Positions overseeing the manufacturing processes within the aviation and space industries are critical for ensuring efficient operations and meeting stringent quality standards. These roles involve planning, directing, and coordinating the activities required to produce aircraft, spacecraft, and related components. An example includes a professional who manages the assembly line for commercial airplane wings, ensuring adherence to design specifications and production deadlines.

These roles are vital due to their direct impact on project success, cost control, and regulatory compliance. Efficient production management translates to reduced manufacturing costs, timely project delivery, and adherence to strict aerospace regulations concerning safety and performance. Historically, the importance of such roles has grown alongside the increasing complexity of aircraft and spacecraft, as well as the tightening of industry standards.

The following sections will explore the specific responsibilities, required skills, educational background, and career outlook associated with this crucial area of aerospace engineering and manufacturing.

This section offers essential guidance for individuals seeking or currently fulfilling positions related to overseeing manufacturing in the aerospace sector. These tips are designed to enhance professional performance and career advancement.

Tip 1: Cultivate a Deep Understanding of Aerospace Standards: Familiarity with regulatory frameworks such as AS9100 and FAA guidelines is paramount. Demonstrate expertise in these standards to ensure compliance and product quality.

Tip 2: Master Resource Allocation and Optimization: Efficient management requires astute allocation of personnel, equipment, and materials. Implement strategies to minimize waste and maximize productivity within budgetary constraints.

Tip 3: Develop Strong Leadership and Communication Skills: Effective leadership is crucial for motivating teams and fostering collaboration. Clearly articulate goals, delegate tasks effectively, and provide constructive feedback to improve performance.

Tip 4: Embrace Continuous Improvement Methodologies: Implement Lean Manufacturing principles and Six Sigma methodologies to identify and eliminate inefficiencies in production processes. Regularly evaluate performance metrics and adapt strategies accordingly.

Tip 5: Prioritize Safety and Risk Mitigation: Adherence to stringent safety protocols is non-negotiable. Implement comprehensive safety training programs and conduct regular risk assessments to prevent accidents and ensure a safe working environment.

Tip 6: Foster Collaboration with Engineering and Design Teams: Seamless integration between production and design is critical for efficient manufacturing. Establish clear communication channels and actively participate in design reviews to identify potential production challenges early on.

Tip 7: Stay Abreast of Technological Advancements: The aerospace industry is constantly evolving. Invest in professional development to stay informed about the latest manufacturing technologies, such as additive manufacturing and automation, to maintain a competitive edge.

By implementing these strategies, professionals can significantly enhance their effectiveness and contribute to the success of aerospace manufacturing operations. A commitment to continuous learning and adaptation is essential for long-term career growth in this dynamic field.

The subsequent section will address the educational requirements and typical career paths associated with these roles.

1. Leadership

Leadership constitutes a foundational element for professionals overseeing manufacturing within the aerospace sector. These roles necessitate the ability to guide, motivate, and coordinate diverse teams of engineers, technicians, and production staff toward shared objectives. Effective leadership directly impacts production efficiency, product quality, and the overall morale of the workforce. Without strong direction, projects are susceptible to delays, errors, and budgetary overruns.

Consider, for example, a scenario where a new aircraft component design requires implementation on an existing production line. A leader must articulate the changes clearly, provide adequate training, and address concerns from team members who may be resistant to change. Moreover, they must manage conflicts that may arise from differing perspectives or resource allocation. Poor leadership in this instance could lead to a breakdown in communication, resulting in misinterpretations of the design specifications and, ultimately, defective parts. In contrast, a strong leader fosters a collaborative environment where team members feel empowered to voice concerns and contribute to problem-solving, leading to a smoother transition and higher-quality output.

The capacity to inspire trust, delegate tasks effectively, and provide constructive feedback are critical attributes of successful aerospace production managers. Furthermore, a leader must demonstrate a commitment to continuous improvement and prioritize safety above all else. Understanding the integral role of leadership enables individuals to cultivate these essential qualities, thereby enhancing their effectiveness in this demanding field and contributing to the advancement of aerospace manufacturing as a whole.

2. Optimization

Optimization is intrinsically linked to the role of professionals overseeing manufacturing operations in the aerospace sector. The capacity to streamline processes, reduce waste, and maximize resource utilization is paramount to meeting stringent industry demands and maintaining a competitive edge.

- Resource Allocation Efficiency

Effective distribution of personnel, equipment, and raw materials directly impacts production throughput and cost efficiency. Aerospace production managers must analyze workflows, identify bottlenecks, and implement strategies to minimize idle time and maximize output. For example, optimizing the scheduling of machine maintenance to coincide with periods of lower production demand prevents disruptions and ensures consistent operation.

- Process Streamlining

Identifying and eliminating redundancies or inefficiencies in manufacturing processes is critical for reducing lead times and improving overall productivity. This may involve implementing Lean Manufacturing principles, such as value stream mapping, to identify non-value-added activities. An aerospace production manager might oversee the redesign of a component assembly process to reduce the number of steps or automate repetitive tasks.

- Supply Chain Management Optimization

The aerospace industry relies on a complex network of suppliers for raw materials and components. Optimizing the supply chain involves minimizing lead times, reducing inventory costs, and ensuring timely delivery of materials. This requires building strong relationships with suppliers, implementing just-in-time inventory management systems, and proactively managing potential supply chain disruptions.

- Technological Integration for Enhanced Performance

The adoption and integration of advanced technologies, such as automation, robotics, and data analytics, play a significant role in optimizing aerospace manufacturing processes. Aerospace production managers must evaluate emerging technologies, assess their potential impact on production efficiency, and oversee their implementation. An example includes integrating automated inspection systems to improve quality control and reduce manual inspection time.

These interconnected facets of optimization collectively contribute to enhanced efficiency, reduced costs, and improved product quality within aerospace manufacturing operations. The successful implementation of optimization strategies is directly linked to the effectiveness of professionals in these oversight roles, demonstrating the crucial intersection between optimized processes and successful project outcomes within the industry.

3. Compliance

Compliance serves as a non-negotiable cornerstone within the realm of aerospace production management. The intricate relationship between these roles and adherence to regulations stems from the industry’s commitment to safety, reliability, and performance standards. A primary cause of non-compliance can be traced to inadequate understanding or enforcement of industry-specific standards, such as AS9100, which outlines quality management system requirements for aviation, space, and defense organizations. The effect of non-compliance can range from production delays and financial penalties to, more critically, compromised product integrity and safety risks. The importance of compliance is underscored by the fact that aerospace products are subject to rigorous scrutiny throughout their lifecycle, from design and manufacturing to maintenance and operation.

The practical significance of understanding compliance is exemplified by the responsibilities of production managers in maintaining meticulous documentation and traceability. For instance, a production manager overseeing the fabrication of aircraft engine components must ensure that each part is manufactured according to approved specifications and that every stage of the production process is documented accurately. This includes verifying material certifications, conducting inspections, and recording test results. Failure to maintain proper documentation can lead to difficulties in identifying and resolving defects, as well as jeopardizing the airworthiness certification of the aircraft. Furthermore, aerospace production managers must foster a culture of compliance within their teams, providing adequate training and promoting adherence to established procedures. This proactive approach helps to mitigate the risk of errors and ensures that all employees understand the critical importance of following regulatory guidelines.

In summary, compliance forms an indispensable component of aerospace production management, driven by the imperative to uphold safety and maintain product quality. Challenges in maintaining compliance often stem from the complexity of industry regulations and the potential for human error. Addressing these challenges requires a comprehensive approach that encompasses thorough training, robust quality control processes, and a commitment to continuous improvement. By prioritizing compliance, aerospace production managers contribute directly to the overall integrity and reliability of the industry, safeguarding lives and promoting technological advancement.

4. Budgeting

Budgeting is an essential function within aerospace manufacturing oversight, directly impacting project viability and long-term financial stability. Competent budget management ensures resources are allocated effectively, cost overruns are minimized, and profitability targets are achieved. The accuracy and efficiency with which budgets are constructed and managed are key indicators of a production manager’s overall performance.

- Capital Expenditure Management

This encompasses the planning and oversight of significant investments in equipment, facilities, and technology. An aerospace production manager must justify capital expenditures by demonstrating a clear return on investment, such as increased production capacity, reduced labor costs, or improved product quality. For example, the decision to invest in a new automated assembly line requires a detailed analysis of its upfront costs, projected savings, and impact on overall production efficiency. Failure to accurately forecast these factors can lead to budget deficits and delayed project timelines.

- Operating Expense Control

This involves the day-to-day management of expenses related to labor, materials, energy, and maintenance. Maintaining control over operating expenses requires careful monitoring of key performance indicators (KPIs) and the implementation of cost-saving measures. For example, an aerospace production manager might negotiate contracts with suppliers to reduce material costs, implement energy-efficient practices to lower utility bills, or optimize workforce scheduling to minimize overtime expenses. Neglecting operating expense control can erode profitability and compromise the financial health of the organization.

- Variance Analysis and Corrective Action

This entails the regular comparison of actual financial performance against the approved budget. When significant variances occur, an aerospace production manager must investigate the underlying causes and implement corrective actions to bring spending back in line with budgetary targets. For example, if material costs unexpectedly increase due to supply chain disruptions, the production manager might explore alternative sourcing options or implement process improvements to reduce material waste. Proactive variance analysis is crucial for identifying potential financial problems early on and preventing them from escalating.

- Forecasting and Resource Planning

Budgeting in aerospace production is not static; it requires accurate forecasting of future demand, production volumes, and market conditions. This information is used to develop realistic budgets and allocate resources effectively. For example, if a new aircraft program is launched, the aerospace production manager must forecast the demand for parts and components, estimate the associated production costs, and secure the necessary funding and resources. Accurate forecasting is essential for ensuring that the organization has the capacity to meet customer demand while remaining within budgetary constraints.

These elements of budgeting are inextricably linked to the responsibilities of professionals in overseeing aerospace manufacturing. Effective budgeting enables these professionals to make informed decisions, optimize resource allocation, and ultimately contribute to the financial success and sustainable growth of the organization. Conversely, poor budgeting practices can lead to cost overruns, production inefficiencies, and compromised product quality, highlighting the importance of financial acumen in these roles.

5. Problem-solving

Problem-solving is a core competency intrinsic to positions overseeing manufacturing within the aerospace sector. These roles necessitate the ability to identify, analyze, and resolve challenges that arise during the production process to maintain efficiency and adhere to rigorous industry standards. Effective problem-solving directly impacts production schedules, product quality, and overall operational effectiveness.

- Root Cause Analysis Expertise

Aerospace production managers must possess the skill to determine the underlying causes of production issues, rather than merely addressing surface-level symptoms. The application of methodologies such as the “5 Whys” or Ishikawa diagrams is crucial. For example, if a batch of composite material exhibits inconsistencies, the manager must investigate whether the issue stems from improper storage, flawed mixing ratios, or equipment malfunctions. Accurately identifying the root cause ensures that corrective actions are targeted and effective, preventing recurrence.

- Decision-Making Under Pressure

Unexpected disruptions, such as equipment breakdowns or material shortages, often require swift and decisive action. Aerospace production managers must evaluate the potential consequences of various solutions, weigh competing priorities, and make informed decisions under pressure. Consider a scenario where a critical piece of machinery malfunctions, potentially halting a major assembly line. The manager must assess the feasibility of repair options, evaluate alternative production methods, and communicate effectively with stakeholders to minimize downtime.

- Implementation of Corrective Actions

After identifying the root cause of a problem and selecting a suitable solution, aerospace production managers must oversee the implementation of corrective actions and monitor their effectiveness. This may involve modifying production processes, retraining personnel, or collaborating with engineering teams to implement design changes. The manager must track key performance indicators (KPIs) to ensure that the implemented solutions achieve the desired results and prevent the problem from reoccurring.

- Collaboration and Communication

Effective problem-solving in aerospace production frequently requires collaboration across different departments and levels of expertise. Aerospace production managers must be able to communicate clearly and concisely with engineers, technicians, and other stakeholders to gather information, solicit input, and coordinate efforts. For example, resolving a recurring issue with a particular component might necessitate collaboration between the production team, the design engineers, and the quality control department. Fostering open communication and teamwork is essential for identifying and implementing effective solutions.

These facets of problem-solving highlight the critical role these skills play in positions overseeing manufacturing in aerospace. Success in these roles is directly linked to the ability to proactively address challenges, optimize production processes, and maintain adherence to stringent industry requirements. Consequently, individuals in these positions are expected to demonstrate proficiency in problem-solving methodologies, decision-making, and communication to ensure the continuous improvement and reliability of aerospace manufacturing operations.

6. Scheduling

Effective scheduling is paramount in aerospace manufacturing, serving as a critical function overseen by production managers. Its role encompasses the meticulous planning and coordination of resources, activities, and timelines to ensure efficient production processes and timely delivery of products. This element directly influences project success, cost control, and adherence to regulatory requirements within the aerospace sector.

- Resource Allocation Efficiency

Scheduling directly dictates the assignment of personnel, equipment, and materials to specific tasks and production stages. Aerospace production managers must optimize resource allocation to minimize idle time, prevent bottlenecks, and maximize throughput. For example, scheduling skilled technicians for critical assembly tasks and ensuring the availability of specialized equipment when needed are essential for maintaining production momentum. Inefficient resource allocation can result in delays, increased costs, and compromised product quality.

- Workflow Optimization and Sequencing

Scheduling involves determining the optimal sequence of tasks and activities to minimize production cycle times and improve overall efficiency. Aerospace production managers must analyze workflows, identify dependencies, and prioritize tasks based on criticality and resource availability. An example includes scheduling the fabrication of sub-assemblies to align with the final assembly schedule, preventing delays in the overall production process. Poor sequencing can lead to bottlenecks and disruptions, impeding the timely completion of projects.

- Mitigation of Disruptions and Contingency Planning

Effective scheduling includes anticipating potential disruptions, such as equipment breakdowns, material shortages, or workforce absences, and developing contingency plans to minimize their impact. Aerospace production managers must incorporate buffer times into schedules, establish alternative sourcing options for critical materials, and implement flexible work arrangements to mitigate unforeseen circumstances. For example, having backup machinery available and trained personnel capable of operating it can help minimize downtime in the event of equipment failure. Failure to plan for disruptions can result in significant delays and cost overruns.

- Adherence to Regulatory Timelines and Milestones

Scheduling in aerospace manufacturing must align with stringent regulatory timelines and project milestones to ensure compliance with industry standards and contractual obligations. Aerospace production managers must track progress against established timelines, identify potential delays, and implement corrective actions to maintain schedule adherence. For instance, scheduling regular inspections and tests to meet airworthiness certification requirements is critical for ensuring that aircraft are delivered on time and meet regulatory standards. Non-compliance with regulatory timelines can result in penalties and delays in product delivery.

These aspects of scheduling are inextricably linked to the responsibilities of aerospace production managers, emphasizing the critical role they play in optimizing production processes, mitigating risks, and ensuring timely project completion. Proficiency in scheduling techniques and tools is essential for professionals in these roles to maintain efficiency, control costs, and meet the stringent demands of the aerospace industry.

7. Quality Assurance

Quality assurance forms an integral component of manufacturing operations within the aerospace sector. Its significance is amplified by the stringent safety and performance requirements inherent in aviation and space applications. The responsibilities of professionals in oversight positions are inextricably linked to ensuring the maintenance of rigorous quality standards throughout the production lifecycle.

- Implementation of Quality Management Systems

Aerospace production managers are tasked with implementing and maintaining comprehensive quality management systems, such as AS9100. These systems provide a framework for ensuring that all processes, from design and procurement to manufacturing and testing, meet established quality standards. For example, a production manager may oversee the implementation of statistical process control (SPC) techniques to monitor key production parameters and identify potential deviations from specified limits. Effective quality management systems minimize the risk of defects and ensure consistent product quality.

- Oversight of Inspection and Testing Procedures

Aerospace production managers are responsible for overseeing the execution of thorough inspection and testing procedures at various stages of the manufacturing process. This includes visual inspections, non-destructive testing (NDT), and functional testing to verify that products meet design specifications and performance requirements. For example, a production manager may supervise the radiographic inspection of welded joints on aircraft structures to detect internal flaws. Rigorous inspection and testing procedures are essential for identifying and rectifying defects before products are released for use.

- Management of Non-Conformance and Corrective Actions

Aerospace production managers must establish processes for managing non-conforming materials or products, including identifying the root causes of defects, implementing corrective actions to prevent recurrence, and verifying the effectiveness of those actions. For example, if a batch of machined parts fails to meet dimensional tolerances, the production manager must investigate the manufacturing process, identify the source of the error, and implement corrective measures, such as recalibrating machinery or retraining personnel. Effective management of non-conformance is crucial for preventing defective products from reaching customers and maintaining product integrity.

- Continuous Improvement Initiatives

Aerospace production managers are expected to drive continuous improvement in quality performance by identifying opportunities for process optimization, implementing best practices, and promoting a culture of quality throughout the organization. This may involve implementing Lean Manufacturing principles, such as Six Sigma, to reduce variation and improve process capability. For example, a production manager may lead a cross-functional team to streamline the assembly process for a particular component, reducing the number of steps and improving overall efficiency. Continuous improvement initiatives are essential for maintaining a competitive edge and ensuring long-term quality excellence.

These interconnected facets of quality assurance underscore its significance within the responsibilities of professionals overseeing aerospace manufacturing operations. Maintaining rigorous quality standards is not only essential for ensuring the safety and reliability of aerospace products, but also for meeting customer expectations and complying with regulatory requirements. The effectiveness with which aerospace production managers implement and manage quality assurance processes directly impacts the success and sustainability of the organization.

Frequently Asked Questions

This section addresses common inquiries regarding positions overseeing manufacturing processes within the aerospace sector. The information aims to provide clarity and valuable insights.

Question 1: What are the primary responsibilities associated with positions overseeing manufacturing in the aerospace industry?

Primary responsibilities encompass the planning, direction, and coordination of all activities necessary for the efficient manufacturing of aircraft, spacecraft, and related components. This includes ensuring adherence to design specifications, regulatory requirements, and project deadlines.

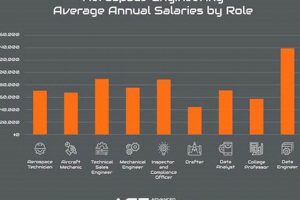

Question 2: What educational background is typically required for positions overseeing manufacturing in the aerospace sector?

A bachelor’s degree in engineering, manufacturing technology, or a related field is generally expected. Advanced degrees, such as a master’s in business administration or engineering management, may be beneficial for career advancement.

Question 3: What specific skills are essential for success in positions overseeing manufacturing in the aerospace industry?

Essential skills include strong leadership abilities, proficiency in resource allocation, familiarity with aerospace quality standards (e.g., AS9100), and the capacity for effective problem-solving and decision-making under pressure.

Question 4: What types of challenges might one encounter in positions overseeing manufacturing in the aerospace industry?

Challenges may include managing complex projects within stringent budgetary constraints, navigating rapidly evolving technologies, maintaining compliance with strict regulatory requirements, and mitigating risks associated with safety-critical components.

Question 5: How can one enhance their prospects for securing a position overseeing manufacturing in the aerospace sector?

Enhancing prospects involves acquiring relevant certifications, gaining experience through internships or entry-level positions, developing a deep understanding of aerospace manufacturing processes, and demonstrating a commitment to continuous learning and professional development.

Question 6: What is the typical career progression path for individuals in positions overseeing manufacturing in the aerospace industry?

A typical career path may involve starting as a production supervisor or engineer, progressing to a management role overseeing specific departments or projects, and ultimately advancing to senior leadership positions with broader responsibilities for overall manufacturing operations.

The information presented in these FAQs underscores the multifaceted nature of roles overseeing manufacturing within the aerospace sector. Individuals seeking to enter or advance in these positions should prioritize acquiring the necessary skills, education, and experience.

The following section summarizes key takeaways and concluding thoughts on the subject.

Conclusion

This examination of aerospace production manager jobs has revealed the intricate nature and substantial demands of the profession. The role necessitates a comprehensive understanding of aerospace manufacturing processes, stringent regulatory compliance, and exceptional leadership capabilities. Effective management of resources, meticulous scheduling, and unwavering commitment to quality assurance are paramount for success.

Securing and excelling within aerospace production manager jobs requires dedication to continuous improvement, proactive problem-solving, and a steadfast adherence to safety protocols. The aerospace industry demands professionals who are not only technically proficient but also possess the vision to navigate evolving technological landscapes and contribute to the ongoing advancement of aviation and space exploration. Those who meet these challenges will find themselves at the forefront of an industry shaping the future.