Positions at Howmet Aerospace’s Waco, Texas, facility encompass a range of employment opportunities within the aerospace manufacturing sector. These roles span various disciplines, including engineering, production, quality control, and administrative support, all focused on the creation of advanced components for the aerospace industry. An example would be a manufacturing engineer optimizing the production process for turbine airfoils.

These employment prospects are significant to the local Waco economy, providing skilled labor positions and contributing to regional economic development. Historically, the presence of aerospace manufacturing facilities has created stable, well-compensated jobs and driven technological advancement within the community. Furthermore, it positions Waco as a key location within the broader aerospace supply chain.

The subsequent sections will provide a detailed overview of the types of positions available at this location, the required qualifications and application process, and an assessment of the overall impact on the Waco labor market.

The following guidelines are designed to assist potential candidates in successfully pursuing career opportunities with Howmet Aerospace in Waco, Texas.

Tip 1: Research Specific Roles: Prior to applying, thoroughly investigate the specific responsibilities and requirements of each position listed for the Waco facility. This ensures alignment between applicant skills and job expectations. For example, understanding the software proficiency required for a quality assurance role is critical.

Tip 2: Highlight Relevant Experience: Resumes and cover letters should explicitly detail prior experience directly related to the aerospace industry or the specific functions performed at the Waco facility. Quantifiable achievements, such as improved production efficiency or reduced defect rates, are particularly compelling.

Tip 3: Emphasize Technical Skills: Howmet Aerospace values employees with strong technical aptitudes. Candidates should clearly demonstrate their proficiency in relevant software, machinery, and manufacturing processes utilized in aerospace component production. Certifications and training programs should be highlighted.

Tip 4: Prepare for Technical Interviews: Expect a rigorous interview process that includes technical questions designed to assess problem-solving abilities and understanding of aerospace manufacturing principles. Be prepared to discuss specific technical challenges encountered in previous roles and the solutions implemented.

Tip 5: Demonstrate a Commitment to Quality: The aerospace industry places a premium on quality control and adherence to stringent standards. Applicants should articulate their understanding of quality management systems and their commitment to producing defect-free components.

Tip 6: Understand Company Culture: Research Howmet Aerospace’s values and culture. Demonstrating an understanding of their commitment to safety, innovation, and integrity can set an applicant apart.

Tip 7: Network Strategically: Explore opportunities to connect with current Howmet Aerospace employees through professional networking platforms. Informational interviews can provide valuable insights into the company culture and hiring practices.

Following these recommendations increases the likelihood of a successful application and interview process, ultimately positioning the candidate as a strong contender for positions available at the Howmet Aerospace Waco plant.

The subsequent sections will delve into the community benefits of this manufacturing plant.

1. Manufacturing Opportunities

Manufacturing opportunities at Howmet Aerospace in Waco are central to its operations and directly define a significant segment of its workforce. These roles involve the creation, assembly, and quality control of aerospace components, requiring a diverse range of skills and expertise.

- Production Line Operation

These positions are directly involved in the day-to-day manufacturing process, operating machinery, monitoring production parameters, and ensuring adherence to quality standards. An example includes operating a casting furnace for producing turbine blades. These roles are crucial for maintaining output levels and meeting customer demand, forming the backbone of the production process.

- Quality Control and Inspection

Maintaining stringent quality standards is paramount in aerospace manufacturing. Quality control personnel inspect components at various stages of production, identifying defects and ensuring conformance to specifications. For instance, using non-destructive testing methods to detect subsurface flaws in turbine disks. This facet ensures product reliability and safety, critical for the aerospace industry.

- Machining and Fabrication

Skilled machinists and fabricators are essential for shaping raw materials into finished aerospace components. This involves operating sophisticated machinery such as CNC mills and lathes, interpreting blueprints, and performing precision measurements. For example, crafting intricate fuel nozzle components with tolerances measured in microns. These roles require a high degree of precision and technical expertise.

- Process Improvement and Optimization

Dedicated teams focus on optimizing manufacturing processes to enhance efficiency, reduce waste, and improve product quality. This involves data analysis, process experimentation, and implementation of lean manufacturing principles. An example includes streamlining the workflow in the heat treatment area to reduce cycle time. This facet promotes continuous improvement and innovation within the manufacturing operations.

The manufacturing opportunities at Howmet Aerospace Waco are diverse, encompassing various skill levels and specializations. The stability and growth of these positions are directly linked to the overall success of the Waco facility, contributing to local economic prosperity and technological advancement.

2. Skilled Labor Demand

The presence of Howmet Aerospace’s Waco facility directly generates a significant demand for skilled labor within the region. This demand is not merely for general manufacturing roles but focuses on individuals possessing specialized technical expertise relevant to aerospace component production. The facility’s operations require professionals adept in fields such as precision machining, advanced materials processing, quality control engineering, and non-destructive testing. For example, the need for certified welders capable of working with specialized aerospace alloys is a consistent requirement.

The skilled labor demand influences educational and training programs within Waco and surrounding areas. Local community colleges and technical schools often tailor curricula to meet the specific needs of companies like Howmet Aerospace. This creates a symbiotic relationship where industry demand drives educational focus, producing a workforce better prepared for available positions. The availability of trained personnel, in turn, reinforces the attractiveness of Waco as a location for aerospace manufacturing operations. This is evidenced by the establishment of specialized training programs in composite materials and advanced manufacturing techniques by local institutions.

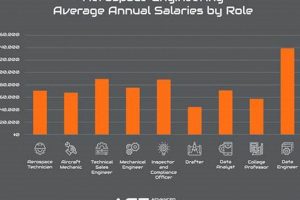

The imperative for skilled labor acts as a catalyst for economic growth and stability in the Waco region. These roles typically offer higher wages and benefits compared to other manufacturing sectors, leading to increased household income and consumer spending. Furthermore, the demand for skilled trades attracts talent from outside the region, contributing to a more diverse and qualified workforce. Addressing this demand necessitates ongoing investment in education, training, and workforce development initiatives to ensure the long-term competitiveness of the local economy and the sustained success of Howmet Aerospace’s Waco operations.

3. Competitive Compensation

Competitive compensation is a critical element in attracting and retaining qualified personnel at Howmet Aerospace’s Waco facility. It directly influences the company’s ability to maintain a skilled workforce capable of meeting the demands of advanced aerospace manufacturing.

- Base Salary Benchmarking

Howmet Aerospace likely engages in regular salary benchmarking against similar aerospace manufacturers and other industrial employers in the Waco region and nationally. This process ensures that base salaries are competitive with prevailing market rates for comparable positions. The outcome influences the appeal of positions within Howmet Aerospace Waco, affecting recruitment success.

- Benefits Packages and Incentives

Compensation extends beyond base salary to encompass benefits packages, including health insurance, retirement plans, paid time off, and other perks. The comprehensiveness and value of these benefits directly contribute to the overall attractiveness of employment at Howmet Aerospace Waco. Incentive programs, such as performance-based bonuses or stock options, can further enhance compensation and motivate employees.

- Skill-Based Compensation Premiums

Given the specialized technical skills required for many positions at Howmet Aerospace, compensation structures often include premiums for individuals possessing in-demand certifications, experience, or expertise. This incentivizes employees to acquire and maintain relevant skills, bolstering the company’s technical capabilities. For instance, a certified welding inspector would likely command a higher salary than a general production worker.

- Cost of Living Adjustments

While not always explicitly stated, compensation levels may implicitly account for the cost of living in Waco, Texas. While the cost of living in Waco is generally lower than in major metropolitan areas, competitive wages must still enable employees to maintain a reasonable standard of living. This consideration helps to ensure that Howmet Aerospace Waco remains an attractive employer in the local labor market.

These facets of competitive compensation are integral to Howmet Aerospace’s ability to attract and retain a skilled workforce at its Waco facility. By offering attractive salaries, benefits, and incentives, the company enhances its reputation as a desirable employer, supporting long-term operational success and contributing to the economic well-being of the Waco community.

4. Economic Development Impact

The presence of Howmet Aerospace and its associated employment opportunities exert a significant influence on the economic landscape of Waco, Texas. The establishment and operation of a manufacturing facility of this scale generates a ripple effect throughout the local economy. Direct employment at Howmet creates a base of salaried workers who contribute to the tax base and support local businesses through their consumption. Furthermore, the company’s procurement of goods and services from local suppliers stimulates additional economic activity, creating indirect employment opportunities within the support sector. The overall effect is a multiplier effect, where the initial investment and job creation by Howmet Aerospace generates a proportionally larger impact on the regional economy. A concrete example is the increased demand for housing and retail services in the vicinity of the Waco facility.

The focus on aerospace manufacturing contributes to the diversification of Waco’s economic base. Previously reliant on other sectors, the city benefits from the influx of a technologically advanced industry. Howmet’s presence attracts other related businesses and fosters a culture of innovation, contributing to long-term economic resilience. The investment in skilled labor training and development also elevates the quality of the local workforce, making Waco more attractive to other potential employers. For instance, the establishment of partnerships between Howmet and local educational institutions to provide specialized aerospace training. In addition to job creation and tax revenue, Howmet’s corporate social responsibility initiatives, such as community outreach programs and charitable contributions, further enhance its positive impact on the Waco community.

In summary, the economic development impact of Howmet Aerospace in Waco is multifaceted and far-reaching. The company’s presence generates direct and indirect employment, diversifies the economic base, stimulates local businesses, and enhances the quality of the local workforce. While challenges such as infrastructure limitations and workforce availability may exist, the overall impact of Howmet Aerospace on the Waco economy is demonstrably positive, contributing to the city’s growth and prosperity. This impact emphasizes the symbiotic relationship between the company and the community, highlighting the importance of fostering a supportive environment for advanced manufacturing in Waco.

5. Advanced Technology Integration

Advanced technology integration is intrinsically linked to positions at Howmet Aerospace in Waco, shaping the skill sets required and the nature of the work performed. The facility’s operational efficiency and competitive advantage rely on the effective implementation and utilization of cutting-edge technologies.

- Automated Manufacturing Systems

The integration of automated manufacturing systems, including robotics and computer numerical control (CNC) machinery, is prevalent. These systems perform repetitive and precision-oriented tasks, necessitating personnel capable of programming, maintaining, and troubleshooting these technologies. Example: Technicians specializing in robotic welding or automated inspection systems. This facet directly affects the required skills for production-related positions.

- Digital Twin Technology

Digital twin technology, creating virtual replicas of physical assets and processes, is increasingly used for simulation, optimization, and predictive maintenance. This demands engineers and analysts capable of interpreting data generated by digital twins, identifying potential issues, and implementing corrective actions. Example: Aerospace engineers using digital twins to simulate the performance of turbine blades under various operating conditions. This integration drives the need for advanced analytical and modeling skills.

- Additive Manufacturing (3D Printing)

Additive manufacturing, or 3D printing, is used to create complex aerospace components with customized geometries. The implementation of additive manufacturing requires specialists in material science, design for additive manufacturing, and process control. Example: Production of lightweight aerospace brackets using selective laser melting. This technology impacts the need for expertise in advanced materials and design principles.

- Data Analytics and Machine Learning

Data analytics and machine learning algorithms are employed to optimize manufacturing processes, predict equipment failures, and improve product quality. Data scientists and engineers are needed to develop and implement these analytical tools. Example: Using machine learning to predict maintenance schedules for critical machinery, minimizing downtime and maximizing operational efficiency. This facet creates opportunities for data-driven decision-making and process improvement.

These examples of advanced technology integration illustrate the evolving demands of positions at Howmet Aerospace in Waco. The ability to adapt to and master these technologies is crucial for employees seeking to thrive in this technologically advanced manufacturing environment. Success in these roles requires a commitment to continuous learning and a strong foundation in relevant scientific and engineering principles.

6. Local Workforce Enhancement

The presence of Howmet Aerospace in Waco necessitates and simultaneously fosters local workforce enhancement. The specialized nature of aerospace manufacturing demands a workforce proficient in advanced technologies, precision machining, and quality control. This demand acts as a catalyst for the development of targeted training programs and educational initiatives within the Waco community. Local workforce enhancement, therefore, becomes a critical component of sustained operations at the Howmet Aerospace Waco facility. Without a readily available and skilled workforce, the facility’s productivity and competitiveness would be significantly compromised. For example, the establishment of specialized courses at McLennan Community College aimed at preparing students for positions in aerospace manufacturing illustrates a direct response to the workforce needs of Howmet Aerospace.

Furthermore, Howmet Aerospace itself often invests in internal training programs and apprenticeship opportunities. These initiatives not only equip new employees with the necessary skills but also provide existing employees with avenues for career advancement. Such investments contribute to the long-term development of a skilled workforce that is deeply rooted in the local community. These initiatives often result in higher retention rates and a more stable workforce, benefiting both the company and the community. An example includes Howmet Aerospace providing tuition reimbursement for employees pursuing advanced degrees or certifications in relevant fields.

In conclusion, local workforce enhancement is not merely a peripheral benefit of Howmet Aerospace’s presence in Waco; it is an essential prerequisite for its operational success. The company’s reliance on a skilled workforce drives investment in education and training, creating a positive feedback loop that strengthens both the company and the local community. The challenges remain in ensuring that these initiatives are aligned with evolving technological demands and that opportunities are accessible to all segments of the population. This ongoing commitment to workforce development is crucial for sustaining the long-term prosperity of the Waco region.

Frequently Asked Questions

The following questions address common inquiries regarding employment opportunities at Howmet Aerospace’s Waco, Texas, facility. This information is intended to provide clarity and guidance for potential applicants.

Question 1: What types of positions are typically available at the Howmet Aerospace Waco plant?

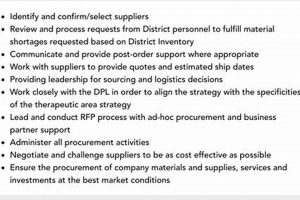

Positions encompass a wide range of roles, including manufacturing technicians, quality control inspectors, engineers (mechanical, industrial, and aerospace), maintenance personnel, and administrative staff. The specific availability fluctuates based on production demands and company growth.

Question 2: What are the minimum qualifications required for entry-level manufacturing positions?

Minimum qualifications generally include a high school diploma or equivalent. Specific positions may require additional certifications, such as welding certifications or experience with specific machinery. A strong work ethic and willingness to learn are also highly valued.

Question 3: How does Howmet Aerospace support employee training and development in Waco?

Howmet Aerospace typically offers a range of training programs, including on-the-job training, mentorship programs, and opportunities for professional development. Tuition reimbursement programs may be available for employees pursuing relevant certifications or degrees.

Question 4: What is the application process for positions at the Waco facility?

The application process generally involves submitting an online application through the Howmet Aerospace careers website. Selected candidates will be contacted for interviews, which may include technical assessments or panel interviews.

Question 5: What is the work environment like at the Howmet Aerospace Waco plant?

The work environment is typically fast-paced and demanding, requiring adherence to strict safety and quality standards. Collaboration and teamwork are essential for successful operation. The facility is equipped with advanced manufacturing technology.

Question 6: How does Howmet Aerospace contribute to the Waco community?

Howmet Aerospace contributes to the Waco community through job creation, economic investment, and community outreach programs. The company supports local educational initiatives and charitable organizations.

These FAQs provide a concise overview of employment-related aspects at Howmet Aerospace in Waco. Further details are available on the company’s career website.

The following section will summarize the key advantages of Howmet Aerospace Waco jobs.

Conclusion

This article has explored the multifaceted nature of “howmet aerospace waco jobs,” emphasizing their significance within the regional economy. These positions span a spectrum of disciplines, from manufacturing and quality control to engineering and administration. The skilled labor demand generated by Howmet Aerospace supports local educational institutions and contributes to the diversification of Waco’s economic base. Furthermore, competitive compensation packages attract qualified candidates, fostering a skilled workforce and driving technological advancement.

The presence of Howmet Aerospace in Waco presents valuable career opportunities within a dynamic and technologically advanced manufacturing environment. Potential applicants are encouraged to thoroughly research available positions and prepare to demonstrate relevant skills and qualifications. The continued success of Howmet Aerospace in Waco hinges on a skilled and dedicated workforce, highlighting the enduring importance of these employment opportunities for both the company and the community.