Employment opportunities within the aviation and space industry located in the state of Kansas represent a significant sector of the regional economy. These positions encompass a broad range of technical and professional roles, contributing to the design, manufacture, and maintenance of aircraft and related systems.

The availability of these roles provides substantial economic benefits to the region, fostering innovation, attracting skilled workers, and supporting related industries. Historically, Kansas has played a vital role in aircraft production, a legacy that continues to drive growth and development within the sector.

The following sections will delve into the specific types of positions available, the required skills and training, and the major employers within this dynamic field.

Securing a position in the Kansas aviation and space sector requires a strategic approach. The following tips provide guidance for prospective candidates.

Tip 1: Target Specific Skill Development: Focus on acquiring skills demanded by Kansas-based aerospace companies. Common requirements include CAD/CAM proficiency, composite materials expertise, and FAA certification relevant to aircraft maintenance or avionics.

Tip 2: Emphasize Relevant Education: Completion of a degree or certification program from an accredited institution is crucial. Consider programs offered by universities and technical colleges within Kansas known for their aerospace engineering, aviation technology, or manufacturing programs.

Tip 3: Network Strategically: Attend industry events, join professional organizations (e.g., AIAA, SAE), and connect with professionals working in Kansas-based aerospace companies through platforms like LinkedIn. Networking can provide access to unadvertised openings and valuable insights.

Tip 4: Tailor Resumes and Cover Letters: Customize application materials to highlight relevant experience and skills, demonstrating a clear understanding of the specific requirements of each position. Showcase projects and accomplishments that align with the company’s activities.

Tip 5: Research Key Employers: Identify major aerospace employers in Kansas (e.g., Textron Aviation, Spirit AeroSystems) and understand their specific areas of operation, company culture, and current projects. This knowledge allows for more targeted applications and informed interview preparation.

Tip 6: Prepare for Technical Interviews: Anticipate technical questions related to engineering principles, manufacturing processes, and industry standards. Be prepared to demonstrate problem-solving abilities and a strong understanding of core aerospace concepts.

By focusing on targeted skill development, relevant education, strategic networking, and thorough preparation, individuals can significantly enhance their prospects of securing opportunities within the aviation and space sector of Kansas.

The next section will provide an overview of the prominent companies operating within this critical industry segment.

1. Engineering Design

Engineering design constitutes a critical component of the aerospace sector in Kansas. Its importance stems from the state’s established history in aircraft manufacturing and the ongoing need for innovation and optimization in aerospace technology. The functionality, safety, and efficiency of aircraft and related systems developed in Kansas depend directly on the expertise and capabilities of engineering design professionals.

- Structural Analysis and Design

Aerospace engineers analyze structural integrity to ensure aircraft components withstand stress. For example, designing a wing that can bear loads during flight, or optimizing fuselage geometry for fuel efficiency are crucial. In Kansas, many engineering positions focus on refining existing aircraft designs or developing novel structural solutions for next-generation aircraft. This ensures the safety and performance standards are met during operation.

- Systems Integration

Integrating diverse systems like avionics, propulsion, and control systems is a core facet of engineering design. Professionals design interfaces and protocols to ensure seamless communication and coordinated operation. For instance, designing the integration of new sensor technologies into existing aircraft platforms allows for greater efficiency. This is often applied to aircraft manufactured in Kansas.

- Aerodynamics and Fluid Dynamics

Aerodynamic engineers model airflow around aircraft to minimize drag and maximize lift. Computational Fluid Dynamics (CFD) tools are commonly employed to simulate airflow and optimize airfoil designs. For example, optimizing the shape of an aircraft wing reduces air resistance which results in a more efficient airplane. Kansas companies often focus on modifying existing designs to enhance performance within specific operational parameters.

- Materials Science and Engineering

Selection of appropriate materials for aircraft construction, considering strength, weight, and corrosion resistance, is essential. The increasing use of composite materials requires expertise in their design and application. For instance, creating a composite material that is both lightweight and strong requires an expert. Kansas employers are increasingly seeking materials engineers to support the adoption of advanced materials in aerospace applications, enhancing the performance and durability of aircraft components.

Collectively, these facets of engineering design directly impact the availability and nature of aerospace jobs in Kansas. A strong emphasis on structural integrity, efficient systems integration, aerodynamic performance, and advanced materials underpins the state’s aerospace industry, creating a demand for qualified engineers with specialized skills and knowledge. The growth and competitiveness of the sector are intrinsically linked to the continued advancement and application of engineering design principles within Kansas-based aerospace companies.

2. Manufacturing Technicians

Manufacturing technicians form a vital component of Kansas aerospace employment, representing a direct link between engineering design and the tangible production of aircraft and aerospace systems. These professionals are responsible for executing manufacturing processes, operating specialized machinery, and ensuring the quality and precision of components according to strict industry standards. The presence of skilled manufacturing technicians in Kansas is a critical factor in attracting and retaining aerospace companies within the state.

The skills of these technicians directly impact the efficiency and output of aerospace manufacturing operations. For example, a technician proficient in CNC machining can produce intricate parts with minimal errors, while a technician trained in composite layup can create lightweight and strong aircraft structures. Kansas aerospace companies, such as Textron Aviation and Spirit AeroSystems, rely heavily on a skilled workforce of manufacturing technicians to maintain production schedules and meet stringent quality requirements. The availability of this workforce directly influences the ability of these companies to compete in the global aerospace market.

In summary, manufacturing technicians are an indispensable element of Kansas’s aerospace industry. Their expertise directly translates to the successful production and maintenance of aircraft systems. Without a competent and readily available pool of these technicians, Kansas would face significant challenges in maintaining its position as a prominent aerospace manufacturing hub. Investing in training and development programs for manufacturing technicians is crucial for the continued growth and competitiveness of Kansas aerospace jobs.

3. FAA Regulations

Federal Aviation Administration (FAA) regulations exert a pervasive influence on Kansas aerospace employment. Compliance with these mandates dictates nearly every facet of design, manufacturing, maintenance, and operation within the industry. As a consequence, a substantial portion of related positions directly involves ensuring adherence to these legal and safety standards.

The impact is multifaceted. Engineering positions require a thorough understanding of airworthiness directives and certification processes. Manufacturing roles necessitate strict adherence to quality control procedures stipulated by the FAA. Maintenance jobs demand FAA-certified technicians capable of performing inspections and repairs according to established guidelines. For instance, any modification to an aircraft built in Kansas must undergo rigorous testing and documentation to meet FAA requirements. Similarly, pilot training programs and aircraft maintenance facilities operate under close FAA scrutiny to guarantee safety and adherence to protocol.

This understanding is practically significant because it shapes the skills required of the workforce and defines the responsibilities associated with many Kansas aerospace jobs. The ability to interpret and apply FAA regulations is a core competency valued by employers. Therefore, a continuing challenge is the need for specialized training and education to maintain a workforce equipped to meet the ever-evolving demands of FAA compliance. Kansas’s ability to provide such training is crucial to the continued health and growth of its aerospace sector.

4. Supply Chain Management

Supply chain management is an indispensable function within the Kansas aerospace sector, directly affecting efficiency, cost, and overall competitiveness. Its effectiveness ensures the smooth flow of materials and components necessary for aircraft production and maintenance, thus shaping the landscape of related employment opportunities.

- Procurement and Sourcing

Aerospace companies in Kansas rely on efficient procurement processes to acquire raw materials, parts, and specialized equipment from global suppliers. Positions within this area involve identifying reliable vendors, negotiating contracts, and ensuring timely delivery of high-quality materials. For example, securing a consistent supply of aluminum alloys for aircraft fuselages is critical for companies like Spirit AeroSystems. A skilled procurement specialist ensures the availability of these materials at competitive prices, impacting the profitability and stability of manufacturing jobs.

- Logistics and Transportation

Moving components from suppliers to manufacturing facilities and finished products to customers requires sophisticated logistics management. Kansas aerospace companies employ logistics professionals to optimize transportation routes, manage inventory levels, and coordinate shipments. An instance of this would be coordinating the shipment of completed aircraft sections from a Wichita facility to a final assembly plant. Effective logistics reduces lead times, minimizes transportation costs, and prevents production delays, indirectly supporting jobs in manufacturing and assembly.

- Inventory Management

Maintaining appropriate inventory levels is critical to avoid both shortages and excessive holding costs. Aerospace companies in Kansas utilize inventory management systems and professionals to track materials, forecast demand, and optimize stock levels. An example includes managing the inventory of specialized fasteners used in aircraft assembly, ensuring that the correct types and quantities are available when needed. Efficient inventory management minimizes waste, reduces storage expenses, and prevents disruptions to the production process, ultimately safeguarding jobs related to manufacturing and assembly.

- Supplier Relationship Management

Building and maintaining strong relationships with suppliers is essential for ensuring the reliability and quality of the supply chain. Kansas aerospace companies employ supplier relationship managers to communicate effectively with vendors, address issues proactively, and foster collaboration. A case in point would be working closely with a supplier of avionics systems to ensure timely delivery of components and resolve any technical challenges. Strong supplier relationships contribute to a more stable and responsive supply chain, protecting jobs linked to manufacturing, engineering, and maintenance.

In conclusion, effective supply chain management underpins the success of the Kansas aerospace industry, creating diverse employment opportunities in procurement, logistics, inventory control, and supplier relations. Skilled professionals in these roles are essential for maintaining the competitiveness and efficiency of aerospace manufacturing and maintenance operations in the state. Their expertise ensures that the necessary materials and components are available when needed, supporting the broader aerospace workforce.

5. Quality Control

Quality control represents a critical function within the Kansas aerospace sector, influencing every stage from initial design to final product delivery. Its implementation dictates the integrity, reliability, and safety of aircraft components and systems, directly impacting the nature and availability of related positions. Stringent quality standards, mandated by regulatory agencies and customer expectations, create a significant demand for qualified professionals in this field.

- Inspection and Testing

Inspection and testing roles are central to quality control within Kansas aerospace jobs. These positions require meticulously examining components, assemblies, and finished aircraft for defects, deviations from specifications, or non-compliance with standards. For example, non-destructive testing (NDT) technicians use techniques like radiography or ultrasonic testing to identify internal flaws in aircraft structures without causing damage. This rigorous inspection process helps prevent defective products from reaching customers and ensures the safety of flight operations, protecting the integrity of manufacturing jobs.

- Process Monitoring and Auditing

Process monitoring and auditing involve observing and evaluating manufacturing processes to identify potential sources of error or variability. Quality control specialists conduct audits to ensure compliance with established procedures and industry best practices. For instance, an auditor might review the calibration records of equipment used in machining critical aircraft parts to ensure accuracy. This proactive monitoring helps prevent defects from occurring in the first place, reducing waste and improving the efficiency of manufacturing jobs.

- Root Cause Analysis and Corrective Action

When defects or non-conformances are identified, quality control professionals conduct root cause analysis to determine the underlying factors contributing to the problem. They then develop and implement corrective actions to prevent recurrence. An example could involve investigating the cause of inconsistent paint application on aircraft fuselages and implementing revised painting procedures. Addressing the root cause of quality issues improves product reliability and prevents future problems, enhancing the value and stability of jobs involved in production.

- Quality Management Systems

The implementation and maintenance of robust quality management systems (QMS) are crucial for ensuring consistent product quality and regulatory compliance. Quality managers and specialists oversee the development, implementation, and continuous improvement of QMS, such as AS9100. An example is documenting all manufacturing processes, inspection procedures, and training records to demonstrate adherence to industry standards. A well-maintained QMS provides a framework for quality control activities and helps ensure that the Kansas aerospace industry maintains its reputation for excellence.

Collectively, these facets of quality control contribute to the integrity and safety of the aerospace products manufactured in Kansas. A strong emphasis on inspection, process monitoring, root cause analysis, and robust quality management systems creates a demand for qualified professionals across various roles. The continued growth and competitiveness of the Kansas aerospace sector hinges on maintaining high standards of quality control, driving the need for a skilled and dedicated workforce in this critical area.

6. Avionics Systems

Avionics systems, encompassing the electronic systems used on aircraft, constitute a significant component of the Kansas aerospace sector, thereby directly influencing the nature and availability of related job opportunities. The design, development, testing, and maintenance of these systems necessitate a specialized workforce, making avionics expertise a crucial determinant for securing employment within the state’s aerospace industry. The functionality and safety of aircraft depend heavily on the proper operation of avionics; therefore, the demand for skilled avionics technicians and engineers remains consistently high. For example, the integration of advanced navigation systems, flight control systems, and communication systems into aircraft manufactured or maintained in Kansas requires highly specialized expertise.

The practical applications of avionics systems range from enhancing flight safety and efficiency to enabling advanced capabilities in modern aircraft. For instance, the installation and calibration of sophisticated autopilot systems or weather radar systems necessitate skilled technicians who understand the intricacies of these technologies and can ensure their proper functioning. Furthermore, the increasing integration of digital technologies into aircraft cockpits and control systems creates a growing demand for avionics specialists capable of working with complex software and hardware interfaces. Companies in Kansas are actively seeking professionals with expertise in areas such as signal processing, embedded systems, and human-machine interface design to support these advancements.

In conclusion, avionics systems play a pivotal role in shaping the Kansas aerospace job market. The continued advancement of avionics technology drives the demand for skilled technicians, engineers, and specialists. Addressing the challenges of workforce development and ensuring access to specialized training programs are critical for sustaining the competitiveness of the Kansas aerospace industry in this dynamic field. The successful integration and maintenance of avionics systems remain essential to the safety, efficiency, and functionality of aircraft manufactured and operated within the state.

7. Research & Development

Research and Development (R&D) constitutes a fundamental driver of innovation and competitiveness within the Kansas aerospace sector. Its impact extends to various facets of the industry, creating opportunities and shaping the nature of employment throughout the state. Investment in R&D is crucial for sustaining long-term growth and ensuring Kansas remains at the forefront of aerospace technology.

- Advanced Materials Research

This area focuses on developing and testing new materials for aircraft construction, aiming for enhanced strength, reduced weight, and improved resistance to extreme conditions. For example, research into novel composite materials, such as carbon fiber reinforced polymers, can lead to the creation of lighter and more fuel-efficient aircraft. This, in turn, generates Kansas aerospace jobs in materials science, engineering, and manufacturing, as well as in the testing and validation of these new materials.

- Aerodynamics and Propulsion Innovation

R&D efforts in aerodynamics and propulsion seek to improve aircraft performance through more efficient designs and advanced engine technologies. This includes research into wing shapes, turbofan engine designs, and alternative fuels. An example could be the development of a more efficient engine design that reduces fuel consumption and emissions. This research leads to Kansas aerospace jobs in aeronautical engineering, mechanical engineering, and related fields, as well as in the testing and certification of new aircraft and engine designs.

- Autonomous Systems and Robotics

This facet focuses on the development of autonomous systems and robotics for use in aircraft manufacturing, maintenance, and operation. For example, research into autonomous inspection systems could enable automated detection of defects in aircraft structures, reducing the need for manual inspection. This creates Kansas aerospace jobs in robotics, software engineering, and control systems engineering, as well as in the development and implementation of these technologies within aerospace manufacturing facilities.

- Digitalization and Data Analytics

R&D in digitalization and data analytics focuses on leveraging data to improve aircraft design, manufacturing processes, and operational efficiency. This includes developing data analytics tools for predictive maintenance, optimizing supply chain operations, and enhancing aircraft performance monitoring. For example, implementing a system that analyzes flight data to predict component failures can lead to reduced downtime and improved safety. This generates Kansas aerospace jobs in data science, software engineering, and data analytics, as well as in the development and implementation of these data-driven solutions within aerospace companies.

The impact of R&D on the Kansas aerospace sector is multifaceted. By driving innovation in materials, aerodynamics, autonomous systems, and data analytics, R&D creates opportunities for skilled professionals in a variety of fields. Investment in these areas is essential for sustaining the long-term competitiveness of the Kansas aerospace industry and ensuring its continued contribution to the state’s economy.

Frequently Asked Questions

This section addresses common inquiries regarding career opportunities within the aerospace sector in Kansas.

Question 1: What types of positions are commonly available in Kansas aerospace?

Positions span engineering (aeronautical, mechanical, electrical), manufacturing (technicians, machinists, assemblers), quality control (inspectors, auditors), and support functions (supply chain, logistics, management).

Question 2: What are the major employers within the Kansas aerospace industry?

Prominent employers include Textron Aviation, Spirit AeroSystems, and numerous smaller suppliers and service providers supporting these larger entities.

Question 3: What educational qualifications are typically required for Kansas aerospace roles?

Requirements vary by position. Engineering roles generally necessitate a bachelor’s or master’s degree in a relevant engineering discipline. Manufacturing and technician roles may require associate degrees or vocational certifications.

Question 4: Is prior military experience valued in the Kansas aerospace job market?

Yes, prior military experience, particularly in aviation maintenance or avionics, is often highly regarded due to the transferable skills and disciplined work ethic associated with military service.

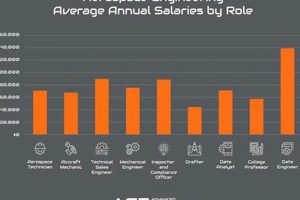

Question 5: What is the expected salary range for aerospace positions in Kansas?

Salary ranges are dependent on experience, education, and the specific role. Entry-level positions may offer lower compensation compared to roles requiring specialized skills and extensive experience. Industry surveys provide detailed salary data.

Question 6: How can individuals increase their chances of securing Kansas aerospace employment?

Focused skill development, relevant education, strategic networking, and tailored application materials are essential. Additionally, demonstrating a strong understanding of FAA regulations and industry standards is crucial.

In summary, the Kansas aerospace sector presents a diverse range of career opportunities for qualified individuals. Preparation and a targeted approach can greatly enhance the likelihood of securing employment within this dynamic industry.

The following section provides guidance on available resources for those seeking opportunities.

Kansas Aerospace Jobs

This exposition has detailed the multifaceted landscape of employment opportunities within the aviation and space industry of Kansas. The analysis spanned specific job categories, required skills, key employers, regulatory influences, and effective job-seeking strategies. It highlighted the sector’s economic significance and the critical need for a skilled workforce to sustain its competitiveness.

The continued vitality of the Kansas aerospace sector hinges on proactive measures to address workforce development challenges and embrace technological advancements. Those seeking to contribute to this vital industry are encouraged to pursue targeted training, cultivate relevant expertise, and actively engage with the professional community. The future prosperity of Kansas aerospace depends on a commitment to innovation and a focus on maintaining its position as a leader in aviation and space technology.

![Is Aerospace Engineer Job Availability Rising? [2024 Trends] Innovating the Future of Flight with Reliable Aviation Solutions Is Aerospace Engineer Job Availability Rising? [2024 Trends] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-520-300x200.jpg)