The generation of thrust to move an object through a medium, or through space, is a fundamental requirement in aerospace vehicle design. This encompasses a wide range of technologies and principles, from simple propellers used in early aircraft to complex rocket engines employed in space exploration. It is the driving force behind flight and space travel, enabling vehicles to overcome gravity and atmospheric resistance.

Its significance lies in enabling exploration, transportation, and defense capabilities. Advancements in this field directly translate to faster travel times, increased payload capacities, and the ability to reach previously inaccessible destinations. Historically, progress in this area has consistently pushed the boundaries of what is achievable in flight and space endeavors, driving innovation across related engineering disciplines.

Subsequent sections will delve into various systems, including air-breathing and non-air-breathing mechanisms, examining their principles of operation, performance characteristics, and application domains. Further discussion will address emerging technologies and future trends shaping the landscape of flight and space vehicle design.

Key Considerations in Aerospace Vehicle Thrust Generation

Effective design and implementation require careful attention to detail and a thorough understanding of underlying principles. The following points highlight crucial aspects for consideration.

Tip 1: Optimize Thermodynamic Cycles: Maximize efficiency by carefully selecting and optimizing thermodynamic cycles, such as the Brayton cycle for gas turbines or the Rankine cycle for steam rockets, to extract the most energy from the available fuel.

Tip 2: Manage Heat Transfer Effectively: Implement robust heat management systems to dissipate the extreme temperatures generated in combustion chambers and other high-energy components, preventing material failure and ensuring operational longevity.

Tip 3: Minimize Weight and Drag: Reduce overall vehicle weight and aerodynamic drag to improve fuel efficiency and maximize range or payload capacity. This requires a meticulous approach to material selection and aerodynamic design.

Tip 4: Ensure Combustion Stability: Design stable combustion systems to prevent unwanted oscillations or instabilities that can lead to reduced performance or even catastrophic engine failure. This often involves sophisticated modeling and control strategies.

Tip 5: Consider Environmental Impact: Implement strategies to minimize emissions and noise pollution, adhering to environmental regulations and promoting sustainable practices in aerospace operations.

Tip 6: Evaluate Alternative Fuels: Research and develop alternative fuel sources, such as biofuels or hydrogen, to reduce reliance on fossil fuels and enhance the environmental sustainability of flight and space vehicle design.

Tip 7: Enhance Material Science: Employ high-strength, lightweight materials that withstand extreme temperatures and pressures, improving engine performance and reducing overall weight. Consider advanced composites and alloys.

Effective implementation of these considerations is crucial for developing efficient, reliable, and sustainable systems for flight and space exploration. A comprehensive approach integrating these factors leads to superior designs and optimized performance.

The following sections will further explore specific components and design methodologies, providing a more detailed understanding of critical aspects of system development.

1. Thrust Generation

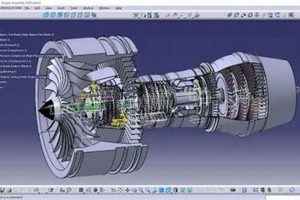

Thrust generation forms the core operational principle that underpins all systems categorized under “propulsion in aerospace engineering.” It is the direct application of force that overcomes drag and gravitational forces, enabling movement through the atmosphere or space. Without effective thrust generation, flight or orbital maneuvers would be impossible. The design and implementation of this component dictates the performance envelope of any aerospace vehicle. For example, the development of high-bypass turbofan engines dramatically improved fuel efficiency and range in commercial aviation by generating a large proportion of thrust through air accelerated by a fan, rather than solely through hot gas exhaust. This illustrates how advancements in thrust generation directly translate to enhanced capabilities in flight operations.

The efficiency of thrust generation is equally critical. Different methods of generating thrust, such as rocket propulsion, jet propulsion, or propeller-driven systems, offer varying levels of efficiency depending on the application. For instance, rocket engines, while capable of producing significant thrust, are typically less efficient than air-breathing jet engines within the atmosphere due to the need to carry their own oxidizer. Therefore, the selection of the appropriate thrust generation method is paramount and is driven by mission requirements, including velocity, altitude, and payload capacity. The Space Shuttle’s use of both solid rocket boosters for initial thrust and liquid-fueled main engines for orbital maneuvering demonstrates a system optimized for different phases of flight.

In summary, thrust generation is not merely a component of “propulsion in aerospace engineering”; it is the fundamental effect that all elements of the system are designed to achieve. Improving thrust output, efficiency, and control remains the central challenge. Future advancements in materials science, combustion techniques, and engine architectures will continue to refine thrust generation methods, thereby expanding the possibilities for flight and space exploration. The ongoing pursuit of more effective thrust mechanisms reflects the continuous effort to push the boundaries of what can be achieved in flight and beyond.

2. Engine Efficiency

Engine efficiency is a paramount determinant of the overall effectiveness of “propulsion in aerospace engineering.” It directly influences fuel consumption, range, payload capacity, and operational costs of aircraft and spacecraft. A more efficient engine extracts a greater proportion of energy from a given amount of fuel, converting it into useful work in the form of thrust, while minimizing waste heat and exhaust products. This leads to lower fuel requirements for a given mission profile, reducing the vehicle’s takeoff weight and allowing for increased payload or extended range. Conversely, a less efficient engine necessitates a larger fuel load to achieve the same mission objectives, increasing weight and cost, and potentially limiting performance. The development of high-bypass turbofan engines in commercial aviation exemplifies this connection, where increased bypass ratios led to significant reductions in fuel consumption compared to earlier turbojet designs. This improvement has directly contributed to the economic viability of long-distance air travel.

Furthermore, engine efficiency is intricately linked to environmental impact. Higher efficiency translates to reduced emissions of greenhouse gases and other pollutants per unit of thrust generated. This is particularly significant in the context of increasing concerns about climate change and the need for sustainable aviation practices. Initiatives to develop more efficient engine technologies, such as advanced turbine materials, improved combustion techniques, and innovative engine architectures like geared turbofans and open rotor designs, are driven by the need to reduce the environmental footprint of air transportation. Similarly, in space exploration, the development of more efficient rocket engines, such as those employing staged combustion cycles, is crucial for reducing the cost and complexity of space missions.

In conclusion, engine efficiency is not merely a desirable attribute in “propulsion in aerospace engineering”; it is a critical requirement for achieving practical, economical, and environmentally sustainable flight and space travel. Ongoing research and development efforts focused on improving engine efficiency are essential for pushing the boundaries of aerospace technology and addressing the challenges of the future. Achieving substantial gains in this area will require a multifaceted approach, integrating advancements in thermodynamics, materials science, aerodynamics, and combustion engineering, as well as innovative design concepts.

3. Fuel Consumption

Fuel consumption stands as a critical parameter in “propulsion in aerospace engineering,” directly influencing operational costs, mission range, and environmental impact. The minimization of fuel consumption, while maintaining or improving performance, remains a central objective in the design and development of aerospace systems.

- Engine Design and Efficiency

Engine design significantly dictates fuel consumption rates. High-bypass turbofan engines, for example, are designed to improve propulsive efficiency, thereby reducing fuel burn compared to older turbojet designs. Variations in compressor and turbine blade designs, combustion chamber configurations, and nozzle geometries all impact the overall efficiency and thus the fuel consumption characteristics of an engine. The Rolls-Royce Trent XWB, used in the Airbus A350, showcases how advanced materials and aerodynamic designs can lead to significant improvements in fuel efficiency. This has direct implications for airline profitability and operational feasibility on long-haul routes.

- Aerodynamic Drag Reduction

Aerodynamic drag directly affects the amount of thrust required to maintain flight, which subsequently impacts fuel consumption. The design of aircraft wings, fuselage, and other external surfaces aims to minimize drag. Laminar flow control techniques, winglets, and advanced airfoil designs contribute to reduced drag coefficients, leading to lower fuel consumption rates. For instance, the Boeing 787 Dreamliner’s raked wingtips are designed to reduce induced drag, contributing to a noticeable improvement in fuel efficiency compared to earlier generation aircraft. This is particularly relevant for long-distance flights, where even small reductions in drag can result in substantial fuel savings.

- Aircraft Weight Optimization

Aircraft weight is a major determinant of fuel consumption. Lighter aircraft require less thrust to achieve and maintain flight, thereby reducing fuel burn. The use of composite materials, such as carbon fiber reinforced polymers, enables the construction of lighter airframes without compromising structural integrity. The Airbus A350, with its predominantly composite structure, demonstrates the benefits of weight optimization in reducing fuel consumption and improving overall performance. This emphasis on lightweight materials extends to engine components and interior furnishings, contributing to an overall reduction in fuel requirements.

- Flight Operations and Route Optimization

Operational practices and route planning exert a considerable influence on fuel consumption. Optimized flight paths that take advantage of favorable wind conditions and minimize distance traveled contribute to reduced fuel burn. Continuous descent approaches and efficient taxiing procedures also help minimize fuel consumption during airport operations. The implementation of modern air traffic management systems, such as those employing trajectory-based operations, aims to optimize flight paths and reduce delays, resulting in lower overall fuel consumption for the aviation industry. This requires collaboration between airlines, air navigation service providers, and regulatory bodies to implement best practices for fuel efficiency.

These facets collectively demonstrate the intricate relationship between fuel consumption and “propulsion in aerospace engineering.” The pursuit of reduced fuel consumption necessitates a holistic approach, integrating advancements in engine technology, aerodynamic design, materials science, and operational practices. The ongoing drive to improve fuel efficiency is not only essential for economic viability but also critical for mitigating the environmental impact of aerospace operations and ensuring a sustainable future for air and space travel.

4. Materials Science

The performance and reliability of systems central to propulsion in aerospace engineering are inextricably linked to materials science. The extreme operating conditions within aerospace engines and vehicle structureshigh temperatures, intense pressures, and corrosive environmentsdemand materials with exceptional properties. Consequently, advancements in materials science directly enable progress in aerospace capabilities. For example, the development of nickel-based superalloys with enhanced creep resistance has permitted the construction of turbine blades capable of withstanding higher operating temperatures in jet engines. This, in turn, increases thermal efficiency and thrust output. Without these material innovations, the current performance levels of modern aircraft engines would be unattainable. Similarly, lightweight composite materials, such as carbon fiber reinforced polymers, are critical for reducing the structural weight of aerospace vehicles, leading to improved fuel efficiency and payload capacity.

The cause-and-effect relationship between materials science and advancements in propulsion is multifaceted. Improved materials allow for more aggressive engine designs, pushing the boundaries of thermodynamic efficiency. For instance, ceramic matrix composites (CMCs) are increasingly being used in hot-section components of gas turbine engines due to their high-temperature strength and low density. This allows for higher turbine inlet temperatures, which directly translates to increased engine efficiency and reduced fuel consumption. Furthermore, materials science plays a vital role in addressing challenges related to material degradation, such as fatigue, corrosion, and erosion. The development of protective coatings and surface treatments can significantly extend the lifespan of critical engine components, reducing maintenance costs and improving overall system reliability. The selection and application of appropriate materials are, therefore, essential for ensuring the safe and efficient operation of aerospace systems.

In conclusion, materials science is not merely a supporting discipline but an integral and enabling component of propulsion in aerospace engineering. The ability to design and manufacture materials with tailored properties to withstand extreme conditions is essential for achieving advancements in engine performance, fuel efficiency, and structural integrity. Ongoing research and development efforts focused on materials innovation are critical for addressing the challenges of future aerospace systems and pushing the boundaries of what is possible in flight and space exploration. The interplay between materials science and aerospace engineering will continue to drive progress in this field, enabling the development of more efficient, reliable, and sustainable aerospace technologies.

5. Thermodynamics

Thermodynamics provides the fundamental principles governing energy transfer and conversion processes critical to “propulsion in aerospace engineering.” The efficiency and performance of aerospace propulsion systems are directly dictated by thermodynamic cycles and processes occurring within them.

- Engine Cycle Efficiency

Thermodynamic cycles, such as the Brayton cycle for gas turbines and the Rankine cycle for steam rockets, form the basis of aerospace engine operation. The efficiency of these cycles, which dictates the conversion of fuel energy into useful thrust, is governed by thermodynamic principles. Higher cycle efficiencies result in reduced fuel consumption and increased range. Practical examples include the optimization of compressor and turbine stages in jet engines to maximize pressure ratio and minimize losses, directly enhancing cycle efficiency and improving engine performance.

- Combustion Processes

The combustion process, a central element in many aerospace engines, is governed by thermodynamic laws. The completeness of combustion and the temperature achieved within the combustion chamber directly impact the amount of energy released and the overall efficiency of the engine. Strategies for improving combustion efficiency include optimizing fuel-air mixing, controlling flame stability, and minimizing heat losses. Advanced combustion technologies, such as lean premixed prevaporized (LPP) combustion, are designed to reduce emissions and improve fuel efficiency by ensuring more complete combustion at lower temperatures.

- Heat Transfer Management

Effective heat transfer management is crucial for the reliable operation of aerospace propulsion systems. Thermodynamics dictates the mechanisms of heat transfer within the engine, including conduction, convection, and radiation. Managing heat loads generated during combustion and other high-temperature processes is essential for preventing material failure and ensuring engine longevity. Techniques for heat transfer management include the use of cooling channels, thermal barrier coatings, and advanced heat exchangers. Proper management of these systems dictates the survivability and continued operational capacity of the engine.

- Nozzle Design and Performance

The design of the nozzle, which expands and accelerates exhaust gases to generate thrust, is heavily influenced by thermodynamic principles. The nozzle’s geometry is optimized to achieve maximum exhaust velocity and thrust based on the thermodynamic properties of the exhaust gases. Convergent-divergent nozzles, commonly used in rocket engines and supersonic aircraft, are designed to efficiently expand the exhaust flow to supersonic speeds. The performance of the nozzle is directly linked to the pressure ratio across the nozzle and the thermodynamic properties of the working fluid. Proper nozzle design is essential for maximizing thrust and minimizing losses.

These facets underscore the profound influence of thermodynamics on “propulsion in aerospace engineering.” Enhancements in thermodynamic understanding and its application directly translate to improvements in engine efficiency, performance, and reliability. Future advancements in aerospace propulsion will continue to rely on a deep understanding and innovative application of thermodynamic principles to push the boundaries of what is achievable in flight and space exploration. The design of more efficient scramjets and advanced rocket engines require intensive knowledge in this area to maximise their performance.

6. Vehicle Aerodynamics

Vehicle aerodynamics plays a critical role in determining the efficiency and performance of aerospace propulsion systems. The interaction between the vehicle’s shape and the surrounding airflow directly impacts the propulsive requirements, fuel consumption, and overall flight characteristics. Effective aerodynamic design minimizes drag and optimizes lift, thereby reducing the power or thrust required from the engines.

- Drag Reduction

Drag, the force resisting an aircraft’s motion through the air, directly increases the thrust required to maintain airspeed. Aerodynamic design focuses on minimizing various forms of drag, including pressure drag (due to shape), friction drag (due to surface roughness), and induced drag (due to lift generation). Streamlining the fuselage, optimizing wing shapes, and incorporating winglets are common strategies for drag reduction. For example, the blended wing body design, explored by Boeing and NASA, aims to reduce drag by seamlessly integrating the wings and fuselage, creating a more aerodynamically efficient shape. Reduced drag translates directly to lower fuel consumption and increased range for a given propulsive system.

- Lift Generation and Control

Lift, the force that counteracts gravity, is essential for sustained flight. Aerodynamic design aims to maximize lift generation at the desired flight conditions while minimizing drag. High-lift devices, such as flaps and slats, increase the wing’s camber and surface area, enhancing lift at lower speeds. The proper balance between lift and drag is crucial for optimizing flight performance. Furthermore, control surfaces, such as ailerons, elevators, and rudders, allow the pilot to control the aircraft’s attitude and direction by manipulating the airflow over the wings and tail. The effectiveness of these control surfaces is directly influenced by the aerodynamic design of the aircraft.

- Air Intake Design

For air-breathing engines, such as those found in jet aircraft, the design of the air intake is critical for ensuring a smooth and efficient flow of air into the engine compressor. The intake must capture the incoming airflow and decelerate it to subsonic speeds before it enters the compressor, minimizing turbulence and pressure losses. Poor intake design can lead to compressor stall and reduced engine performance. Supersonic aircraft require more complex intake designs, such as those incorporating variable geometry, to manage shockwaves and ensure efficient airflow to the engine. The Concorde’s intakes, for instance, were carefully designed to manage supersonic airflow and deliver it efficiently to the engines.

- Propeller and Rotor Aerodynamics

For propeller-driven aircraft and helicopters, the aerodynamics of the propeller or rotor blades directly affects the propulsive efficiency and thrust generated. Propeller and rotor blades are designed to generate lift while minimizing drag, creating thrust that propels the vehicle forward or upward. The blade geometry, airfoil shape, and pitch angle are carefully optimized to achieve maximum efficiency. For helicopters, the rotor blades must also be designed to withstand complex aerodynamic forces and vibrations. Advancements in blade design, such as the use of swept tips and advanced airfoil sections, have led to significant improvements in propeller and rotor efficiency.

In summation, vehicle aerodynamics and propulsion are inextricably linked. A well-designed aerodynamic vehicle minimizes drag, optimizes lift, and ensures efficient airflow to the engines, reducing the propulsive requirements and improving overall performance. Conversely, a poorly designed aerodynamic vehicle requires more power from the engines, leading to increased fuel consumption and reduced range. Continued advancements in aerodynamic design, coupled with innovations in propulsion technology, are essential for pushing the boundaries of aerospace capabilities.

Frequently Asked Questions Regarding Propulsion in Aerospace Engineering

This section addresses common inquiries and misconceptions surrounding propulsion systems in aerospace engineering, providing concise and authoritative answers.

Question 1: What differentiates air-breathing engines from rocket engines?

Air-breathing engines, such as turbojets and turbofans, utilize atmospheric oxygen as an oxidizer for fuel combustion, whereas rocket engines carry their own oxidizer supply, enabling operation in the vacuum of space.

Question 2: How does engine bypass ratio affect fuel efficiency in jet engines?

Higher bypass ratios generally result in improved fuel efficiency by increasing propulsive efficiency. A greater proportion of the thrust is produced by accelerating a larger mass of air at a lower velocity, reducing energy losses.

Question 3: What are the primary challenges in developing hypersonic propulsion systems?

Challenges include managing extreme temperatures generated by air compression at high speeds, maintaining stable combustion within the engine, and designing materials that can withstand the severe thermal and structural loads.

Question 4: How does specific impulse relate to rocket engine performance?

Specific impulse is a measure of a rocket engine’s efficiency, representing the thrust produced per unit weight of propellant consumed per unit time. Higher specific impulse indicates greater efficiency and longer burn times for a given amount of propellant.

Question 5: What role does computational fluid dynamics (CFD) play in propulsion system design?

CFD simulations are used to model and analyze airflow patterns, combustion processes, and heat transfer within propulsion systems, aiding in the optimization of engine components and performance characteristics before physical prototyping.

Question 6: What are the key factors influencing the choice of a propulsion system for a specific aerospace mission?

Mission requirements, including range, payload capacity, operating environment (atmosphere or vacuum), and cost constraints, dictate the selection of the most suitable propulsion system. No single system is universally optimal; trade-offs are often necessary.

These FAQs highlight the complexity and multifaceted nature of propulsion systems in aerospace engineering. A thorough understanding of these principles is essential for developing efficient, reliable, and sustainable aerospace technologies.

The subsequent section will explore emerging trends and future directions in this dynamic field.

Conclusion

This exploration has illuminated the multifaceted nature of propulsion in aerospace engineering, underscoring its significance as a driving force behind advancements in flight and space exploration. Key aspects, encompassing thrust generation, engine efficiency, materials science, thermodynamics, and aerodynamics, were examined to emphasize their interdependencies and individual contributions to overall system performance. The continuous refinement of these elements directly impacts the capabilities of aerospace vehicles.

Continued research and innovation in propulsion in aerospace engineering are paramount for enabling future progress. The pursuit of more efficient, reliable, and sustainable propulsion systems will be essential for expanding humanity’s reach in the skies and beyond, necessitating sustained investment and dedicated effort across related scientific and engineering disciplines. The future of aerospace hinges on advancements in this field.