The sector confronts a complex array of difficulties that hinder progress and profitability. These encompass cost overruns in development programs, supply chain disruptions, and regulatory hurdles. For example, a new aircraft development can face repeated delays and significant budget increases due to unforeseen engineering issues and evolving safety standards.

Addressing these multifaceted concerns is essential for maintaining national security, fostering economic growth, and enabling scientific advancements. Historically, overcoming challenges in this sector has led to technological breakthroughs with widespread societal benefits, influencing fields from materials science to computing. Efficiently navigating these difficulties supports competitiveness and allows for continued innovation.

The following discussion will examine specific challenges in detail, including talent shortages, cybersecurity threats, and the increasing demand for sustainable practices, thereby providing a more granular understanding of the current operational environment.

Addressing Operational Challenges in the Sector

The following recommendations aim to provide guidance in mitigating some key operational difficulties prevalent in the sector. These suggestions focus on strategic adjustments and proactive measures to foster resilience and efficiency.

Tip 1: Enhance Supply Chain Resilience: Diversify the supplier base and implement robust risk assessment protocols. Dependence on single suppliers elevates vulnerability to disruptions stemming from geopolitical instability or natural disasters. Maintaining a geographically dispersed network minimizes such risks.

Tip 2: Invest in Advanced Manufacturing Technologies: Automation, additive manufacturing, and robotics can improve production efficiency and reduce labor costs. Implementing these technologies requires a strategic plan and investment in workforce training.

Tip 3: Prioritize Cybersecurity Measures: Implement comprehensive cybersecurity protocols and conduct regular vulnerability assessments. The sector is a prime target for cyberattacks that can compromise sensitive data and disrupt operations. A multi-layered security approach is crucial.

Tip 4: Foster Workforce Development Programs: Establish partnerships with universities and vocational schools to address the talent shortage. Investment in education and training programs is essential to cultivate a skilled workforce capable of meeting the sector’s evolving needs.

Tip 5: Streamline Regulatory Compliance Processes: Employ advanced data analytics and digital tools to improve compliance with evolving regulations. Reducing the burden of regulatory compliance allows companies to focus resources on innovation and growth.

Tip 6: Embrace Sustainable Practices: Implement initiatives to reduce carbon emissions and improve fuel efficiency. The demand for environmentally responsible solutions is increasing, and sustainable practices can provide a competitive advantage.

Effective implementation of these recommendations can improve operational effectiveness, mitigate risks, and ensure long-term viability in a dynamic and competitive landscape.

The subsequent section will synthesize the preceding discussion and offer concluding observations on the current state and future trajectory of the domain.

1. Cost Overruns

Cost overruns represent a significant and persistent element contributing to overarching difficulties. The sector’s complex projects, characterized by advanced technologies and rigorous safety standards, render them particularly susceptible to budget escalations. These stem from several intertwined sources, including unforeseen technical complexities, evolving regulatory requirements, and inefficient project management practices. The development of new aircraft or spacecraft, for instance, often involves encountering unexpected engineering hurdles that necessitate redesigns and additional testing, directly increasing expenses.

The impact of these excess expenditures extends beyond immediate financial strain. Project delays resulting from budget constraints can disrupt production schedules, affect delivery timelines, and ultimately undermine the competitive position of involved companies. Furthermore, cost increases can necessitate government subsidies or financial bailouts, placing a burden on taxpayers. A notable example includes certain defense procurement programs where initial budget estimates were significantly exceeded, leading to public scrutiny and calls for greater accountability.

Effective cost management is therefore essential for the sectors sustainability and success. Addressing this challenge requires enhanced project planning, rigorous risk assessment, and the implementation of advanced cost control measures. By mitigating unnecessary expenditures, the industry can promote innovation, improve competitiveness, and ensure the efficient allocation of resources. The integration of best practices in project management and greater transparency throughout the development process are vital steps toward containing this costly burden.

2. Supply Chain

The integrity of supply networks is critical to the aerospace sector, and disruptions within these networks frequently manifest as operational and financial impediments. The complex global nature of these supply chains, characterized by numerous tiers of suppliers, specialized components, and stringent regulatory oversight, amplifies their vulnerability.

- Component Shortages

A significant disruption involves the scarcity of essential components such as semiconductors, specialized alloys, and electronic parts. These shortages, often triggered by geopolitical events, natural disasters, or unexpected surges in demand, impede production timelines. For instance, a temporary closure of a semiconductor manufacturing plant in Asia can have cascading effects on aircraft production lines globally, leading to delayed deliveries and increased costs.

- Geopolitical Risks

The concentration of specific materials or manufacturing capabilities in politically unstable regions poses a considerable risk. Trade disputes, sanctions, or armed conflicts can disrupt the flow of essential resources, leading to production bottlenecks. The reliance on rare earth minerals sourced from countries with complex political landscapes exemplifies this vulnerability, potentially impacting the production of critical aerospace components.

- Supplier Insolvency

Economic downturns or mismanagement can lead to the financial distress or even bankruptcy of key suppliers, creating a void in the supply chain. The failure of a critical supplier of specialized avionics equipment, for instance, can halt production lines until an alternative source is secured and qualified. This can also trigger legal and contractual complexities, further prolonging disruptions.

- Logistics and Transportation Challenges

Inefficiencies in logistics and transportation networks, including port congestion, customs delays, and rising shipping costs, impede the timely delivery of components. The transportation of oversized or sensitive aerospace components requires specialized handling and infrastructure, which can be further constrained by capacity limitations or unforeseen events. This can lead to delays, increased costs, and even damage to critical components.

These facets illustrate how supply chain vulnerabilities can directly affect operational efficiency, project timelines, and financial performance. Mitigating these risks requires proactive strategies such as diversification of the supplier base, strategic inventory management, and the establishment of robust contingency plans. Strengthening supply chain resilience is essential for maintaining competitiveness and ensuring the uninterrupted operation of the sector.

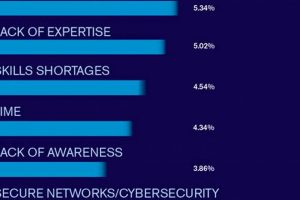

3. Talent Shortage

A significant impediment to advancement is the deficiency of qualified personnel across critical areas. This shortage directly compounds existing difficulties, leading to delayed project timelines, compromised innovation, and increased operational costs. The need for skilled engineers, technicians, and project managers far outstrips the current supply, particularly those possessing expertise in emerging technologies such as artificial intelligence, advanced materials, and sustainable propulsion systems. This deficit extends beyond technical roles, affecting the availability of experienced professionals in cybersecurity, regulatory compliance, and supply chain management. The result is a constriction of operational capacity and an escalation of competition for available talent, driving up labor costs and potentially attracting less qualified candidates to fill critical positions.

The scarcity of qualified individuals manifests in various tangible ways. For example, companies often struggle to meet aggressive production targets due to a lack of skilled technicians capable of operating and maintaining advanced manufacturing equipment. This can lead to production bottlenecks, increased error rates, and higher maintenance costs. Similarly, a shortage of cybersecurity experts leaves organizations vulnerable to sophisticated cyberattacks, potentially compromising sensitive data and disrupting operations. The increasing complexity of aerospace systems and the evolving regulatory landscape further exacerbate the demand for specialized skills, intensifying the strain on available resources. A practical demonstration lies in the prolonged development cycles of next-generation aircraft, where the limited pool of experienced aerospace engineers contributes to delays and increased development expenses.

Addressing this fundamental challenge requires a multi-pronged approach encompassing investments in education and training programs, strategic partnerships with universities and vocational schools, and the implementation of effective talent retention strategies. Furthermore, efforts to attract and retain diverse talent pools are essential for fostering innovation and creativity. By proactively addressing the talent shortage, the sector can mitigate its negative impact and ensure the availability of a skilled workforce capable of driving future growth and competitiveness. Failing to address this issue will undoubtedly amplify the existing issues, hindering progress and potentially jeopardizing the long-term health of the industry.

4. Cybersecurity

Cybersecurity vulnerabilities constitute a critical and escalating threat to the aerospace sector, presenting a multifaceted challenge that undermines operational integrity, intellectual property, and national security. The interconnectedness of modern aerospace systems, coupled with the sector’s reliance on digital technologies, creates an expansive attack surface susceptible to various forms of cyber intrusion.

- Compromised Aircraft Systems

Malicious actors targeting aircraft control systems, navigation systems, or in-flight entertainment can jeopardize passenger safety and operational reliability. A successful cyberattack could potentially disrupt flight operations, alter flight paths, or even disable critical aircraft functions. For example, vulnerabilities in aircraft communication protocols could be exploited to intercept sensitive data or inject malicious commands, creating significant safety hazards.

- Data Breaches and Intellectual Property Theft

The aerospace sector possesses vast amounts of sensitive data, including proprietary designs, manufacturing processes, and customer information, making it a prime target for data breaches. Cyberattacks aimed at stealing intellectual property can provide competitors with unfair advantages, compromise national security, and undermine the competitiveness of involved companies. Real-world examples include the theft of design schematics for advanced aircraft components, leading to significant financial losses and potential security risks.

- Supply Chain Vulnerabilities

The complex supply chains inherent in the aerospace sector introduce numerous potential entry points for cyberattacks. Compromised suppliers can inadvertently introduce malware or counterfeit components into the system, creating systemic vulnerabilities. An attack on a supplier’s network could allow malicious actors to gain access to sensitive data or inject malicious code into critical aircraft components, impacting the integrity and safety of the final product.

- Operational Disruption

Cyberattacks targeting ground-based infrastructure, such as air traffic control systems, maintenance facilities, or airline reservation systems, can disrupt operations and cause significant financial losses. A successful attack could paralyze air traffic control operations, delay or cancel flights, and undermine public confidence in air travel. The disruption of airline reservation systems could also lead to chaos and confusion, impacting passenger experience and airline revenue.

The interconnected nature of these facets underscores the pervasive impact of cybersecurity challenges. Implementing robust cybersecurity measures, including advanced threat detection systems, incident response plans, and employee training programs, is essential for mitigating these risks and protecting the aerospace sector from evolving cyber threats. Without proactive defenses, the industry remains vulnerable to potentially devastating attacks that could compromise safety, security, and economic stability.

5. Sustainability

The increasing emphasis on sustainability represents a significant paradigm shift with profound implications for the aerospace sector. Regulatory pressures, societal expectations, and the escalating threat of climate change necessitate a fundamental reevaluation of traditional practices. Sustainability is no longer a peripheral concern, but a central driver shaping innovation, investment decisions, and operational strategies.

- Emissions Reduction

The generation of greenhouse gases from aircraft operations contributes significantly to global warming. Reducing carbon emissions is paramount, requiring the development and adoption of alternative fuels, more efficient engine designs, and optimized flight operations. The transition to sustainable aviation fuels (SAF), while promising, presents challenges related to scalability, cost, and infrastructure compatibility. Furthermore, the design of more fuel-efficient aircraft necessitates significant investments in research and development, potentially impacting project timelines and budgets.

- Noise Pollution

Aircraft noise remains a persistent concern for communities located near airports. Reducing noise pollution requires the implementation of quieter engine technologies, optimized flight paths, and noise mitigation strategies. The development of quieter aircraft engines often involves trade-offs with fuel efficiency and performance, posing engineering challenges. Additionally, community engagement and proactive communication are essential for managing public perception and mitigating potential conflicts.

- Waste Management

The aerospace sector generates substantial amounts of waste, including manufacturing byproducts, end-of-life aircraft components, and cabin waste. Implementing effective waste management strategies, such as recycling, reuse, and waste-to-energy technologies, is crucial for minimizing environmental impact. The recycling of aircraft components, particularly those containing hazardous materials, requires specialized facilities and processes. Furthermore, reducing cabin waste involves collaboration with suppliers and passengers to minimize single-use plastics and promote sustainable alternatives.

- Resource Depletion

The manufacturing of aircraft relies on the extraction and processing of various resources, including rare earth minerals, aluminum, and titanium. Sustainable sourcing and responsible resource management are essential for mitigating environmental impact and ensuring long-term supply chain stability. The development of alternative materials and manufacturing processes can reduce reliance on scarce resources. Additionally, promoting circular economy principles, such as product life extension and remanufacturing, can minimize resource consumption.

Addressing these multifaceted sustainability challenges requires a concerted effort involving collaboration between governments, industry stakeholders, and research institutions. The transition to a more sustainable aerospace sector necessitates substantial investments, technological innovation, and a fundamental shift in operational practices. Overcoming these hurdles is not merely an ethical imperative, but also a strategic necessity for ensuring the long-term viability and competitiveness of the sector.

6. Regulatory Burdens

Regulatory burdens significantly contribute to the difficulties faced within the aerospace sector. These mandates, encompassing safety standards, environmental regulations, and export controls, while designed to ensure public safety and national security, can impose substantial costs and complexities on aerospace companies. The need for rigorous testing, extensive documentation, and ongoing compliance efforts diverts resources from innovation and operational efficiency. For example, the certification process for new aircraft models often involves years of testing and documentation, requiring significant investment and potentially delaying market entry. This, in turn, impacts the financial viability of projects and the competitive position of manufacturers. Strict export controls on sensitive technologies further complicate international collaborations and market access, limiting growth opportunities.

The intricacies of navigating these regulations can lead to increased administrative overhead, specialized legal counsel, and dedicated compliance teams. Smaller companies, in particular, may struggle to bear the financial burden of compliance, hindering their ability to participate in the sector. Furthermore, overlapping or conflicting regulations from different governing bodies can create confusion and uncertainty, complicating decision-making processes. A practical example is the implementation of new environmental regulations regarding aircraft emissions, requiring costly modifications to existing fleets or the development of entirely new propulsion systems. This illustrates how regulatory burdens directly impact technological innovation and the financial performance of aerospace companies.

In conclusion, regulatory burdens, although essential for safety and security, represent a significant component of the overarching challenges within the aerospace industry. Streamlining regulatory processes, promoting international harmonization of standards, and providing support for smaller companies can help mitigate the negative impacts of these burdens while maintaining the necessary levels of oversight. Addressing this facet is critical for fostering a more innovative, competitive, and sustainable aerospace sector.

Frequently Asked Questions Regarding Difficulties Within the Aerospace Sector

The following section addresses commonly raised inquiries related to existing problems. The aim is to provide clear, concise, and informative answers based on publicly available data and industry analysis.

Question 1: What are the primary sources contributing to cost overruns in aerospace projects?

Cost overruns typically arise from unforeseen technical complexities, evolving regulatory requirements, and insufficient project management practices. These factors can lead to redesigns, additional testing, and delayed production schedules, thereby inflating project expenses.

Question 2: How do supply chain disruptions impact the operational efficiency of aerospace companies?

Disruptions in supply chains can result in component shortages, production delays, and increased manufacturing costs. Geopolitical events, natural disasters, and supplier insolvency can all trigger these disruptions, impacting project timelines and financial performance.

Question 3: What are the key drivers behind the talent shortage in the aerospace industry?

The talent shortage is primarily driven by a lack of skilled engineers, technicians, and project managers, particularly those with expertise in emerging technologies. The increasing complexity of aerospace systems and evolving regulatory requirements further exacerbate the demand for specialized skills.

Question 4: What types of cybersecurity threats are most prevalent in the aerospace sector?

The aerospace sector faces various cybersecurity threats, including attacks targeting aircraft systems, data breaches aimed at stealing intellectual property, supply chain vulnerabilities, and disruptions of ground-based infrastructure such as air traffic control systems.

Question 5: What are the major challenges in achieving sustainability within the aerospace industry?

Achieving sustainability requires addressing emissions reduction, noise pollution, waste management, and resource depletion. The transition to sustainable aviation fuels, the development of quieter engines, and the implementation of effective waste management strategies all present significant technological and logistical challenges.

Question 6: How do regulatory burdens affect the competitiveness of aerospace companies?

Regulatory burdens, encompassing safety standards, environmental regulations, and export controls, impose substantial costs and complexities on aerospace companies. The need for rigorous testing, extensive documentation, and ongoing compliance efforts can divert resources from innovation and operational efficiency, thereby impacting competitiveness.

In summary, understanding these frequently asked questions provides valuable insights into the complex landscape of difficulties and the actions that must be addressed.

The subsequent section will analyze potential strategies and solutions for mitigating the aforementioned challenges.

Conclusion

This exploration has detailed numerous significant problems in the aerospace industry, revealing a complex interplay of cost overruns, supply chain vulnerabilities, talent deficits, cybersecurity threats, sustainability imperatives, and regulatory burdens. Each of these challenges demands focused attention and proactive strategies to mitigate their impact on operational efficiency, innovation, and long-term viability.

Addressing these fundamental problems requires a collective commitment from industry stakeholders, government agencies, and research institutions. Sustained investment in technological innovation, workforce development, and streamlined regulatory processes is crucial for ensuring the continued advancement and competitiveness of the aerospace sector. Failure to confront these issues decisively will impede progress and compromise the sector’s vital role in global transportation, economic growth, and national security.

![Israel Aerospace Industries North America: [Insights] Innovating the Future of Flight with Reliable Aviation Solutions Israel Aerospace Industries North America: [Insights] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/01/th-592-300x200.jpg)