The disciplines of aeronautical and aerospace engineering are frequently used interchangeably, yet significant distinctions exist. One focuses primarily on the design, development, and maintenance of aircraft that operate within Earth’s atmosphere. The other expands upon this knowledge to encompass the design, development, and maintenance of spacecraft and aircraft operating both within and outside the Earth’s atmosphere. For instance, aeronautical engineers might work on improving the fuel efficiency of commercial airplanes, while aerospace engineers could be involved in designing satellites or rockets.

Understanding the specific areas of focus is crucial for students choosing a career path and for employers seeking specialized expertise. The historical context reveals that aeronautical engineering emerged first, followed by the broader field of aerospace engineering as space exploration became a reality. This evolution highlights the increasing complexity and diversification of the field, leading to distinct skill sets and knowledge bases required for each specialization. The impact of both fields is immense, driving advancements in transportation, communication, and scientific discovery.

The following sections will delve into the specific curriculum differences, career opportunities, and required skill sets associated with each discipline. A closer examination of these aspects will provide a clearer understanding of the distinct characteristics defining each engineering field.

Selecting the appropriate engineering discipline requires careful consideration of individual interests and career aspirations. Understanding the nuances between aeronautical and aerospace engineering is paramount for making an informed decision.

Tip 1: Assess Core Interests. If your passion lies primarily with aircraft and flight within Earth’s atmosphere, aeronautical engineering is likely a better fit. Conversely, if you are drawn to space exploration, satellites, and systems operating beyond the atmosphere, aerospace engineering should be strongly considered.

Tip 2: Examine Curriculum Differences. Aeronautical engineering curricula typically focus on aerodynamics, propulsion systems, and aircraft structures. Aerospace engineering extends these topics to include spacecraft design, orbital mechanics, and space environment considerations. Review course catalogs to identify areas of alignment with your interests.

Tip 3: Research Career Paths. Aeronautical engineers often find employment in aircraft manufacturing, airline operations, and government regulatory agencies. Aerospace engineers may work in satellite design and development, rocket propulsion, and space exploration programs. Investigate potential employers and job roles within each field.

Tip 4: Consider Specialization Options. Both disciplines offer opportunities for specialization. Within aeronautical engineering, one might specialize in areas such as flight control systems or aircraft design. Within aerospace engineering, specializations could include astrodynamics or spacecraft propulsion. Consider how these specializations align with your long-term career goals.

Tip 5: Evaluate Skill Sets. Aeronautical engineers generally require strong skills in aerodynamics, structural analysis, and materials science. Aerospace engineers necessitate a broader skillset that includes these areas, as well as knowledge of orbital mechanics, control systems, and space environment effects. Evaluate your existing skills and identify areas for development.

Tip 6: Seek Industry Insights. Attend industry conferences, read relevant publications, and network with professionals in both aeronautical and aerospace engineering. Gaining firsthand perspectives can provide valuable insights into the realities of each career path and help refine your decision-making process.

Tip 7: Explore Dual Degree Programs. For individuals with broad interests, a dual degree program encompassing elements of both aeronautical and aerospace engineering may be a viable option. This approach provides a more comprehensive education and potentially expands future career opportunities.

By carefully evaluating your interests, examining curricula, researching career paths, considering specialization options, and evaluating necessary skill sets, you can make an informed decision regarding which engineering discipline best aligns with your aspirations. This proactive approach will ultimately contribute to a more fulfilling and successful career.

Understanding these key considerations will facilitate a smoother transition from academic pursuits to professional practice in the chosen field. The subsequent sections will address specific aspects of career progression and required competencies for each discipline.

1. Atmospheric limitations

Atmospheric limitations represent a fundamental point of divergence between aeronautical and aerospace engineering. The presence and characteristics of Earth’s atmosphere dictate the operational parameters and design considerations within each field, shaping the specific skill sets and knowledge bases required.

- Aerodynamic Constraints

Aeronautical engineering is fundamentally constrained by atmospheric density, pressure, and temperature variations. Aircraft design must optimize lift, drag, and stability within these parameters. For instance, wing shape, airfoil design, and engine performance are all critically dependent on atmospheric conditions. In contrast, aerospace engineering deals with spacecraft operating in near-vacuum conditions where aerodynamic forces are negligible or absent.

- Material Properties

Atmospheric conditions influence the choice of materials used in aircraft construction. Aeronautical engineers must consider factors such as corrosion, fatigue, and temperature effects on materials exposed to atmospheric elements. Spacecraft, on the other hand, require materials resistant to extreme temperature variations, radiation exposure, and micrometeoroid impacts, aspects not typically emphasized in aeronautical engineering.

- Propulsion Systems

Aeronautical propulsion systems, such as jet engines and propellers, rely on atmospheric oxygen for combustion. Aerospace engineering necessitates the development of propulsion systems capable of operating in the absence of atmospheric oxygen, such as rocket engines carrying their own oxidizer. This distinction leads to vastly different design principles and operational characteristics.

- Control Systems

Aircraft control systems depend on aerodynamic surfaces and atmospheric pressure to maneuver. Spacecraft control systems rely on reaction control systems, momentum wheels, or gravity gradients to maintain attitude and trajectory in the vacuum of space. The difference in operational environment necessitates distinct control methodologies and engineering expertise.

The atmospheric limitations imposed on aeronautical engineering necessitate a focused understanding of aerodynamic principles, atmospheric phenomena, and their impact on aircraft performance. Conversely, the absence of such limitations in many aerospace applications demands expertise in areas such as vacuum mechanics, orbital mechanics, and space environment effects. These fundamental differences underscore the need for specialized training and knowledge within each respective field.

2. Extraterrestrial applications

Extraterrestrial applications constitute a pivotal element differentiating aeronautical and aerospace engineering. The pursuit of space exploration and the utilization of space-based technologies necessitate engineering principles and skill sets distinct from those primarily focused on atmospheric flight. These distinct requirements significantly shape the training, research, and career paths within each discipline.

- Satellite Design and Development

Aerospace engineers are instrumental in designing and developing satellites for various purposes, including communication, Earth observation, and scientific research. This involves considerations such as orbital mechanics, power generation, thermal management, and radiation shielding aspects largely irrelevant to aeronautical engineering. The design of a communication satellite, for example, requires expertise in signal transmission through the vacuum of space, a skill set not typically within the purview of aeronautical engineers.

- Spacecraft Propulsion Systems

The development of propulsion systems for spacecraft operating beyond Earth’s atmosphere falls exclusively within the domain of aerospace engineering. This includes designing rocket engines, ion thrusters, and other propulsion technologies capable of functioning in the absence of atmospheric oxygen. The challenges of launching payloads into orbit and maneuvering in deep space require a deep understanding of physics and engineering principles absent from typical aeronautical engineering applications.

- Robotic Exploration and Planetary Landers

Aerospace engineers are at the forefront of designing and developing robotic probes, rovers, and landers for exploring other planets and celestial bodies. This necessitates expertise in areas such as autonomous navigation, remote sensing, and material science for extreme environments. Building a Mars rover, for instance, requires engineering solutions capable of withstanding the planet’s thin atmosphere, extreme temperatures, and radiation levels, factors of limited concern in aeronautical engineering.

- Space Habitats and Life Support Systems

The development of space habitats and life support systems for long-duration space missions represents a significant focus within aerospace engineering. This involves designing closed-loop systems for air and water recycling, waste management, and food production areas of engineering distinct from the design and operation of aircraft, which rely on Earth’s atmosphere and resources. Creating a sustainable habitat on the Moon or Mars necessitates expertise in ecological engineering and resource utilization far beyond the scope of aeronautical engineering.

The multifaceted nature of extraterrestrial applications, from satellite technology to interplanetary exploration, distinguishes aerospace engineering as a distinct field from aeronautical engineering. These applications demand specialized knowledge and skill sets related to space environments, orbital mechanics, and spacecraft design, highlighting the fundamental differences between the two disciplines. The pursuit of these technologies continues to drive advancements and innovation within aerospace engineering, solidifying its role in shaping the future of space exploration and utilization.

3. Aircraft focus

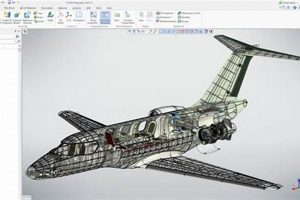

Aircraft focus constitutes a defining characteristic in differentiating aeronautical engineering from its broader counterpart, aerospace engineering. This emphasis on vehicles designed for atmospheric flight necessitates a specialized understanding of aerodynamics, propulsion systems optimized for air-breathing engines, and structural considerations specific to flight within the Earth’s atmosphere. As a result, aeronautical engineers often specialize in areas such as wing design, flight control systems, and airframe construction. The practical significance lies in the development of safer, more efficient, and more reliable aircraft for commercial, military, and general aviation purposes. For example, an aeronautical engineer might work on improving the fuel efficiency of a new aircraft wing design, a task fundamentally rooted in the principles of atmospheric flight.

The aircraft focus also influences the curriculum and research priorities within aeronautical engineering programs. Students are typically exposed to advanced topics in aerodynamics, flight mechanics, and aircraft stability and control. Research efforts often concentrate on innovations in aircraft design, materials, and propulsion technologies aimed at enhancing aircraft performance and reducing environmental impact. Consider the development of advanced composite materials for aircraft structures; aeronautical engineers are actively involved in researching and implementing these materials to reduce weight and improve fuel efficiency. The development of more efficient turbofan engines is another example, focusing on improvements specific to atmospheric flight.

In summary, the “aircraft focus” underscores a fundamental divergence between aeronautical and aerospace engineering. This concentration on vehicles designed for atmospheric flight necessitates a specialized skillset and knowledge base within aeronautical engineering. Understanding this distinction is crucial for students seeking to pursue careers in aircraft design and development, as well as for employers seeking engineers with specific expertise in atmospheric flight. The continued advancement of aviation relies heavily on the specialized knowledge and innovation fostered within the field of aeronautical engineering.

4. Spacecraft emphasis

The “spacecraft emphasis” serves as a critical differentiator between aeronautical and aerospace engineering. It denotes a specialized focus within aerospace engineering on the design, development, and operation of vehicles and systems intended for use in outer space, thus defining a unique set of engineering challenges and expertise.

- Orbital Mechanics and Astrodynamics

The design and operation of spacecraft necessitate a deep understanding of orbital mechanics and astrodynamics. This includes calculating trajectories, predicting orbital behavior, and designing maneuvers to achieve specific mission objectives. Aeronautical engineering, concerned with atmospheric flight, does not typically require this level of expertise in orbital dynamics. Designing a mission to rendezvous with a satellite, for instance, demands a thorough understanding of orbital mechanics to ensure successful docking, knowledge that is not typically part of the aeronautical engineer’s toolkit.

- Space Environment Engineering

Spacecraft must be designed to withstand the harsh environment of outer space, including extreme temperatures, vacuum conditions, and radiation exposure. Space environment engineering focuses on mitigating the effects of these factors on spacecraft components and systems. Aeronautical engineering, by contrast, deals with the relatively benign environment of Earth’s atmosphere. Developing radiation-hardened electronics for a spacecraft requires specialized knowledge absent from the aeronautical field.

- Spacecraft Propulsion Systems

The propulsion systems used for spacecraft differ significantly from those used for aircraft. Spacecraft propulsion often relies on rocket engines or other non-air-breathing systems, requiring specialized knowledge of propellant chemistry, nozzle design, and thrust vector control. Aeronautical engineering primarily deals with air-breathing engines such as turbofans and turbojets. The design of a high-efficiency rocket engine for a deep-space mission presents challenges distinct from those encountered in designing an aircraft engine.

- Spacecraft Communication and Control

Communicating with and controlling spacecraft over vast distances requires specialized communication systems and control algorithms. This includes designing antennas, signal processing systems, and fault-tolerant control systems capable of operating autonomously for extended periods. While aeronautical engineers also deal with communication and control systems, the challenges of communicating with and controlling spacecraft over interplanetary distances necessitate a distinct set of skills. Maintaining communication with a spacecraft millions of miles from Earth requires advanced signal processing techniques not typically employed in aircraft communication systems.

In conclusion, the “spacecraft emphasis” highlights a significant divergence between aeronautical and aerospace engineering. The specialized challenges associated with designing, building, and operating spacecraft necessitate a distinct skill set and body of knowledge within aerospace engineering, setting it apart from its more atmospherically focused counterpart. The continued advancement of space exploration and utilization depends on the expertise of engineers specializing in spacecraft design and related technologies.

5. Specialized curricula

Specialized curricula represent a crucial factor differentiating aeronautical and aerospace engineering programs. The distinct challenges and knowledge domains inherent to each field necessitate tailored coursework, shaping the expertise and career paths of graduates.

- Aerodynamics and Fluid Mechanics

Aeronautical engineering curricula typically emphasize aerodynamics within the Earth’s atmosphere, covering topics such as boundary layer theory, airfoil design, and compressible flow. Aerospace engineering extends this knowledge to include rarefied gas dynamics and hypersonic flow, relevant to spacecraft re-entry. This difference reflects the distinct operating environments and design considerations for aircraft and spacecraft. The detailed study of wingtip vortices for increased aircraft efficiency, a common topic in aeronautical curricula, finds less emphasis in aerospace curricula where orbital mechanics become a priority.

- Propulsion Systems

Aeronautical programs concentrate on air-breathing engines such as turbojets, turbofans, and propellers. Aerospace curricula broaden the scope to encompass rocket propulsion, ion propulsion, and other systems suitable for operation in the vacuum of space. The study of combustion processes in a jet engine, integral to aeronautical engineering, differs substantially from the study of chemical rocket engine design, which is central to aerospace engineering.

- Structural Analysis and Materials Science

While both disciplines require a strong foundation in structural analysis and materials science, aeronautical engineering curricula often focus on the specific materials and structural designs used in aircraft construction. Aerospace programs extend this to include the unique challenges of spacecraft structures, such as resistance to extreme temperatures and radiation. The design of an aircraft fuselage using aluminum alloys receives extensive coverage in aeronautical curricula, whereas aerospace programs devote attention to composite materials and heat shields for re-entry vehicles.

- Control Systems and Avionics

Aeronautical engineering curricula delve into flight control systems, stability augmentation, and navigation systems specific to aircraft. Aerospace programs expand upon this to include spacecraft attitude control, orbital maneuvering, and autonomous navigation in space. The design of an autopilot system for an aircraft is a core element of aeronautical studies, while aerospace curricula address the complexities of controlling a satellite’s orientation in orbit.

In conclusion, the specialized curricula associated with aeronautical and aerospace engineering reflect the distinct knowledge and skill sets required for each field. These curricular differences prepare graduates for careers in aircraft design and operation versus spacecraft development and space exploration, solidifying the fundamental distinction between these closely related engineering disciplines.

6. Career specialization

Career specialization directly correlates with the distinctions between aeronautical and aerospace engineering, influencing the professional paths available to graduates of each discipline. The specific knowledge and skills acquired during academic training predetermine the types of roles engineers are qualified to pursue. Understanding these specializations is essential for students choosing a career path and for employers seeking qualified personnel.

- Aircraft Design and Manufacturing

Aeronautical engineers frequently specialize in aircraft design and manufacturing, focusing on the structural integrity, aerodynamic efficiency, and propulsion systems of aircraft operating within Earth’s atmosphere. This specialization includes roles in designing wings, fuselages, and control surfaces, as well as optimizing engine performance for fuel efficiency. Real-world examples include designing the wing structure for a new commercial airliner or improving the aerodynamic performance of a military aircraft. Such specializations rarely extend into the realm of spacecraft design due to the distinct engineering principles involved.

- Spacecraft Systems Engineering

Aerospace engineers often specialize in spacecraft systems engineering, which encompasses the design, integration, and testing of satellites, probes, and other vehicles operating in space. This specialization requires expertise in orbital mechanics, spacecraft propulsion, thermal control, and communication systems. Examples include designing the communication system for a satellite or developing the thermal management system for a lunar lander. Aeronautical engineers typically lack the specialized knowledge in orbital mechanics and space environment engineering necessary for these roles.

- Flight Control Systems

Both aeronautical and aerospace engineers may specialize in flight control systems, but the context differs significantly. Aeronautical engineers focus on flight control systems for aircraft, including autopilots, stability augmentation systems, and fly-by-wire technology. Aerospace engineers extend this to include attitude control systems for spacecraft, which rely on reaction wheels, thrusters, and other non-aerodynamic control methods. An aeronautical engineer might design a new autopilot system for a commercial aircraft, while an aerospace engineer might develop a control system for a satellite that maintains its orientation in orbit. The specialization differences reflect the distinct operational environments and control methodologies.

- Propulsion System Development

Propulsion system development offers another area of specialization, with aeronautical engineers focusing on air-breathing engines such as turbojets and turbofans, while aerospace engineers concentrate on rocket engines and other non-air-breathing propulsion systems. This specialization includes designing engine components, optimizing fuel efficiency, and testing performance. An aeronautical engineer might work on improving the efficiency of a jet engine for a commercial airliner, while an aerospace engineer might design a new rocket engine for a space launch vehicle. The difference in specialization stems from the fundamental requirement for spacecraft to operate in the vacuum of space, necessitating propulsion systems that do not rely on atmospheric oxygen.

In summary, career specialization is a direct consequence of the differences between aeronautical and aerospace engineering. The specialized knowledge and skills acquired during academic training dictate the types of professional roles engineers are qualified to pursue, leading to distinct career paths in aircraft design, spacecraft systems, flight control, and propulsion system development. These specializations reflect the fundamental differences in operating environments, engineering principles, and design considerations inherent to each discipline.

Frequently Asked Questions

The following section addresses common inquiries regarding the “difference between aeronautical engineering and aerospace engineering” aiming to provide clarity on this frequently debated topic.

Question 1: Is aerospace engineering simply a more advanced version of aeronautical engineering?

No, while aerospace engineering builds upon the foundational principles of aeronautical engineering, it is not merely a more advanced version. Aerospace engineering encompasses the design, development, and operation of vehicles and systems that operate both within and outside Earth’s atmosphere, whereas aeronautical engineering focuses specifically on vehicles operating within the atmosphere. The distinction lies in the breadth of scope, not necessarily the level of advancement.

Question 2: Can an aeronautical engineer work on spacecraft?

While possible, it is generally uncommon. An aeronautical engineer’s expertise primarily lies in atmospheric flight. Working on spacecraft would typically require additional training or experience in areas such as orbital mechanics, spacecraft propulsion, and space environment engineering, disciplines typically emphasized within aerospace engineering curricula.

Question 3: Does aerospace engineering offer better career prospects than aeronautical engineering?

The “better” career prospect is subjective and depends on individual interests and skills. Both fields offer ample opportunities. Aerospace engineering might provide access to space-related industries, while aeronautical engineering offers possibilities in the aviation sector. Job availability fluctuates based on industry trends and technological advancements.

Question 4: Is the starting salary significantly different between aeronautical and aerospace engineers?

Starting salaries can vary based on factors such as location, employer, and specific job role. However, there is generally no substantial difference in starting salaries between the two fields. Experience, specialization, and market demand often play a more significant role in salary determination than the specific degree designation.

Question 5: Which engineering discipline is “easier” to study: aeronautical or aerospace?

The perceived difficulty is subjective and depends on individual aptitude and interests. Both disciplines require a strong foundation in mathematics, physics, and engineering principles. Aerospace engineering may demand a broader range of knowledge due to its expanded scope, but neither discipline can be deemed inherently “easier.”

Question 6: Are there universities that only offer aeronautical engineering and not aerospace engineering?

Yes, some universities offer specialized programs in aeronautical engineering without offering a separate aerospace engineering program. This is often due to a specific focus on aviation and atmospheric flight within the institution’s research and educational priorities. However, the trend leans towards offering aerospace engineering programs due to their broader applicability.

Understanding the nuances between these fields is critical for informed decision-making. The choice between aeronautical and aerospace engineering should align with individual passions and career goals.

The subsequent section will examine emerging trends impacting both aeronautical and aerospace engineering disciplines.

Distinguishing Aeronautical and Aerospace Engineering

The preceding analysis has elucidated the core tenets differentiating aeronautical and aerospace engineering. The former concentrates on atmospheric flight, while the latter broadens its scope to encompass space-based systems. These distinctions manifest in specialized curricula, influencing career trajectories and skill-set requirements. Atmospheric limitations, extraterrestrial applications, and the explicit emphasis on either aircraft or spacecraft underscore the fundamental divergence between these disciplines.

Navigating the choice between these engineering paths necessitates careful consideration of individual aptitudes and professional aspirations. The ongoing evolution of both fields promises continued advancements in air and space travel, underscoring the enduring significance of discerning the precise contours of aeronautical and aerospace engineering. Further research and diligent self-assessment remain crucial for aspiring engineers seeking to contribute to these dynamic domains.