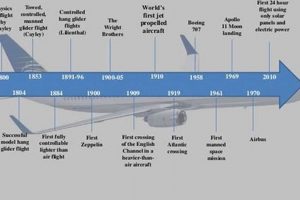

The field encompassing the design, development, testing, and production of aircraft and spacecraft offers opportunities for specialization. Professionals in this arena may concentrate their efforts on particular aspects of these complex systems, ranging from the airframe itself to the propulsion systems that enable flight.

Expertise in this field is vital for advancing air travel efficiency, enhancing space exploration capabilities, and ensuring national security. Historically, advancements in this discipline have led to significant improvements in transportation, communication, and scientific discovery, benefiting society as a whole.

The subsequent sections will detail specific roles within this broad discipline, highlighting the diverse skills and knowledge required for each.

Selecting a specialization within the aerospace engineering field necessitates careful consideration of individual aptitudes and career aspirations. A strategic approach to this decision can significantly impact professional trajectory and fulfillment.

Tip 1: Assess Core Interests and Strengths: A thorough evaluation of one’s intrinsic interests and demonstrated abilities forms the foundation for informed decision-making. For example, individuals with a strong mathematical background and an inclination towards problem-solving might find a focus on aerodynamics or astrodynamics particularly appealing.

Tip 2: Explore Academic Coursework: Carefully review the curriculum of various aerospace engineering programs, paying close attention to elective courses and specializations offered. Participation in relevant projects and research opportunities can provide valuable practical experience and insight.

Tip 3: Seek Mentorship and Guidance: Engaging with experienced professionals in the field provides invaluable perspectives on different career paths and the skills required for success. Mentors can offer realistic assessments of individual strengths and weaknesses, guiding students towards appropriate specializations.

Tip 4: Research Industry Trends: A comprehensive understanding of current and emerging trends within the aerospace industry is crucial for selecting a specialization with long-term career prospects. Areas such as unmanned aerial vehicles (UAVs) and sustainable aviation are experiencing rapid growth and offer promising opportunities.

Tip 5: Consider Employment Opportunities: Research the specific job market for different aerospace engineering specializations. Investigate the types of companies and organizations that hire specialists in each area, and assess the availability of positions and potential for career advancement.

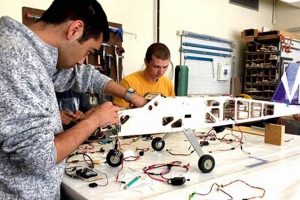

Tip 6: Gain Practical Experience Through Internships: Internships provide invaluable real-world experience and exposure to various aspects of aerospace engineering. Actively seek internship opportunities that align with desired areas of specialization, gaining firsthand knowledge of the day-to-day tasks and challenges involved.

By carefully considering these points, aspiring engineers can make well-informed decisions about specialization, maximizing their potential for a successful and rewarding career in the aerospace industry.

The following sections will delve into specific examples of specialization and their respective responsibilities.

1. Aerodynamics Specialist

An aerodynamics specialist represents a critical specialization within the broader field. This engineer concentrates on the behavior of air and other gases in motion, particularly as they interact with vehicles designed to operate within or beyond Earth’s atmosphere. This specialized knowledge directly impacts aircraft and spacecraft design and efficiency. The principles governing air resistance, lift generation, and stability are central to their work. An aerodynamics specialist can influence the safety, fuel efficiency, and overall performance characteristics.

The influence of an aerodynamics specialist becomes evident in numerous aspects of aerospace engineering. Consider the design of an aircraft wing. Through sophisticated computational fluid dynamics (CFD) simulations and wind tunnel testing, the aerodynamicist optimizes the wing’s shape to minimize drag and maximize lift at various speeds and flight conditions. The winglets at the tips of many modern aircraft wings are a direct result of aerodynamic research, reducing induced drag and improving fuel efficiency. In spacecraft design, aerodynamics play a crucial role during atmospheric re-entry, with the vehicle’s shape and heat shield designed to manage extreme temperatures and decelerate safely.

In summary, the role of an aerodynamics specialist is integral. Without this expertise, aerospace vehicles would be less efficient, less stable, and potentially unsafe. Their understanding of fluid dynamics and application within the broader types of aerospace engineering ensures that aircraft and spacecraft meet performance requirements and operate effectively within their intended environments. As the aerospace industry pursues greater fuel efficiency and develops hypersonic flight technologies, this specialization will continue to play a crucial role.

2. Propulsion Systems Expert

A propulsion systems expert represents a vital specialization. This professional is responsible for the design, development, and testing of engines and related systems that provide the thrust necessary for aircraft and spacecraft to operate. This specialization stands as a cornerstone. The efficacy of a propulsion system dictates an aerospace vehicle’s ability to achieve desired speeds, altitudes, and ranges. This role requires an in-depth knowledge of thermodynamics, fluid mechanics, combustion, and materials science. Without effective propulsion, sustained flight or space travel would remain unrealized.

The influence of propulsion engineers permeates the entire aerospace field. For example, the development of high-bypass turbofan engines has significantly enhanced the fuel efficiency of commercial airliners, reducing operating costs and environmental impact. Rocket engine design, crucial for space exploration, demands innovative solutions to manage extreme temperatures and pressures. A notable instance is the development of staged combustion cycles in rocket engines, allowing for higher performance and efficiency. Further, advances in electric propulsion systems are enabling new possibilities for deep-space missions, providing continuous, low-thrust propulsion for extended periods. These examples demonstrate how specialists in this area directly affect the capabilities and limitations of aerospace technology.

In conclusion, the propulsion systems expert is indispensable. Their expertise translates directly into the performance metrics of aircraft and spacecraft. The ongoing pursuit of more efficient, powerful, and environmentally friendly propulsion systems ensures that this specialization remains at the forefront of innovation. Challenges in this domain, such as mitigating emissions and developing hypersonic propulsion technologies, necessitate continued research and development, linking this specific function directly to broader advancements.

3. Structural Design Engineer

The role of a Structural Design Engineer is a critical element. These engineers are responsible for ensuring the integrity and safety of aerospace vehicles. This specialization is fundamentally related to the various responsibilities that must be fulfilled during design and build. Their primary task involves designing and analyzing the physical structure of aircraft and spacecraft to withstand forces encountered during flight or space travel. This includes load calculations, stress analysis, and material selection, with safety being the paramount consideration. Without their expertise, aerospace vehicles could suffer catastrophic failures, highlighting the inherent importance of their role.

The contributions of structural design engineers become evident in numerous practical applications. For instance, the development of lightweight composite materials in aircraft construction has been instrumental in improving fuel efficiency and performance. Structural engineers play a vital role in determining the optimal use of these materials, ensuring that they meet stringent strength and durability requirements. Another example lies in the design of spacecraft structures capable of withstanding the extreme conditions of space, including thermal stresses and radiation exposure. Furthermore, structural engineers analyze and mitigate the effects of fatigue and corrosion, extending the operational life of aerospace vehicles. These efforts illustrate the direct impact of their work on safety and operational effectiveness.

In summary, the structural design engineer is an indispensable member. Their expertise guarantees the reliability and safety of all flight-capable systems. The continued advancement of aerospace technology relies on structural engineers to develop innovative designs and solutions that meet ever-increasing performance demands. Their contributions are essential for safe and reliable operation in both atmospheric and space environments.

4. Avionics Integration Professional

The avionics integration professional represents a specialized discipline. This expert ensures the seamless operation of electronic systems within aircraft and spacecraft. As a subset of types of aerospace engineers, their role is integral to modern aerospace design. Avionics encompass communication, navigation, flight control, and electronic warfare systems. The integration process involves harmonizing these diverse components to function cohesively. Improper integration can lead to system malfunctions, posing significant safety risks. Therefore, specialized knowledge is essential for this work. The effectiveness of an aircraft’s navigation system, for example, directly depends on the successful integration of sensors, displays, and processing units by an avionics integration professional. Such professionals contribute to the safe and efficient operation of aerospace vehicles.

Practical applications of avionics integration are widespread. In commercial aviation, the integration of autopilot systems with flight management computers enhances safety and reduces pilot workload. Military aircraft rely on integrated radar, electronic countermeasures, and targeting systems to achieve mission objectives. Spacecraft require sophisticated avionics for guidance, navigation, and communication with ground control. The development of fly-by-wire systems, where flight control surfaces are operated electronically rather than mechanically, exemplifies the complexity and importance of avionics integration. These systems require meticulous design and testing to ensure reliability and responsiveness. The growing reliance on autonomous systems and unmanned aerial vehicles further underscores the increasing demand for expertise in avionics integration.

In conclusion, the avionics integration professional represents a vital component. Their ability to create cohesive systems from diverse electronic components is essential for the safe and efficient operation. Challenges arise from increasing system complexity, the need for cybersecurity, and the demand for reduced size, weight, and power consumption. Continued advancements in avionics integration will directly influence the capabilities and future trajectory, ensuring that this function remains crucial.

5. Materials Science Focus

A specialization in materials science within aerospace engineering concentrates on the development, testing, and application of materials used in the construction of aircraft and spacecraft. This focus area is vital due to the extreme conditions encountered in aerospace environments, necessitating materials with specific properties such as high strength-to-weight ratio, thermal resistance, and corrosion resistance. Understanding and applying these material properties requires specialized knowledge distinct from other fields of engineering.

- Material Selection for Specific Environments

Aerospace engineers with a materials science focus are responsible for selecting the appropriate materials for different components based on their intended operating environment. For example, the leading edges of aircraft wings, exposed to high aerodynamic heating, require materials with exceptional thermal resistance, such as nickel-based superalloys or ceramic matrix composites. Similarly, spacecraft operating in low Earth orbit need materials resistant to atomic oxygen erosion and radiation damage. The selection process involves trade-offs between performance, cost, and manufacturability.

- Development of Advanced Materials

This facet involves research and development of novel materials tailored to aerospace applications. Carbon fiber reinforced polymers (CFRPs), for instance, offer high strength and low weight, making them ideal for aircraft structures. Materials scientists contribute to the development of new alloys with enhanced strength, toughness, and fatigue resistance. Nanomaterials, such as carbon nanotubes, are being explored for their potential to create even lighter and stronger composites. These advancements directly influence the performance and efficiency of aerospace vehicles.

- Material Testing and Characterization

Comprehensive testing is essential to validate the performance of aerospace materials under simulated operating conditions. This includes mechanical testing (tensile, compression, fatigue), thermal testing (high-temperature exposure, thermal cycling), and environmental testing (corrosion, radiation). Materials scientists employ a range of techniques, such as microscopy and spectroscopy, to characterize the microstructure and properties of materials. The data obtained from these tests informs design decisions and ensures the structural integrity of aerospace components.

- Failure Analysis and Prevention

When aerospace components fail, materials scientists conduct thorough investigations to determine the root cause. This involves examining fracture surfaces, analyzing material composition, and simulating failure mechanisms. The insights gained from failure analysis inform design improvements and prevent similar incidents from occurring in the future. Understanding the failure behavior of materials is crucial for enhancing safety and reliability in aerospace applications. Addressing issues such as stress corrosion cracking in aluminum alloys or delamination in composite structures requires specialized expertise.

The specializations above, within the “types of aerospace engineers”, highlight the interplay between material properties and vehicle performance, contributing to increased safety and reliability. Their expertise is indispensable in optimizing the performance and safety of aerospace vehicles. As new challenges arise in space exploration and hypersonic flight, the demand for materials science expertise within aerospace engineering will only continue to grow, illustrating its fundamental importance.

6. Control Systems Development

Control systems development constitutes a critical area of specialization within aerospace engineering. The design, implementation, and validation of systems that govern the behavior of aircraft and spacecraft fall under this domain. Stability, maneuverability, and overall performance depend on the efficacy of these systems. Therefore, professionals specializing in control systems play a vital role in aerospace engineering.

Consider, for example, the development of flight control systems for commercial airliners. These systems, encompassing autopilot, autothrottle, and flight management functions, require precise control algorithms to maintain stability during various flight phases. Incorrectly tuned control parameters can lead to oscillations, instability, or even loss of control. Another example is the development of attitude control systems for satellites. These systems utilize sensors and actuators to maintain the satellite’s orientation in space, enabling accurate data collection and communication. The design must account for factors such as solar radiation pressure, gravitational torques, and thruster performance variations. These examples demonstrate the complexity and importance of control systems development in ensuring stability. The ability to model system dynamics accurately, design robust control algorithms, and validate performance through simulation and testing are essential skills for these engineers.

In conclusion, control systems development is fundamental. Its importance stems from its direct influence on safety, performance, and reliability. The field’s future relies on advancements in areas such as adaptive control, fault-tolerant control, and autonomous systems. These evolving demands will require engineers with expertise in control systems. The development of robust control systems is essential for supporting future progress.

7. Testing and Validation Expertise

Testing and validation expertise forms a crucial component within the spectrum. This specialized function ensures that aerospace systems meet stringent performance and safety standards. The expertise is applied throughout the design and development lifecycle, guaranteeing that both individual components and integrated systems operate as intended.

- Component-Level Testing

Component-level testing involves subjecting individual parts or sub-assemblies to various environmental and operational conditions. Examples include vibration testing, thermal cycling, and electromagnetic compatibility (EMC) testing. An aerodynamics specialist, for example, might rely on wind tunnel tests to validate computational fluid dynamics models of a newly designed wing. These tests can uncover design flaws or material weaknesses early in the development process, preventing costly rework and potential failures later. In the context of diverse skill sets, expertise in component-level testing is essential. This impacts product reliability, with those specialized in structural analysis focusing on load testing and fatigue analysis to confirm the structural integrity of aircraft components. The ability to interpret test results and provide actionable feedback is vital.

- System Integration Testing

System integration testing focuses on the interaction between different components and subsystems within an aerospace vehicle. This phase aims to identify and resolve integration issues that may not be apparent during component-level testing. Flight control systems, for instance, undergo rigorous testing to ensure seamless operation with navigation and communication systems. Simulators play a crucial role, allowing engineers to simulate a wide range of flight scenarios and assess system performance under various conditions. Avionics integration specialists are heavily involved, ensuring proper data flow and communication between electronic systems. Effective system integration testing requires a broad understanding of aerospace systems and the ability to troubleshoot complex interactions. System integration testing helps aerospace engineers assess and ensure compatibility among various vehicle systems. This ensures proper communication, coordination, and functionality across different subsystems.

- Flight Testing

Flight testing represents the culmination of the testing and validation process for aircraft and spacecraft. These tests evaluate the vehicle’s performance and handling characteristics under real-world operating conditions. Flight test engineers work closely with pilots and technicians to collect data on parameters such as airspeed, altitude, engine performance, and structural loads. The data are then analyzed to verify that the vehicle meets design specifications and regulatory requirements. For spacecraft, flight testing may involve orbital maneuvers, deployment of solar panels, and activation of scientific instruments. The results inform design refinements and validate the overall integrity. Flight test data are critical for aircraft certification and operational approval. Flight testing provides final validation of designs, especially pertaining to aerodynamics and control systems. During testing, parameters like airspeed, altitude, and engine performance are evaluated to verify if aerospace vehicles function as designed.

- Software Validation

Given the increasing reliance on software in modern aerospace systems, software validation is an increasingly important aspect of testing and validation. This process involves verifying that the software performs its intended functions correctly and reliably, adhering to safety standards. Software validation activities include code reviews, unit testing, integration testing, and system testing. Formal methods, such as model checking, are used to detect potential errors and vulnerabilities. As software controls critical functions, its validation becomes critical for engineers focused on avionics and control systems. Formal verification methods and rigorous testing ensure correct and reliable software performance.

Expertise is thus intrinsically linked to the success of engineers. Rigorous testing, from individual components to integrated systems and flight operations, guarantees the reliability and safety. The expertise needed during development underscores the importance. As aerospace technology continues to advance, this expertise will remain indispensable.

Frequently Asked Questions About Specializations Within Aerospace Engineering

The following addresses common inquiries concerning various roles in aerospace engineering. The aim is to provide concise, factual responses to clarify typical misconceptions or areas of uncertainty.

Question 1: What distinguishes an aerodynamics specialist from a structural design engineer?

An aerodynamics specialist focuses on the motion of air and its interaction with aerospace vehicles, aiming to optimize performance by minimizing drag and maximizing lift. A structural design engineer, conversely, concentrates on the integrity of the vehicle’s physical structure, ensuring it can withstand the forces encountered during flight or space travel.

Question 2: Does propulsion systems engineering solely involve rocket engine design?

No, propulsion systems engineering encompasses a broader range of technologies. It includes the design and development of various engines, including jet engines for aircraft, as well as advanced propulsion systems for spacecraft such as ion drives and plasma thrusters.

Question 3: How important is computer programming for an avionics integration professional?

Computer programming skills are essential for an avionics integration professional. Expertise in programming languages and software development tools is necessary to configure, test, and validate the complex electronic systems within aerospace vehicles.

Question 4: What are the primary responsibilities of an engineer with a materials science focus?

The main responsibilities include selecting suitable materials based on performance characteristics, developing new materials with enhanced properties, and conducting comprehensive tests to ensure that materials meet safety and operational requirements.

Question 5: Is experience with flight simulators valuable for a control systems development engineer?

Yes, experience with flight simulators is highly valuable. Simulators allow control systems engineers to test and refine control algorithms under a wide range of flight conditions. This helps to identify potential problems and optimize system performance before actual flight testing.

Question 6: Why is testing and validation expertise necessary?

Testing and validation expertise is critical to ensure that aerospace vehicles and their subsystems meet stringent performance and safety standards. Comprehensive testing at the component, system, and flight levels is essential to identify and resolve any issues before deployment.

The key takeaway is that specialization in aerospace engineering allows for detailed involvement in design, build and maintenance. Individual strengths should be identified early in the selection process. Consider each path early to allow maximum benefit for skills development.

The following section will delve into the career paths available and future prospects for aerospace engineers.

Aerospace Engineering Specializations

The preceding exploration of different engineering specializations has illuminated the breadth of this field. From the nuances of aerodynamics to the complexities of avionics integration, each role necessitates a unique skillset and contributes to the success. These are critical specializations for the future of aerospace. The effective development and integration across these domains is critical for technological advancement.

Consideration of the opportunities detailed within is a fundamental element for those considering their individual roles in this domain. Further dedication to the development of specialized skills and the consideration of the broader influence ensures a meaningful contribution to the ongoing advancement of flight and space travel. The future trajectory hinges on continued contributions and focus.