This field integrates principles of aerodynamics, propulsion, materials science, and structural analysis to design, develop, and test aircraft and spacecraft. It encompasses the creation of vehicles that operate within Earth’s atmosphere and beyond, including commercial airliners, military aircraft, satellites, and space exploration vehicles.

The advancement of this discipline is critical to national security, global communication, and scientific discovery. It fosters innovation in materials, propulsion systems, and autonomous technologies, contributing to economic growth and improving the quality of life through advancements in transportation and environmental monitoring. Historically, breakthroughs in this area have led to significant leaps in travel speed, distance, and our understanding of the universe.

The following sections will delve into specific topics related to this multifaceted subject, including computational fluid dynamics, control systems, and the impact of emerging technologies on the future of air and space vehicle design.

Essential Considerations in the Field

The following guidelines are presented to offer key considerations within this complex and demanding sphere. Adherence to these points can contribute to success and innovation within related projects and endeavors.

Tip 1: Emphasize a Strong Foundation in Fundamental Sciences: A thorough understanding of mathematics, physics, and chemistry is paramount. These disciplines underpin the theoretical framework upon which all engineering principles are built. For example, a firm grasp of fluid dynamics is essential for designing aerodynamic surfaces.

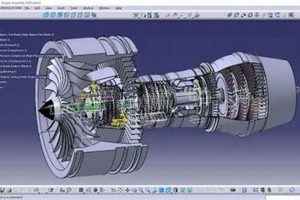

Tip 2: Develop Proficiency in Computational Tools: Expertise in computer-aided design (CAD), computational fluid dynamics (CFD), and finite element analysis (FEA) software is crucial. These tools enable the simulation and analysis of complex systems, facilitating efficient design and problem-solving.

Tip 3: Prioritize a Systems Engineering Approach: Consider the entire system, not just individual components. This involves understanding how different parts interact and influence one another. For instance, changes to the propulsion system will inevitably impact the structural integrity and aerodynamic performance of the aircraft.

Tip 4: Cultivate Effective Communication Skills: The ability to clearly communicate technical information is essential for collaboration and project success. This includes written reports, presentations, and interpersonal communication within a multidisciplinary team.

Tip 5: Remain Abreast of Technological Advancements: This field is constantly evolving. Continuous learning and professional development are necessary to stay informed about new materials, propulsion systems, and control technologies. Regularly reviewing academic journals and attending industry conferences is recommended.

Tip 6: Embrace Interdisciplinary Collaboration: Complex projects often require the expertise of engineers from various disciplines, including mechanical, electrical, and computer engineering. The ability to work effectively in a team environment is critical for success.

Tip 7: Focus on Optimization and Efficiency: Design should prioritize performance optimization, resource efficiency, and environmental sustainability. This involves minimizing weight, reducing fuel consumption, and mitigating emissions.

These considerations represent crucial elements for individuals and organizations operating within the domain. Integrating these principles can contribute to improved project outcomes, enhanced innovation, and sustainable progress.

The subsequent sections will build upon these key considerations, providing further context and analysis of specific challenges and opportunities within this vital area of engineering.

1. Aerodynamics

Aerodynamics represents a fundamental pillar within the broad discipline of aerospace engineering. It governs the motion of air and other gaseous fluids and their interaction with solid objects, directly influencing the performance, stability, and safety of aircraft and spacecraft.

- Lift Generation

Lift, the force that counteracts gravity, is critical for sustained flight. Airfoil design, based on aerodynamic principles, manipulates airflow to create pressure differences, generating lift. For example, the curved upper surface of an aircraft wing forces air to travel a longer distance, reducing pressure and creating an upward force. Inadequate lift results in stall and potential loss of control.

- Drag Reduction

Drag, the force that opposes motion, reduces efficiency and increases fuel consumption. Aerodynamic design seeks to minimize drag through streamlining, boundary layer control, and the use of low-drag airfoils. Winglets, for instance, reduce induced drag by minimizing wingtip vortices. Excessive drag can significantly limit the range and payload capacity of an aircraft.

- Stability and Control

Aerodynamic forces and moments determine an aircraft’s stability and control characteristics. Control surfaces, such as ailerons, elevators, and rudders, are used to manipulate these forces and moments, enabling pilots to control the aircraft’s attitude and trajectory. Poor aerodynamic design can lead to instability, making the aircraft difficult or impossible to control.

- Supersonic and Hypersonic Flow

At supersonic and hypersonic speeds, the behavior of air becomes significantly more complex. Shock waves form, and aerodynamic heating becomes a major concern. Aerodynamic design for high-speed vehicles requires careful consideration of these effects, often involving specialized airfoils, heat shields, and active cooling systems. Failure to address these issues can result in catastrophic structural failure.

In summary, aerodynamics plays a crucial role in all facets of aerospace engineering. From the initial design of airfoils to the development of advanced control systems, a thorough understanding of aerodynamic principles is essential for creating safe, efficient, and high-performance air and space vehicles. Advancements in computational fluid dynamics and wind tunnel testing continue to refine our understanding of aerodynamic phenomena, pushing the boundaries of what is possible in the design of aerospace systems.

2. Propulsion Systems

Propulsion systems are inextricably linked to the core tenets of this discipline. These systems provide the motive force necessary for aircraft to overcome drag and achieve sustained flight within the atmosphere. For spacecraft, propulsion facilitates orbital maneuvers, interplanetary travel, and the maintenance of satellite positioning. Without effective propulsion, the practical applications of air and space vehicles are fundamentally limited.

The selection of a propulsion system is dictated by mission requirements. For instance, commercial aircraft rely on turbofan engines that provide high thrust and fuel efficiency for long-distance travel at subsonic speeds. Military aircraft often utilize turbojet or turbofan engines with afterburners to achieve supersonic speeds and enhanced maneuverability. Spacecraft employ rocket engines, which generate thrust by expelling mass at high velocities. Ion propulsion systems, while offering lower thrust, are highly efficient for long-duration space missions, exemplified by their use in deep-space probes. In each instance, the propulsion system is integral to the vehicle’s performance and operational capabilities.

Advancements in this field are perpetually driven by the need for increased efficiency, reduced emissions, and enhanced performance. Research efforts focus on developing novel engine designs, improving fuel efficiency through advanced materials and combustion techniques, and exploring alternative propellants. Furthermore, challenges remain in developing propulsion systems for hypersonic flight and deep-space exploration, necessitating ongoing innovation and the application of fundamental scientific principles. These continuous improvements are the driving force in aerospace innovation.

3. Materials Science

Materials science plays a pivotal role in this engineering field. The selection and application of materials directly influence the performance, safety, and longevity of aircraft and spacecraft. Material properties, such as strength-to-weight ratio, thermal resistance, and corrosion resistance, are primary considerations in aerospace design. The use of aluminum alloys in early aircraft designs, for instance, significantly reduced weight compared to previous wooden structures, enabling greater payloads and flight ranges. The connection is causal: advancements in material science directly enable progress and innovation.

The demands of extreme environments, including high and low temperatures, radiation exposure in space, and intense mechanical stress, necessitate the development of advanced materials. Examples include titanium alloys for high-temperature engine components, composite materials for lightweight aircraft structures, and heat-resistant tiles for spacecraft re-entry. The composite materials in the Boeing 787 Dreamliner exemplify the application of material science principles, leading to a lighter, more fuel-efficient aircraft. Understanding the practical significance of material properties allows engineers to optimize designs for specific operational conditions.

In conclusion, materials science is a cornerstone of aerospace engineering. The continuous development of new materials with enhanced properties is critical for achieving advancements in aerospace vehicle performance, efficiency, and safety. Ongoing research focuses on areas such as nanomaterials, self-healing materials, and advanced composites to address the challenges of future aerospace applications. Furthermore, careful consideration of material selection and application is essential for ensuring the structural integrity and reliability of aerospace systems throughout their operational lifespan.

4. Structural Integrity

Structural integrity is a cornerstone of all aspects of aerospace engineering. It refers to the ability of an aerospace vehicle or component to withstand applied loads and environmental conditions without failure or unacceptable deformation throughout its operational lifespan. Deficiencies in structural integrity can lead to catastrophic consequences, including loss of life and equipment. Therefore, ensuring robust structural performance is paramount.

The design and analysis of aerospace structures involve rigorous application of engineering principles. Finite element analysis (FEA) is extensively used to simulate the behavior of structures under various loading scenarios, accounting for factors such as stress concentrations, material properties, and geometric imperfections. Furthermore, experimental testing, including fatigue testing and non-destructive inspection techniques, validates the analytical models and identifies potential weaknesses. The Comet airliner disasters of the 1950s, caused by metal fatigue around the square windows, serve as a stark reminder of the consequences of neglecting structural integrity during design and testing. That tragic accident led to significant advancements in understanding fatigue behavior and improved design practices.

Advancements in materials science and manufacturing techniques are constantly pushing the boundaries of structural design. The use of composite materials, such as carbon fiber reinforced polymers, allows for the creation of lighter and stronger structures compared to traditional metallic materials. However, the complex behavior of composites requires sophisticated analysis techniques to ensure structural integrity. As aerospace vehicles become more complex and operate in more demanding environments, the importance of structural integrity and its relationship to all aspects of engineering will only continue to grow.

5. Control Systems

Control systems form an integral aspect of aerospace engineering, enabling the stable and precise operation of aircraft, spacecraft, and associated equipment. These systems regulate various parameters, ensuring desired performance and mitigating the effects of disturbances. The complexity and sophistication of control systems are directly proportional to the vehicle’s mission requirements and operational environment.

- Flight Control Systems

Flight control systems govern the attitude and trajectory of aircraft. These systems utilize sensors, actuators, and control algorithms to maintain stability, respond to pilot inputs, and execute automated maneuvers. Fly-by-wire systems, prevalent in modern aircraft, replace mechanical linkages with electronic signals, enhancing control precision and reducing weight. The Airbus A320, for instance, employs a fly-by-wire system that incorporates envelope protection, preventing the aircraft from exceeding its operational limits. This enhances safety and reduces pilot workload.

- Attitude Control Systems

Attitude control systems are essential for spacecraft to maintain a desired orientation in space. These systems employ reaction wheels, thrusters, or magnetic torquers to counteract external torques and achieve precise pointing accuracy. For example, the Hubble Space Telescope utilizes a sophisticated attitude control system to maintain its pointing direction within fractions of an arcsecond, enabling high-resolution astronomical observations. Precise attitude control is critical for scientific missions and communication satellites.

- Engine Control Systems

Engine control systems regulate the operation of aircraft and spacecraft propulsion systems. These systems manage fuel flow, airflow, and other engine parameters to optimize performance, efficiency, and emissions. Full Authority Digital Engine Control (FADEC) systems, commonly used in modern jet engines, automatically control engine operation based on various sensor inputs, maximizing fuel efficiency and minimizing pilot workload. Furthermore, engine control systems play a crucial role in ensuring engine reliability and preventing catastrophic failures.

- Guidance, Navigation, and Control (GNC) Systems

GNC systems integrate guidance, navigation, and control functions to enable autonomous operation of aerospace vehicles. These systems utilize sensors, such as GPS receivers, inertial measurement units (IMUs), and star trackers, to determine the vehicle’s position, velocity, and attitude. Control algorithms then generate commands to steer the vehicle along a desired trajectory. Autonomous landing systems on spacecraft and autopilot systems in aircraft represent examples of GNC systems. GNC systems are critical for missions where human intervention is limited or impossible.

In summary, control systems are indispensable for the safe, efficient, and reliable operation of all aerospace vehicles. Continuous advancements in control theory, sensor technology, and computing power are driving the development of increasingly sophisticated and capable control systems, enabling more complex missions and enhancing the performance of aerospace systems.

6. Orbital Mechanics

Orbital mechanics, a specialized branch of astrodynamics, constitutes a vital component of aerospace engineering. This discipline applies celestial mechanics to analyze the motion of spacecraft and other celestial bodies under the influence of gravitational forces. The principles of orbital mechanics are foundational for mission planning, satellite deployment, trajectory optimization, and space debris management. A thorough understanding of these principles is not merely beneficial, but essential for successful space missions.

The design of satellite orbits, for example, directly impacts the functionality and lifespan of a mission. Geostationary orbits, where satellites remain fixed relative to a point on Earth, are crucial for communication and weather monitoring. These orbits require precise calculations to maintain their position and counter perturbations caused by solar radiation pressure and gravitational anomalies. Similarly, interplanetary missions rely heavily on orbital mechanics to design fuel-efficient trajectories, such as Hohmann transfer orbits, that minimize the energy required for travel between planets. Incorrect orbital calculations can result in mission failure, loss of spacecraft, and significant financial repercussions, like the failed Mars Climate Orbiter mission which suffered from a navigation error.

In conclusion, orbital mechanics underpins numerous critical activities within aerospace engineering. Challenges remain in accurately predicting long-term orbital behavior, particularly in the presence of space debris and complex gravitational fields. Continued advancements in computational methods and space-based observation technologies are crucial for improving our understanding of orbital mechanics and ensuring the sustainability of space activities. The direct practical applications and theoretical underpinnings solidify the connection.

Frequently Asked Questions

The following section addresses common inquiries concerning the discipline. These answers aim to provide clear and concise information, clarifying misconceptions and offering a deeper understanding of relevant principles and practices.

Question 1: What are the core disciplines encompassed?

The field integrates several key areas of study. These include aerodynamics, propulsion, materials science, structural analysis, control systems, and orbital mechanics. A comprehensive understanding of these disciplines is essential for designing and developing successful air and space vehicles.

Question 2: How has computational fluid dynamics (CFD) impacted the field?

CFD has revolutionized the design and analysis of aerospace vehicles. It allows engineers to simulate airflow around complex shapes, predict aerodynamic performance, and optimize designs before physical testing. This reduces the cost and time required for development while improving vehicle efficiency and safety.

Question 3: What role do composite materials play?

Composite materials offer high strength-to-weight ratios, making them ideal for aerospace structures. They reduce vehicle weight, improve fuel efficiency, and enhance performance. Furthermore, composites can be tailored to specific applications, providing increased resistance to corrosion and fatigue.

Question 4: What are the primary considerations in designing propulsion systems?

Key considerations include thrust-to-weight ratio, fuel efficiency, reliability, and environmental impact. The selection of a propulsion system depends on the specific mission requirements, ranging from high-speed flight to long-duration space travel.

Question 5: How is structural integrity ensured?

Structural integrity is ensured through rigorous design, analysis, and testing. Finite element analysis (FEA) is used to simulate stress and strain under various loading conditions. Additionally, experimental testing validates analytical models and identifies potential weaknesses. Non-destructive inspection techniques are employed to detect flaws and ensure continued structural health throughout the vehicle’s operational lifespan.

Question 6: What are the challenges in managing space debris?

Space debris poses a significant threat to operational satellites and future space missions. Mitigation strategies include designing spacecraft to deorbit at the end of their lives, actively removing debris from orbit, and improving tracking and monitoring capabilities. International cooperation is essential for addressing this growing problem.

In summary, these questions and answers address fundamental aspects. Continuous advancements in these areas drive progress and innovation, ensuring safer, more efficient, and more sustainable aerospace operations. The following sections will expand on these concepts.

The subsequent discussions will build upon this foundation, offering more in-depth analyses of specific topics.

Conclusion

This exploration of aerospace engineering has underscored the multifaceted nature of this discipline. From the fundamental principles of aerodynamics and propulsion to the advanced applications of materials science and control systems, the integration of these elements is paramount for successful vehicle design and operation. The complexities of orbital mechanics further highlight the demands placed upon engineers in this field.

Continued advancement in this discipline is essential for maintaining technological leadership, fostering economic growth, and ensuring national security. Addressing challenges related to sustainability, efficiency, and safety will require sustained investment in research and development, as well as a commitment to rigorous education and training for the next generation of engineers. The future demands innovation and a dedication to pushing the boundaries of what is currently possible.