A typical workday for a professional in this field is characterized by complex problem-solving and the application of scientific principles to the design, development, and testing of aircraft, spacecraft, satellites, and missiles. Responsibilities can range from conceptualizing new vehicle designs to ensuring the safety and efficiency of existing systems. For example, an engineer might spend a portion of their day running simulations to analyze aerodynamic performance, followed by a meeting to discuss structural integrity with colleagues.

Understanding the routine of these professionals is vital for aspiring engineers and students considering career paths. It provides a realistic perspective on the challenges and rewards associated with this demanding yet intellectually stimulating occupation. Historically, advancements in aviation and space exploration have been driven by the dedication and expertise of these engineers, making their contributions essential to technological progress and national security. The benefit of understanding their daily functions allows for better career preparation and expectation management.

The subsequent sections will delve into the specific tasks, responsibilities, and required skills that constitute a professional’s daily experience, offering a deeper understanding of this dynamic and crucial role within the aerospace industry. Topics include project management, collaboration, data analysis, and the continuous learning necessary to stay at the forefront of technological advancements.

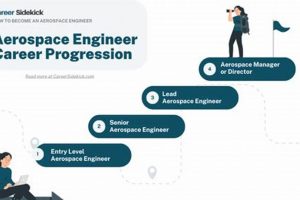

Essential Guidance for a Career in Aerospace Engineering

The following points offer pragmatic recommendations for individuals pursuing a career path focused on the design, development, and testing of aircraft and spacecraft. These are informed by the demands and realities of the daily professional experience.

Tip 1: Cultivate a Strong Foundation in Mathematics and Physics: A comprehensive understanding of calculus, differential equations, linear algebra, and physics is indispensable. The application of these principles is fundamental to analyzing aerodynamic forces, structural integrity, and propulsion systems. Regular practice and a focus on conceptual understanding, not just memorization, are key.

Tip 2: Develop Proficiency in Computer-Aided Design (CAD) and Simulation Software: Familiarity with industry-standard software such as SolidWorks, CATIA, ANSYS, and MATLAB is essential. These tools are used daily for creating detailed designs, performing simulations, and analyzing data. Consider pursuing relevant certifications to demonstrate proficiency.

Tip 3: Seek Internships and Co-op Opportunities: Practical experience is invaluable. Internships and co-op programs provide exposure to real-world engineering challenges and allow for the application of theoretical knowledge in a professional setting. These experiences also offer networking opportunities and potential pathways to full-time employment.

Tip 4: Sharpen Problem-Solving and Analytical Skills: Aerospace engineering often involves complex problems requiring innovative solutions. Develop the ability to break down complex issues into manageable components, analyze data critically, and formulate effective solutions. Consider participating in engineering competitions or design projects to hone these skills.

Tip 5: Emphasize Communication and Teamwork: Aerospace projects are typically collaborative endeavors. Effective communication, both written and verbal, is crucial for conveying technical information, coordinating with colleagues, and presenting findings to stakeholders. Actively participate in group projects and seek opportunities to improve communication skills through presentations and technical writing.

Tip 6: Prioritize Continuous Learning and Professional Development: The aerospace industry is constantly evolving. Staying abreast of the latest technological advancements requires a commitment to lifelong learning. Attend conferences, read industry publications, and pursue continuing education opportunities to remain competitive and expand knowledge base.

These recommendations underscore the significance of a well-rounded education, practical experience, and continuous professional development in preparing for a successful career. The application of these strategies will enhance preparedness for the challenges and rewards inherent in the aerospace field.

The subsequent sections will expand on the importance of networking and professional affiliations within the aerospace community.

1. Design & Analysis

Design and analysis are central functions within the aerospace engineering profession. They constitute a significant portion of an engineers daily workload and are integral to the successful creation and operation of aerospace vehicles and systems. A typical workday often hinges on the application of engineering principles to design, model, simulate, and analyze various components and systems.

- Conceptual Design and Modeling

Conceptual design involves the initial phases of creating aerospace components or systems. Engineers develop preliminary designs based on mission requirements and performance objectives. This includes generating 3D models using CAD software and assessing feasibility. An example includes sketching out the wing configuration of a new aircraft based on aerodynamic requirements, which can impact fuel efficiency and flight stability.

- Computational Fluid Dynamics (CFD) Analysis

CFD simulations are employed to analyze fluid flow around aerospace vehicles. Engineers use CFD software to predict aerodynamic forces, heat transfer, and pressure distributions. For instance, during the design of a new engine nozzle, CFD analysis helps optimize the shape for maximizing thrust while minimizing drag, a crucial factor in overall engine performance and efficiency.

- Finite Element Analysis (FEA) for Structural Integrity

FEA is used to evaluate the structural integrity of aerospace components under various loading conditions. Engineers create detailed models of structures and simulate stress, strain, and deformation. This is vital for ensuring components can withstand operational stresses. A real-world example includes simulating the stress on an aircraft wing during turbulence to ensure structural failure does not occur.

- System Performance Analysis

System performance analysis evaluates the overall performance of integrated aerospace systems. This includes analyzing factors like fuel consumption, range, payload capacity, and reliability. Engineers use simulation tools to model system behavior and identify potential issues. For example, optimizing the flight control system parameters of an unmanned aerial vehicle (UAV) to maximize its flight duration and operational effectiveness.

The aforementioned design and analysis facets demonstrate the crucial role of engineering principles and computational tools in aerospace engineering. From initial concept development to system-level performance assessments, these activities are interwoven into the daily tasks of engineers, ensuring the safety, reliability, and efficiency of aerospace systems. It is essential to understand the significance of engineering concepts and tools in these activities.

2. Testing & Validation

Testing and validation constitute a critical element within the daily workflow of an aerospace engineer. This phase ensures that designs adhere to specified performance criteria and safety standards, directly impacting the operational reliability of aerospace systems. The execution of tests and the subsequent validation of results frequently involve rigorous application of established protocols, data analysis, and iterative design refinement. A primary cause for testing stems from the inherent complexity of aerospace systems, demanding empirical verification to complement theoretical modeling. Conversely, the effect of inadequate testing can lead to catastrophic failures, highlighting the paramount importance of thorough validation procedures.

A tangible example of the integration of testing and validation into the daily routine involves wind tunnel testing of aircraft wing designs. Engineers monitor aerodynamic characteristics under varying conditions, collecting data on lift, drag, and stability. This data is then compared against computational fluid dynamics (CFD) predictions, allowing for model refinement and validation. Another example can be seen in materials testing. An aerospace engineer will do an fatigue analysis to validate the material that they choose is safe and meets the criteria of a lifespan. The practical significance of this understanding lies in its contribution to risk mitigation and optimization of system performance. Furthermore, validation against regulatory requirements is an essential aspect of the daily process. Without testing and validation, the designs are just theories that has no value in the practical world

In conclusion, testing and validation are not merely post-design activities but are integral to the entire aerospace engineering lifecycle. The rigorous application of these processes demands expertise in data acquisition, statistical analysis, and a deep understanding of system behavior. Challenges include accurately simulating real-world operating conditions and addressing unforeseen anomalies. The ultimate objective remains ensuring the airworthiness and operational readiness of aerospace vehicles and systems, reinforcing the critical linkage between testing, validation, and the broader responsibilities associated with the professional practice.

3. Collaboration Meetings

Collaboration meetings are a central component in the daily activities within the aerospace engineering field. These meetings facilitate the exchange of information, coordinate tasks, and resolve technical challenges across various engineering disciplines involved in aerospace projects. The cause is the complex nature of aerospace endeavors, necessitating diverse expertise to achieve project goals. The effect is enhanced communication, streamlined workflows, and improved problem-solving capabilities. Absent effective collaboration, projects risk delays, increased costs, and compromised performance. An example is a daily stand-up meeting between structural, aerodynamic, and propulsion engineers to discuss the integration of a new engine design, where each discipline’s considerations are addressed to ensure seamless compatibility and avoid potential conflicts. Another example is the regular meetings to review test and validation data, to make changes that is needed for the product.

These meetings are not simply procedural; they represent critical points where design decisions are scrutinized, potential risks are identified, and innovative solutions are developed collectively. Engineers frequently present design reviews, progress reports, and technical analyses to their peers, fostering a culture of transparency and accountability. For example, a team working on satellite development might hold weekly meetings to discuss power consumption, thermal management, and communication protocols, ensuring all subsystems operate effectively in concert. Collaboration can sometimes be challenging when there are disagreements, to mitigate that problem, everyone should listen, present, discuss, and reach a single and unified conclusion.

In summary, collaboration meetings are indispensable to the daily routine, promoting efficient teamwork and enabling the successful execution of intricate projects. Challenges such as resolving conflicting requirements or managing diverse opinions are inherent, but the benefits of enhanced communication and collective problem-solving outweigh the drawbacks. The ability to participate effectively in these discussions is therefore an essential skill for aerospace engineers. These activities are the core of a engineer’s work day, it is an crucial part of the job.

4. Problem Solving

Problem-solving constitutes a foundational element in the daily practice of aerospace engineering. Given the inherent complexity and stringent performance demands of aerospace systems, the ability to identify, analyze, and resolve technical challenges is paramount. The following points detail specific facets of problem-solving as it manifests in a professional’s routine.

- Troubleshooting Design Flaws

Aerospace engineers frequently encounter design flaws during the development and testing phases. These issues may arise from inadequate material selection, unforeseen aerodynamic effects, or manufacturing errors. For example, an engineer might identify unexpected vibrations in an aircraft wing during flight testing. Resolution requires analyzing flight data, conducting simulations, and potentially redesigning structural components to mitigate the vibrations. This iterative process is a common aspect of the daily problem-solving activities, ensuring the safe and reliable operation of aircraft.

- Optimizing System Performance

Improving the efficiency and performance of aerospace systems is a continuous endeavor. Engineers routinely seek ways to enhance fuel efficiency, increase payload capacity, or reduce emissions. Optimizing system performance demands innovative solutions and a thorough understanding of engineering principles. For instance, an aerospace engineer working on rocket propulsion systems may face challenges in optimizing combustion efficiency. This can be solved by adjusting fuel injection patterns, oxidizer ratios, or combustion chamber geometries. Success relies on careful analysis and testing to achieve optimal performance.

- Addressing Manufacturing Challenges

The manufacturing of aerospace components often presents unique challenges due to the precision required and the use of advanced materials. Engineers must address issues such as defects in composite materials, dimensional inaccuracies in machined parts, or difficulties in assembling complex structures. An engineer may encounter porosity in a composite aircraft component, necessitating the revision of manufacturing processes to ensure structural integrity. This involves collaborating with manufacturing specialists to identify and resolve the root cause of the defect. These challenges are important for engineers to master their knowledge of manufacturing.

- Mitigating Risks and Ensuring Safety

Safety is of utmost importance in the aerospace industry, and engineers play a critical role in identifying and mitigating potential risks. This includes analyzing failure modes, assessing the impact of environmental factors, and implementing safety protocols. An engineer might be tasked with evaluating the risk of a potential collision between an aircraft and debris in space. This evaluation requires analyzing orbital trajectories, assessing the probability of impact, and developing mitigation strategies. Mitigating the consequences of such events is an essential aspect of ensuring the long-term safety and sustainability of aerospace operations. To achieve this, engineers has to be in sync and up to date with current situation.

These examples highlight the multifaceted nature of problem-solving in the daily experience. Aerospace engineers apply their technical expertise and analytical skills to overcome diverse challenges, from design flaws to manufacturing issues and safety concerns. The ability to effectively address these problems is crucial for the success of aerospace projects and the advancement of technology.

5. Research & Development

Research and Development (R&D) forms an integral part of the professional life of many aerospace engineers. It encompasses activities undertaken to improve existing products and procedures, as well as to develop new ones. The extent to which R&D figures into a professional’s daily routine varies depending on the specific role, employer, and project stage. However, the common thread is the application of scientific and engineering principles to advance knowledge and capabilities in the aerospace domain.

- Literature Review and Analysis

A substantial portion of R&D involves staying current with the latest advancements and breakthroughs in the field. This requires aerospace engineers to regularly conduct literature reviews, analyzing scientific publications, technical reports, and patents. For example, an engineer working on hypersonic flight might spend time reviewing recent studies on scramjet engine performance or heat shield materials. This activity informs subsequent experimental design and theoretical modeling efforts, directly influencing the direction of research.

- Experimental Design and Testing

R&D frequently entails designing and conducting experiments to validate theoretical models or explore new concepts. This can range from bench-scale tests of materials to wind tunnel experiments of aerodynamic configurations. An engineer focused on improving fuel efficiency might design experiments to evaluate the performance of novel airfoil shapes. Data collected during these tests are then analyzed to refine designs and optimize performance parameters. This cyclical process of experimentation and refinement is a core activity.

- Computational Modeling and Simulation

Computational tools are indispensable in modern aerospace R&D. Engineers develop and utilize sophisticated computer models to simulate complex phenomena, such as fluid flow, structural behavior, and combustion processes. For instance, an engineer researching new propulsion systems might employ computational fluid dynamics (CFD) software to simulate the performance of different engine designs under various operating conditions. The insights gained from these simulations guide the development and optimization of experimental prototypes.

- Data Analysis and Interpretation

The collection of data during experiments and simulations is only one step in the R&D process. Aerospace engineers must also be adept at analyzing and interpreting this data to draw meaningful conclusions. This involves applying statistical methods, identifying trends, and validating results against theoretical predictions. For example, after conducting a series of wind tunnel tests, an engineer would analyze the lift and drag data to assess the performance of different wing designs. The insights gained would then be used to refine the designs and optimize their aerodynamic characteristics.

These facets collectively illustrate the significant role of R&D in the daily work. Although not every aerospace engineer is directly engaged in cutting-edge research, a solid grounding in research methodologies and principles is essential for all professionals in the field. The capacity to critically evaluate existing technologies, adapt to new developments, and contribute to the advancement of aerospace knowledge forms the bedrock of a successful career.

6. Project Management

Project management is an indispensable aspect of the daily routine for numerous aerospace engineers. It provides the framework for organizing, planning, and executing complex engineering projects, ensuring that they are completed within specified timelines, budgets, and quality standards. The relevance of project management skills is amplified by the intricate and multidisciplinary nature of aerospace endeavors.

- Task Definition and Work Breakdown

A significant portion of an engineer’s time is devoted to defining project tasks and creating work breakdown structures (WBS). This involves breaking down large, complex projects into smaller, more manageable components. For example, in the development of a new satellite, the WBS might include tasks related to payload design, power systems, communication, and orbital mechanics. Engineers then assign these tasks to specific team members and establish clear deliverables, timelines, and dependencies. The consequences of poorly defined tasks include schedule delays, budget overruns, and miscommunication among team members.

- Scheduling and Resource Allocation

Aerospace engineers must effectively schedule project activities and allocate resources, including personnel, equipment, and funding. This entails using project management software to create Gantt charts, track progress, and identify critical path activities. For example, an engineer managing the construction of a new aircraft assembly line would need to schedule the delivery of equipment, coordinate the training of personnel, and ensure that all resources are available when needed. Inadequate scheduling and resource allocation can lead to bottlenecks, delays, and increased costs.

- Risk Management and Mitigation

Identifying and mitigating potential risks is a crucial responsibility. Aerospace projects are inherently risky due to their complexity and the stringent safety requirements. Engineers routinely conduct risk assessments, identifying potential hazards and developing mitigation strategies. For instance, during the design of a new spacecraft, engineers might identify the risk of radiation exposure to astronauts. Mitigation strategies could include using radiation-shielding materials, optimizing orbital trajectories, and developing contingency plans for emergency situations. Failure to effectively manage risks can result in catastrophic failures and significant financial losses.

- Monitoring and Control

Aerospace engineers actively monitor project progress and control deviations from the planned schedule and budget. This involves tracking key performance indicators (KPIs), conducting regular status meetings, and implementing corrective actions as needed. For example, an engineer overseeing the development of a new aircraft engine would monitor parameters such as thrust, fuel consumption, and emissions. If performance falls short of expectations, the engineer would work with the team to identify the cause and implement design modifications. Effective monitoring and control are essential for ensuring that projects stay on track and meet their objectives.

These facets underscore the integral relationship between project management and the routine. While specific tasks may vary depending on the project and the engineer’s role, the underlying principles of project management remain consistent. By effectively applying these principles, aerospace engineers can enhance their productivity, improve the quality of their work, and contribute to the successful completion of complex and challenging projects. Additional applications include managing research projects, testing cycles, and system integrations.

7. Continuous Learning

The aerospace engineering landscape is characterized by constant innovation and technological advancement, making continuous learning an indispensable component of a professional’s daily routine. New materials, design methodologies, and computational tools emerge regularly, necessitating a commitment to lifelong learning to maintain competence and contribute effectively. This commitment is not merely a suggestion, but a necessity for remaining relevant in a field where obsolescence can occur rapidly. One of the most common causes engineers need to continuous learning is because of the rapidly changing technologies. The effect of continuous learning ensures the work is up to standards and is efficient. An example of this can be seen in the adoption of additive manufacturing techniques. As 3D printing becomes more prevalent in aerospace, engineers must acquire expertise in material science, process control, and design for additive manufacturing. Without this knowledge, their contributions may be limited, and their designs may become outdated.

The pursuit of knowledge takes diverse forms. Engineers may participate in workshops, attend conferences, pursue advanced degrees, or engage in self-directed study through online resources. For example, an engineer might dedicate time each week to reading technical journals, attending webinars on new simulation software, or completing online courses on artificial intelligence and its applications in aerospace. The practical application of this continuous learning manifests in improved designs, optimized performance, and enhanced problem-solving capabilities. An engineer who understands the principles of machine learning, for instance, might develop algorithms for autonomous flight control or predictive maintenance of aircraft components. An additional practical application can be engineers going back to school to achieve additional certifications to validate their competency.

In conclusion, continuous learning is not a supplementary activity but an intrinsic aspect of the professional experience. The challenge lies in effectively managing time and resources to stay current amidst demanding project deadlines and evolving technologies. However, the long-term benefits of enhanced expertise, career advancement, and contribution to the aerospace industry far outweigh these challenges. The commitment ensures aerospace engineers are equipped to meet the demands of a dynamic and technologically driven environment, ultimately improving the quality, safety, and sustainability of aerospace systems. A common issue is engineers not wanting to change what they are currently doing, however, there is a high chance that their current job becomes outdated and it can be replaced by another job. So to maintain the possibility of future growth, continuous learning is highly recommended.

Frequently Asked Questions

The following section addresses common inquiries regarding the daily realities of a professional within the aerospace engineering discipline. These questions are intended to provide clarity and insight into the responsibilities, challenges, and rewards associated with this career path.

Question 1: What are the primary technical skills required for success in this field?

A strong foundation in mathematics, physics, and computer science is indispensable. Proficiency in CAD software, simulation tools (e.g., CFD, FEA), and programming languages (e.g., MATLAB, Python) is also essential. A thorough understanding of aerodynamics, structural mechanics, propulsion, and control systems is likewise critical.

Question 2: How much collaboration with other engineers or scientists is typically involved?

Aerospace projects are inherently collaborative, necessitating frequent interaction with engineers from various disciplines (e.g., mechanical, electrical, software) as well as scientists and technicians. Effective communication, teamwork, and interpersonal skills are thus paramount.

Question 3: What level of physical activity is involved in the daily routine?

The typical workday primarily involves desk-based activities such as design, analysis, and report writing. However, occasional visits to manufacturing facilities, test sites, or wind tunnels may require physical exertion. The specific level of physical activity varies depending on the specific role and project requirements.

Question 4: How is time typically allocated among different types of tasks?

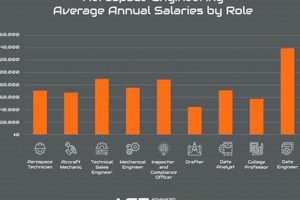

Time allocation is project-dependent. However, a typical day may involve a mix of design and analysis (30-40%), meetings and communication (20-30%), testing and validation (10-20%), and administrative tasks (10-20%). Research and development activities may also consume a significant portion of time, depending on the role.

Question 5: What types of safety measures or protocols must be followed on a daily basis?

Adherence to strict safety protocols is mandatory, particularly in testing environments or manufacturing facilities. These protocols may include the use of personal protective equipment (PPE), adherence to lockout/tagout procedures, and compliance with safety regulations. A commitment to safety is integral to the professional practice.

Question 6: How much opportunity exists for continued professional development and advancement?

The aerospace industry is constantly evolving, necessitating a commitment to lifelong learning. Opportunities for professional development include attending conferences, participating in workshops, pursuing advanced degrees, and obtaining professional certifications. Career advancement is often contingent upon demonstrating expertise, leadership, and a commitment to continuous improvement.

These questions and answers are only meant as informational and general in nature. Specifics can be differ and vary on the profession that an aerospace engineer does.

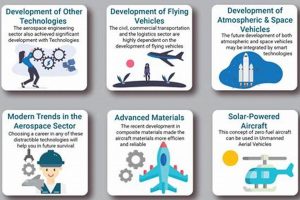

The subsequent section will transition into more comprehensive discussion, exploring the emerging trend in aerospace engineering. These insights aim to provide a forward-looking perspective on the evolving challenges and opportunities within the field.

Conclusion

This examination of the “day in the life of aerospace engineer” has illuminated the multifaceted nature of the profession. The diverse responsibilities, ranging from design and analysis to testing, validation, and project management, demand a unique blend of technical expertise, problem-solving acumen, and collaborative spirit. The inherent requirement for continuous learning underscores the dynamic character of this field, emphasizing the need for adaptability and a commitment to staying at the forefront of technological advancements.

Understanding the realities of this career path, encompassing both its challenges and rewards, is crucial for aspiring engineers and those seeking a deeper appreciation of the aerospace industry’s complexities. As technology continues to evolve and new frontiers are explored, the role of the aerospace engineer will remain pivotal in shaping the future of air and space travel. Continued investment in education, research, and innovation is essential to ensure that these professionals are equipped to meet the demands of an ever-changing world, driving progress and ensuring safety in the skies and beyond.