Mechanical engineering principles are fundamental to the design, development, and manufacturing of aircraft, spacecraft, and related systems. This discipline’s focus encompasses thermodynamics, fluid mechanics, materials science, and structural analysis, all of which are critical for the aerospace sector. For example, mechanical engineers design the engines that power aircraft, ensuring optimal performance and fuel efficiency, and develop the landing gear systems that enable safe landings.

The contributions of this engineering field are vital for ensuring the safety, reliability, and performance of aerospace vehicles. Historically, advancements in mechanical engineering have directly led to breakthroughs in flight technology, from the Wright brothers’ early experiments to the development of modern jet engines and rocket propulsion systems. Efficient structural designs, robust materials selection, and precise control systems are all essential for overcoming the extreme conditions encountered in flight, making the role indispensable.

Further discussion will explore the specific applications of mechanical engineering within the aerospace domain. This includes examining the design of aircraft structures and propulsion systems, the development of advanced materials, and the implementation of sophisticated control systems. Furthermore, the ongoing research and development efforts aimed at improving the efficiency and sustainability of air and space travel will be detailed.

Guidance on Leveraging Mechanical Engineering in Aerospace

The following points highlight critical areas of focus for those seeking to maximize the benefits from a mechanical engineering background within the aerospace sector.

Tip 1: Master Fundamental Principles: A strong foundation in thermodynamics, fluid mechanics, heat transfer, and materials science is paramount. These principles underpin all aspects of aerospace design and analysis.

Tip 2: Develop Proficiency in CAD/CAM Software: Expertise in computer-aided design (CAD) and computer-aided manufacturing (CAM) software is essential for designing and manufacturing aerospace components. Familiarity with industry-standard tools is highly valued.

Tip 3: Gain Expertise in Finite Element Analysis (FEA): FEA is critical for simulating the behavior of aerospace structures under various loads. Proficiency in FEA software allows for the optimization of designs and the prediction of structural integrity.

Tip 4: Understand Aerospace Materials: The aerospace industry relies on specialized materials, such as titanium alloys, composites, and aluminum alloys. Comprehending their properties and applications is crucial for selecting the appropriate material for a given application.

Tip 5: Focus on Aerodynamics: A deep understanding of aerodynamics is necessary for designing efficient aircraft and spacecraft. This includes knowledge of airfoil design, drag reduction techniques, and computational fluid dynamics (CFD).

Tip 6: Prioritize System Integration: The integration of mechanical systems with other aerospace systems, such as avionics and electrical systems, is a vital skill. Understanding the interfaces and interactions between different systems is essential.

Tip 7: Emphasize Project Management Skills: Aerospace projects are typically large and complex, requiring strong project management skills. The ability to plan, organize, and execute projects effectively is highly valued.

By focusing on these areas, individuals can position themselves for success in the aerospace engineering domain and contribute significantly to the advancement of air and space technology.

These tips provide a framework for individuals aiming to excel in aerospace. The subsequent section will summarize the article’s key arguments.

1. Propulsion Systems

Propulsion systems are at the core of aerospace engineering, enabling aircraft and spacecraft to overcome gravity and atmospheric drag. The design, development, and optimization of these systems heavily rely on mechanical engineering principles, making it a critical area within the broader scope of the field’s involvement in the aerospace sector.

- Thermodynamic Cycles and Efficiency

Mechanical engineers apply thermodynamic principles to design efficient engines. For instance, the Brayton cycle is fundamental to gas turbine engines used in jet aircraft. Improving the efficiency of these cycles reduces fuel consumption and emissions. Mechanical engineering drives advancements in compressor and turbine design to optimize performance under varying conditions, directly impacting the operational range and payload capacity.

- Combustion Processes and Fuel Injection

Efficient combustion is critical for maximizing thrust while minimizing pollutant formation. Mechanical engineers design fuel injection systems that atomize fuel and mix it with air in precise proportions. Understanding the fluid dynamics and heat transfer within combustion chambers is essential for achieving stable and complete combustion. This expertise contributes to developing engines that meet increasingly stringent environmental regulations.

- Rocket Nozzle Design and Thrust Vectoring

Rocket engines rely on precisely shaped nozzles to accelerate exhaust gases to supersonic speeds, generating thrust. Mechanical engineers use computational fluid dynamics (CFD) and structural analysis to design nozzles that optimize thrust and withstand extreme temperatures and pressures. Thrust vectoring systems, which allow rockets to change direction, also require sophisticated mechanical designs, enabling precise maneuvering and control in space.

- Material Selection and High-Temperature Applications

Propulsion systems operate at extremely high temperatures and pressures, requiring the use of advanced materials. Mechanical engineers select materials with high strength, creep resistance, and oxidation resistance, such as nickel-based superalloys and ceramic matrix composites. They also develop cooling techniques to protect critical components from overheating, ensuring the longevity and reliability of the propulsion system.

In summary, mechanical engineering is integral to every aspect of propulsion system design, from the fundamental thermodynamic cycles to the advanced materials used in extreme conditions. Progress in propulsion directly translates to improvements in aircraft and spacecraft performance, range, and environmental impact, solidifying the role of mechanical engineers as key innovators in aerospace.

2. Structural Integrity

Structural integrity is paramount in aerospace engineering, directly influencing the safety and performance of aircraft and spacecraft. Mechanical engineering plays a central role in ensuring this integrity through design, analysis, and material selection. The stresses and strains experienced during flight, launch, and re-entry demand robust structures capable of withstanding extreme conditions. Without rigorous mechanical engineering input, the risks of structural failure become unacceptably high.

A primary aspect involves stress analysis and fatigue prediction. Mechanical engineers employ finite element analysis (FEA) to simulate the distribution of stresses within aerospace structures under various loading scenarios. This allows for the identification of potential weak points and the optimization of designs to minimize stress concentrations. Furthermore, understanding fatigue behavior is crucial for predicting the lifespan of components subjected to cyclic loading. For example, the wings of an aircraft experience repeated stress cycles during each flight. Mechanical engineers utilize fatigue analysis techniques to ensure that wings can withstand the intended service life without failure. The Comet airliner disasters of the 1950s, caused by metal fatigue around the square windows, underscore the critical importance of this aspect. Subsequent design changes, incorporating oval windows and improved stress distribution, were a direct result of mechanical engineering investigations.

Ultimately, structural integrity is an inseparable component of the field’s engagement in the aerospace domain. By focusing on design optimization, material selection, and rigorous analysis, this field helps to guarantee that aircraft and spacecraft can operate safely and reliably. This commitment is essential for the continued advancement of air and space travel, presenting challenges as well as expanding the possibilities for future innovations.

3. Materials Innovation

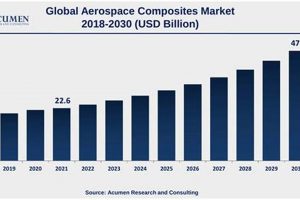

Materials innovation is a cornerstone of the field’s impact on the aerospace sector. The pursuit of lighter, stronger, and more heat-resistant materials directly enables the design of more efficient and capable aircraft and spacecraft. Developments in materials technology, driven by mechanical engineers, are essential for pushing the boundaries of aerospace performance. This relationship is causal: advancements in materials directly lead to improved aerospace vehicle characteristics, such as increased payload capacity, extended range, and enhanced durability.

The importance of materials innovation within the field stems from the extreme operating conditions encountered in aerospace applications. Aircraft and spacecraft must withstand high temperatures, intense pressures, and corrosive environments. Traditional materials often fall short of these requirements, necessitating the development of novel alloys, composites, and ceramics. For instance, the development of titanium alloys, with their high strength-to-weight ratio, revolutionized aircraft design, allowing for larger and more efficient aircraft. Similarly, the use of carbon fiber reinforced polymers (CFRP) in aircraft structures, such as the Boeing 787 Dreamliner, significantly reduced weight and improved fuel efficiency. These examples highlight the practical significance of understanding materials properties and their application in aerospace systems.

Challenges remain in the field of materials innovation for aerospace, including the high cost of development and certification, as well as the need for improved manufacturing techniques. However, ongoing research into advanced materials, such as shape memory alloys and self-healing composites, holds the promise of further revolutionizing the industry. Ultimately, the continued success of the aerospace sector is inextricably linked to the relentless pursuit of materials innovation, driven by the expertise and ingenuity of mechanical engineers.

4. Thermal Management

Thermal management is a critical aspect of the discipline’s contribution to the aerospace industry. Maintaining optimal temperatures for components and systems is vital for performance, reliability, and safety. The ability to control heat generation and dissipation is fundamental to the successful operation of aircraft and spacecraft in diverse and often extreme thermal environments.

- Heat Generation from Electronic Components

Electronic devices within aircraft and spacecraft generate significant heat. Overheating can lead to decreased performance, malfunction, or premature failure. Mechanical engineers design cooling systems, such as heat sinks, heat pipes, and forced-air convection systems, to dissipate this heat. For example, avionics systems in commercial aircraft rely on liquid cooling loops to maintain stable operating temperatures. Effective management is essential for ensuring the reliability of these critical systems.

- Aerodynamic Heating at High Speeds

Aircraft and spacecraft traveling at high speeds experience significant aerodynamic heating due to air friction. The heat generated can reach extreme levels, particularly during atmospheric re-entry. Mechanical engineers develop thermal protection systems (TPS), such as heat shields and ablative materials, to insulate the vehicle and prevent structural damage. The Space Shuttle, for instance, employed ceramic tiles as part of its TPS to withstand the intense heat of re-entry. Understanding the physics of heat transfer is crucial for designing effective protection systems.

- Temperature Control in Space Environments

Spacecraft in orbit are exposed to extreme temperature variations, ranging from intense solar radiation to frigid shade. Mechanical engineers design thermal control systems that utilize radiators, multi-layer insulation (MLI), and heaters to maintain stable internal temperatures. For example, the James Webb Space Telescope relies on a sophisticated sunshield and active cooling systems to keep its instruments at cryogenic temperatures. Precise control is vital for the accuracy and functionality of scientific instruments and other onboard systems.

- Engine Thermal Management

Aircraft engines generate substantial heat during operation. Mechanical engineers develop cooling systems, such as air-cooled turbine blades and oil-cooled components, to prevent overheating and maintain engine efficiency. Turbine blade cooling, for example, involves intricate internal passages that allow air to flow through the blades, reducing their temperature. Effective engine management is essential for maximizing performance and extending engine lifespan.

These elements underscore the discipline’s impact on aerospace thermal management. Effective heat control is indispensable for the safe and reliable operation of aircraft and spacecraft, influencing system design and performance. Innovations in thermal management technologies are continuously sought to address the evolving challenges of air and space travel.

5. Control Systems

Control systems are indispensable to the field’s function in the aerospace sector, providing the means to regulate and stabilize the movement and operation of aircraft and spacecraft. These systems, heavily reliant on mechanical engineering principles, enable precise maneuvering, automated flight, and safe operation under diverse conditions. The connection is causal: sophisticated control systems translate directly into enhanced aircraft performance and safety margins. Without effective control systems, the complex dynamics of flight become unmanageable, rendering aerospace vehicles unstable and potentially dangerous. The importance of these systems is further amplified by the increasing demand for autonomous and remotely operated aircraft.

Several real-world examples underscore this significance. The fly-by-wire systems in modern commercial airliners, which replace traditional mechanical linkages with electronic controls, exemplify the application of mechanical engineering principles in control system design. These systems utilize sensors and actuators to maintain stability and optimize flight performance, enhancing safety and reducing pilot workload. Similarly, the control systems in spacecraft, such as reaction control systems (RCS) and control moment gyroscopes (CMGs), allow for precise attitude control and orbital adjustments. These systems are crucial for maintaining spacecraft orientation, enabling scientific observations, and facilitating docking maneuvers. The development and implementation of these systems demand expertise in mechanics, fluid dynamics, and control theory, areas central to mechanical engineering.

In conclusion, control systems are a vital component, enabling the safe, reliable, and efficient operation of aircraft and spacecraft. Mechanical engineering principles are fundamental to their design, development, and implementation. The continued advancement of aerospace technology hinges on progress in control systems. These will address the challenges of increased autonomy, higher speeds, and more extreme operating environments, solidifying its continuing vital role.

6. Manufacturing Processes

Manufacturing processes are intrinsic to the field’s extensive engagement in the aerospace sector. The design, fabrication, and assembly of aircraft and spacecraft components necessitate sophisticated manufacturing techniques. These techniques, often pioneered and refined by mechanical engineers, are crucial for ensuring the precision, reliability, and performance of aerospace vehicles. A clear cause-and-effect relationship exists: improved manufacturing processes directly lead to enhanced aerospace vehicle characteristics, such as increased structural integrity, reduced weight, and improved aerodynamic efficiency. The ability to manufacture complex geometries, utilize advanced materials, and meet stringent quality control standards is paramount for aerospace success.

The importance of manufacturing processes as a component of the field’s role is exemplified by the application of additive manufacturing (3D printing) in the production of aerospace components. Additive manufacturing enables the creation of complex, lightweight structures with optimized material properties. For instance, General Electric utilizes additive manufacturing to produce fuel nozzles for its LEAP jet engine, resulting in a lighter, more durable, and more fuel-efficient engine. Similarly, Boeing employs additive manufacturing to produce structural components for its aircraft, reducing weight and improving performance. These examples demonstrate how advancements in manufacturing processes, driven by the discipline, directly translate into tangible benefits for the aerospace industry. Precision machining, another critical manufacturing process, is essential for producing high-tolerance aerospace components, such as turbine blades and landing gear components. Mechanical engineers oversee the design and optimization of machining processes to ensure that these components meet stringent dimensional and surface finish requirements.

In conclusion, manufacturing processes are an integral and indispensable element of the mechanical engineering’s influence in the aerospace industry. The ability to design, develop, and implement innovative manufacturing techniques is vital for ensuring the quality, performance, and reliability of aircraft and spacecraft. As the aerospace sector continues to evolve, with increasing demands for efficiency, sustainability, and advanced capabilities, the role of mechanical engineers in manufacturing processes will become even more critical. Future advancements in manufacturing technologies will undoubtedly shape the future of air and space travel, solidifying its place as a driving force in aerospace innovation.

Frequently Asked Questions

The following questions and answers provide insight into aspects of the mechanical engineering within the aerospace industry. These are intended to address common inquiries and provide clarification on specific topics.

Question 1: What are the core areas of focus?

The discipline’s involvement primarily centers on propulsion systems, structural integrity, materials innovation, thermal management, control systems, and manufacturing processes. These areas collectively influence the design, performance, and safety of aerospace vehicles.

Question 2: How does it contribute to aircraft fuel efficiency?

Mechanical engineers optimize engine designs, develop lightweight materials, and improve aerodynamic efficiency. These efforts directly reduce fuel consumption, lower emissions, and extend the range of aircraft.

Question 3: What role does it play in ensuring spacecraft safety?

It contributes by designing robust structures, developing thermal protection systems, and implementing reliable control systems. These measures protect spacecraft from extreme conditions and ensure mission success.

Question 4: How are advanced materials incorporated?

Mechanical engineers research, test, and implement advanced materials, such as composites, titanium alloys, and ceramics. These materials offer high strength-to-weight ratios and resistance to extreme temperatures and corrosive environments.

Question 5: What is the significance of additive manufacturing?

Additive manufacturing enables the creation of complex, lightweight structures with optimized material properties. This technology reduces manufacturing time, lowers costs, and allows for the production of customized aerospace components.

Question 6: How does it address the challenges of space exploration?

It tackles challenges through the design of life support systems, robotic systems, and advanced propulsion technologies. These innovations enable humans to explore space and conduct scientific research in extreme environments.

In summary, this engagement is multifaceted and essential for the continued advancement of air and space travel. By addressing key challenges in design, manufacturing, and performance, mechanical engineers play a vital role in shaping the future of the aerospace sector.

The subsequent section will provide a concluding summary of the comprehensive aspects.

Conclusion

The preceding analysis has underscored the indispensable role of mechanical engineering in aerospace industry. This involvement spans a spectrum of critical functions, from the design and optimization of propulsion systems to ensuring structural integrity, innovating materials, managing thermal challenges, and developing sophisticated control and manufacturing processes. These diverse contributions collectively define the landscape of air and space vehicle development, performance, and safety.

As the aerospace sector continues to evolve, demanding heightened efficiency, enhanced sustainability, and groundbreaking capabilities, the expertise of mechanical engineers will remain paramount. Future advancements in air and space technology will inextricably depend on the continued innovation and rigorous application of mechanical engineering principles, solidifying its pivotal position in shaping the future of aerospace exploration and transportation.

![KAI's HQ: Korea Aerospace Industries Address [Location] Innovating the Future of Flight with Reliable Aviation Solutions KAI's HQ: Korea Aerospace Industries Address [Location] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-536-300x200.jpg)