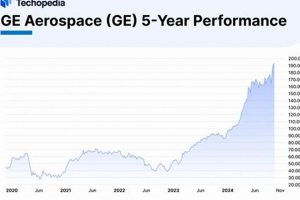

General Electric’s aerospace division represents a significant component of the multinational conglomerate’s operations. It encompasses the design, production, and servicing of aircraft engines, systems, and components for commercial and military aviation. A publicly traded financial instrument reflects the performance and valuation of this sector within the broader GE enterprise.

This segment is crucial due to its substantial revenue generation, technological innovation, and impact on the global aviation industry. Historically, advancements in engine technology and aircraft systems have stemmed from this division, contributing to improved fuel efficiency, safety, and performance for airlines and defense forces. The financial performance of this area provides insights into the health of the aerospace market and investor confidence in GE’s future prospects.

The subsequent discussion will examine the current market position, financial metrics, and future outlook of this key business segment, considering both opportunities and challenges within the evolving aerospace landscape. These analyses are essential for understanding its impact on investment strategies and the broader economy.

Guidance on Analyzing GE Aerospace Equity

This section offers directives for assessing the equity associated with General Electric’s aerospace sector. The following points are designed to provide a structured approach to investment analysis.

Tip 1: Monitor Industry Trends: The aerospace industry is subject to cyclical patterns and technological advancements. Track industry reports, regulatory changes, and competitor activities to understand the context in which this GE division operates.

Tip 2: Scrutinize Financial Statements: Carefully examine GE’s quarterly and annual reports, paying close attention to revenue growth, profit margins, and debt levels specifically attributed to the aerospace segment. Analyze key performance indicators (KPIs) such as order backlog and engine deliveries.

Tip 3: Evaluate Technological Innovation: Assess the company’s investment in research and development, and its success in bringing new technologies to market. Evaluate the competitive advantage gained through proprietary technology in engine design, materials science, or avionics.

Tip 4: Consider Geopolitical Factors: The aerospace and defense sectors are sensitive to geopolitical events and government spending. Monitor defense budgets, international trade agreements, and political stability in key markets.

Tip 5: Assess Supply Chain Resilience: The global supply chain can impact production and profitability. Evaluate GE’s ability to manage disruptions and maintain a reliable flow of materials and components.

Tip 6: Analyze Management Strategy: Understand the strategic direction of GE’s leadership team, their capital allocation decisions, and their approach to mergers and acquisitions within the aerospace domain.

Tip 7: Understand Carbon Footprint: The industry and organization under the environment impact, so investors have to understanding the carbon footprint for future development.

These guidelines provide a framework for informed decision-making when evaluating the equity associated with GE’s aerospace division. A holistic approach, combining financial analysis with an understanding of industry dynamics and geopolitical factors, is crucial.

The ensuing segment will address the limitations and risks inherent in relying solely on these directives, emphasizing the need for diversification and professional financial advice.

1. Engine Order Backlog

An engine order backlog represents the total value of confirmed orders for aircraft engines that have not yet been fulfilled. For General Electric’s aerospace division, a substantial order backlog signifies strong future revenue streams. This backlog directly influences investor perceptions of the equity’s worth, as it provides a degree of predictability regarding future financial performance. For example, a multi-year, billion-dollar contract with a major airline to supply engines for a new fleet of aircraft immediately bolsters confidence in the division’s long-term financial health and prospects. Conversely, a shrinking backlog, or a significant delay in fulfilling existing orders, can negatively impact the investment community’s view of the division’s value and lead to downward pressure on the stock price.

The composition and quality of the engine order backlog are critical considerations. A backlog dominated by orders from financially stable airlines or government entities is viewed more favorably than one heavily reliant on smaller, less secure customers. Furthermore, the backlog’s sensitivity to economic cycles plays a role. During periods of economic recession, airlines may defer or cancel engine orders, impacting the backlog’s overall stability and, consequently, the equity’s valuation. GE Aerospace’s ability to manage its backlog efficiently, including navigating supply chain constraints and production challenges, further affects its stock performance. The ability to translate those orders into delivered engines and recognized revenue is vital to maintaining investor confidence.

In conclusion, the engine order backlog serves as a key indicator of GE Aerospace’s future financial performance and significantly influences its perceived equity value. A healthy, diversified, and well-managed backlog signals stability and growth potential, attracting investors and supporting a higher stock price. Conversely, a weak or poorly managed backlog can erode investor confidence and negatively affect the equity’s performance. Understanding this relationship is crucial for investors seeking to assess the long-term prospects of the division and make informed investment decisions.

2. Defense Spending Trends and GE Aerospace

Defense spending trends exert a direct and substantial influence on the financial performance of GE Aerospace. As a significant provider of aircraft engines and related systems to military entities globally, the company’s revenue stream is intrinsically linked to governmental defense budgets. Increased defense expenditures, driven by geopolitical tensions, technological advancements in military aviation, or strategic policy shifts, typically translate into larger contracts and increased demand for GE Aerospace’s products and services. For instance, a government decision to upgrade its existing fighter jet fleet with newer, more powerful engines from GE Aerospace directly impacts the company’s sales and profitability. Similarly, the development of new military aircraft platforms often necessitates collaboration with GE Aerospace for engine design and production, securing long-term revenue streams.

Conversely, declines in defense spending or shifts in budgetary priorities can negatively affect GE Aerospace’s financial performance. Periods of reduced military activity or a focus on cost-cutting measures within defense agencies may lead to contract cancellations, delayed procurement decisions, or reduced demand for maintenance and support services. The aftermath of major conflicts, for example, often sees a decrease in defense spending as governments reassess their military needs and reallocate resources. GE Aerospace must adapt to these fluctuations by diversifying its portfolio, pursuing international defense contracts, and focusing on technological innovation to maintain its competitive edge. Moreover, the company’s ability to secure and execute contracts efficiently, manage costs, and maintain strong relationships with defense agencies are critical factors determining its resilience to changes in defense spending.

In summary, defense spending trends constitute a critical factor in determining the financial health and strategic direction of GE Aerospace. Understanding the dynamics of these trends, including their drivers and potential impacts, is essential for investors seeking to assess the long-term prospects of the company. While defense spending is subject to volatility, GE Aerospace’s ability to adapt, innovate, and maintain strong relationships with its military customers will ultimately determine its success in navigating the evolving defense landscape and delivering sustainable value to its shareholders.

3. Technological Advancements and GE Aerospace

Technological advancements serve as a primary driver of value and competitive advantage within the aerospace industry, directly influencing the performance of equities associated with GE Aerospace. Sustained investment in research and development, coupled with successful implementation of innovative technologies, is crucial for maintaining market leadership and attracting investor capital.

- Advanced Engine Designs

The development of more fuel-efficient and powerful aircraft engines significantly impacts airline operating costs and environmental footprint. GE Aerospace’s advancements in engine technologies, such as ceramic matrix composites and advanced turbine designs, translate to increased demand, larger order backlogs, and improved profitability. For example, the LEAP engine, developed by CFM International (a joint venture between GE Aviation and Safran Aircraft Engines), has secured substantial orders due to its enhanced fuel efficiency, positively impacting GE’s stock valuation.

- Digitalization and Analytics

The integration of digital technologies, including predictive maintenance analytics and data-driven insights, enables GE Aerospace to optimize engine performance, reduce downtime, and enhance customer service. These digital solutions not only create new revenue streams through service contracts but also improve operational efficiency, leading to higher profit margins. Real-time engine monitoring and predictive analytics, for example, allow airlines to proactively address potential issues, minimizing disruptions and lowering maintenance costs, thereby strengthening customer relationships and driving long-term growth.

- Materials Science Innovations

Breakthroughs in materials science, such as the development of lighter and more durable composite materials, contribute to improved engine performance, reduced weight, and enhanced fuel efficiency. GE Aerospace’s investments in advanced materials enable the creation of more efficient and reliable aircraft components, resulting in a competitive edge and increased market share. For instance, the use of ceramic matrix composites in turbine blades allows for higher operating temperatures, boosting engine efficiency and reducing fuel consumption.

- Autonomous Systems and AI Integration

The integration of autonomous systems and artificial intelligence (AI) into aerospace applications holds the potential to revolutionize flight operations, maintenance, and air traffic management. GE Aerospace’s exploration of AI-powered solutions for aircraft autonomy, predictive maintenance, and supply chain optimization can drive significant efficiency gains and cost reductions. While still in early stages of development, these technologies represent a long-term growth opportunity and contribute to a positive outlook for GE’s aerospace equity.

These technological advancements collectively contribute to GE Aerospace’s ability to deliver superior products, enhance operational efficiency, and capitalize on emerging market opportunities. The successful development and deployment of these innovations directly influence the company’s revenue growth, profitability, and competitive positioning, ultimately impacting its stock performance and long-term value creation.

4. Fuel efficiency mandates

Fuel efficiency mandates, enacted by governing bodies worldwide, exert significant influence on the aerospace sector, particularly impacting General Electric’s aerospace division. These mandates, aimed at reducing aviation’s environmental footprint, dictate stringent requirements for aircraft engine performance, driving demand for more fuel-efficient technologies. Consequently, GE Aerospace, a major provider of aircraft engines, must continuously innovate to meet these evolving regulatory standards. The company’s ability to develop and market engines that surpass these mandates directly influences its competitiveness and financial performance. For example, the International Civil Aviation Organization’s (ICAO) Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) incentivizes airlines to adopt more fuel-efficient aircraft, thereby increasing demand for GE’s advanced engine offerings. Failure to comply with these mandates could result in penalties, reputational damage, and a loss of market share, negatively affecting the equity value.

The practical significance of understanding the connection between fuel efficiency mandates and General Electric’s aerospace equity lies in its impact on investment decisions. Investors closely monitor GE’s technological advancements in fuel efficiency as an indicator of its long-term growth potential. For instance, the success of GE’s LEAP engine, known for its fuel-saving capabilities, has contributed to positive investor sentiment. Moreover, the mandates encourage airlines to replace older, less efficient aircraft with newer models equipped with fuel-efficient engines, creating a recurring revenue stream for GE through engine sales and maintenance contracts. This dynamic makes it imperative for GE to stay ahead of regulatory requirements by investing in research and development of next-generation technologies, such as hybrid-electric propulsion systems.

In summary, fuel efficiency mandates are a critical external factor shaping the strategic direction and financial prospects of GE Aerospace. These mandates necessitate continuous innovation and adaptation, impacting the company’s competitive positioning, revenue streams, and ultimately, its equity value. Monitoring regulatory developments and assessing GE’s response to these mandates is crucial for investors seeking to evaluate the long-term sustainability and growth potential of its aerospace division. The challenges lie in the high cost of research and development, the long lead times for engine development, and the uncertainty surrounding future regulatory changes. However, effective navigation of this landscape can translate into a significant competitive advantage and sustained shareholder value.

5. Supply chain resilience

Supply chain resilience represents a critical operational and strategic factor influencing the financial performance and overall stability of General Electric’s aerospace sector. This division’s capacity to withstand disruptions and maintain consistent production directly impacts revenue streams, profitability, and investor confidence.

- Sourcing Diversification

Reliance on single-source suppliers for critical components exposes the aerospace division to significant risks. Diversifying the supplier base, across geographical regions and vendor types, mitigates the impact of disruptions caused by geopolitical events, natural disasters, or supplier bankruptcies. A proactive strategy involves establishing relationships with alternative suppliers and qualifying them for rapid deployment in emergency scenarios. For instance, a disruption in the supply of specialized alloys from a single overseas provider could halt engine production if alternative sources are not readily available.

- Inventory Management

Effective inventory management balances the need to minimize holding costs with the requirement to maintain sufficient stock to buffer against supply chain disruptions. Employing strategies such as just-in-case inventory for critical components and predictive analytics to anticipate demand fluctuations can enhance resilience. The division must avoid both excessive inventory, which ties up capital, and stockouts, which lead to production delays and lost sales. Maintaining a strategic reserve of key components, particularly those with long lead times, provides a safety net against unforeseen circumstances.

- Logistics Network Optimization

An optimized logistics network, encompassing transportation, warehousing, and distribution, is essential for ensuring the timely delivery of components and finished products. This involves selecting reliable transportation partners, utilizing multiple transportation modes, and establishing strategically located distribution centers. For example, consolidating shipments, employing advanced tracking technologies, and leveraging regional distribution hubs can mitigate delays and reduce transportation costs. A resilient logistics network allows the division to adapt quickly to unexpected events, such as port congestion or transportation infrastructure failures.

- Cybersecurity Protocols

The increasing reliance on digital technologies in supply chain management exposes the aerospace division to cyber threats. Implementing robust cybersecurity protocols, including data encryption, access controls, and regular vulnerability assessments, is critical for protecting sensitive information and preventing disruptions caused by cyberattacks. A successful cyberattack on a key supplier’s systems could compromise the integrity of components, disrupt production schedules, and damage the division’s reputation. Proactive cybersecurity measures are essential for maintaining supply chain integrity and ensuring the continuity of operations.

The interconnectedness of these facets underscores the importance of a holistic approach to supply chain resilience within General Electric’s aerospace division. Effective management of sourcing, inventory, logistics, and cybersecurity contributes to operational stability, financial performance, and investor confidence. A resilient supply chain not only mitigates risks but also creates opportunities for innovation, cost reduction, and enhanced customer service, ultimately supporting long-term value creation for the company.

Frequently Asked Questions

This section addresses common inquiries regarding the financial aspects and investment considerations related to General Electric’s (GE) aerospace division.

Question 1: What factors primarily influence the stock price of GE Aerospace?

The equity value of GE Aerospace is subject to fluctuations based on several key factors, including global air travel trends, defense spending allocations, technological advancements in engine design, prevailing interest rates, and overall market sentiment. Performance is also affected by major contract wins and losses, supply chain stability, and successful integration of acquisitions.

Question 2: How is the financial performance of GE Aerospace assessed?

The financial health of GE Aerospace is typically evaluated through key metrics such as revenue growth, operating margins, order backlog, cash flow generation, and return on invested capital. Investors scrutinize these indicators to gauge the division’s profitability, efficiency, and long-term growth potential. Comparisons against industry benchmarks and competitor performance provide further context.

Question 3: What risks are associated with investing in GE Aerospace stock?

Potential risks include cyclical downturns in the aerospace industry, geopolitical instability affecting defense contracts, technological obsolescence due to disruptive innovations, supply chain disruptions, regulatory changes impacting engine emissions, and unforeseen events such as major accidents or global pandemics.

Question 4: How does GE Aerospace contribute to General Electric’s overall financial performance?

GE Aerospace is a significant revenue and profit driver for General Electric. Its financial contributions impact GE’s consolidated financial statements, including revenue, earnings per share, and cash flow. The aerospace division’s performance influences investor perception of the entire corporation’s value.

Question 5: What is the impact of government regulations on GE Aerospace’s operations?

Government regulations, including those related to engine emissions, safety standards, and defense contracting, exert a considerable influence on GE Aerospace. Compliance with these regulations necessitates ongoing investment in research and development, operational adjustments, and adherence to stringent quality control measures. Changes in regulations can create both opportunities and challenges for the company.

Question 6: How important is the aftermarket services business to GE Aerospace?

The aftermarket services business, encompassing engine maintenance, repair, and overhaul (MRO), represents a substantial and recurring revenue stream for GE Aerospace. This segment contributes significantly to overall profitability and helps to mitigate the impact of cyclical fluctuations in engine sales. Strong aftermarket service capabilities enhance customer relationships and generate long-term value.

These answers provide a concise overview of essential considerations related to GE Aerospace stock. A thorough understanding of these factors is crucial for making informed investment decisions.

The following segment will explore the impact of market trends and competitive landscape on GE Aerospace.

Concluding Assessment of GE Stock Aerospace

The preceding analysis underscores the multifaceted nature of General Electric aerospace equity. The division’s performance is demonstrably affected by industry trends, defense spending policies, technological advancements, fuel efficiency regulations, and supply chain resilience. A comprehensive understanding of these elements is essential for discerning the intrinsic value and potential growth trajectory of the investment. Careful scrutiny of financial metrics, including order backlogs, revenue streams, and profit margins, provides further clarity on the division’s operational effectiveness and market positioning.

The financial community is encouraged to conduct thorough due diligence and ongoing monitoring of relevant market indicators. Independent financial counsel should be sought to align investment decisions with individual risk tolerance and long-term objectives. The future success of this area is contingent upon its ability to adapt to evolving market dynamics, maintain technological leadership, and navigate geopolitical uncertainties. Prudent evaluation and strategic foresight remain paramount for investors seeking to capitalize on opportunities within the aerospace sector.

![Is Radian Aerospace Stock A Buy? + [YEAR] Guide Innovating the Future of Flight with Reliable Aviation Solutions Is Radian Aerospace Stock A Buy? + [YEAR] Guide | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-29-300x200.jpg)

![Is Korea Aerospace Industries Stock [KAI] a Buy? Analysis & Outlook Innovating the Future of Flight with Reliable Aviation Solutions Is Korea Aerospace Industries Stock [KAI] a Buy? Analysis & Outlook | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/01/th-871-300x200.jpg)