Positions within the aerospace sector that focus on evaluating and managing the forces acting upon aircraft and spacecraft structures are critical. These roles require professionals to analyze potential failure points and ensure structural integrity under various operational conditions. For example, engineers may use finite element analysis to predict how a wing will respond to aerodynamic loads during flight.

The assessment and mitigation of potential structural weaknesses are paramount to ensuring the safety and reliability of aerospace vehicles. This specialized area contributes directly to preventing catastrophic failures and optimizing designs for efficiency and longevity. The origins of this discipline trace back to early aviation, where structural failures were a significant concern, leading to the development of rigorous analytical techniques.

The following sections will delve into the specific responsibilities, required skills, career paths, and industry outlook associated with these specialized engineering roles. Furthermore, the discussion will cover educational prerequisites, necessary certifications, and emerging trends that shape the future of this critical field.

Guidance for Pursuing Roles in Structural Integrity within Aerospace

This section offers practical advice for individuals aspiring to careers focused on ensuring the structural integrity of aircraft and spacecraft. The following points provide guidance on skill development, career preparation, and industry engagement.

Tip 1: Solidify Foundational Knowledge: A robust understanding of mechanics of materials, structural analysis, and finite element analysis is essential. Focus on mastering these core principles through rigorous academic study and practical application.

Tip 2: Acquire Proficiency in Industry-Standard Software: Familiarity with software packages such as ANSYS, Abaqus, and NASTRAN is highly valued. Seek opportunities to gain hands-on experience with these tools through internships or academic projects.

Tip 3: Develop Strong Analytical and Problem-Solving Skills: These positions demand the ability to identify and solve complex engineering problems. Cultivate these skills through coursework, research, and participation in engineering design challenges.

Tip 4: Pursue Relevant Certifications: Consider obtaining certifications such as the Professional Engineer (PE) license, as it can enhance credibility and career prospects. Investigate other industry-specific certifications related to structural analysis and testing.

Tip 5: Gain Practical Experience Through Internships: Internships within aerospace companies or research institutions provide invaluable real-world experience. Seek opportunities to work on projects involving structural analysis, testing, or design.

Tip 6: Network with Industry Professionals: Attend industry conferences, join professional organizations such as the American Institute of Aeronautics and Astronautics (AIAA), and connect with engineers on professional networking platforms. Building relationships can open doors to career opportunities and provide valuable insights.

Tip 7: Stay Abreast of Emerging Technologies: The aerospace industry is constantly evolving. Keep informed about advancements in materials science, manufacturing processes, and simulation techniques. This continuous learning will ensure long-term career relevance.

By focusing on building a strong foundation of knowledge, developing essential skills, gaining practical experience, and staying informed about industry trends, individuals can enhance their prospects in this specialized field.

The subsequent discussion will explore the future challenges and opportunities facing professionals in this domain, highlighting the ongoing importance of structural integrity in advancing aerospace technology.

1. Analysis

Analysis forms the bedrock of any role concerned with evaluating structural integrity in the aerospace sector. It provides the foundation for understanding how aerospace components respond to diverse operational loads, guiding design decisions and ensuring safety margins.

- Stress Analysis

Stress analysis involves determining the internal stresses and strains within a structure subjected to external forces. This often employs techniques like finite element analysis (FEA) to model complex geometries and loading conditions. For instance, analyzing the stress distribution in a turbine blade under high centrifugal forces and thermal gradients is crucial for preventing fatigue failure. The accuracy of the stress analysis directly impacts the reliability and lifespan of aerospace components.

- Modal Analysis

Modal analysis identifies the natural frequencies and mode shapes of a structure. This is critical for avoiding resonance, a phenomenon where external vibrations amplify structural oscillations, potentially leading to catastrophic failure. An example would be analyzing the vibrational modes of an aircraft wing to ensure it does not resonate with engine vibrations or aerodynamic flutter. Understanding these vibrational characteristics is essential for designing vibration-damping systems and preventing structural damage.

- Fatigue Analysis

Fatigue analysis predicts the lifespan of a component under cyclic loading. Aerospace structures experience repeated stress cycles during flight, leading to fatigue crack initiation and propagation. Analysis involves estimating the number of cycles to failure based on material properties, stress levels, and operational conditions. For example, conducting fatigue analysis on an aircraft fuselage subjected to pressurization cycles is essential for determining inspection intervals and ensuring structural integrity throughout its service life. Accurate fatigue predictions are vital for minimizing maintenance costs and preventing in-flight failures.

- Thermal Analysis

Thermal analysis evaluates the temperature distribution within a structure and its impact on material properties and structural integrity. Aerospace vehicles experience extreme temperature variations during flight, affecting material strength and causing thermal stresses. For instance, analyzing the thermal stresses in a spacecraft heat shield during atmospheric reentry is critical for preventing burn-through and ensuring crew safety. Thermal analysis informs the selection of appropriate materials and the design of thermal management systems.

These analytical facets are interconnected and contribute to a comprehensive understanding of structural behavior in aerospace applications. Accurate and thorough analysis mitigates risks, optimizes designs, and ultimately ensures the safety and reliability of aerospace vehicles.

2. Simulation

Simulation plays a pivotal role in the execution of responsibilities within aerospace structural analysis roles. Its significance stems from the ability to predict the behavior of components and systems under a range of operating conditions, thereby mitigating risks associated with physical testing and accelerating the design cycle. The accuracy of these simulations directly impacts the reliability of aerospace vehicles. For example, computational fluid dynamics (CFD) simulations are used to predict aerodynamic forces on aircraft wings, while finite element analysis (FEA) is employed to assess stress concentrations in critical structural joints. These simulations provide insights into potential failure modes and inform design modifications to enhance structural integrity.

The practical application of simulation extends beyond initial design phases. Simulations are used to assess the impact of fatigue, corrosion, and other degradation mechanisms on structural performance over time. This informs maintenance schedules and ensures the continued airworthiness of aircraft. Furthermore, simulation allows for the exploration of design alternatives that might be impractical or cost-prohibitive to prototype and test physically. The use of high-fidelity models, validated against experimental data, provides a level of confidence that is essential for regulatory approval and public safety. The ability to virtually replicate extreme scenarios, such as engine failure or bird strikes, enhances the resilience of designs.

In conclusion, simulation is an indispensable tool for engineers in structural analysis. It enables them to predict performance, optimize designs, and mitigate risks associated with aerospace vehicles. While challenges remain in improving the accuracy and computational efficiency of simulations, its continued development is critical for advancing aerospace technology. The integration of simulation with machine learning and artificial intelligence offers the potential to further enhance design processes and improve structural safety.

3. Certification

Certification is inextricably linked to roles in aerospace structural integrity. These jobs, focused on evaluating stress and ensuring the safety of aerospace vehicles, require professionals to demonstrate adherence to stringent industry and regulatory standards. Certification processes validate that designs, materials, manufacturing processes, and operational procedures meet established criteria. For instance, structural engineers performing stress analyses on aircraft wings must ensure their calculations comply with Federal Aviation Administration (FAA) regulations. Failure to meet these standards can lead to significant delays in aircraft development, costly redesigns, and potential safety hazards. The engineers performing these jobs need to accurately verify and demonstrate that their calculations and proposed designs adhere to FAA and/or related agencies requirements to receive approval to fly.

The importance of certification extends beyond compliance. It fosters a culture of quality and accountability within aerospace organizations. Independent audits and reviews ensure that structural analyses are conducted rigorously and that potential risks are identified and mitigated effectively. For example, the European Union Aviation Safety Agency (EASA) mandates specific testing and analysis requirements for composite materials used in aircraft structures. These mandates ensure that these materials can withstand the stresses of flight. Professionals involved in the analytical assessment process must possess a thorough understanding of these requirements and the methods used to demonstrate compliance. Therefore, relevant professional certifications are extremely valuable and, in many instances, a requirement for these jobs.

In summary, certification is not merely a procedural requirement but a fundamental aspect of ensuring safety and reliability in the aerospace industry. The assessment process drives continuous improvement in structural design, analysis, and manufacturing. As aerospace technology advances, the criteria for certification become increasingly complex. These jobs are critical to integrating these elements effectively to maintain the highest safety standards. Professionals adept in managing this interplay are vital to maintaining the integrity of the aerospace sector.

4. Materials

The selection and application of materials are integral to the responsibilities associated with aerospace structural analysis roles. These professionals must possess a thorough understanding of material properties and their behavior under various stress conditions to ensure the safety and reliability of aerospace vehicles. The appropriate material must be selected based on the structural and environmental constraints of the system. The improper use of a material can lead to premature failure and safety concerns.

- Alloys

Alloys, such as aluminum, titanium, and nickel-based alloys, are frequently employed in aerospace structures due to their high strength-to-weight ratios and resistance to corrosion. For instance, aluminum alloys are used extensively in aircraft fuselages and wings, while titanium alloys find application in high-temperature components like engine turbine blades. Engineers are responsible for evaluating the suitability of these alloys for specific applications, considering factors such as yield strength, fatigue resistance, and creep behavior. The assessment of an alloy’s mechanical properties under operational conditions is crucial for preventing structural failure.

- Composites

Composite materials, such as carbon fiber reinforced polymers (CFRP), offer exceptional strength-to-weight ratios and design flexibility. CFRP is increasingly used in aircraft wings, control surfaces, and fuselage structures. Professionals analyze the behavior of composites under complex loading conditions, accounting for factors like fiber orientation, interlaminar stresses, and environmental degradation. Accurate prediction of composite material behavior is essential for optimizing structural performance and ensuring long-term durability. These professionals must also have an understanding of anisotropic material properties when assessing composites.

- Coatings

Protective coatings are applied to aerospace materials to enhance their resistance to corrosion, erosion, and thermal degradation. For example, thermal barrier coatings are used on turbine blades to withstand high temperatures, while corrosion-resistant coatings protect aluminum alloys from environmental exposure. The evaluation of coating performance, including adhesion strength, thermal stability, and environmental resistance, is a critical aspect of material selection and design. The proper selection of coatings can significantly extend the service life of aerospace components.

- Material Testing

Comprehensive material testing is essential for validating material properties and ensuring compliance with industry standards. Tests such as tensile testing, fatigue testing, and non-destructive evaluation are conducted to assess material performance under various conditions. These tests provide critical data for structural analysis and design. These data-driven assessments are vital for preventing material-related failures and ensuring the safety of aerospace vehicles. These testing methods also ensure that the selected materials meet industry or safety requirements, such as FAA guidelines.

These material-related aspects directly influence the responsibilities and challenges encountered within roles focused on evaluating structural integrity in the aerospace sector. A thorough understanding of these material properties is paramount for mitigating risks and ensuring the safety and reliability of aerospace vehicles. As aerospace technology advances, the role of material selection and analysis will continue to grow in importance.

5. Testing

Testing forms a critical cornerstone in the realm of aerospace structural integrity, serving as the empirical validation for analytical predictions and design assumptions. Roles focused on evaluating stress in aerospace components rely heavily on rigorous testing methodologies to ensure safety and performance under extreme conditions.

- Non-Destructive Testing (NDT)

NDT techniques, such as ultrasonic testing, radiographic inspection, and eddy current testing, are used to detect internal flaws or defects in materials and components without causing damage. For example, NDT is employed to inspect welds in aircraft fuselages for cracks or porosity that could compromise structural integrity. The ability to identify these defects early in the manufacturing process, or during routine maintenance, is crucial for preventing catastrophic failures during flight. Accurate interpretation of NDT results requires specialized training and expertise, highlighting its importance.

- Destructive Testing

Destructive testing involves subjecting components to extreme loads or environmental conditions until failure occurs. This provides valuable data on material strength, fatigue life, and failure modes. A common example is the static load testing of an aircraft wing to verify its ability to withstand maximum aerodynamic forces. While destructive testing results in the destruction of the test article, the data obtained is essential for validating design models and establishing safety margins.

- Environmental Testing

Aerospace components are subjected to a wide range of environmental conditions during their service life, including extreme temperatures, pressures, and humidity. Environmental testing simulates these conditions to assess the impact on structural performance. For instance, a satellite component may undergo thermal vacuum testing to simulate the harsh conditions of space. Environmental testing helps identify potential vulnerabilities and ensures that components can withstand the rigors of their intended operating environment.

- Flight Testing

Flight testing represents the culmination of the testing process, where aircraft are subjected to a series of maneuvers and operating conditions to validate their performance and handling characteristics. Flight testing involves monitoring a wide range of parameters, including stress levels, vibration, and aerodynamic loads. Data obtained from flight testing is used to refine design models and validate analytical predictions, ensuring that the aircraft meets all performance and safety requirements.

These testing methods are inextricably linked to the work of engineers focused on evaluating structural integrity in the aerospace sector. These results are critical for validating designs, identifying potential weaknesses, and ultimately ensuring the safety and reliability of aerospace vehicles. As aerospace technology advances, the sophistication and importance of testing methodologies will continue to increase.

6. Design

The design phase is a critical juncture where theoretical concepts are translated into tangible aerospace structures. The success of this stage hinges on a robust integration of structural integrity considerations, making design a central focus of aerospace professionals focused on evaluating stress.

- Load Path Optimization

Load path optimization entails strategically designing structural elements to efficiently distribute applied forces. For example, aircraft wings are designed with internal spars and ribs to channel aerodynamic loads towards the fuselage, minimizing stress concentrations. Optimization considers weight reduction, material properties, and manufacturing constraints. Improper load path design can lead to localized stress concentrations, potentially causing premature failure. Thus, proficiency in this area is essential for those in aerospace stress-related roles.

- Material Selection

Selecting appropriate materials is fundamental to ensuring structural integrity. The material’s strength-to-weight ratio, fatigue resistance, and environmental compatibility dictate the overall performance of an aerospace component. For instance, the use of carbon fiber composites in aircraft fuselages provides significant weight savings compared to traditional aluminum alloys. However, composites also exhibit unique failure modes requiring specialized analysis techniques. The materials selection process is a core element of structural design and necessitates thorough understanding of material science principles.

- Joint Design

Aerospace structures consist of numerous interconnected components. The design of these joints is critical for transferring loads effectively and preventing stress concentrations. Examples include bolted joints in aircraft wings and bonded joints in composite structures. The selection of appropriate fastening methods, adhesives, and geometric configurations dictates the joint’s strength and durability. Engineers focused on structural analysis must carefully consider the effects of joint stiffness and stress distribution to ensure structural integrity.

- Geometric Considerations

The geometric configuration of a structure significantly influences its stress distribution and overall performance. For example, sharp corners and abrupt changes in cross-section can create stress concentrations, increasing the risk of fatigue failure. The implementation of smooth transitions and optimized shapes can mitigate these effects. The geometric design of aerospace components involves a delicate balance between aerodynamic requirements, structural constraints, and manufacturing feasibility. An effective geometrical design requires an understanding of design’s potential impact on overall mechanical integrity.

These facets of design underscore its critical role in mitigating stress-related failures in aerospace structures. These elements interact in a complex manner to determine the overall performance of an aircraft or spacecraft. These processes demonstrate the necessity for experts dedicated to optimizing and validating their structural integrity. As aerospace technology advances, the importance of these specialists will continue to grow.

Frequently Asked Questions

The following addresses common inquiries regarding roles focused on structural analysis and integrity within the aerospace sector.

Question 1: What educational background is typically required for positions involving the assessment of structural integrity in aerospace?

A bachelor’s degree in aerospace engineering, mechanical engineering, or a closely related field is generally considered a minimum requirement. Many positions, particularly those involving advanced analysis or research, may require a master’s degree or doctorate.

Question 2: What specific skills are most valued by employers seeking individuals to fill roles in aerospace structural analysis?

Proficiency in finite element analysis (FEA) software, a strong understanding of mechanics of materials, and experience with aerospace materials are highly valued. Knowledge of industry standards, such as those set by the FAA or EASA, is also essential.

Question 3: What are some common career paths for professionals specializing in the evaluation of structural loads in aerospace?

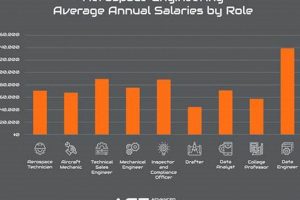

Potential career paths include structural analyst, stress engineer, design engineer (with a focus on structural integrity), and materials engineer. Advancement opportunities may lead to roles in project management, technical leadership, or research and development.

Question 4: What types of projects might a structural analyst typically work on in the aerospace industry?

Projects may include analyzing the structural integrity of aircraft wings, fuselages, engine components, or spacecraft structures. Tasks could range from performing stress calculations and fatigue analysis to validating designs through testing and simulation.

Question 5: What are the key challenges faced by professionals in aerospace stress-related jobs?

Challenges include dealing with complex geometries, extreme loading conditions, and stringent safety requirements. Professionals must stay abreast of new materials, technologies, and regulatory changes. Ensuring accuracy and reliability in analytical models is paramount.

Question 6: How is the increasing use of composite materials impacting the demand for structural engineers in the aerospace industry?

The growing adoption of composite materials is increasing the demand for engineers with expertise in composite analysis and design. Understanding the unique properties and failure modes of composites is essential for ensuring structural integrity.

These responses offer a general overview of typical qualifications, skills, and responsibilities. Specific requirements may vary depending on the employer and the nature of the role.

The subsequent segment will cover actionable insights for career advancement.

Conclusion

This exposition has detailed the multifaceted nature of aerospace stress jobs, emphasizing the critical role these positions play in ensuring the safety and reliability of aircraft and spacecraft. The discussions spanned essential elements such as analysis, simulation, certification, materials science, testing methodologies, and design principles, underscoring the breadth of expertise required in this field.

The ongoing pursuit of innovation and safety within the aerospace sector demands a continued commitment to rigorous analysis and comprehensive understanding of structural integrity. Aerospace stress jobs remain vital for maintaining the highest standards of airworthiness and spacefaring capability. The future success of aerospace endeavors depends on the dedication and expertise of these specialized professionals.