These specialized facilities are pivotal in the rigorous evaluation of aircraft, spacecraft, and related components. They provide a controlled environment for subjecting aerospace systems to a wide array of simulated operational conditions. For instance, a full-scale aircraft might undergo structural testing to assess its ability to withstand extreme aerodynamic loads, or a rocket engine could be evaluated for performance under varying atmospheric pressures and temperatures. These procedures are essential for ensuring the safety and reliability of flight hardware.

The ability to comprehensively examine design specifications and identify potential flaws before deployment translates directly into enhanced flight safety, reduced operational risks, and optimized performance. The origins of such facilities can be traced back to the early days of aviation, with continuous advancements driven by the increasing complexity of aerospace vehicles and the demand for greater mission assurance. Investment in these capabilities signifies a commitment to technological advancement and leadership in the aerospace sector, leading to improved designs and materials.

Understanding the specific roles and functions within these entities is crucial. This includes delving into the types of tests conducted, the instrumentation employed, and the personnel involved in the validation process. Further examination will reveal the relationship between this crucial infrastructure and the overall success of aerospace endeavors.

Guidance for Effective Utilization

The following recommendations emphasize best practices when engaging with specialized validation resources. These principles promote thorough assessment and contribute to the advancement of aerospace technologies.

Tip 1: Define Clear Test Objectives. Precise articulation of objectives ensures that resources are applied efficiently and that generated data directly addresses critical performance parameters. For example, a clearly defined objective for a structural test might be to determine the maximum load an aircraft wing can withstand before failure.

Tip 2: Prioritize Early Engagement. Involving specialists early in the design process allows for proactive identification of potential issues and facilitates the development of tailored examination protocols. This prevents costly redesigns later in the development cycle.

Tip 3: Leverage Specialized Expertise. Facility personnel possess extensive knowledge of testing methodologies and instrumentation. Their expertise should be actively sought to optimize experimental design and data acquisition.

Tip 4: Implement Rigorous Data Management Protocols. Comprehensive documentation of all test parameters, procedures, and results is essential for ensuring data integrity and traceability. This includes calibration records for instrumentation and detailed logs of environmental conditions.

Tip 5: Embrace a Data-Driven Approach. Decisions regarding design modifications and performance enhancements should be based on a thorough analysis of generated data. Statistical methods and modeling techniques can be employed to extract meaningful insights.

Tip 6: Ensure Proper Instrumentation Calibration. Reliable data is contingent on calibrated instruments. Regular calibration ensures instruments are within defined tolerances and reduces measurement uncertainty.

Tip 7: Conduct Regular Facility Audits. Periodic audits ensure the facility meets quality standards. This ensures the testing environment is maintained, equipment is in proper working condition, and operations are adhering to safety standards.

Adherence to these guidelines optimizes the utilization of these essential facilities, leading to more robust aerospace designs and improved mission outcomes. Focusing on objective clarity, expert collaboration, and comprehensive data handling ensures the efficient allocation of resources and the generation of actionable insights.

The continued development and refinement of testing methodologies remains paramount to advancing the boundaries of aerospace innovation. Subsequent analysis will further explore the future trajectory of aerospace engineering.

1. Validation Infrastructure

Validation infrastructure is integral to the operation of any aerospace engineering test establishment. It provides the necessary resources and frameworks for rigorously evaluating the performance, safety, and reliability of aerospace systems and components. The comprehensiveness and sophistication of this infrastructure directly influence the integrity and accuracy of the test results, ultimately impacting the success of aerospace programs.

- Advanced Testing Equipment

This encompasses a wide array of specialized tools and machinery designed to simulate operational environments and apply controlled stress to aerospace hardware. Examples include wind tunnels for aerodynamic testing, thermal vacuum chambers for simulating space conditions, and hydraulic test rigs for assessing structural integrity under extreme loads. These instruments allow engineers to collect precise data on system behavior under various conditions, enabling them to identify potential weaknesses and refine designs.

- Data Acquisition and Analysis Systems

The infrastructure includes sophisticated systems for collecting, processing, and interpreting test data. High-speed data acquisition systems capture vast amounts of information from sensors embedded within the test article, while advanced analysis software allows engineers to visualize trends, identify anomalies, and validate models. This analytical capability is critical for understanding the complex interactions within aerospace systems and for making informed decisions about design and performance.

- Quality Assurance and Control Protocols

Rigorous quality assurance and control protocols are fundamental to ensuring the reliability and accuracy of the validation process. These protocols encompass calibration procedures for instrumentation, standardized testing methodologies, and comprehensive documentation practices. Adherence to these protocols ensures that test results are traceable, reproducible, and compliant with industry standards and regulatory requirements.

- Specialized Personnel and Expertise

The validation infrastructure relies heavily on the expertise of engineers, technicians, and scientists with specialized knowledge of testing methodologies, data analysis techniques, and aerospace systems. These personnel are responsible for designing test plans, operating equipment, interpreting data, and providing recommendations for design improvements. Their expertise is essential for ensuring that tests are conducted effectively and that the results are accurately interpreted.

In summary, validation infrastructure is a critical element of aerospace engineering test establishments. It encompasses a combination of advanced equipment, sophisticated data systems, rigorous quality control measures, and specialized expertise. The effective integration of these elements is essential for ensuring the reliability and safety of aerospace systems and for driving innovation in the aerospace industry. Without this robust infrastructure, the development and deployment of advanced aerospace technologies would be significantly hindered.

2. Simulation Environments

Simulation environments are an indispensable component of any aerospace engineering test establishment. They provide a cost-effective and safe means of replicating real-world operational conditions, allowing engineers to evaluate the performance of aerospace systems and components without the risks and expenses associated with actual flight testing. These simulated conditions, ranging from extreme temperatures and pressures to dynamic mechanical loads and electromagnetic interference, are crucial for identifying potential design flaws and validating system resilience.

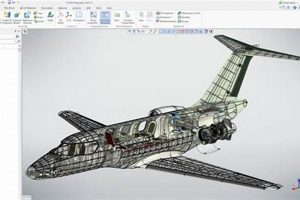

The incorporation of simulation environments enables a range of capabilities within these establishments. For example, computational fluid dynamics (CFD) simulations can model airflow around aircraft wings to optimize aerodynamic efficiency, while finite element analysis (FEA) can predict structural stress and strain under various loading scenarios. Hardware-in-the-loop (HIL) simulations allow engineers to test the interaction between software and hardware components in a realistic operating environment before integration into the final system. A practical illustration can be found in the development of new aircraft control systems; extensive simulations of various flight profiles and emergency scenarios are conducted before any physical flight tests are performed. This iterative process of simulation and refinement reduces the likelihood of unforeseen issues during actual flight, leading to safer and more reliable aerospace systems.

In summary, simulation environments play a vital role in the success of aerospace engineering endeavors. By providing a controlled and versatile platform for testing and analysis, these environments mitigate risks, reduce costs, and accelerate the development of advanced aerospace technologies. The continued advancement of simulation capabilities remains a key priority for aerospace engineering test establishments, ensuring that systems are thoroughly validated before deployment in real-world applications. The accuracy and comprehensiveness of these simulations directly translate to increased safety, improved performance, and reduced operational costs throughout the lifecycle of aerospace vehicles.

3. Performance Evaluation

Performance evaluation is a cornerstone activity within aerospace engineering test establishments. It constitutes a systematic process of measuring, analyzing, and interpreting the operational capabilities of aerospace systems and their constituent components. This evaluation process is fundamentally linked to the purpose of these establishments, which are designed to subject hardware and software to rigorous testing under controlled and representative conditions. The data derived from these assessments provide critical insights into the system’s ability to meet specified performance requirements and safety standards. For example, evaluating a new jet engine within a controlled test cell involves measuring thrust output, fuel consumption, and exhaust emissions under various simulated flight conditions. These measurements are then compared against design specifications to validate performance parameters and identify areas for improvement.

The importance of performance evaluation stems from its direct impact on flight safety, mission success, and operational efficiency. Rigorous evaluation procedures ensure that systems operate reliably within defined parameters and can withstand the stresses of real-world operation. Furthermore, performance evaluation facilitates the identification of potential failure modes and vulnerabilities, enabling engineers to implement proactive mitigation strategies. Consider the case of a satellite undergoing thermal vacuum testing. Performance data, such as the temperature stability of electronic components and the efficiency of thermal control systems, are collected to verify that the satellite can operate reliably in the extreme temperature fluctuations of space. If performance falls short of expectations, modifications can be made before launch, thus preventing costly and potentially catastrophic in-orbit failures.

In conclusion, performance evaluation is an essential component of aerospace engineering test establishments. It provides the means to quantify system capabilities, identify potential weaknesses, and validate designs against established performance criteria. Through rigorous testing and analysis, these establishments contribute significantly to enhancing the safety, reliability, and effectiveness of aerospace systems. The insights derived from performance evaluations are critical for informing design decisions, optimizing operational procedures, and ensuring mission success across a wide range of aerospace applications. Continuous refinement of evaluation methodologies and the integration of advanced sensor technologies will continue to drive improvements in the performance and resilience of future aerospace systems.

4. Structural Integrity

Structural integrity, the ability of an aerospace vehicle to withstand applied loads and environmental conditions without failure, is paramount. Within aerospace engineering test establishments, specialized processes meticulously evaluate structural performance. The goal is to confirm designs meet stringent safety margins.

- Material Testing and Characterization

Characterizing material behavior under varied stress levels is fundamental. Test establishments conduct tensile, compressive, and fatigue tests to determine material properties. This data is subsequently used in structural analysis and design verification, ensuring structural safety under operational conditions. Real-world examples include composite materials used in aircraft wings, which must withstand repeated stress cycles.

- Full-Scale Structural Testing

This facet involves subjecting complete airframes or major structural components to simulated flight loads. Hydraulic actuators apply precisely controlled forces mimicking aerodynamic pressures. Strain gauges and displacement sensors monitor structural response, identifying potential weaknesses. Full-scale testing is exemplified by wing bending tests, where wings are loaded to levels exceeding design limits to demonstrate ultimate load capacity.

- Non-Destructive Inspection (NDI)

NDI techniques are vital for identifying internal flaws or damage without compromising structural integrity. Methods like ultrasonic testing, radiography, and eddy current inspection detect cracks, voids, or corrosion that might initiate structural failure. Routine NDI inspections of aircraft components, such as engine turbine blades, are crucial for preventing catastrophic failures.

- Computational Structural Analysis

This involves employing finite element analysis (FEA) software to simulate structural behavior under various loading conditions. FEA predicts stress distributions, deflections, and buckling modes, allowing engineers to optimize designs. Simulation informs physical testing, reducing cost and time to market. For instance, FEA models can predict the response of a fuselage section to crash loads, enhancing passenger safety.

These interconnected facets demonstrate the integral role of structural integrity assessment within aerospace engineering test establishments. Each element contributes to validating designs, ensuring airworthiness, and mitigating risks throughout the operational lifespan of aerospace vehicles. By integrating advanced testing techniques and computational tools, these establishments facilitate the development of safe and reliable aerospace systems.

5. System Reliability

System reliability, defined as the probability that a system will perform its intended function for a specified period under defined conditions, is a paramount concern in aerospace engineering. Aerospace engineering test establishments serve as the primary venues for rigorously assessing and enhancing system reliability. These facilities provide the controlled environments and specialized equipment necessary to subject aerospace systems to a wide range of simulated operational stresses, uncovering potential failure modes and vulnerabilities that might not be apparent through design analysis alone. The cause-and-effect relationship is direct: comprehensive testing within these establishments leads to increased confidence in system reliability; conversely, insufficient or inadequate testing elevates the risk of in-flight failures or mission compromises.

The importance of system reliability as a component of aerospace engineering test establishments is underscored by the diverse array of testing methodologies employed. These include accelerated life testing, which compresses years of operational use into a shorter timeframe; environmental testing, which simulates extreme temperatures, pressures, and vibration; and fault injection testing, which deliberately introduces errors to assess system response and fault tolerance. Consider the example of satellite components undergoing radiation testing. These tests simulate the effects of prolonged exposure to cosmic radiation in space, identifying components that may degrade or fail over time. The data gathered from these tests informs design modifications, component selection, and the implementation of redundancy measures to enhance overall system reliability. Another practical application is the rigorous testing of aircraft flight control systems, where simulations and hardware-in-the-loop testing are used to validate the system’s ability to maintain stability and control under various flight conditions and in the presence of simulated failures.

In conclusion, aerospace engineering test establishments are indispensable for ensuring system reliability in the aerospace domain. The ability to proactively identify and mitigate potential failure modes through comprehensive testing is crucial for minimizing risks, enhancing operational performance, and extending the lifespan of aerospace systems. While challenges remain in accurately simulating complex real-world conditions and predicting long-term system behavior, ongoing advancements in testing methodologies and computational modeling continue to improve the effectiveness of these establishments in safeguarding system reliability. These efforts are inextricably linked to the overarching goals of enhancing flight safety, ensuring mission success, and advancing the frontiers of aerospace technology.

6. Safety Assurance

Safety assurance is inextricably linked to the fundamental purpose of an aerospace engineering test establishment. These specialized facilities are designed to proactively identify and mitigate potential hazards associated with aerospace vehicles and components. The cause-and-effect relationship is direct: rigorous testing within these establishments enhances safety assurance, while inadequate or absent testing elevates the risk of accidents and failures. Safety assurance serves as the overarching goal, guiding the testing methodologies, data analysis, and risk management practices within these facilities.

The importance of safety assurance as a core component is manifested through a wide array of testing procedures. These include failure modes and effects analysis (FMEA), which systematically identifies potential failure points and their consequences; structural testing, which subjects airframes and components to simulated flight loads to verify their integrity; and environmental testing, which exposes systems to extreme temperatures, pressures, and vibration to assess their resilience. For example, during the development of a new aircraft, the fuselage undergoes extensive pressure testing to simulate the stress of high-altitude flight. Sensors monitor strain and deformation, providing critical data on the structural integrity of the fuselage. If weaknesses are detected, design modifications are implemented to ensure the aircraft meets stringent safety standards. Furthermore, software testing, which is vital to ensure the reliability and safety of flight control and navigation systems, is conducted. By employing techniques such as static analysis, dynamic analysis, and formal verification, safety-critical software is thoroughly assessed to identify and correct any potential vulnerabilities before flight.

In summary, aerospace engineering test establishments play a critical role in ensuring the safety of aerospace vehicles and operations. Through the application of rigorous testing methodologies and comprehensive risk assessments, these facilities provide the data and insights needed to proactively address potential hazards. The practical significance of this understanding is evident in the reduced risk of accidents, improved operational reliability, and enhanced public confidence in the aerospace industry. Continuously refining testing techniques and adopting advanced safety management practices will remain essential for maintaining and improving safety assurance in the face of increasingly complex aerospace systems.

Frequently Asked Questions

This section addresses common inquiries regarding the function and importance of specialized facilities in the validation of aerospace systems.

Question 1: What specific types of assessments are typically conducted?

Aerospace engineering test establishments conduct a wide range of assessments, including structural testing (static and fatigue), aerodynamic testing (wind tunnel simulations), propulsion system evaluation (engine performance and emissions), environmental testing (temperature, pressure, vibration), and systems integration testing (hardware and software interactions).

Question 2: What differentiates these facilities from standard engineering laboratories?

These establishments possess specialized equipment and infrastructure designed to simulate the extreme conditions encountered during aerospace operations. This includes high-speed wind tunnels, thermal vacuum chambers, and vibration tables capable of replicating launch and flight environments. Standard engineering laboratories typically lack these capabilities.

Question 3: How do these entities contribute to the overall safety of air travel?

By subjecting aerospace systems to rigorous testing, these establishments identify potential weaknesses and vulnerabilities before deployment. This allows engineers to implement design modifications and risk mitigation strategies, ultimately reducing the likelihood of accidents and enhancing the safety of air travel.

Question 4: What role do computational simulations play within these facilities?

Computational simulations, such as finite element analysis (FEA) and computational fluid dynamics (CFD), are integral to the testing process. These simulations provide insights into system behavior under various conditions, complementing physical testing and allowing for efficient design optimization.

Question 5: What are the primary skills and expertise of personnel working within these establishments?

Personnel typically possess expertise in areas such as aerospace engineering, mechanical engineering, electrical engineering, materials science, and data analysis. Strong problem-solving skills, attention to detail, and a commitment to safety are also essential.

Question 6: How has the evolution of these specialized facilities impacted the aerospace industry?

Advancements in testing methodologies and instrumentation have enabled the development of increasingly complex and reliable aerospace systems. This has led to improved flight performance, enhanced safety, and reduced operational costs. Furthermore, these entities drive innovation by providing a platform for evaluating new technologies and materials.

These FAQs illuminate the integral function in ensuring the airworthiness and reliability of aerospace vehicles.

Subsequent sections will explore future challenges and directions in the development of these key establishments.

Conclusion

This exploration has underscored the critical role of aerospace engineering test establishments in ensuring the safety and reliability of modern aerospace systems. These facilities provide the essential infrastructure for rigorous testing, validation, and performance evaluation, contributing directly to the airworthiness of aircraft and spacecraft. From structural integrity assessments to system reliability analyses, the processes conducted within these establishments serve as a crucial safeguard against potential failures and operational risks.

Continued investment in and advancement of these specialized facilities remain paramount for the sustained progress of the aerospace industry. Ongoing refinement of testing methodologies, coupled with the adoption of emerging technologies, will be essential for addressing the challenges posed by increasingly complex aerospace designs. The future of safe and reliable air travel hinges on the unwavering commitment to rigorous validation processes within the aerospace engineering test establishment framework.