This specialized field integrates principles from aeronautical, astronautical, and structural engineering to design, construct, and maintain the infrastructure essential for air and space transportation. This encompasses structures like launchpads, wind tunnels, aircraft hangars, and facilities for spacecraft assembly and testing. For instance, a launch complex requires specialized foundations to withstand extreme forces, sophisticated fluid handling systems, and precise alignment for vehicle launch.

Its significance lies in ensuring the safety, efficiency, and reliability of space exploration and air travel. A solid foundation and meticulously designed facilities decrease the risk of mishaps, and enhance the performance of aircraft and spacecraft. Historically, its development has paralleled advancements in aviation and spaceflight, constantly adapting to new materials, technologies, and operational demands. A good structural integrity is essential.

With that introduction, the following sections will delve into specific aspects of this area of practice, including unique material considerations, environmental factors, and innovative approaches to design and construction that characterize the field.

Guidance for Succeeding in This Specialized Field

The following recommendations offer key considerations for those involved in this multidisciplinary area, encompassing design, construction, and maintenance aspects of relevant infrastructure.

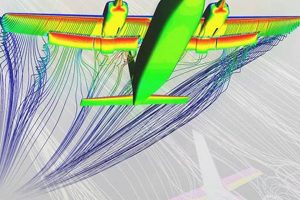

Tip 1: Prioritize Comprehensive Structural Analysis: Rigorous analysis is paramount, considering static and dynamic loads, thermal stresses, and potential impacts from events like rocket launches or high-speed aircraft maneuvers. Utilizing finite element analysis and computational fluid dynamics is crucial for accurate predictions.

Tip 2: Adopt Advanced Material Science Principles: This discipline demands expertise in specialized materials, including high-strength alloys, composites, and heat-resistant ceramics. Understanding material behavior under extreme conditions is essential for ensuring structural integrity and longevity.

Tip 3: Implement Stringent Quality Control Measures: Given the criticality of the structures involved, rigorous quality control protocols are essential throughout the entire lifecycle. This encompasses material testing, construction oversight, and regular inspections.

Tip 4: Adhere to Strict Regulatory Compliance: The field operates under stringent regulatory frameworks, including those established by aviation authorities and space agencies. A thorough understanding of these regulations and meticulous adherence to them is critical.

Tip 5: Integrate Risk Management Strategies: Effective risk management is critical given the potential for catastrophic failures. This includes identifying potential hazards, assessing their likelihood and consequences, and implementing appropriate mitigation measures.

Tip 6: Embrace Interdisciplinary Collaboration: Projects frequently require collaboration between structural engineers, aerospace engineers, material scientists, and construction specialists. Effective communication and coordination are paramount for project success.

Tip 7: Focus on Sustainable Design Practices: Employ sustainable design principles to minimize environmental impact and improve long-term performance. This includes optimizing material use, reducing energy consumption, and incorporating renewable energy sources.

These recommendations highlight the need for rigorous technical competence, meticulous execution, and a commitment to safety and sustainability. By adopting these practices, those involved contribute to the ongoing advancement and reliability of this crucial field.

With this guidance in mind, the subsequent discussion will examine potential challenges and future directions of this specialized area.

1. Structural Integrity

Structural integrity is fundamental to infrastructure within the aerospace sector. The demands placed on facilities by extreme forces, volatile substances, and stringent safety regulations necessitate a rigorous approach to design, construction, and maintenance. Compromised integrity can have catastrophic consequences, underscoring its critical role.

- Load Bearing Capacity

This is the ability of structures to withstand static and dynamic loads, including the weight of aircraft, spacecraft, equipment, and environmental forces like wind and seismic activity. Launch complexes, for example, must endure the immense thrust generated during liftoff. Failure in this area could lead to structural collapse, endangering personnel and equipment.

- Material Fatigue Resistance

Aerospace facilities are subjected to cyclical loading and extreme temperatures, which can cause material fatigue over time. Constant takeoffs and landings impart stress cycles on runways and taxiways, and cryogenic propellant storage tanks experience thermal stress. The selection of materials and design techniques to mitigate fatigue is critical to ensuring long-term safety.

- Corrosion Protection

Exposure to harsh environmental conditions, including corrosive fuels, propellants, and atmospheric elements, can degrade structural components. Structures near coastal launch sites are particularly vulnerable to saltwater corrosion. Effective corrosion prevention measures, such as protective coatings and cathodic protection systems, are essential for maintaining integrity.

- Non-Destructive Testing (NDT) and Monitoring

Regular inspections and NDT methods are crucial for detecting hidden flaws and potential weaknesses before they escalate into failures. Techniques like ultrasonic testing, radiography, and visual inspections help identify cracks, corrosion, and other defects. Continuous monitoring systems can also track structural health in real-time, providing early warning of potential problems.

These facets underscore the importance of a holistic approach to ensuring structural integrity. By addressing load bearing capacity, fatigue resistance, corrosion protection, and implementing rigorous inspection programs, professionals in this field contribute to the safety and reliability of aerospace operations. The challenges associated with maintaining this integrity demand constant innovation in materials, design, and inspection technologies.

2. Material Innovation

Material innovation is a cornerstone in this field, directly influencing the design, performance, and longevity of critical infrastructure. The extreme conditions experienced by aerospace facilities necessitate continuous advancement in material science and engineering, pushing the boundaries of what is structurally possible.

- High-Strength, Lightweight Composites

Composite materials, such as carbon fiber reinforced polymers (CFRP) and fiberglass, offer exceptional strength-to-weight ratios. Their application in aircraft hangars, launch structures, and specialized test facilities reduces overall structural mass while maintaining required load-bearing capacity. For instance, CFRP is increasingly used in the construction of large span hangar roofs due to its ability to cover vast areas with minimal support, reducing the overall weight and cost of the structure.

- Heat-Resistant Alloys and Ceramics

Launch complexes and engine testing facilities are subjected to extreme temperatures. Heat-resistant alloys, such as nickel-based superalloys, and ceramic materials are employed to withstand these conditions. These materials are integral in protecting structural elements from thermal degradation and failure. For example, specialized refractories are used to line rocket engine test stands to prevent the surrounding concrete structures from melting or weakening.

- Self-Healing Concrete

Self-healing concrete incorporates bacteria or microcapsules containing healing agents that are released when cracks form. This autonomous repair mechanism extends the lifespan of concrete structures, reducing maintenance costs and improving overall durability. The self-healing property prevents water and corrosive substances from penetrating the concrete, preserving the reinforcing steel and enhancing structural longevity in environments prone to weathering and chemical exposure.

- Advanced Coatings

Protective coatings are crucial for mitigating corrosion and environmental degradation in aerospace facilities. Advanced coatings, such as epoxy-based coatings with embedded nanoparticles, offer superior resistance to chemical attack, UV radiation, and abrasion. These coatings are utilized on launch structures, fuel storage tanks, and other exposed elements to extend their service life and reduce maintenance requirements, helping to ensure long term reliability and structural safety.

These material innovations demonstrate a concerted effort to enhance the performance, durability, and sustainability of aerospace infrastructure. By continually developing and implementing cutting-edge materials, this field addresses the unique challenges posed by aerospace operations, ensuring the safety and efficiency of both current and future projects.

3. Environmental Resilience

Environmental resilience, with the respect to the facilities, is the ability to withstand and recover from environmental stressors and disturbances. The construction sites and launch facilities frequently face extreme weather conditions, corrosive marine environments, and unique challenges tied to proximity to environmentally sensitive areas. A failure to adequately address these factors can lead to accelerated degradation of infrastructure, increased maintenance costs, and potential disruptions to operations. For example, a launch complex built in a hurricane-prone region must incorporate designs that can withstand high wind speeds and storm surges. Inadequate planning could result in structural damage, launch delays, and environmental contamination. Furthermore, the environmental impact assessments for such projects must consider the effects on local ecosystems and mitigation strategies to minimize ecological disruption.

Practical applications are evident in the selection of construction materials and implementation of protective measures. For coastal facilities, corrosion-resistant alloys and specialized coatings are necessary to combat saltwater exposure. Stormwater management systems prevent erosion and pollutant runoff during heavy rainfall events. Green infrastructure practices, like vegetated roofs and permeable pavements, help reduce the urban heat island effect and manage water resources. The integration of renewable energy sources, such as solar panels and wind turbines, minimizes the carbon footprint and increases the overall sustainability of these large-scale operations. Successful examples demonstrate the long-term benefits of incorporating environmental resilience into the design and operation of the projects, improving the stability of the structures.

In summary, environmental resilience is an indispensable aspect of effective construction. Addressing environmental vulnerabilities through informed design, proactive mitigation, and sustainable practices ensures the long-term durability, reliability, and ecological compatibility of these critical facilities. Overlooking environmental resilience poses significant risks, including structural failure, environmental damage, and operational disruptions. The future of the field demands a holistic approach to environmental stewardship and responsible infrastructure development to ensure sustainable and safe operations.

4. Precision Construction

Precision construction is an indispensable element within aerospace civil engineering, characterized by the stringent tolerances and exacting standards necessary to ensure the safety, functionality, and reliability of specialized infrastructure. This methodology exceeds conventional construction practices, necessitating advanced techniques and rigorous quality control throughout every phase of project development.

- Advanced Surveying and Alignment

Aerospace structures, such as launchpads and test stands, require highly accurate spatial positioning. Advanced surveying techniques, including laser scanning and GPS-based systems, ensure that structural components are aligned within millimeters of their designed locations. Misalignments can compromise structural integrity and operational efficiency, necessitating meticulous surveying procedures.

- Controlled Environment Construction

Cleanroom environments are essential for the assembly and integration of sensitive aerospace components. Precision construction techniques, including HEPA filtration systems, temperature control, and humidity regulation, minimize contamination and ensure the integrity of delicate instruments and systems. This is particularly critical in facilities where spacecraft components are assembled.

- Automated Fabrication and Assembly

Robotic systems and automated fabrication processes enhance the precision and efficiency of construction activities. Automated welding systems, for example, ensure consistent weld quality and minimize the risk of human error in critical structural joints. These techniques are particularly valuable for repetitive tasks and complex geometries where manual construction would be impractical or inaccurate.

- Non-Destructive Testing (NDT)

Precision construction incorporates rigorous NDT methodologies to verify the structural integrity of constructed elements. Ultrasonic testing, radiographic inspection, and other NDT techniques detect hidden flaws and imperfections that could compromise structural performance. These methods are applied throughout the construction process to ensure compliance with stringent quality standards and to identify potential issues before they escalate.

The integration of these precision construction techniques is integral to the success of aerospace civil engineering projects. By adhering to exacting standards and employing advanced technologies, engineers and construction professionals ensure that aerospace infrastructure meets the demanding performance requirements and stringent safety criteria necessary for space exploration and aeronautical advancements.

5. Safety Protocols

Safety protocols are paramount in aerospace civil engineering due to the inherent risks associated with space exploration and aviation infrastructure. These protocols are not merely guidelines but rather meticulously crafted procedures designed to mitigate potential hazards and safeguard personnel, equipment, and the environment. The implementation of robust safety protocols is a fundamental aspect of ensuring the success and sustainability of all projects.

- Hazard Identification and Risk Assessment

A systematic process is employed to identify potential hazards, such as structural failures, explosions, and exposure to hazardous materials. Comprehensive risk assessments are then conducted to determine the likelihood and severity of these hazards. This process informs the development of mitigation strategies, including engineering controls, administrative procedures, and personal protective equipment. For example, during launchpad construction, a detailed hazard analysis would assess the risks associated with handling cryogenic propellants and implementing appropriate safety measures to prevent leaks or explosions. Proper risk assessment would involve the use of HAZOP(Hazard and Operability studies) and FMEA (Failure Mode and Effects Analysis)

- Emergency Response Planning

Comprehensive emergency response plans are essential to address potential incidents effectively. These plans outline procedures for evacuation, medical response, fire suppression, and containment of hazardous materials. Regular drills and training exercises ensure that personnel are prepared to respond promptly and efficiently in the event of an emergency. An example would be a simulated emergency during rocket testing, where the plan encompasses rapid deployment of emergency teams, isolation of the test area, and activation of fire suppression systems.

- Structural Integrity Monitoring

Continuous monitoring of structural integrity is crucial for detecting potential weaknesses or degradation that could compromise the safety of facilities. Non-destructive testing (NDT) methods, such as ultrasonic testing and radiographic inspection, are employed to identify hidden flaws or cracks in structural components. Real-time monitoring systems track stress levels, temperature variations, and other parameters that could indicate structural instability. For instance, sensors embedded in the foundation of a launch tower provide continuous data on stress distribution, enabling engineers to detect and address any anomalies before they escalate into structural failures.

- Personnel Training and Certification

Ensuring that all personnel involved in construction and maintenance activities are adequately trained and certified is vital for maintaining high safety standards. Training programs cover topics such as hazard recognition, safe work practices, emergency response procedures, and proper use of equipment. Certification requirements verify that personnel have the necessary skills and knowledge to perform their tasks safely. An example is that all welders working on critical structural components must be certified to specific welding standards, ensuring that they possess the expertise needed to create strong and reliable joints. And all must participate in continues education programs.

These multifaceted safety protocols collectively contribute to a culture of safety within aerospace civil engineering. By prioritizing hazard identification, emergency preparedness, structural monitoring, and personnel training, this field strives to minimize risks and ensure the well-being of those involved in aerospace endeavors. Continual improvement and adaptation of safety protocols are essential to address evolving challenges and ensure the ongoing safety and reliability of aerospace infrastructure.

6. Regulatory Compliance

Regulatory compliance is a non-negotiable aspect of aerospace civil engineering, governing the design, construction, operation, and maintenance of infrastructure associated with space exploration and aviation. Adherence to these regulations ensures safety, mitigates environmental impact, and maintains the integrity of structures crucial for aerospace activities. A lack of compliance can result in significant legal ramifications, financial penalties, and, most critically, compromised safety.

- FAA Regulations and Airspace Standards

The Federal Aviation Administration (FAA) sets stringent standards for infrastructure supporting air travel. These regulations encompass the design and construction of airports, runways, taxiways, and air traffic control facilities. For example, runway length, width, and surface characteristics must adhere to specific FAA guidelines to accommodate various aircraft types safely. Airspace standards dictate the location and height of structures to prevent interference with flight paths. Non-compliance can lead to operational restrictions, safety hazards, and potential legal liabilities.

- NASA Safety and Mission Assurance Requirements

NASA imposes rigorous safety and mission assurance requirements on all infrastructure used for space exploration activities. These regulations cover the design and construction of launch complexes, test facilities, and mission control centers. For instance, launchpads must meet stringent safety standards to withstand the extreme forces and temperatures generated during liftoff. Failure to comply with NASA’s safety protocols can jeopardize mission success and endanger personnel.

- Environmental Regulations and Impact Assessments

Construction and operation of aerospace facilities are subject to various environmental regulations, including the National Environmental Policy Act (NEPA) and the Clean Air Act. Environmental impact assessments (EIAs) are required to evaluate the potential effects of projects on air and water quality, wildlife habitats, and other environmental resources. Mitigating measures must be implemented to minimize environmental damage. For example, construction near wetlands may require the creation of artificial wetlands to offset habitat loss. Failure to comply with environmental regulations can result in project delays, fines, and reputational damage.

- International Building Codes and Standards

Many aerospace projects are governed by international building codes and standards, such as those established by the International Code Council (ICC). These codes provide minimum requirements for structural integrity, fire safety, and accessibility. Aerospace structures must comply with these codes to ensure the safety and welfare of occupants and the general public. For example, wind tunnel facilities must adhere to specific structural design standards to withstand high-velocity winds. Non-compliance can lead to structural failures and safety hazards.

These regulatory facets collectively ensure that aerospace civil engineering projects adhere to the highest standards of safety, environmental responsibility, and structural integrity. Ongoing vigilance and proactive compliance strategies are essential for navigating the complex regulatory landscape and ensuring the long-term success of aerospace ventures. The intertwining of adherence to regulation and its impact on the integrity of this field is profound. It not only ensures safety but also contributes to the innovation by the push to create new and inventive solution for the regulatory environment.

Frequently Asked Questions

The following questions and answers address common inquiries regarding the principles, applications, and challenges associated with aerospace civil engineering. The aim is to provide clear, concise, and authoritative information on this specialized engineering discipline.

Question 1: What distinguishes the projects from conventional civil engineering endeavors?

Projects are distinct due to the specialized demands of aerospace infrastructure, including launch complexes, wind tunnels, and spacecraft assembly facilities. The unique challenges involve extreme loads, hazardous materials, stringent safety requirements, and precise construction tolerances, which necessitate advanced materials and construction techniques beyond conventional civil engineering practices.

Question 2: Which materials are critical in the construction of aerospace infrastructure?

Critical materials include high-strength alloys, composite materials (such as carbon fiber reinforced polymers), heat-resistant ceramics, and specialized concretes with enhanced durability and resistance to extreme temperatures and chemical exposure. The selection of appropriate materials depends on the specific application and the environmental conditions to which the structure will be subjected.

Question 3: How are environmental considerations addressed in aerospace projects?

Environmental considerations are addressed through rigorous environmental impact assessments (EIAs) and the implementation of mitigation measures to minimize ecological disruption. Compliance with environmental regulations, such as the National Environmental Policy Act (NEPA), is essential. Sustainable design practices, including the use of renewable energy sources and the implementation of stormwater management systems, are also incorporated to reduce the environmental footprint of aerospace facilities.

Question 4: What specific safety protocols are enforced during the construction and maintenance of aerospace infrastructure?

Stringent safety protocols are enforced to mitigate potential hazards and ensure the safety of personnel and equipment. These protocols include comprehensive hazard identification and risk assessment, emergency response planning, structural integrity monitoring, and rigorous personnel training and certification. Regular safety audits and inspections are conducted to verify compliance with established safety standards.

Question 5: What regulatory agencies oversee the design and construction of aerospace facilities?

Several regulatory agencies oversee the design and construction of aerospace facilities, including the Federal Aviation Administration (FAA), NASA, and various environmental protection agencies. These agencies establish and enforce regulations pertaining to safety, environmental protection, and structural integrity. Compliance with these regulations is mandatory to ensure the safe and responsible operation of aerospace infrastructure.

Question 6: How is structural integrity monitored and maintained over the lifespan of aerospace facilities?

Structural integrity is monitored through continuous inspection programs, non-destructive testing (NDT) methods, and real-time monitoring systems. NDT techniques, such as ultrasonic testing and radiographic inspection, are used to detect hidden flaws and potential weaknesses. Regular maintenance activities, including repairs and replacements of deteriorated components, are performed to ensure the long-term structural integrity and reliability of aerospace facilities.

In summary, projects demand specialized expertise, advanced materials, rigorous safety protocols, and strict adherence to regulatory requirements. Addressing these challenges effectively is crucial for ensuring the success and sustainability of space exploration and aviation endeavors.

The following section will explore future trends and emerging technologies in the field.

Conclusion

The exploration of aerospace civil engineering has revealed the intricate demands and critical role it plays in enabling space exploration and aviation advancements. It requires specialized knowledge, advanced materials, rigorous safety protocols, and unwavering regulatory compliance. Structural integrity, material innovation, environmental resilience, precision construction, and robust safety measures are all paramount for the successful execution and sustained operation of aerospace infrastructure.

As the field continues to evolve, embracing innovation and upholding the highest standards of safety and responsibility remains imperative. Only through diligence and foresight can this specialized engineering discipline continue to support and facilitate humanity’s ambitious endeavors in the skies and beyond.