?

Several emerging trends are shaping aerospace and mechanical engineering, including the development of sustainable energy technologies, the integration of artificial intelligence and machine learning, advancements in additive manufacturing (3D printing), and the exploration of new materials. Staying abreast of these trends is essential for long-term career growth.

This FAQ section provides a brief overview of key considerations when evaluating these fields. Further research and consultation with professionals are recommended for making informed decisions.

The following sections will examine resources for further learning in these areas.

Concluding Remarks

This exploration has highlighted core aspects of both aerospace and mechanical engineering, underscoring their significance in technological advancement and societal progress. Each field demands a rigorous understanding of fundamental principles and a commitment to continuous learning, driven by innovation and precision. The discussion has identified key distinctions, commonalities, and emerging trends, aiming to provide a comprehensive overview.

The challenges and opportunities within these domains continue to evolve, requiring dedicated professionals to push the boundaries of what is possible. Further investigation and engagement with these disciplines are encouraged for those seeking to contribute to the future of engineering. The future trajectory of both aerospace and mechanical engineering is one of continued advancement, driven by dedicated professionals.