Individuals in this role are responsible for the design, development, and testing of aircraft and related systems within a major aviation manufacturing company. Their work involves applying principles of engineering, physics, and mathematics to create efficient, safe, and innovative aircraft solutions. For example, one might work on optimizing wing aerodynamics to reduce fuel consumption or developing new structural materials to improve aircraft strength and durability.

The contribution of these specialists is crucial for the advancement of the aviation industry. Their expertise ensures the production of reliable and high-performance aircraft, contributing to economic growth, global connectivity, and national security. Historically, advancements in aircraft technology have consistently relied on the ingenuity and problem-solving skills of these engineering professionals, from the early days of flight to the development of modern jetliners.

The following discussion will delve into specific aspects related to career paths, necessary skills, educational requirements, and the impact these individuals have on the aerospace sector, providing a comprehensive overview of this essential profession.

Guidance for Aspiring Professionals

The following points offer insights gleaned from experienced practitioners in the aircraft design and development field, intended to assist those pursuing a career in this highly specialized area.

Tip 1: Solidify Foundational Knowledge: A robust understanding of core engineering principles, including aerodynamics, thermodynamics, and structural mechanics, is paramount. Consistent review and application of these fundamentals are essential.

Tip 2: Emphasize Computational Skills: Proficiency in computer-aided design (CAD), finite element analysis (FEA), and computational fluid dynamics (CFD) software is increasingly critical. Mastering these tools enables efficient design, simulation, and analysis of aircraft components and systems.

Tip 3: Pursue Advanced Education: Consider advanced degrees or specialized certifications in areas such as aerospace engineering, materials science, or control systems. These credentials often provide a competitive advantage and deeper understanding of complex engineering problems.

Tip 4: Develop Strong Communication Skills: Effective communication, both written and verbal, is vital for collaborating with diverse teams, presenting technical information, and documenting design decisions. Practice clear and concise communication in all professional settings.

Tip 5: Seek Internships and Practical Experience: Gaining hands-on experience through internships, co-op programs, or research projects is invaluable. These opportunities provide exposure to real-world engineering challenges and industry practices.

Tip 6: Cultivate a Systems-Thinking Approach: Understand how individual aircraft components and systems interact with each other to achieve overall performance goals. A holistic perspective is crucial for identifying potential design trade-offs and optimizing system integration.

Tip 7: Stay Abreast of Technological Advancements: The aerospace industry is constantly evolving. Regularly review technical journals, attend industry conferences, and engage in continuing education to stay informed about emerging technologies and best practices.

These recommendations highlight the importance of a strong academic foundation, practical experience, and continuous learning for success in the aircraft engineering field. Implementing these strategies can significantly enhance one’s prospects for a fulfilling and impactful career.

The subsequent sections will further explore specific career paths and the ongoing impact of this profession on the future of aviation.

1. Design Innovation

Design innovation is a cornerstone of the role fulfilled by an Airbus aerospace engineer. It drives the evolution of aircraft technology and plays a critical role in enhancing efficiency, safety, and passenger experience. This commitment to innovation necessitates a continuous cycle of research, development, and implementation of new technologies and methodologies.

- Aerodynamic Efficiency

This facet focuses on minimizing drag and maximizing lift to improve fuel economy and aircraft performance. Engineers work on wing designs, winglet configurations, and advanced materials to achieve these goals. For example, the A350’s wing design incorporates advanced airfoil shapes and composite materials to reduce drag, leading to significant fuel savings.

- Sustainable Technologies

With growing environmental concerns, innovation in sustainable technologies is paramount. Engineers are actively exploring alternative fuels, electric propulsion systems, and lightweight materials to reduce the environmental impact of air travel. Research into hybrid-electric aircraft designs and the integration of biofuels are key areas of focus.

- Enhanced Passenger Experience

Design innovation extends beyond performance to encompass passenger comfort and convenience. Engineers work on optimizing cabin layouts, improving noise reduction, and integrating advanced entertainment systems. Examples include the implementation of wider seats, improved cabin lighting, and advanced connectivity solutions in new aircraft models.

- Advanced Manufacturing Techniques

Innovative manufacturing processes, such as additive manufacturing (3D printing), enable the creation of complex aircraft components with reduced weight and improved performance. These techniques allow for the production of customized parts, faster prototyping, and more efficient use of materials, optimizing the entire aircraft production cycle.

The pursuit of design innovation is integral to the responsibilities of these engineers, enabling Airbus to maintain a competitive edge and contribute to the advancement of the aerospace industry. By embracing cutting-edge technologies and methodologies, these professionals are shaping the future of air travel.

2. Structural Integrity

Structural integrity is paramount to the role of an Airbus aerospace engineer, functioning as a critical determinant of aircraft safety and operational longevity. The consequences of compromised structural integrity can range from minor performance degradation to catastrophic failure, making its meticulous assessment and maintenance a core responsibility. Engineers in this capacity conduct rigorous analyses, simulations, and physical testing to ensure aircraft structures withstand operational stresses, aerodynamic forces, and environmental factors such as corrosion and fatigue. The implementation of non-destructive testing (NDT) methods, like ultrasonic inspection and radiographic analysis, exemplifies the proactive measures employed to detect and address potential structural weaknesses before they escalate into critical issues. For instance, the detection of micro-cracks in wing spars through NDT allows for timely repairs, averting potential in-flight structural failures.

The design phase heavily emphasizes the integration of robust structural elements and redundant safety systems. Finite element analysis (FEA) is routinely employed to simulate stress distributions and identify critical areas within the aircraft’s structure. Furthermore, materials selection plays a pivotal role, with advanced composites and alloys chosen for their high strength-to-weight ratios and resistance to fatigue and corrosion. The use of carbon fiber reinforced polymer (CFRP) in the Airbus A350’s fuselage and wings demonstrates the application of advanced materials to enhance structural integrity while reducing overall weight, thereby improving fuel efficiency. This focus on material science and structural design directly impacts the aircraft’s ability to withstand extreme flight conditions and prolonged operational cycles.

In summary, structural integrity represents an indispensable aspect of an Airbus aerospace engineer’s responsibilities. The commitment to maintaining and enhancing structural integrity directly correlates with passenger safety, aircraft reliability, and the overall success of Airbus operations. Challenges persist in addressing emerging threats such as composite material degradation and the need for more efficient inspection techniques, but the ongoing dedication to research and innovation ensures that aircraft structures continue to meet the highest safety standards.

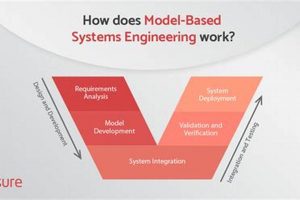

3. Systems Integration

Systems integration represents a core function within the aerospace industry, particularly for professionals at Airbus responsible for the design, development, and maintenance of aircraft. It is the process of bringing together the component subsystems of an aircraft into one functional entity, ensuring seamless interoperability and optimal performance. The complexity of modern aircraft necessitates meticulous planning and execution of systems integration, making it a critical skill for aerospace engineers.

- Avionics Integration

Avionics integration involves combining various electronic systems, such as navigation, communication, flight control, and surveillance systems, into a unified architecture. The aerospace engineer is tasked with ensuring these systems communicate effectively, adhere to safety standards, and provide pilots with accurate and timely information. For example, integrating a new autopilot system requires careful consideration of its compatibility with existing flight management systems, as well as thorough testing to validate its performance under diverse flight conditions. Successful avionics integration is essential for enhancing flight safety, reducing pilot workload, and improving operational efficiency.

- Propulsion System Integration

This facet focuses on integrating the aircraft’s engines with the airframe and other relevant systems, such as fuel supply and exhaust management. The engineer must optimize engine placement to minimize drag, manage thermal effects, and ensure efficient fuel consumption. Integrating a new engine model may require redesigning the engine nacelle, adjusting control systems, and validating performance through wind tunnel testing. Effective propulsion system integration is crucial for maximizing fuel efficiency, reducing emissions, and ensuring the safe and reliable operation of the aircraft.

- Cabin Systems Integration

Cabin systems integration involves incorporating various passenger amenities, such as entertainment systems, lighting, climate control, and seating configurations, into the aircraft’s interior. The engineer must ensure these systems are compatible with the aircraft’s electrical and environmental control systems, as well as meeting safety and regulatory requirements. Integrating a new in-flight entertainment system, for instance, requires careful consideration of power consumption, electromagnetic interference, and passenger safety. Successful cabin systems integration enhances passenger comfort, contributes to the overall flying experience, and supports airline branding strategies.

- Flight Control Systems Integration

Flight control systems integration encompasses combining various control surfaces, actuators, and sensors to ensure precise and responsive aircraft handling. The aerospace engineer is responsible for designing and implementing control laws that govern the aircraft’s stability and maneuverability. Integrating a new fly-by-wire system requires extensive simulations, hardware-in-the-loop testing, and flight trials to validate its performance and safety. Effective flight control systems integration is vital for enhancing aircraft stability, reducing pilot workload, and improving overall flight safety.

These interconnected facets of systems integration underscore the breadth and depth of expertise demanded of Airbus aerospace engineers. Their ability to orchestrate these complex integrations directly influences the performance, safety, and efficiency of Airbus aircraft, solidifying their critical role within the organization and the broader aerospace industry.

4. Performance Optimization

For aerospace engineers at Airbus, performance optimization is a continuous endeavor integral to the design, development, and operational phases of aircraft. It focuses on enhancing key metrics such as fuel efficiency, speed, payload capacity, and overall operational costs. These efforts are driven by both economic considerations and increasingly stringent environmental regulations.

- Aerodynamic Efficiency Enhancement

This facet involves refining the aircraft’s shape and surface characteristics to minimize drag and maximize lift. Computational Fluid Dynamics (CFD) simulations are employed to analyze airflow patterns and identify areas for improvement. The implementation of advanced wing designs, such as blended winglets and laminar flow control surfaces, directly contributes to reduced fuel consumption and increased range. For instance, engineers may work on optimizing the A350’s wing profile to reduce air resistance, leading to significant fuel savings over long-haul flights. Such improvements directly translate to reduced operating costs for airlines and decreased carbon emissions.

- Weight Reduction Strategies

Reducing the overall weight of an aircraft is a critical aspect of performance optimization. Airbus aerospace engineers explore the use of lightweight materials, such as carbon fiber reinforced polymers (CFRP) and advanced aluminum alloys, to replace heavier components. Optimizing structural designs and minimizing non-essential weight also contribute to improved fuel efficiency and payload capacity. The extensive use of composites in the A350’s fuselage and wings, for example, represents a significant weight reduction compared to traditional aluminum structures, enabling longer flight ranges and reduced fuel burn.

- Engine Performance Improvement

Optimizing engine performance is crucial for enhancing fuel efficiency and reducing emissions. Airbus collaborates with engine manufacturers to integrate advanced engine technologies, such as geared turbofans and advanced combustion systems, into their aircraft. Engineers also work on optimizing engine control systems to maximize efficiency under various flight conditions. The integration of new, more efficient engine models into existing aircraft fleets can result in substantial fuel savings and reduced environmental impact.

- Flight Operations Optimization

Performance optimization extends beyond aircraft design to encompass flight operations. Airbus aerospace engineers develop and implement flight management systems (FMS) that optimize flight paths, altitudes, and speeds to minimize fuel consumption and flight time. They also work on improving air traffic management (ATM) systems to reduce congestion and delays. Optimizing flight profiles and minimizing holding patterns can result in significant fuel savings and reduced carbon emissions. Additionally, the development of predictive maintenance algorithms and optimized maintenance schedules contributes to improved aircraft availability and reduced operational costs.

These interconnected facets of performance optimization directly impact the efficiency, sustainability, and economic viability of Airbus aircraft. By continuously seeking improvements in aerodynamic design, material selection, engine technology, and flight operations, aerospace engineers at Airbus contribute to a more efficient and environmentally responsible aviation industry. These advancements not only benefit airlines through reduced operating costs but also contribute to a more sustainable future for air travel.

5. Safety Assurance

Safety assurance is inextricably linked to the role of an Airbus aerospace engineer. The core responsibility of these professionals centers on designing, developing, and maintaining aircraft systems to meet stringent safety standards. Any deviation from these standards can have catastrophic consequences, underscoring the critical importance of safety assurance. One example of this direct connection is the design of redundant systems within the aircraft, such as multiple hydraulic systems or flight control computers. This redundancy ensures that even if one system fails, another can immediately take over, preventing loss of control or other hazardous situations. The rigorous testing and simulation processes, including extreme condition scenarios, further exemplify the engineer’s commitment to safety, ensuring that aircraft can withstand unexpected events without compromising passenger or crew safety.

The practical application of safety assurance principles is evident in the certification process. Before an aircraft can enter commercial service, it must undergo extensive testing and evaluation by regulatory authorities such as the European Aviation Safety Agency (EASA) or the Federal Aviation Administration (FAA). Engineers play a pivotal role in this process, providing detailed documentation, conducting analyses, and demonstrating compliance with all applicable safety regulations. Real-world examples of this include the design of emergency exit systems, which must allow for rapid evacuation of the aircraft in the event of an emergency, and the implementation of fire suppression systems in cargo holds and engine compartments, preventing the spread of fire and protecting the aircraft’s structure. Further applications include continuous monitoring of fleet performance and safety records, identifying trends or potential issues, and proactively implementing corrective actions or design changes to prevent accidents.

In summary, safety assurance is not merely a component of an Airbus aerospace engineer’s job; it is the foundation upon which all design and operational decisions are made. The challenges are ongoing, particularly with the increasing complexity of aircraft systems and the emergence of new technologies. By adhering to stringent safety standards, continuously improving design processes, and rigorously testing aircraft systems, these engineers play a critical role in maintaining the high levels of safety that are expected in modern air travel. This dedication to safety not only protects passengers and crew but also safeguards the reputation and long-term viability of Airbus and the aerospace industry as a whole.

6. Regulatory Compliance

Regulatory compliance represents a central tenet of the responsibilities undertaken by an Airbus aerospace engineer. Adherence to international aviation standards is non-negotiable, directly influencing every stage of aircraft design, production, and operation. The role requires a comprehensive understanding of the legal and technical frameworks established by governing bodies such as the European Aviation Safety Agency (EASA) and the Federal Aviation Administration (FAA).

- Certification Processes

Certification processes form a cornerstone of regulatory compliance. Before an aircraft can enter commercial service, it must undergo rigorous testing and evaluation to demonstrate conformity with airworthiness standards. Engineers are directly involved in preparing documentation, conducting analyses, and providing evidence of compliance to regulatory agencies. Examples include demonstrating that the aircraft meets specific noise emission levels, structural integrity requirements, and emergency evacuation standards. Failure to meet these criteria can result in significant delays and financial penalties.

- Design Standards Adherence

Adherence to design standards is critical throughout the aircraft development lifecycle. Engineers must incorporate specific safety features and design elements mandated by regulatory agencies. This includes complying with requirements related to fire protection, fuel tank inerting, and flight control system redundancy. Non-compliance can lead to design modifications and rework, potentially impacting project timelines and costs. The integration of these standards into the initial design phase is essential for ensuring cost-effective and timely compliance.

- Operational Requirements

Beyond design and certification, regulatory compliance extends to operational requirements. Engineers must consider how aircraft are operated and maintained, ensuring that procedures align with regulatory guidelines. This includes developing maintenance schedules, training programs, and operational manuals that adhere to industry best practices and regulatory mandates. For instance, compliance with Continued Airworthiness requirements dictates how airlines inspect and maintain aircraft to ensure ongoing safety and reliability. Failure to adhere to these requirements can result in operational restrictions or grounding of aircraft.

- Environmental Regulations

Increasingly, environmental regulations play a significant role in aerospace engineering. Engineers must design aircraft that meet stringent emission standards and noise reduction targets. This involves implementing fuel-efficient technologies, reducing engine noise, and exploring alternative fuels. Compliance with regulations such as the International Civil Aviation Organization (ICAO) standards for carbon emissions is essential for airlines to operate in certain regions. Non-compliance can lead to restrictions on aircraft operations and reputational damage.

The multifaceted nature of regulatory compliance necessitates continuous monitoring of evolving standards and proactive adaptation of engineering practices. The consequences of non-compliance extend beyond financial penalties, potentially impacting safety and public trust. Airbus aerospace engineers, therefore, play a crucial role in ensuring that aircraft not only meet performance and efficiency targets but also adhere to the highest levels of safety and regulatory standards, supporting the long-term sustainability of the aviation industry.

7. Continuous Improvement

For an Airbus aerospace engineer, continuous improvement is not merely a procedural requirement but a fundamental ethos underpinning every aspect of their work. It signifies a commitment to perpetually refining processes, designs, and operational efficiencies to enhance aircraft performance, safety, and sustainability. This dedication transcends static adherence to standards, demanding proactive engagement with evolving technologies and methodologies.

- Process Optimization

Process optimization involves systematically analyzing and refining existing workflows to eliminate inefficiencies and reduce production costs. Airbus aerospace engineers actively participate in identifying bottlenecks, streamlining manufacturing processes, and implementing lean methodologies. For instance, adopting automated assembly techniques or optimizing supply chain management can significantly reduce aircraft production time and associated expenses. These efforts directly contribute to enhanced operational efficiency and competitiveness.

- Design Refinement

Design refinement entails continuously evaluating and improving aircraft designs based on operational feedback, technological advancements, and simulation results. Engineers analyze flight data, maintenance records, and pilot reports to identify areas for improvement in aerodynamics, structural integrity, and system performance. The iterative design process allows for incorporating new materials, optimizing wing profiles, and enhancing passenger comfort. These refinements translate into improved fuel efficiency, reduced noise emissions, and enhanced overall aircraft performance.

- Technology Adoption

Technology adoption involves integrating cutting-edge technologies into aircraft design and manufacturing processes. Airbus aerospace engineers actively research and evaluate emerging technologies, such as additive manufacturing, artificial intelligence, and advanced sensor systems, to identify potential applications. For instance, incorporating 3D-printed components can reduce weight and improve design flexibility, while integrating AI-powered diagnostic tools can enhance maintenance efficiency. Strategic technology adoption enables Airbus to maintain a competitive edge and meet evolving market demands.

- Skill Enhancement

Skill enhancement focuses on continuously developing the expertise of aerospace engineers through training, mentorship, and knowledge sharing. Airbus invests in programs that enhance technical skills, promote innovation, and foster collaboration. Encouraging engineers to pursue advanced certifications, attend industry conferences, and participate in research projects contributes to a highly skilled and adaptable workforce. This commitment to skill enhancement ensures that engineers remain at the forefront of aerospace technology and can effectively address complex challenges.

In conclusion, the pursuit of continuous improvement permeates every facet of an Airbus aerospace engineer’s responsibilities. By actively engaging in process optimization, design refinement, technology adoption, and skill enhancement, these professionals contribute to the ongoing evolution of aircraft technology, enhancing safety, efficiency, and sustainability within the aviation industry. The resulting improvements not only benefit airlines through reduced operating costs and enhanced performance but also contribute to a more sustainable and environmentally responsible future for air travel.

Frequently Asked Questions

The following section addresses common inquiries regarding the role and responsibilities associated with the specified professional designation within a leading aerospace manufacturer. The information presented aims to provide clarity and insights based on industry standards and typical practices.

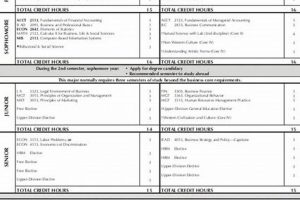

Question 1: What educational qualifications are generally required?

Typically, a minimum of a Bachelor’s degree in Aerospace Engineering, Mechanical Engineering, or a closely related field is required. Many positions, particularly those involving research and development, may necessitate a Master’s degree or Doctorate.

Question 2: What are the core technical skills necessary for success?

Proficiency in areas such as aerodynamics, structural analysis, materials science, and control systems is essential. Additionally, competency in computer-aided design (CAD) software, finite element analysis (FEA) tools, and programming languages is highly valued.

Question 3: What types of projects might one be involved in?

Project involvement can vary widely, ranging from designing new aircraft components to optimizing existing systems for improved performance. Examples include working on wing aerodynamics, developing new structural materials, or integrating advanced avionics systems.

Question 4: How important is regulatory compliance in this role?

Regulatory compliance is of paramount importance. Aerospace engineers must ensure that all designs and modifications adhere to strict airworthiness standards and regulations set by agencies such as EASA and FAA. Failure to comply can have severe consequences, including grounding of aircraft.

Question 5: What opportunities exist for career advancement?

Career advancement opportunities are diverse, ranging from technical specialist roles to project management and leadership positions. Advancement typically requires a combination of experience, expertise, and demonstrated leadership abilities.

Question 6: How significant is the emphasis on safety in this profession?

Safety is the overriding priority. Aerospace engineers are entrusted with designing and maintaining aircraft to the highest safety standards. All decisions and actions must prioritize the safety of passengers, crew, and the general public.

In essence, the role demands a combination of rigorous technical knowledge, unwavering commitment to safety, and proactive engagement with continuous improvement initiatives. The above points should offer a concise overview of critical aspects related to this profession.

The subsequent section will delve into the long-term prospects and challenges facing professionals in this field.

Conclusion

This exposition has thoroughly examined the multifaceted role of an Airbus aerospace engineer. The analysis has underscored the critical importance of design innovation, structural integrity, systems integration, performance optimization, safety assurance, regulatory compliance, and continuous improvement in shaping the landscape of modern aviation. The rigorous demands of the profession necessitate a blend of advanced technical expertise, unwavering dedication to safety, and a commitment to continuous learning and adaptation.

As the aerospace industry continues to evolve, the challenges and opportunities facing these professionals will only intensify. A commitment to excellence, ethical conduct, and proactive engagement with emerging technologies will be paramount in ensuring the continued advancement of safe, efficient, and sustainable air travel. Further research and development, coupled with a focus on cultivating a highly skilled workforce, are essential to meeting the future demands of this vital field. The future of aviation hinges on the competence and dedication of professionals in this critical role.

![Top Aerospace Engineering Masters Programs [Ranked] Innovating the Future of Flight with Reliable Aviation Solutions Top Aerospace Engineering Masters Programs [Ranked] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-459-300x200.jpg)