Compensation for professionals who maintain and repair the complex engine systems of aircraft and spacecraft is a significant factor for individuals considering this career path. This remuneration reflects the specialized skills and technical expertise required to ensure the safe and efficient operation of propulsion systems. As an example, an individual with several years of experience working on jet engines for commercial airlines will typically command a higher rate than someone new to the field.

Understanding potential earnings is crucial for workforce planning and attracting qualified candidates to this vital sector. Competitive pay scales help ensure that the aerospace industry retains the skilled personnel necessary to uphold stringent safety standards and technological advancements. Historically, these positions have offered stable employment opportunities due to the ongoing need for maintenance and repair in both commercial and military aviation.

The following sections will delve into the factors influencing this remuneration, including experience level, geographic location, and the specific type of aircraft or spacecraft being serviced. It will also address industry trends impacting earning potential and provide resources for further research into career advancement opportunities.

Maximizing Earning Potential

Individuals seeking to optimize their compensation in the field of aerospace propulsion mechanics should consider the following strategies. Proactive career management and continuous skill development are key components of long-term financial success.

Tip 1: Pursue Advanced Certifications: Obtaining certifications beyond the basic requirements, such as those related to specific engine types or diagnostic technologies, can significantly increase marketability and justify higher salary expectations. For instance, certification in maintaining specific turbine engines used in commercial airliners demonstrates a higher level of expertise.

Tip 2: Specialize in High-Demand Areas: Focusing on areas where there is a shortage of qualified mechanics, such as working with advanced composite materials or electric propulsion systems, can command a premium. Understanding the evolving needs of the aerospace industry is crucial for identifying these opportunities.

Tip 3: Gain Experience with Diverse Aircraft Types: Exposure to a variety of aircraft, from general aviation to commercial airliners and military aircraft, broadens skill sets and increases versatility. This adaptability makes individuals more attractive to employers and allows for negotiation of higher wages.

Tip 4: Consider Relocation to High-Demand Regions: Areas with significant aerospace manufacturing or maintenance hubs often offer higher salaries due to increased competition for skilled technicians. Researching regional salary variations can reveal opportunities for substantial income growth.

Tip 5: Develop Leadership and Communication Skills: Moving into supervisory or management roles within a maintenance team often results in a significant increase in compensation. Cultivating these skills allows mechanics to progress into higher-paying positions.

Tip 6: Continuously Update Technical Knowledge: The aerospace industry is constantly evolving, with new technologies and regulations being introduced regularly. Staying current with these advancements through ongoing training and professional development is essential for maintaining a competitive edge and justifying higher pay.

Tip 7: Document Accomplishments and Quantify Results: During salary negotiations, demonstrating tangible contributions, such as reduced downtime or improved maintenance efficiency, strengthens the argument for increased compensation. Keeping a detailed record of achievements is vital.

By strategically focusing on skill enhancement, specialization, and career progression, aerospace propulsion mechanics can significantly increase their earning potential. A proactive approach to professional development is essential for long-term financial success in this field.

The concluding section of this article will summarize key considerations for aspiring and current aerospace propulsion mechanics, emphasizing the importance of ongoing education and industry awareness.

1. Experience and certification

The correlation between experience, certifications, and compensation for aerospace propulsion mechanics is demonstrable. Increased experience directly translates to a greater understanding of complex systems and troubleshooting methodologies. This enhanced proficiency allows for more efficient problem-solving, reduced downtime, and ultimately, cost savings for employers. For example, a mechanic with ten years of experience possesses a broader knowledge base than a newly certified individual, enabling quicker diagnosis and resolution of engine malfunctions. This directly correlates with increased productivity and value, thereby justifying higher compensation.

Certifications, such as those offered by the FAA or engine manufacturers, provide standardized validation of specific skill sets and knowledge. These credentials demonstrate a commitment to professional development and adherence to industry best practices. A mechanic certified to work on a specific type of jet engine, for instance, possesses a documented level of competence that sets them apart from uncertified individuals. Employers recognize the reduced risk associated with hiring certified technicians, leading to a willingness to offer higher salaries. This is particularly true for certifications relating to advanced or specialized propulsion systems.

In summary, experience and certifications act as quantifiable indicators of an aerospace propulsion mechanic’s expertise and value. Employers use these factors to assess candidates and determine appropriate compensation levels. A combination of extensive experience and relevant certifications is typically required to reach the highest earning potential within this field. Recognizing the importance of these credentials and continuously investing in professional development remains crucial for aspiring and established mechanics seeking to maximize their remuneration.

2. Geographic location impacts

Geographic location exerts a considerable influence on aerospace propulsion mechanic compensation. The underlying mechanisms stem from variations in the cost of living, the concentration of aerospace industries, and the demand for skilled technicians in specific regions. A higher cost of living, as observed in metropolitan areas or regions with robust economies, often necessitates higher wages to maintain a comparable standard of living. The presence of major aerospace manufacturers, maintenance hubs, or military installations in a given area also drives up demand for qualified mechanics, leading to more competitive salary offerings. For instance, locations near Boeing or Airbus facilities, or major Air Force bases, typically exhibit higher compensation rates than areas with limited aerospace activity.

Real-world examples illustrate this principle effectively. Mechanics working in the Seattle, Washington area, home to Boeing’s primary manufacturing facilities, frequently earn more than their counterparts in regions with fewer aerospace companies. Similarly, areas surrounding major military airfields, such as those in Southern California or Florida, often offer increased compensation packages due to the ongoing need for maintenance and repair of military aircraft. The practical significance of this understanding lies in its value for both job seekers and employers. Mechanics can strategically target geographic areas with high demand and competitive salaries, while employers must adjust their compensation packages to attract and retain qualified personnel in areas with high living costs or intense competition.

In summary, the geographic distribution of aerospace industries and the cost of living are critical factors determining compensation for aerospace propulsion mechanics. Individuals considering a career in this field, or employers seeking to attract skilled technicians, must carefully consider the impact of location on earning potential. Failure to account for these geographic influences can lead to inaccurate salary expectations or difficulties in recruiting qualified personnel. Therefore, understanding the nuances of regional labor markets is essential for both financial planning and workforce management within the aerospace industry.

3. Aircraft type specializations

Aircraft type specializations demonstrably influence compensation levels for aerospace propulsion mechanics. The connection stems from the varying levels of complexity inherent in different aircraft engine systems, the specialized training required for their maintenance, and the relative demand for mechanics possessing specific expertise. Mechanics specializing in complex turbine engines found in commercial airliners, for example, typically command higher salaries compared to those working primarily on piston engines in general aviation aircraft. The increased complexity necessitates advanced troubleshooting skills, intricate repair procedures, and adherence to stringent regulatory requirements, all contributing to the heightened value of the specialized mechanic.

The practical significance of this understanding manifests in career planning and workforce development. Mechanics seeking to maximize their earning potential can strategically pursue training and experience with aircraft types experiencing strong demand and requiring specialized expertise. This might involve obtaining certifications specific to particular engine models or undergoing advanced training in areas such as composite repairs or electronic engine control systems. Employers, conversely, must recognize the value of specialized knowledge and adjust compensation packages accordingly to attract and retain mechanics possessing these in-demand skills. Failure to do so may result in difficulties in maintaining complex aircraft systems or meeting regulatory compliance standards. Consider, for instance, the higher pay scales often seen for mechanics certified to work on the latest generation of wide-body aircraft compared to those specializing in older, less technologically advanced models. This reflects the scarcity of skilled personnel capable of maintaining these sophisticated systems.

In summary, aircraft type specializations represent a key determinant of aerospace propulsion mechanic compensation. The complexity of the aircraft and its engine systems, the specialized training required for maintenance, and the market demand for mechanics with these specific skills all contribute to the variance in earning potential. By recognizing the importance of specialization and proactively pursuing relevant training and experience, mechanics can significantly enhance their career prospects and command higher salaries. Simultaneously, employers must acknowledge the value of specialized expertise and offer competitive compensation to secure the services of qualified professionals. The effective alignment of skills and compensation is crucial for ensuring the safe and efficient operation of aircraft and the continued growth of the aerospace industry.

4. Union representation effects

Union representation significantly impacts compensation structures for aerospace propulsion mechanics. Collective bargaining agreements negotiated by unions influence wages, benefits, and working conditions, creating a distinct compensation landscape compared to non-unionized environments. The influence of unions is multifaceted and warrants careful consideration.

- Standardized Wage Scales

Union contracts often establish standardized wage scales based on experience, seniority, and qualifications. This reduces wage disparities and ensures equitable compensation within the bargaining unit. For example, a union contract might stipulate annual wage increases or cost-of-living adjustments, providing a predictable and stable income trajectory. This contrasts with non-union settings where individual negotiation plays a larger role, potentially leading to wider variations in pay for similar work.

- Enhanced Benefits Packages

Unions typically negotiate comprehensive benefits packages that include health insurance, retirement plans, paid time off, and other benefits. These packages often exceed those offered in non-union workplaces, contributing to a higher overall compensation value. For example, a union might secure employer contributions to a defined-benefit pension plan, providing a guaranteed retirement income for members. The value of these enhanced benefits should be considered when comparing union and non-union pay rates.

- Improved Job Security

Union contracts often include provisions protecting members from arbitrary termination or layoffs. Seniority-based layoff policies, for instance, prioritize retaining experienced employees during workforce reductions. This increased job security can be a significant advantage, particularly in industries subject to economic fluctuations. While non-union employees may be subject to at-will employment, union members often have recourse through grievance procedures and arbitration.

- Influence on Working Conditions

Beyond direct compensation, unions also advocate for improved working conditions, including safety standards, workload limits, and access to training opportunities. These factors indirectly contribute to overall job satisfaction and can reduce the risk of workplace injuries. For example, a union might negotiate for ergonomic equipment or regular safety inspections, creating a safer and more productive work environment.

These facets collectively demonstrate the substantial impact of union representation on the financial well-being of aerospace propulsion mechanics. While union membership entails dues and adherence to collective agreements, the benefits derived in terms of wages, benefits, job security, and working conditions often outweigh these costs. Understanding the specifics of union contracts within a given workplace is essential for accurately assessing the overall compensation package available to these skilled technicians.

5. Demand influences pay

The principle of supply and demand significantly impacts compensation levels for aerospace propulsion mechanics. Market forces dictate that when the demand for skilled technicians exceeds the available supply, employers must offer more competitive remuneration packages to attract and retain qualified personnel. This dynamic is particularly pronounced in the aerospace industry, where specialized expertise is paramount for ensuring safety and operational efficiency.

- Shortage of Qualified Technicians

A documented shortage of qualified aerospace propulsion mechanics amplifies the effect of demand on compensation. Factors contributing to this shortage include an aging workforce, increasing retirement rates, and a potential lag in training programs to meet industry needs. As the pool of available mechanics shrinks relative to the demand for their services, employers face increased pressure to raise salaries and benefits to secure experienced professionals. This is particularly evident in regions with high concentrations of aerospace activity or in areas requiring specialized skills.

- Geographic Imbalances in Demand

Demand for aerospace propulsion mechanics is not evenly distributed across geographic locations. Areas with major aerospace manufacturing facilities, large commercial airlines, or significant military installations typically experience higher demand for skilled technicians. This localized demand can drive up compensation rates in those regions, creating disparities compared to areas with less aerospace activity. Mechanics willing to relocate to high-demand areas often find opportunities for increased earnings and career advancement.

- Technological Advancements and Specialization

Rapid technological advancements in aircraft propulsion systems create a continuous need for mechanics with specialized skills and training. As new engine types and maintenance procedures are introduced, the demand for technicians proficient in these areas increases. Mechanics who proactively acquire the necessary certifications and experience to work on advanced systems are well-positioned to command higher salaries. This highlights the importance of continuous professional development in maintaining a competitive edge in the labor market.

- Economic Fluctuations and Industry Growth

The overall health of the aerospace industry and broader economic conditions directly influence the demand for aerospace propulsion mechanics. Periods of economic expansion and increased air travel typically lead to higher demand for maintenance and repair services, driving up salaries. Conversely, economic downturns or significant reductions in air travel can result in decreased demand and potentially moderate salary growth. Understanding these cyclical trends is crucial for both mechanics planning their careers and employers managing their workforce.

In conclusion, demand plays a crucial role in determining the compensation for aerospace propulsion mechanics. Shortages of qualified personnel, geographic imbalances, technological advancements, and economic factors all contribute to the dynamic interplay between demand and salary levels. Mechanics who strategically position themselves to meet the evolving needs of the aerospace industry are best equipped to benefit from the forces of supply and demand.

Frequently Asked Questions

The following frequently asked questions provide concise answers to common inquiries regarding earnings for aerospace propulsion mechanics. The information presented aims to offer clarity and accurate insights into compensation factors within this field.

Question 1: What is the typical starting salary for an aerospace propulsion mechanic?

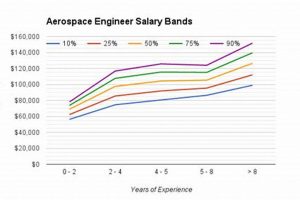

Entry-level salaries vary based on location, specific employer, and educational background. Generally, an aerospace propulsion mechanic can expect a starting salary commensurate with other skilled trades, but opportunities for rapid advancement and pay increases exist with experience and certifications.

Question 2: How does experience level affect earning potential in this field?

Experience is a primary driver of increased earning potential. As mechanics gain experience, they develop advanced troubleshooting skills, become more efficient in maintenance procedures, and are often entrusted with more complex tasks, justifying higher compensation.

Question 3: Do certifications significantly impact salary prospects for aerospace propulsion mechanics?

Yes, certifications related to specific engine types or regulatory standards demonstrate a commitment to professional development and validate specialized knowledge. These credentials often lead to higher salaries and increased job opportunities.

Question 4: How does geographic location influence compensation rates for this occupation?

Geographic location plays a significant role. Areas with a higher cost of living, a greater concentration of aerospace industries, or a strong demand for skilled technicians tend to offer more competitive salaries.

Question 5: What is the potential for salary growth in the aerospace propulsion mechanic profession?

Salary growth potential is substantial, particularly for individuals who pursue advanced certifications, specialize in high-demand areas, and demonstrate leadership qualities. Progression into supervisory or management roles offers significant opportunities for increased compensation.

Question 6: Are there specific industries or sectors that offer higher salaries for aerospace propulsion mechanics?

Commercial airlines, major aerospace manufacturers, and government agencies often offer competitive salaries and comprehensive benefits packages. The specific industry and employer will influence earning potential.

In summary, understanding the factors that influence compensation for aerospace propulsion mechanics is crucial for career planning and professional development. Experience, certifications, geographic location, and industry demand all contribute to earning potential in this field.

The concluding section of this resource will provide actionable advice for aspiring and current aerospace propulsion mechanics seeking to maximize their earning potential and advance their careers.

Aerospace Propulsion Mechanic Salary

This analysis has comprehensively explored the various factors influencing “aerospace propulsion mechanic salary.” The interplay of experience, certifications, geographic location, union representation, and market demand significantly shapes compensation levels. Achieving a comprehensive understanding of these elements is essential for both aspiring and established mechanics seeking to optimize their earning potential within this specialized field.

The future of aerospace propulsion mechanic compensation will likely be influenced by technological advancements, workforce demographics, and economic trends. Continuous professional development and strategic career planning remain crucial for navigating the evolving landscape of this profession. Vigilance in monitoring industry developments and adapting skillsets accordingly will be paramount for sustained financial success and contributing to the ongoing safety and efficiency of air travel.

![Aerospace Engineer Salary: CS vs Aero Eng? [2024] Innovating the Future of Flight with Reliable Aviation Solutions Aerospace Engineer Salary: CS vs Aero Eng? [2024] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-71-300x200.jpg)

![[Guide] Bennett Aerospace Salaries: What to Expect (2024) Innovating the Future of Flight with Reliable Aviation Solutions [Guide] Bennett Aerospace Salaries: What to Expect (2024) | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-52-300x200.jpg)