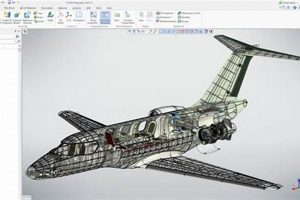

Additive manufacturing, also known as rapid prototyping, is a process of building three-dimensional objects from a digital design. This technology is increasingly applied to the creation of components and systems utilized within the realm of flight vehicle design, manufacturing, and maintenance. For example, complex geometries, previously unattainable through conventional machining methods, can be realized for aircraft engine components or structural elements.

The adoption of this technology offers numerous advantages to the sector. These include reduced material waste, lighter weight components leading to improved fuel efficiency, and accelerated production cycles. Historically, the aerospace industry has relied on subtractive manufacturing, which involves removing material to create a desired shape. The shift towards additive processes allows for the on-demand creation of customized parts and facilitates the integration of multiple components into a single, printed unit.

The following sections will delve into specific applications, material considerations, design principles tailored to additive manufacturing, and the future trajectory of this transformative technology within the aeronautical and astronautical fields.

Best Practices for Implementation

The successful integration of additive manufacturing in aerospace applications necessitates careful consideration of several critical factors. Adherence to these practices ensures the production of reliable and high-performance components.

Tip 1: Material Selection: The choice of appropriate materials is paramount. Aerospace-grade alloys, polymers, and composites must meet stringent requirements for strength, temperature resistance, and weight. Consider factors like powder morphology and chemical composition for optimal printing results.

Tip 2: Design for Additive Manufacturing (DfAM): Leverage DfAM principles to optimize part geometry for the printing process. This includes minimizing support structures, incorporating lattice designs for weight reduction, and orienting parts to enhance mechanical properties.

Tip 3: Process Parameter Optimization: Carefully calibrate printing parameters such as laser power, scan speed, layer thickness, and build plate temperature. These parameters directly influence the density, microstructure, and mechanical characteristics of the finished product.

Tip 4: Non-Destructive Testing (NDT): Implement rigorous NDT methods, including ultrasonic testing, X-ray computed tomography, and dye penetrant inspection, to detect internal flaws and ensure structural integrity. NDT is essential for qualifying printed parts for flight-critical applications.

Tip 5: Post-Processing Techniques: Employ appropriate post-processing techniques, such as heat treatment, hot isostatic pressing (HIP), and surface finishing, to improve mechanical properties, relieve residual stresses, and enhance surface finish. These processes are crucial for meeting aerospace standards.

Tip 6: Qualification and Certification: Adhere to established aerospace standards and certification processes. Thoroughly document the entire manufacturing process, including material traceability, process parameters, and inspection results, to demonstrate compliance and ensure airworthiness.

Tip 7: Data Security and Intellectual Property Protection: Secure digital design files and manufacturing data to prevent unauthorized access and protect intellectual property. Implement robust cybersecurity measures to safeguard against data breaches and ensure the integrity of the manufacturing process.

By incorporating these best practices, organizations can maximize the benefits of additive manufacturing, achieving significant improvements in performance, cost-effectiveness, and innovation.

The subsequent section will discuss future trends and emerging technologies.

1. Weight Reduction

Weight reduction is a paramount concern in aerospace engineering, directly impacting fuel efficiency, payload capacity, and overall performance. The application of additive manufacturing techniques significantly contributes to achieving these critical weight savings.

- Topology Optimization

Additive manufacturing facilitates the realization of topology-optimized designs. This computational method identifies the most efficient material distribution within a component, removing unnecessary mass while maintaining structural integrity. Examples include aircraft brackets and engine components redesigned with intricate, lightweight lattice structures. This directly translates to reduced fuel consumption and increased flight range.

- Lattice Structures

The creation of complex lattice structures is a defining characteristic of additive manufacturing’s contribution to weight reduction. These internal, repeating geometries offer exceptional strength-to-weight ratios compared to solid materials. Applications range from aircraft interior panels to wing spars, significantly reducing structural weight without compromising load-bearing capabilities.

- Material Selection and Waste Reduction

Additive manufacturing allows for the precise deposition of material, minimizing waste associated with traditional subtractive manufacturing processes. Furthermore, the ability to print with high-strength, lightweight materials such as titanium alloys and advanced polymers contributes to overall weight savings. Reduced material waste translates to cost savings and environmental benefits.

- Component Integration

Additive manufacturing enables the consolidation of multiple components into a single, integrated part. This reduces the need for fasteners and assembly processes, further minimizing weight. Examples include fuel nozzles and engine manifolds printed as single units, eliminating joints and improving structural efficiency.

The cumulative effect of these weight-saving strategies, made possible by additive manufacturing, is substantial. By optimizing designs, utilizing advanced materials, and streamlining production processes, the aerospace industry is able to achieve significant improvements in aircraft performance and operational efficiency.

2. Complex Geometries

The intersection of additive manufacturing and aerospace engineering finds a significant point of synergy in the creation of complex geometries. Traditional manufacturing methods, such as machining or casting, often present limitations in producing parts with intricate internal structures, curved surfaces, or intricate details. Additive manufacturing, conversely, allows for the construction of these geometries layer by layer, unlocking new possibilities for component design and performance. The ability to realize complex geometries directly impacts aerospace component design, as it enables the creation of parts with improved aerodynamic properties, enhanced heat transfer capabilities, and optimized structural integrity. For instance, turbine blades with internal cooling channels, impossible to manufacture conventionally, can be readily produced via additive processes, leading to increased engine efficiency and performance.

A direct consequence of achieving complex geometries is the opportunity for significant weight reduction in aircraft components. By utilizing topology optimization algorithms and additive manufacturing, engineers can design parts with minimal material usage while maintaining structural strength. This results in lighter components, leading to improved fuel efficiency and increased payload capacity. Moreover, complex geometries allow for the integration of multiple functions into a single component. Instead of assembling multiple parts, a single additively manufactured component can incorporate features such as fluid channels, sensors, and mounting points, streamlining assembly and reducing overall system complexity. An example of this would be a 3D-printed rocket engine injector that incorporates fuel and oxidizer passages in a single unit, improving performance and simplifying the overall engine design.

In summary, the ability to create complex geometries is a crucial advantage offered by additive manufacturing to the aerospace industry. It enables the design and production of high-performance components with optimized weight, integrated functionality, and enhanced capabilities. While challenges remain in terms of material selection, process control, and certification, the potential benefits of leveraging complex geometries through additive manufacturing are driving continued research and development in this field, pushing the boundaries of what is possible in aerospace engineering.

3. Material Efficiency

Material efficiency, defined as minimizing waste and maximizing the utilization of raw materials, is a critical driver in the aerospace sector. Its alignment with additive manufacturing processes offers significant advantages, particularly in the context of high-value materials and complex component geometries.

- Near-Net Shape Manufacturing

Additive manufacturing builds parts layer by layer, adding material only where needed. This contrasts sharply with traditional subtractive methods, which often involve removing significant portions of material from a larger block. The near-net shape capability minimizes material waste, especially crucial when working with expensive aerospace alloys like titanium or nickel-based superalloys. A component produced via machining might generate 60-70% material waste, while additive manufacturing can reduce this to below 10%.

- Powder Recycling and Reuse

Many additive manufacturing processes utilize powder-based materials. Unused powder can often be collected, reprocessed, and reused in subsequent builds. This reduces overall material consumption and minimizes the environmental impact associated with the production of new materials. Proper powder management and qualification protocols are essential to maintain material properties and ensure consistent part quality throughout multiple recycling cycles.

- Design Optimization for Material Reduction

Additive manufacturing enables the creation of complex internal geometries, such as lattice structures and hollow sections, that would be difficult or impossible to produce with conventional methods. These designs allow for significant weight reduction without compromising structural integrity, leading to further material savings. Topology optimization algorithms can be used to identify the most efficient material distribution for a given component, minimizing material usage while meeting performance requirements.

- On-Demand Manufacturing and Reduced Inventory

Additive manufacturing facilitates on-demand production, allowing parts to be manufactured only when needed. This eliminates the need to maintain large inventories of spare parts, reducing the risk of obsolescence and minimizing material storage costs. The ability to produce customized parts rapidly also reduces the need for multiple design iterations and minimizes material waste associated with design changes.

These facets demonstrate the interconnectedness of material efficiency and additive manufacturing within aerospace. By minimizing waste, optimizing designs, and enabling on-demand production, additive manufacturing contributes significantly to reducing material consumption and enhancing the sustainability of aerospace operations. These advancements drive cost savings, improve environmental performance, and unlock new possibilities for component design and functionality.

4. Rapid Prototyping

Rapid prototyping, facilitated by additive manufacturing, plays a crucial role in aerospace engineering by accelerating the design and development process. This technology enables engineers to quickly create physical models and functional prototypes, allowing for early-stage evaluation, design refinement, and validation of concepts before committing to full-scale production.

- Design Validation and Iteration

Rapid prototyping allows for the tangible assessment of design features, ergonomics, and fit within complex aerospace systems. Engineers can identify potential issues early in the design cycle, reducing costly rework and delays. For example, a prototype cockpit component can be 3D printed to evaluate the placement of controls and displays, ensuring optimal human-machine interface. This iterative process facilitates design refinement based on tangible feedback, significantly improving the final product.

- Functional Testing and Performance Evaluation

Additive manufacturing enables the creation of functional prototypes with representative materials and performance characteristics. These prototypes can be subjected to rigorous testing to evaluate their performance under simulated operational conditions. An example includes 3D-printed turbine blades tested in wind tunnels to assess their aerodynamic performance and structural integrity. This allows for early detection of potential weaknesses and optimization of designs before committing to full-scale manufacturing.

- Cost Reduction and Time Savings

Rapid prototyping significantly reduces the time and cost associated with traditional prototype development methods. Additive manufacturing eliminates the need for specialized tooling and machining processes, enabling the creation of prototypes in a matter of hours or days, compared to weeks or months with conventional techniques. This accelerates the design cycle, reduces development costs, and allows for more design iterations within a given timeframe. For instance, creating a prototype duct using traditional methods may require a significant investment of time and resources, whereas using 3D printing, the costs are dramatically less.

- Communication and Collaboration

Physical prototypes created through additive manufacturing facilitate communication and collaboration among engineers, designers, and stakeholders. A tangible model provides a clear and concise representation of the design intent, allowing for effective feedback and informed decision-making. For example, a 3D-printed model of a satellite component can be used to illustrate the design to non-technical stakeholders, fostering a better understanding of the project and facilitating consensus. This improved communication streamlines the design process and reduces the risk of misunderstandings.

These aspects underscore the synergistic relationship between rapid prototyping and additive manufacturing in aerospace. By enabling rapid design validation, functional testing, cost reduction, and improved communication, additive manufacturing empowers aerospace engineers to innovate more effectively and develop advanced technologies with increased speed and efficiency. The integration of rapid prototyping into the aerospace design process ultimately results in better products, reduced development costs, and faster time-to-market.

5. Customization Options

Additive manufacturing provides unprecedented customization options within aerospace engineering, addressing needs ranging from specialized components for unique mission profiles to personalized in-cabin solutions for passenger comfort. Unlike traditional manufacturing techniques that often require large production runs to justify tooling costs, additive manufacturing economically produces single, highly customized parts. This capability is especially valuable in the aerospace sector where demand for niche components and rapid adaptation to evolving technological advancements is common.

A notable example is the production of customized satellite components. Each satellite mission may have specific requirements for antenna placement, sensor integration, and thermal management. Additive manufacturing enables the creation of bespoke parts tailored to these precise needs, optimizing performance and reducing overall system weight. Further, the ability to rapidly iterate on designs and incorporate feedback from testing allows for continuous improvement and adaptation to changing mission objectives. Another area where customization is increasingly prominent is in aircraft interiors. 3D-printed cabin components, such as seat parts, lighting fixtures, and ventilation systems, can be tailored to meet specific airline branding requirements or passenger comfort preferences, enhancing the overall travel experience.

The ability to produce highly customized components on-demand offers a significant advantage in terms of supply chain management. Rather than maintaining large inventories of spare parts, airlines and aerospace manufacturers can produce parts as needed, reducing storage costs and minimizing the risk of obsolescence. However, the widespread adoption of customized solutions requires robust quality control measures and certification processes to ensure that each part meets the stringent safety and performance standards of the aerospace industry. Despite these challenges, the increasing demand for customized aerospace solutions will continue to drive innovation in additive manufacturing technologies and expand its applications in this critical sector.

6. On-Demand Production

Additive manufacturing facilitates on-demand production of aerospace components, transforming traditional supply chain models. This capability addresses challenges inherent in maintaining fleets of aging aircraft and managing the complexities of spare parts logistics. Instead of relying on extensive inventories and long lead times associated with conventional manufacturing, parts can be produced as needed, minimizing downtime and reducing storage costs. An illustrative example is the rapid production of replacement parts for grounded aircraft, allowing them to return to service more quickly than would be possible with traditional methods. This approach directly contributes to operational efficiency and cost savings for airlines and maintenance providers. The ability to manufacture parts on-demand also supports customization and design iterations, enabling engineers to quickly adapt components to specific mission requirements or address emergent issues.

The adoption of on-demand production through additive manufacturing necessitates a shift in qualification and certification processes. Stringent quality control measures and material traceability protocols are essential to ensure the reliability and performance of additively manufactured parts. Organizations such as the FAA and EASA are actively developing guidelines and standards to address the unique challenges associated with certifying additively manufactured aerospace components. Partnerships between industry, academia, and regulatory agencies are critical to establishing confidence in the safety and integrity of on-demand produced parts. Furthermore, the establishment of digital inventories and secure data transmission protocols is crucial to protect intellectual property and ensure the integrity of design files.

In conclusion, on-demand production enabled by additive manufacturing represents a paradigm shift in aerospace component manufacturing. It offers significant advantages in terms of reduced lead times, minimized inventories, and enhanced customization capabilities. While challenges remain in terms of qualification, certification, and data security, the potential benefits of on-demand production are driving continued investment and innovation in additive manufacturing technologies for aerospace applications. The integration of this approach will ultimately lead to more efficient, resilient, and adaptable aerospace supply chains, further enhancing the competitiveness and sustainability of the industry.

7. Integrated Functionality

Integrated functionality, the incorporation of multiple functions into a single component, represents a key advantage of additive manufacturing in aerospace engineering. This approach departs from traditional assembly methods, where numerous individual parts are joined to form a larger system, and instead leverages additive processes to create complex, multi-functional components as single, unified entities.

- Embedded Sensors and Monitoring Systems

Additive manufacturing enables the embedding of sensors directly within aerospace components during the fabrication process. For example, strain gauges, temperature sensors, or vibration monitors can be integrated into structural elements or engine parts, providing real-time performance data and facilitating predictive maintenance. This integration eliminates the need for separate sensor mounting and wiring, reducing weight and improving system reliability. Such systems can detect early signs of material fatigue or component degradation, enabling proactive maintenance interventions and preventing catastrophic failures.

- Conformal Cooling Channels

Complex geometries achievable through additive manufacturing allow for the creation of conformal cooling channels within components exposed to high temperatures, such as turbine blades or rocket engine nozzles. These channels precisely follow the contours of the part, optimizing heat transfer and preventing localized overheating. This improves component lifespan, enhances engine efficiency, and enables higher operating temperatures. Traditional manufacturing methods struggle to produce such intricate cooling geometries, highlighting the unique capabilities of additive manufacturing in this domain.

- Integrated Fluid and Gas Passages

Additive manufacturing facilitates the integration of fluid and gas passages directly within aerospace components, eliminating the need for external tubing and fittings. This reduces weight, improves system reliability, and simplifies assembly processes. Examples include fuel injectors with integrated fuel and oxidizer passages, hydraulic manifolds with internal fluid channels, and heat exchangers with complex flow paths. The ability to consolidate multiple functions into a single component through integrated fluid passages leads to more compact and efficient aerospace systems.

- Multi-Material Components

Advanced additive manufacturing techniques enable the creation of components from multiple materials with tailored properties. For instance, a structural component could be fabricated with a high-strength alloy in critical load-bearing areas and a lightweight material in non-critical regions. This allows for optimized performance and weight reduction. Another example involves integrating electrically conductive materials into insulating structures to create embedded wiring or antennas. This multi-material capability expands the design possibilities for aerospace components and enables the creation of highly specialized and optimized parts.

The trend toward integrated functionality, driven by additive manufacturing, is reshaping aerospace design and manufacturing. By consolidating multiple functions into single components, additive manufacturing leads to lighter, more efficient, and more reliable aerospace systems. As additive manufacturing technologies continue to advance, the scope and complexity of integrated functionalities will undoubtedly expand, further revolutionizing the aerospace industry.

Frequently Asked Questions About Additive Manufacturing in Aerospace Engineering

The following addresses common queries related to the implementation of additive manufacturing within the aerospace sector. The aim is to provide clear and concise answers based on current industry practices and research.

Question 1: What are the primary limitations hindering wider adoption of additive manufacturing in aerospace?

Key limitations include material selection constraints, the need for robust quality control processes, certification requirements for flight-critical components, and the relatively slow production speeds compared to traditional manufacturing methods. Furthermore, the initial investment cost for additive manufacturing equipment can be substantial.

Question 2: How does additive manufacturing contribute to reducing aircraft weight?

Additive manufacturing enables the creation of complex geometries, such as lattice structures and topology-optimized designs, which minimize material usage while maintaining structural integrity. This leads to lighter components compared to those produced through traditional subtractive manufacturing processes. The use of lightweight materials, such as titanium alloys and advanced polymers, further contributes to weight reduction.

Question 3: What types of materials are commonly used in additive manufacturing for aerospace applications?

Common materials include titanium alloys (Ti-6Al-4V), nickel-based superalloys (Inconel), aluminum alloys, stainless steel, and various polymers (PEEK, ULTEM). Material selection depends on the specific application, considering factors such as strength, temperature resistance, and weight requirements.

Question 4: What non-destructive testing (NDT) methods are employed to ensure the quality of additively manufactured aerospace parts?

Common NDT methods include ultrasonic testing, X-ray computed tomography (CT), dye penetrant inspection, and eddy current testing. These techniques are used to detect internal flaws, porosity, and other defects that could compromise the structural integrity of the component.

Question 5: How does additive manufacturing facilitate customization in aerospace component design?

Additive manufacturing allows for the creation of highly customized parts without the need for specialized tooling or molds. This enables engineers to tailor components to specific performance requirements, optimize designs for weight reduction, and integrate multiple functions into a single part. Customization options are particularly valuable for low-volume production or specialized applications.

Question 6: What are the key considerations for designing aerospace components specifically for additive manufacturing?

Key considerations include design for additive manufacturing (DfAM) principles, such as minimizing support structures, orienting parts to enhance mechanical properties, and incorporating lattice designs for weight reduction. It’s also crucial to account for process limitations, such as build volume constraints and surface finish characteristics. Thermal management during the printing process is essential to minimize residual stresses and prevent warping.

In summary, additive manufacturing offers significant potential for revolutionizing aerospace component design and production. Overcoming current limitations and addressing key design considerations are essential for realizing the full benefits of this technology.

The subsequent section will delve into case studies and real-world examples.

Conclusion

The exploration of 3D printing in aerospace engineering reveals a transformative influence on design, manufacturing, and supply chain dynamics. The technology’s capability to produce complex geometries, optimize material usage, and enable on-demand production has demonstrated significant potential for weight reduction, performance enhancement, and cost savings within the sector. Key advancements in material science, process control, and non-destructive testing are essential for ensuring the reliability and airworthiness of additively manufactured aerospace components. The implementation of rigorous design principles, coupled with adherence to established industry standards, is critical for successful integration of this technology.

The aerospace industry must prioritize continued investment in research and development to address existing limitations and unlock the full potential of additive manufacturing. This includes fostering collaboration between industry stakeholders, regulatory agencies, and academic institutions to establish standardized processes, refine material properties, and accelerate the certification of additively manufactured components. Through focused efforts and a commitment to innovation, 3D printing in aerospace engineering will continue to shape the future of flight, enabling the creation of more efficient, sustainable, and advanced aerospace systems.