A document outlining the responsibilities, qualifications, and required skills for professionals who maintain, repair, and inspect aircraft and spacecraft is essential. This document specifies tasks ranging from routine maintenance checks to complex troubleshooting and component replacement. For instance, it will detail the specific certifications required for working on certain types of aircraft and the physical demands of the role.

Clarity in expectations and requirements benefits both the employer and the potential employee. It ensures that the organization finds candidates with the appropriate skills and experience, reducing training costs and improving efficiency. Historically, such documentation evolved from simple task lists to comprehensive outlines reflecting the increasing complexity of aviation technology and regulatory requirements. A well-defined role aids in legal compliance and minimizes potential liabilities.

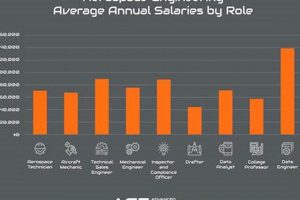

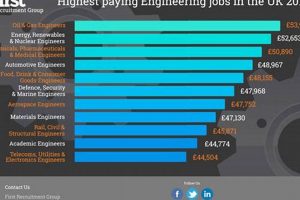

The subsequent sections will delve into the core duties, essential qualifications, necessary skills, and the career outlook for individuals working in this field. Additionally, information on potential salary ranges and opportunities for professional development will be provided.

Guidance for Crafting Effective Role Outlines

The subsequent points highlight crucial considerations when developing comprehensive role outlines for those maintaining and repairing aircraft.

Tip 1: Include Specific Tasks: The document should precisely delineate daily operational duties. For example, specifying “Conduct pre-flight inspections according to FAA guidelines” offers greater clarity than a generalized statement.

Tip 2: State Required Certifications: Clearly indicate the necessary certifications and licenses, such as Airframe and Powerplant (A&P) license, as mandated by regulatory bodies like the FAA or EASA. Explicitly state recency requirements for these certifications.

Tip 3: Detail Physical Requirements: Accurately portray the physical demands of the role, including lifting weight, working in confined spaces, and exposure to varying weather conditions. This transparency allows applicants to self-assess their suitability.

Tip 4: Emphasize Safety Protocols: A robust emphasis on adherence to safety regulations and procedures must be incorporated. For instance, the outline should specify the use of personal protective equipment (PPE) and compliance with hazardous material handling protocols.

Tip 5: Define Problem-Solving Expectations: Articulate the level of independent problem-solving expected. The description should delineate the types of malfunctions the individual should be able to diagnose and rectify, as well as when to escalate issues to senior personnel.

Tip 6: Address Documentation Standards: The importance of accurate and timely record-keeping must be underlined. The description should specify the type of documentation required, such as maintenance logs, repair orders, and inspection reports, and the tools used for documenting.

A well-crafted role outline serves as a cornerstone for attracting qualified candidates, managing expectations, and ensuring regulatory compliance. It reduces ambiguity and contributes to a safer and more efficient working environment.

Following sections will explore the implications of these descriptions on career advancement and professional development.

1. Core Responsibilities

The “Core Responsibilities” section forms the bedrock of any role outline, precisely defining the duties and accountabilities of professionals within the aerospace sector. Its thoroughness directly impacts the efficacy of recruitment, training, and performance management related to the position.

- Aircraft Maintenance and Repair

This facet involves the practical application of diagnostic and repair techniques on aircraft systems. It includes tasks ranging from routine inspections and preventative maintenance to complex troubleshooting and component replacement. For example, technicians might overhaul an aircraft engine, repair hydraulic systems, or replace damaged structural components. Failure to execute these duties with precision can lead to catastrophic consequences, underscoring the need for meticulous adherence to protocols.

- System Diagnostics and Troubleshooting

This area requires the ability to identify and resolve malfunctions in complex aircraft systems. Technicians utilize diagnostic tools and manuals to pinpoint the root cause of issues, which may range from faulty wiring to software glitches. An instance would be identifying a problem with the flight control system using specialized diagnostic equipment and then implementing the appropriate repair procedure. This skill directly affects aircraft safety and operational efficiency.

- Documentation and Record-Keeping

Meticulous documentation of all maintenance and repair activities is paramount. Technicians must maintain accurate records of inspections, repairs, and parts replacements, ensuring compliance with regulatory requirements and providing a clear audit trail. A real-world example is completing maintenance logs that detail the work performed on an aircraft, including the specific parts used and the time spent. Accurate record-keeping supports safety, traceability, and future maintenance planning.

- Compliance with Safety Regulations

Adherence to stringent safety regulations is non-negotiable. Technicians must follow prescribed procedures and protocols to mitigate risks associated with working on complex machinery and potentially hazardous materials. For instance, technicians are required to use personal protective equipment (PPE) and adhere to strict guidelines for handling hazardous materials. This facet is critical for preventing accidents and ensuring a safe working environment.

These core responsibilities collectively define the essence of the position, highlighting the blend of technical expertise, problem-solving skills, and unwavering commitment to safety required. A detailed understanding of these accountabilities ensures that qualified individuals are selected, properly trained, and effectively managed, thus contributing to the overall safety and reliability of aircraft operations.

2. Required Qualifications

The “Required Qualifications” section of any aerospace technician position outline is paramount. It delineates the essential prerequisites a candidate must possess to effectively fulfill the responsibilities associated with maintaining and repairing aircraft. These qualifications serve as a critical filter, ensuring that individuals entering this highly technical field possess the foundational knowledge, skills, and certifications necessary to uphold safety and regulatory standards.

- Educational Attainment

A high school diploma or equivalent is generally the minimum educational requirement. However, many employers prefer candidates with an associate’s or bachelor’s degree in aviation maintenance technology or a related field. Formal education provides a structured learning environment where aspiring technicians acquire fundamental knowledge of aircraft systems, aerodynamics, and materials science. For instance, courses in engine mechanics, avionics, and airframe repair are common. Higher levels of education often translate to a greater understanding of complex systems and advanced troubleshooting skills, improving the caliber of potential candidates.

- Licensure and Certification

Possession of an Airframe and Powerplant (A&P) license is a near-universal requirement for technicians working on civil aircraft in many countries. This license, issued by regulatory agencies like the FAA, demonstrates that an individual has met specific training and testing standards. The licensing process typically involves completing a prescribed course of study at an approved aviation maintenance school and passing rigorous written, oral, and practical examinations. The A&P license signifies a technician’s competency in maintaining both the airframe (structural components) and powerplant (engines) of an aircraft, assuring employers of a baseline level of expertise.

- Relevant Experience

While formal education and licensure provide a theoretical and regulatory foundation, practical experience is invaluable. Many employers seek candidates with several years of hands-on experience in aircraft maintenance. This experience can be gained through apprenticeships, on-the-job training, or military service. For example, experience repairing and overhauling aircraft engines or troubleshooting complex electrical systems is highly sought after. Practical experience allows technicians to apply their theoretical knowledge to real-world scenarios, hone their problem-solving skills, and develop a deep understanding of aircraft systems.

- Physical Requirements

The role of an aerospace technician often demands a certain level of physical fitness. Technicians may be required to lift heavy objects, work in confined spaces, and perform tasks that require manual dexterity and coordination. For instance, technicians may need to climb ladders to inspect aircraft wings, crawl into tight spaces to access wiring, or use specialized tools to perform intricate repairs. As a result, role outlines frequently specify minimum physical requirements, such as the ability to lift a certain weight or pass a vision test. These requirements ensure that technicians can safely and effectively perform their duties in demanding environments.

In essence, the “Required Qualifications” form a comprehensive profile of the ideal candidate. By specifying the necessary educational background, certifications, experience, and physical capabilities, employers seek to identify individuals who are not only technically competent but also capable of upholding the highest standards of safety and quality within the aerospace industry. A meticulously crafted qualifications section ensures that the pool of applicants is appropriately vetted, increasing the likelihood of hiring individuals who can excel in this critical role.

3. Essential Skills

Essential skills are intrinsic to the “aerospace technician job description” as they dictate the practical application of theoretical knowledge and acquired expertise. The specific attributes outlined within this section determine a technician’s capacity to execute core responsibilities, adhere to stringent safety protocols, and contribute to the overall operational efficiency of aircraft maintenance. Deficiencies in these areas directly impact the quality of work performed, potentially leading to safety compromises and costly errors. For example, if a role outline emphasizes proficiency in non-destructive testing (NDT) methods, then a candidate lacking such skills could fail to detect critical structural flaws, resulting in potential in-flight failures. Therefore, clearly defining and assessing these competencies during the selection process is critical.

The connection between these skills and the job description manifests in several practical applications. A role outline that stresses troubleshooting capabilities, for instance, should involve detailed descriptions of diagnostic procedures, the application of specialized tools, and the interpretation of technical manuals. A technician adept at these skills can efficiently diagnose and rectify malfunctions, minimizing aircraft downtime and reducing maintenance costs. Similarly, a role demanding expertise in avionics systems should specify familiarity with relevant software platforms, communication protocols, and electrical schematics. These skills empower technicians to perform tasks such as calibrating navigation systems, repairing communication equipment, and integrating new technologies into existing aircraft architecture. Ultimately, the skills detailed reflect the specific demands and complexities of modern aerospace maintenance.

Comprehending the significance of essential skills as a component of an aerospace technician position is vital for multiple reasons. It ensures that organizations hire individuals with the right skill set to perform the job effectively and safely. Also, it allows for the creation of targeted training programs that address specific skill gaps, fostering continuous professional development. Moreover, it establishes a clear performance benchmark, enabling the fair and objective evaluation of technician competence. The challenge lies in accurately identifying and articulating the most critical skills for a particular role and in devising effective methods for assessing these skills during the hiring process. Recognizing this interconnectedness enhances the overall quality and safety of aerospace operations.

4. Maintenance Procedures

Maintenance Procedures are integral to the responsibilities outlined in any role in aerospace maintenance, establishing standardized processes for ensuring the continued airworthiness and safety of aircraft. These procedures dictate the specific steps technicians must follow during inspections, repairs, and overhauls, guaranteeing adherence to regulatory standards and manufacturer specifications. The existence and rigorous application of these procedures directly affect the competence and effectiveness of those performing aircraft maintenance.

- Adherence to Regulatory Standards

Maintenance procedures are often directly derived from, or heavily influenced by, regulations set forth by aviation authorities such as the FAA, EASA, or Transport Canada. These regulations mandate specific inspection intervals, maintenance tasks, and documentation requirements. Technicians working within an aerospace maintenance role must be thoroughly versed in these regulations and adhere to the prescribed procedures. For instance, a procedure for inspecting an aircraft’s control surfaces would explicitly reference the relevant regulatory guidelines, ensuring that all required checks are performed to the necessary standard. Failure to adhere to regulatory standards can lead to significant fines, grounding of aircraft, and, most importantly, safety hazards.

- Utilization of Technical Manuals

Aircraft manufacturers provide detailed technical manuals that outline approved maintenance procedures for each specific aircraft model. These manuals contain step-by-step instructions, diagrams, and specifications for performing various maintenance tasks. Technicians must utilize these manuals as the primary source of information when performing maintenance. An example would be following the manufacturer’s procedure for replacing a landing gear strut, which includes specific torque values, component alignments, and safety precautions. Using technical manuals ensures that maintenance is performed in accordance with the aircraft’s design and intended operating parameters.

- Implementation of Inspection Checklists

Inspection checklists are structured documents that guide technicians through a series of checks to identify potential defects or discrepancies. These checklists ensure that all critical areas of an aircraft are thoroughly inspected and that no items are overlooked. For instance, an inspection checklist for an engine might include checks for oil leaks, worn components, and proper operation of critical systems. Completing inspection checklists systematically reduces the risk of human error and helps to maintain the overall integrity of the aircraft.

- Documentation of Maintenance Activities

Accurate and comprehensive documentation of all maintenance activities is essential. Technicians must maintain detailed records of inspections, repairs, and parts replacements, including the date, time, and specific actions taken. This documentation serves as a historical record of the aircraft’s maintenance history and is crucial for tracking component life, identifying recurring problems, and ensuring regulatory compliance. For example, a maintenance log entry would detail the specific repairs performed on a damaged wing section, including the materials used and the technicians involved. Proper documentation provides a clear audit trail and supports the continued safe operation of the aircraft.

These facets highlight the crucial role that Maintenance Procedures play within the domain of aerospace maintenance and the work of aerospace technicians. A technicians understanding and application of these procedures is not merely a matter of compliance; it is a fundamental aspect of ensuring the safety and reliability of air travel. The aerospace maintenance position relies on a foundation of standardized procedures that minimize risk and maximize performance.

5. Safety Compliance

Safety compliance is paramount within the parameters of an aerospace technician’s responsibilities. It forms the bedrock of all maintenance procedures, influencing how work is performed, documented, and verified. This ensures the continued airworthiness and operational integrity of aircraft.

- Adherence to Regulatory Mandates

Aerospace technicians operate under strict regulatory frameworks established by agencies such as the FAA and EASA. Compliance involves understanding and implementing these mandates, which cover everything from inspection intervals to approved repair techniques. For example, technicians must adhere to specific guidelines for torqueing bolts on critical engine components, as outlined in the manufacturer’s service manual and verified by regulatory standards. Failure to comply can result in penalties, aircraft grounding, and, more critically, compromised safety.

- Use of Personal Protective Equipment (PPE)

The role entails working with hazardous materials, heavy machinery, and potential fall hazards. Safety compliance mandates the consistent and correct use of PPE, including eye protection, hearing protection, and specialized respirators. An example includes technicians wearing fire-resistant clothing when working near fuel systems or utilizing specialized gloves when handling corrosive chemicals. The correct use of PPE mitigates the risk of injury and exposure to hazardous substances, safeguarding the technician’s well-being.

- Hazard Identification and Mitigation

Technicians are responsible for identifying potential hazards within their work environment and implementing appropriate mitigation strategies. This involves conducting pre-task risk assessments, implementing lockout/tagout procedures during maintenance, and ensuring proper ventilation in confined spaces. For instance, a technician might identify a trip hazard in a hangar and promptly address it by placing warning signs or removing the obstruction. Proactive hazard identification and mitigation minimizes the risk of accidents and injuries.

- Emergency Response Preparedness

Safety compliance includes being prepared to respond effectively to emergencies, such as fuel spills, fires, or injuries. Technicians must be trained in emergency procedures, including evacuation protocols, first aid, and the use of fire suppression equipment. For example, technicians should know how to activate emergency shut-off valves in the event of a fuel leak or administer basic first aid to an injured colleague. Preparedness enhances the likelihood of a successful and safe response during critical situations.

These facets highlight the interconnectedness between safety compliance and the duties outlined in the responsibilities of aerospace maintenance technicians. An unwavering commitment to safety underpins the integrity of aircraft maintenance and the wellbeing of all stakeholders involved in aviation operations.

6. Equipment Expertise

Equipment expertise is a core component of the capabilities required for individuals fulfilling roles within aerospace maintenance. The specific instruments, machinery, and diagnostic systems necessitate a depth of understanding crucial to the safety and efficiency of aircraft maintenance procedures. Without thorough competence in operating and interpreting data from specialized equipment, technicians risk misdiagnosis, improper repairs, and compromised airworthiness.

- Diagnostic Equipment Operation

Aerospace technicians must possess proficiency in operating various diagnostic tools, including multimeters, oscilloscopes, and borescope. These instruments enable the identification of electrical faults, hydraulic leaks, and structural anomalies. For instance, technicians use multimeters to measure voltage and resistance in electrical circuits to diagnose faulty wiring, and borescope to inspect turbine blades. The correct operation and interpretation of data from these tools are essential for accurate troubleshooting and repair.

- Specialized Tool Utilization

The work of an aerospace technician involves the use of specialized tools designed for specific tasks, such as torque wrenches, rivet guns, and safety wire pliers. Proper tool selection and application is critical to prevent damage to aircraft components and ensure secure fastening. Technicians must also understand the calibration requirements and maintenance procedures for these tools to ensure accuracy and reliability. For example, torque wrenches must be calibrated regularly to ensure that fasteners are tightened to the specified torque value, preventing over-stressing or loosening of components.

- Ground Support Equipment (GSE) Handling

Many maintenance tasks require the use of ground support equipment, such as aircraft jacks, tow tractors, and hydraulic power units. Technicians must be trained in the safe operation and maintenance of this equipment to prevent accidents and ensure efficient workflow. This includes understanding load limits, operating procedures, and emergency shutdown protocols. For example, when jacking an aircraft, technicians must follow specific procedures to ensure stability and prevent damage to the airframe.

- Software and Data Analysis Systems

Modern aircraft incorporate sophisticated avionics and engine management systems that require the use of specialized software for diagnostics and data analysis. Technicians must be capable of interpreting fault codes, reviewing maintenance logs, and using software tools to troubleshoot complex system problems. This includes familiarity with aircraft maintenance manuals and technical publications, which are often accessed electronically. The ability to navigate and extract relevant information from these systems is essential for efficient and effective maintenance.

The ability to adeptly handle equipment is not merely a procedural necessity; it forms a cornerstone of a qualified professional. Effective execution of maintenance responsibilities hinges on a technicians ability to interpret data, manipulate specialized tools, and operate intricate machinery. By mastering these elements, an aerospace technician contributes significantly to ensuring aircraft safety and operational readiness, fulfilling the core expectations for this role.

7. Documentation Standards

In the realm of aerospace maintenance, the meticulous adherence to “Documentation Standards” is not merely a procedural formality but a critical element inherent in an aerospace technician’s responsibilities. These standards dictate how maintenance activities are recorded, tracked, and verified, ensuring compliance with regulatory requirements and providing a comprehensive audit trail for all maintenance actions.

- Maintenance Logs and Records

Technicians are responsible for maintaining accurate and detailed maintenance logs that document all inspections, repairs, and modifications performed on aircraft. These logs must include specific information such as the date, time, and nature of the work performed, the parts used, and the signatures of the technicians involved. For example, if a technician replaces a faulty engine sensor, they must record the sensor’s part number, serial number, and the reason for its replacement in the maintenance log. Accurate and complete maintenance logs are essential for tracking component life, identifying recurring problems, and ensuring compliance with regulatory requirements.

- Inspection Reports

Inspection reports are generated following routine and non-routine inspections of aircraft components and systems. These reports detail the findings of the inspection, including any discrepancies, defects, or areas of concern. Inspection reports must be completed thoroughly and accurately, with clear descriptions of any issues identified and the corrective actions taken. For instance, an inspection report for a wing might note the presence of corrosion, cracks, or other structural damage. Detailed inspection reports provide valuable information for assessing the overall condition of the aircraft and planning future maintenance activities.

- Repair Orders and Work Orders

Repair orders and work orders authorize and track the performance of specific maintenance tasks. These documents typically include a description of the work to be performed, the estimated cost, and the required parts and materials. Technicians must follow the instructions outlined in the repair order and document all work completed. An example would be a repair order for fixing a malfunctioning landing gear system, detailing the steps required to troubleshoot the problem, replace faulty components, and test the system’s functionality. Completed repair orders serve as a record of the maintenance performed and provide a basis for billing and invoicing.

- Component Traceability Records

Maintaining traceability records for aircraft components is crucial for ensuring that parts are properly identified, tracked, and maintained throughout their lifecycle. These records include information such as the component’s part number, serial number, date of manufacture, and installation history. Technicians are responsible for ensuring that all parts installed on an aircraft are properly documented and that their history can be traced back to the original manufacturer. For instance, if a technician installs a new engine on an aircraft, they must record the engine’s serial number and installation date in the component traceability records. Accurate component traceability is essential for preventing the installation of counterfeit or unapproved parts and for ensuring that components are properly maintained.

In conclusion, stringent adherence to Documentation Standards is an indispensable aspect of an aerospace technician’s responsibilities. Thorough and accurate documentation ensures regulatory compliance, facilitates effective maintenance planning, and ultimately contributes to the safety and reliability of aircraft operations. These standards are not simply bureaucratic requirements; they are a cornerstone of the profession.

Frequently Asked Questions

The following section addresses common inquiries regarding the roles, responsibilities, and requirements associated with positions in aerospace maintenance. The information provided aims to clarify expectations and offer insights into this specialized field.

Question 1: What are the minimum educational requirements for a position involving aircraft maintenance?

Generally, a high school diploma or its equivalent is the minimum requirement. However, employers frequently prefer candidates holding an associate’s or bachelor’s degree in aviation maintenance technology or a closely related discipline. Formal education provides the foundational knowledge necessary for understanding complex aircraft systems.

Question 2: Is an Airframe and Powerplant (A&P) license always required?

For positions involving the maintenance of civil aircraft, an A&P license is almost universally required. This license, issued by regulatory bodies, demonstrates that an individual has met specific training and testing standards, attesting to their competence in maintaining both the airframe and powerplant of an aircraft.

Question 3: What types of physical demands can one expect in this line of work?

The work often demands physical fitness. Personnel may be required to lift heavy objects, work in confined spaces, and perform tasks that require manual dexterity and coordination. The role may necessitate climbing, crawling, and prolonged periods of standing or bending.

Question 4: What are some common diagnostic tools used in aircraft maintenance?

Common diagnostic tools include multimeters for electrical testing, oscilloscopes for analyzing electronic signals, borescopes for internal inspections of engines and structures, and hydraulic pressure testers for evaluating hydraulic systems. The ability to operate and interpret data from these tools is essential.

Question 5: What is the significance of technical manuals in this setting?

Technical manuals provided by aircraft manufacturers are indispensable resources. These manuals contain detailed step-by-step procedures, diagrams, and specifications for performing maintenance tasks. Following these manuals ensures that maintenance is performed according to the aircraft’s design and intended operating parameters.

Question 6: How important is safety compliance in aerospace maintenance?

Safety compliance is of paramount importance. Personnel must adhere to stringent safety regulations and procedures to mitigate risks associated with working on complex machinery and potentially hazardous materials. This includes the correct use of personal protective equipment and adherence to hazardous material handling protocols.

In summary, aerospace maintenance demands a blend of formal education, specialized licensure, physical fitness, technical proficiency, and unwavering commitment to safety. Addressing these elements ensures that qualified individuals are selected and managed effectively.

The next section will explore career paths and salary expectations within the aviation maintenance field.

Conclusion

The preceding exploration of “aerospace technician job description” has illuminated the multifaceted nature of this critical role. The discourse has encompassed essential qualifications, core responsibilities, essential skills, maintenance procedures, safety compliance, equipment expertise, and documentation standards. A comprehensive understanding of these elements is crucial for attracting, training, and retaining qualified professionals in the aerospace industry.

The information presented herein should serve as a foundational resource for those seeking to define, understand, or pursue careers in aerospace maintenance. A commitment to continuous learning, meticulous adherence to standards, and unwavering dedication to safety remain paramount for ensuring the continued airworthiness and operational integrity of aircraft. The future of aviation safety depends on the competence and vigilance of professionals working in this vital field.

![Top Countries: Best Aerospace Engineering Jobs [2024] Innovating the Future of Flight with Reliable Aviation Solutions Top Countries: Best Aerospace Engineering Jobs [2024] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/03/th-91-300x200.jpg)