Positions within this field involve the design, development, testing, and production of aircraft, spacecraft, and related systems. These roles frequently demand a strong understanding of aerodynamics, propulsion, materials science, and structural analysis. For instance, an individual might be responsible for optimizing the wing design of a new commercial airliner to reduce fuel consumption or developing guidance systems for satellites.

The significance of these careers stems from their direct contribution to advancements in air and space travel, national defense, and scientific exploration. Historically, these roles have been vital in pushing the boundaries of technological innovation, leading to improved transportation efficiency, enhanced communication capabilities, and a deeper understanding of the universe. The economic impact is also considerable, driving job creation and stimulating growth in related industries.

The following sections will delve into specific career paths, required educational qualifications, essential skills, and potential career growth opportunities within this dynamic and challenging sector. Exploration of typical responsibilities and the overall job market outlook will also be provided, offering a comprehensive overview of the field.

Tips for Pursuing Careers in the Aerospace Sector

Individuals seeking to enter the aerospace field should consider these recommendations to enhance their prospects and navigate the complexities of this competitive industry.

Tip 1: Develop a Strong Foundation in STEM: A robust understanding of science, technology, engineering, and mathematics is paramount. Focus on core subjects such as physics, calculus, and differential equations. These principles underpin all aspects of aerospace design and analysis.

Tip 2: Gain Hands-On Experience: Seek internships, co-op programs, or research opportunities with aerospace companies or university laboratories. Practical experience provides valuable insights into real-world applications and enhances problem-solving skills.

Tip 3: Specialize in a Niche Area: Aerospace is a broad field. Consider specializing in areas such as aerodynamics, propulsion, structures, or avionics. Focused expertise increases employability and allows for deeper engagement with specific challenges.

Tip 4: Cultivate Strong Communication Skills: Effective communication, both written and verbal, is essential for collaborating with engineers, technicians, and project managers. Practice presenting technical information clearly and concisely.

Tip 5: Stay Current with Industry Trends: The aerospace sector is constantly evolving. Remain informed about emerging technologies, materials, and design methodologies through journals, conferences, and professional organizations.

Tip 6: Consider Advanced Education: While entry-level positions may be accessible with a bachelor’s degree, a master’s or doctoral degree can significantly expand career opportunities and earning potential, particularly in research and development roles.

Tip 7: Network with Professionals: Attend industry events, join professional societies (e.g., AIAA), and connect with individuals working in the field. Networking can provide valuable insights, mentorship, and potential job leads.

Adhering to these suggestions can significantly enhance an individual’s preparedness for, and success within, this demanding yet rewarding field. Prioritizing academic excellence, practical experience, and continuous learning is crucial.

The subsequent section will address common misconceptions about careers in this field and offer a realistic perspective on the challenges and opportunities that lie ahead.

1. Design and Development

Design and development are fundamental components within the spectrum of roles associated with the aerospace field. These activities encompass the conceptualization, creation, and refinement of aircraft, spacecraft, satellites, and related systems. The execution of design and development tasks requires a comprehensive understanding of engineering principles, materials science, and manufacturing processes. A cause-and-effect relationship exists where advancements in design methodologies and materials directly lead to improvements in vehicle performance, efficiency, and safety. For instance, the adoption of computational fluid dynamics (CFD) in aerodynamic design allows engineers to optimize wing shapes for reduced drag, thereby increasing fuel efficiency and range. This optimization process is a direct consequence of applying design and development principles.

The importance of design and development within this field stems from its critical role in pushing technological boundaries and enabling new capabilities. Consider the development of reusable spacecraft like the Space Shuttle and, more recently, the SpaceX Falcon series. These projects required significant innovation in design to achieve reliable, cost-effective access to space. The design phase involves complex trade studies to balance competing requirements such as payload capacity, structural integrity, and thermal management. The development phase translates these designs into tangible prototypes and production-ready systems. The practical significance lies in the resulting advancements, such as reduced launch costs and increased accessibility to space for scientific research and commercial applications.

In conclusion, design and development represent a core set of activities without which progress in the aerospace domain would be unattainable. The challenges inherent in these activitiessuch as managing complexity, ensuring reliability, and mitigating risksdemand highly skilled engineers and a commitment to continuous improvement. A solid grasp of design and development principles is not merely beneficial but essential for individuals seeking to contribute meaningfully to the evolution of air and space technology.

2. Research and Innovation

Research and innovation are critical drivers of progress within the aerospace sector. These activities directly impact the nature and scope of available positions, shaping the skill sets and expertise required of aerospace professionals. Examination of specific facets reveals the profound connection between research breakthroughs and the evolution of these careers.

- Advanced Materials Research

The development of new materials, such as lightweight composites and high-temperature alloys, is central to enhancing aircraft and spacecraft performance. Professionals in materials science and engineering conduct research to identify, test, and implement these materials. This work leads to roles focused on materials characterization, structural analysis, and the optimization of manufacturing processes.

- Propulsion Systems Innovation

Research into advanced propulsion systems, including electric propulsion, scramjets, and hybrid engines, is essential for achieving greater efficiency and reduced emissions. Engineering positions related to propulsion involve designing, simulating, and testing these novel systems. These jobs often require expertise in thermodynamics, fluid dynamics, and combustion.

- Autonomous Systems and Robotics

The integration of autonomous systems and robotics into aerospace applications, such as unmanned aerial vehicles (UAVs) and robotic spacecraft, is a rapidly growing field. Research in this area necessitates expertise in artificial intelligence, sensor technology, and control systems. Related positions involve developing algorithms, designing robotic platforms, and integrating these systems into operational environments.

- Aerodynamics and Flight Control

Continued research in aerodynamics and flight control is vital for improving aircraft stability, maneuverability, and fuel efficiency. This includes the development of new wing designs, control surfaces, and flight control algorithms. Relevant opportunities involve conducting wind tunnel testing, performing computational fluid dynamics simulations, and developing advanced flight control strategies.

These facets of research and innovation directly influence the demand for skilled professionals across various domains. A commitment to continuous learning and adaptation is essential for individuals seeking to thrive in the evolving landscape of aerospace positions. The ongoing pursuit of knowledge ensures that professionals are equipped to tackle future challenges and contribute to the advancement of air and space technology.

3. Testing and Analysis

Testing and analysis are integral to the creation and maintenance of safe and effective aerospace systems. These processes ensure that components and systems meet stringent performance criteria and adhere to regulatory standards. The diverse facets of testing and analysis directly influence the nature of available positions within the field.

- Structural Testing

Structural testing involves subjecting aerospace components and assemblies to simulated flight loads and environmental conditions. This testing verifies the structural integrity and durability of designs. Positions in this area include structural test engineers, who design and execute tests, and stress analysts, who predict structural behavior using computational methods. For example, a full-scale aircraft wing might undergo static and fatigue testing to validate its ability to withstand operational stresses.

- Non-Destructive Testing (NDT)

NDT methods are employed to detect flaws or defects in materials and components without causing damage. Techniques such as ultrasonic testing, radiography, and eddy current testing are used to inspect critical parts. NDT technicians and engineers are responsible for conducting inspections, interpreting results, and ensuring the reliability of aerospace structures. The inspection of turbine blades for cracks is a typical application of NDT.

- Flight Testing

Flight testing evaluates the performance and handling characteristics of aircraft under various flight conditions. Test pilots, flight test engineers, and instrumentation specialists collaborate to collect data on aircraft stability, control, and system performance. These tests validate design assumptions and identify potential safety concerns. Testing new avionics or evaluating aircraft performance at extreme altitudes are examples of flight test activities.

- Systems Integration Testing

Systems integration testing verifies the compatibility and functionality of interconnected aerospace systems. This includes testing avionics, propulsion systems, and control systems to ensure they operate seamlessly together. Systems engineers and test engineers conduct these tests to identify and resolve integration issues before deployment. Testing the integration of a new autopilot system with existing aircraft sensors is a typical example.

These facets of testing and analysis highlight the importance of skilled professionals in ensuring the safety and reliability of aerospace systems. The demand for qualified engineers and technicians in these areas remains strong, driven by the continuous need to validate designs and maintain operational readiness.

4. Manufacturing Processes

Manufacturing processes are fundamental to the aerospace sector, directly influencing the creation of aircraft, spacecraft, and associated components. The efficiency, precision, and reliability of these processes determine the quality and performance of finished products, which, in turn, shape the demand for specialized roles.

- Advanced Machining

Advanced machining techniques, such as CNC machining and laser cutting, are essential for producing complex aerospace components with tight tolerances. These processes require skilled machinists, programmers, and manufacturing engineers who can operate and maintain sophisticated equipment. For instance, the production of turbine blades for jet engines involves intricate machining processes to achieve optimal aerodynamic performance.

- Composite Manufacturing

Composite materials are increasingly used in aerospace structures due to their high strength-to-weight ratio. Manufacturing processes for composites, such as layup, curing, and resin transfer molding, demand specialized expertise in materials science and manufacturing. Composite technicians, engineers, and quality control inspectors are critical for ensuring the integrity of composite structures, such as aircraft wings and fuselage sections.

- Additive Manufacturing (3D Printing)

Additive manufacturing offers the potential to create complex geometries and customized parts with reduced material waste. This technology is employed in the production of prototypes, tooling, and even end-use aerospace components. Roles in additive manufacturing include design engineers, process engineers, and machine operators who are proficient in 3D printing techniques and materials.

- Assembly and Integration

The assembly and integration of aerospace components require meticulous planning and execution to ensure proper fit, alignment, and functionality. Assembly technicians, integration engineers, and quality assurance specialists are responsible for assembling and integrating various parts into larger systems, such as aircraft engines or satellite payloads. The integration of avionics systems into an aircraft cockpit is a critical assembly process.

These facets of manufacturing underscore the critical role of skilled personnel in ensuring the production of high-quality aerospace components and systems. The continuous advancement of manufacturing technologies drives the need for ongoing training and development to maintain a competitive workforce.

5. Project Management

Project management is a critical function within the aerospace industry, essential for overseeing the design, development, and deployment of complex engineering projects. These projects often involve significant financial investments, stringent regulatory requirements, and demanding timelines, making effective project management paramount for success.

- Scheduling and Resource Allocation

Aerospace projects require meticulous scheduling and resource allocation to ensure timely completion. Project managers are responsible for creating detailed project plans, identifying critical path activities, and allocating resources effectively. For example, a project manager overseeing the development of a new satellite must coordinate the efforts of engineers, scientists, and technicians while managing budgets and timelines. Delays or resource constraints in one area can have cascading effects on the entire project.

- Risk Management

The aerospace industry inherently involves significant technical and financial risks. Project managers must identify, assess, and mitigate these risks throughout the project lifecycle. Risk management activities include conducting risk assessments, developing contingency plans, and monitoring project performance against key risk indicators. For instance, a project manager responsible for developing a new aircraft engine must address risks related to technical feasibility, regulatory compliance, and market acceptance.

- Stakeholder Communication

Effective communication with stakeholders, including engineers, customers, regulatory agencies, and funding sources, is crucial for project success. Project managers are responsible for keeping stakeholders informed of project progress, risks, and changes. Clear and consistent communication helps to build trust, manage expectations, and ensure that project objectives are aligned with stakeholder needs. Regular progress reports, project meetings, and formal presentations are common communication tools.

- Quality Assurance and Compliance

Aerospace projects must adhere to stringent quality standards and regulatory requirements to ensure safety and reliability. Project managers are responsible for implementing quality assurance processes and ensuring compliance with relevant regulations. This includes conducting audits, performing inspections, and maintaining detailed documentation. For example, a project manager overseeing the production of aircraft components must ensure that all parts meet FAA requirements and that manufacturing processes are properly documented.

The successful execution of aerospace projects relies heavily on skilled project managers who can effectively plan, organize, and control complex activities. The ability to manage risks, communicate effectively, and ensure quality and compliance is essential for achieving project objectives and delivering value to stakeholders. These factors directly influence the career paths and required skill sets for various positions in this engineering sector, highlighting the increasing demand for qualified individuals in this domain.

6. Regulatory Compliance

Regulatory compliance is a central tenet governing the aerospace industry, dictating the design, manufacturing, operation, and maintenance of aircraft and spacecraft. Adherence to these regulations ensures safety, security, and environmental protection. Numerous roles within the field are directly or indirectly involved in ensuring compliance with these standards, shaping the responsibilities and skill sets required of aerospace professionals.

- Airworthiness Standards and Certification

Airworthiness standards, such as those established by the Federal Aviation Administration (FAA) in the United States or the European Aviation Safety Agency (EASA) in Europe, define the minimum safety requirements for aircraft design and operation. Aerospace engineers involved in design and certification must demonstrate that their products meet these standards through rigorous testing and documentation. This process can involve roles focused on structural analysis, flight performance, and systems safety, all with the common goal of proving compliance.

- Environmental Regulations

Environmental regulations aim to minimize the impact of aviation and space activities on the environment. These regulations address noise pollution, emissions, and waste management. Professionals in environmental engineering and regulatory affairs are tasked with ensuring that aerospace operations comply with these regulations. This may involve designing quieter aircraft engines, developing sustainable aviation fuels, or implementing environmentally responsible manufacturing practices. Failure to comply can result in significant penalties and reputational damage.

- Export Control and Security Regulations

Export control regulations govern the transfer of sensitive aerospace technologies and equipment to foreign countries. These regulations are designed to prevent the proliferation of weapons and protect national security. Compliance with export control regulations requires expertise in international trade law and security protocols. Export compliance officers and security specialists are responsible for ensuring that aerospace companies adhere to these regulations, which may involve obtaining export licenses, conducting security screenings, and implementing safeguards to protect sensitive information.

- Maintenance and Operations Compliance

Maintenance and operations compliance ensures that aircraft and spacecraft are maintained and operated in accordance with regulatory requirements. Maintenance technicians, inspectors, and operations managers are responsible for ensuring that maintenance procedures are followed, inspections are conducted regularly, and operational practices adhere to safety standards. This includes tasks such as performing routine maintenance, documenting repairs, and ensuring that pilots and flight crews are properly trained and certified.

Collectively, these facets of regulatory compliance demonstrate the pervasive influence of regulatory frameworks on positions within the aerospace field. From design engineers ensuring airworthiness to compliance officers managing export controls, professionals across the sector must navigate a complex web of regulations to ensure safety, security, and environmental responsibility. The demand for expertise in regulatory compliance is expected to remain strong, driven by the increasing complexity of aerospace technologies and the growing emphasis on safety and sustainability.

7. Specialized Engineering Roles

Specialized engineering roles represent a critical subset within the broader landscape of positions related to aerospace engineering. These roles demand in-depth knowledge and expertise in specific technical areas, contributing directly to the advancement and innovation of air and space technologies. The existence of these specialized functions is a direct consequence of the complex and multifaceted nature of modern aerospace systems. For example, a stress analyst specializing in composite materials plays a crucial role in ensuring the structural integrity of aircraft wings, a function that cannot be adequately addressed by general engineering knowledge. Without such specialization, the performance and safety of aerospace vehicles would be significantly compromised.

The importance of specialized roles stems from their ability to address highly specific challenges and optimize particular aspects of aerospace systems. Consider a propulsion engineer specializing in hypersonic combustion. Their focused expertise is essential for developing engines capable of powering vehicles at speeds exceeding Mach 5. These roles drive innovation by pushing the boundaries of existing technologies and enabling the creation of next-generation aerospace systems. The practical significance is evident in the development of advanced defense systems, high-speed transportation, and space exploration capabilities. The success of projects like the development of reusable rockets, for instance, relies heavily on engineers specializing in areas such as guidance and control, thermal protection systems, and propulsion.

In conclusion, specialized engineering roles are indispensable for advancing the capabilities of the aerospace sector. These roles enable the development of cutting-edge technologies, improve the performance and safety of aerospace systems, and drive innovation in air and space travel. The challenges associated with these roles, such as maintaining expertise in rapidly evolving fields and collaborating effectively across disciplines, underscore the need for continuous learning and professional development. Understanding the significance of these specialized functions is essential for individuals seeking to contribute meaningfully to the aerospace industry.

Frequently Asked Questions Regarding Careers in Aerospace

The following questions and answers address common inquiries concerning careers related to aerospace engineering, providing clarity on typical job requirements, prospects, and educational paths.

Question 1: What are the core educational requirements for entry-level positions in aerospace?

A bachelor’s degree in aerospace engineering, mechanical engineering, or a closely related field is generally required for entry-level positions. Some roles may necessitate a master’s degree, particularly those involving research and development.

Question 2: Which specific technical skills are most valuable for individuals pursuing careers in this field?

Proficiency in areas such as computational fluid dynamics (CFD), finite element analysis (FEA), CAD/CAM software, and programming languages (e.g., MATLAB, Python) is highly valuable. A strong foundation in mathematics and physics is also essential.

Question 3: What is the typical career progression for individuals starting in entry-level roles?

Entry-level engineers often progress to roles with increasing responsibility, such as project engineer, senior engineer, or team lead. Advancement may also involve specialization in a specific area, such as propulsion, structures, or avionics.

Question 4: What are the key challenges facing professionals in these careers?

Challenges include keeping pace with rapidly evolving technologies, managing complex projects with tight deadlines and budgets, and ensuring compliance with stringent regulatory requirements.

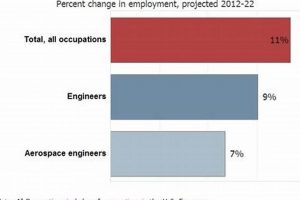

Question 5: What is the job market outlook for individuals in these occupations?

The job market outlook is generally positive, with projected growth in employment driven by increasing demand for air travel, space exploration, and defense technologies. However, specific opportunities may vary depending on the sector and geographic location.

Question 6: What are the primary industries that employ professionals with expertise in aerospace engineering?

Key industries include aerospace manufacturers (e.g., Boeing, Airbus, Lockheed Martin), government agencies (e.g., NASA, Department of Defense), research institutions, and airlines.

In summary, pursuing a career in this engineering field demands a solid educational foundation, continuous learning, and adaptability to evolving technological landscapes.

The following section will explore resources and organizations that can provide valuable support for individuals interested in entering or advancing within this dynamic field.

Conclusion

The preceding sections have provided a comprehensive overview of opportunities related to this engineering discipline, encompassing essential aspects such as career paths, required skills, and educational qualifications. Emphasis has been placed on understanding the diversity of roles within the sector, from design and development to regulatory compliance, illustrating the multifaceted nature of this field.

The information presented serves as a resource for individuals seeking to enter or advance within this challenging yet rewarding industry. Continued dedication to acquiring knowledge and adapting to technological advancements remains crucial for sustained success and contribution to the ongoing evolution of air and space technology.

![Guide to Aerospace Welder Job Description [+Skills] Innovating the Future of Flight with Reliable Aviation Solutions Guide to Aerospace Welder Job Description [+Skills] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/02/th-692-300x200.jpg)