Opportunities within the United States for professionals who design, develop, test, and supervise the manufacturing of aircraft, spacecraft, satellites, and missiles represent a significant sector of the engineering landscape. These positions encompass a broad range of activities, from conceptual design and theoretical analysis to practical application and project management. For example, roles may involve developing propulsion systems for rockets, improving the aerodynamic efficiency of commercial airplanes, or designing satellite communication systems.

The value of a career in this field stems from its contribution to advancements in air travel, space exploration, national security, and scientific research. Historically, demand for qualified individuals has been driven by both government investment in defense and space programs, and by commercial interests in air transportation and satellite technology. This field has consistently pushed the boundaries of technological innovation, leading to developments that have far-reaching impacts beyond the immediate aerospace industry.

The following sections will provide a detailed overview of the specific roles available, the necessary qualifications, typical responsibilities, salary expectations, and the key geographic locations where these roles are concentrated. Furthermore, it will explore the factors influencing employment trends and future prospects within this dynamic and competitive sector.

Strategies for Securing Roles in the Aerospace Sector within the United States

The acquisition of a position in this competitive environment necessitates a strategic approach. Several key actions can significantly enhance a candidate’s prospects.

Tip 1: Cultivate Specialized Expertise: Focus on developing in-depth knowledge in a specific area, such as propulsion, aerodynamics, or structural analysis. For example, expertise in computational fluid dynamics (CFD) can be highly valuable for roles involving aircraft design.

Tip 2: Prioritize Advanced Education: A master’s degree or doctorate often provides a competitive advantage, particularly for research and development roles. Specialized graduate programs can provide the advanced knowledge and skills required for complex projects.

Tip 3: Gain Practical Experience Through Internships: Securing internships with aerospace companies or government agencies offers invaluable hands-on experience and networking opportunities. These experiences demonstrate a candidate’s ability to apply theoretical knowledge to real-world challenges.

Tip 4: Develop Strong Analytical and Problem-Solving Skills: The ability to analyze complex data, identify problems, and develop effective solutions is crucial. Examples include troubleshooting design flaws, optimizing system performance, and conducting failure analysis.

Tip 5: Master Relevant Software and Tools: Proficiency in industry-standard software such as MATLAB, ANSYS, or CATIA is essential. Demonstrating experience with these tools showcases a candidate’s readiness to contribute to ongoing projects.

Tip 6: Network Strategically: Attending industry conferences, joining professional organizations (e.g., AIAA), and connecting with professionals on platforms like LinkedIn can significantly expand a candidate’s network and open doors to potential opportunities.

Tip 7: Tailor Resumes and Cover Letters: Each application should be carefully tailored to the specific requirements of the position. Highlighting relevant skills, experience, and accomplishments demonstrates a clear understanding of the employer’s needs.

By focusing on acquiring specialized knowledge, gaining practical experience, and developing strong analytical skills, individuals can significantly increase their chances of securing a fulfilling and impactful role. These strategic approaches will also allow for career advancement and increased earnings.

The subsequent sections will delve into the specific skills and qualifications that are highly valued by employers, along with a forecast of future industry trends and emerging technologies.

1. Design

Within the context of aerospace engineering employment within the United States, the “Design” phase represents a critical and multifaceted activity, significantly influencing project success and overall performance. It demands a rigorous application of engineering principles, innovative thinking, and a deep understanding of regulatory requirements.

- Conceptual Design

This initial phase involves defining overall system architecture and performance parameters. For example, a conceptual design for a new commercial aircraft might involve defining fuselage shape, wing configuration, and engine type based on projected passenger capacity and fuel efficiency targets. This stage requires a broad understanding of aerodynamics, propulsion, and materials science, with engineers generating trade studies to evaluate various design options.

- Detailed Design

Once the conceptual design is approved, detailed design commences, focusing on specific components and systems. This phase involves creating precise engineering drawings, specifying material properties, and conducting finite element analysis to ensure structural integrity. An example includes designing the internal structure of an aircraft wing, including spars, ribs, and skin panels, to withstand aerodynamic loads and minimize weight.

- Computer-Aided Design (CAD) and Modeling

Modern aerospace design heavily relies on CAD software and advanced modeling techniques. Engineers use software like CATIA, SolidWorks, or NX to create 3D models of aircraft components and systems. These models are used for visualization, simulation, and manufacturing purposes. For instance, engineers use CAD to design complex engine components, ensuring precise fit and functionality.

- Design for Manufacturing (DFM)

DFM considerations are integral to the design process, focusing on optimizing designs for efficient and cost-effective manufacturing. This involves selecting materials and manufacturing processes that minimize production costs and ensure high-quality components. An example is designing an aircraft fuselage using composite materials that can be easily molded and cured, reducing manufacturing time and labor costs.

The various facets of design, from initial conceptualization to detailed engineering and manufacturing considerations, are central to many positions within the aerospace sector. Expertise in these areas is highly sought after by companies involved in aircraft development, spacecraft design, and related technologies, directly impacting employment prospects and career trajectories for engineers within the United States.

2. Analysis

Within the United States aerospace engineering sector, rigorous analysis forms the bedrock of safe and efficient system design and operation. It is a core competency directly impacting job roles, responsibilities, and career progression for engineers in this field.

- Structural Analysis

This facet involves evaluating the structural integrity of aircraft and spacecraft components under various loading conditions. Finite Element Analysis (FEA) is a common tool employed to simulate stresses, strains, and deflections. For example, an engineer might perform structural analysis on a new aircraft wing design to ensure it can withstand aerodynamic forces during flight, meeting stringent safety regulations. The ability to conduct and interpret structural analyses is a critical skill for many aerospace engineering positions in the US, particularly those related to design and certification.

- Aerodynamic Analysis

Aerodynamic analysis focuses on understanding how air flows around aircraft and spacecraft. Computational Fluid Dynamics (CFD) simulations are extensively used to predict aerodynamic performance, optimize wing designs, and minimize drag. For instance, an engineer might use CFD to analyze the airflow around a hypersonic vehicle to understand the effects of shockwaves and heat transfer. Proficiency in aerodynamic analysis is essential for roles involving aircraft design, flight control systems, and propulsion system development.

- Thermal Analysis

Thermal analysis involves evaluating temperature distributions and heat transfer rates within aerospace systems. This is crucial for ensuring the proper functioning of components and preventing overheating. For example, an engineer might perform thermal analysis on a satellite to ensure that its electronic components remain within their operating temperature range in the extreme environment of space. Expertise in thermal analysis is valuable for positions involving spacecraft design, engine development, and thermal management systems.

- Performance Analysis

Performance analysis focuses on evaluating the overall performance of aircraft and spacecraft, including factors such as fuel efficiency, range, and payload capacity. Simulation tools and mathematical models are used to predict performance under various operating conditions. For instance, an engineer might conduct performance analysis on a new launch vehicle to determine its payload capacity to different orbital altitudes. The ability to conduct performance analyses is critical for roles involving system design, mission planning, and flight operations.

The various aspects of analysis – structural, aerodynamic, thermal, and performance – are fundamental to securing and succeeding in numerous engineering roles in the USA. These analyses ensure the safety, efficiency, and effectiveness of all aircraft and spacecraft, therefore being a critical part of many roles. The proficiency in related software and techniques impacts career progression and the capacity to contribute meaningfully to aerospace projects.

3. Testing

The “Testing” phase is a critical component of aerospace engineering, ensuring the reliability, safety, and performance of aircraft, spacecraft, and related systems. Its robust application directly translates into specific job functions and career paths within the United States aerospace sector.

- Flight Testing

Flight testing involves evaluating the performance and handling characteristics of aircraft in actual flight conditions. Test pilots and flight test engineers collect data on parameters such as airspeed, altitude, engine performance, and control surface effectiveness. This data is used to validate design models and identify any potential issues. For example, flight testing of a new commercial airliner involves evaluating its performance during takeoff, landing, cruise, and various maneuvers. Flight test engineers are responsible for planning test flights, collecting and analyzing data, and documenting findings. This activity is vital to obtaining regulatory certification and ensuring the aircraft meets performance requirements.

- Wind Tunnel Testing

Wind tunnel testing is used to simulate airflow around aircraft and spacecraft models. Engineers use wind tunnels to measure aerodynamic forces, pressure distributions, and flow visualization. This data helps to validate aerodynamic designs and optimize performance. For example, wind tunnel testing of a new spacecraft design can help to determine the optimal shape and configuration for re-entry into the Earth’s atmosphere. Wind tunnel testing positions demand skills in fluid mechanics, instrumentation, and data analysis.

- Environmental Testing

Environmental testing simulates the harsh conditions that aircraft and spacecraft will encounter during operation, including extreme temperatures, vibration, and vacuum. Engineers use specialized test chambers to subject components and systems to these conditions to identify potential failure points. For example, environmental testing of a satellite might involve subjecting it to extreme temperature cycles and vacuum conditions to simulate the space environment. These processes ensure that components can withstand the rigors of their intended operational environment.

- Non-Destructive Testing (NDT)

NDT techniques are used to inspect aircraft and spacecraft components for defects without causing damage. Common NDT methods include ultrasonic testing, radiography, and visual inspection. For example, ultrasonic testing can be used to detect cracks in aircraft wings or fuselage structures. NDT technicians and engineers play a vital role in ensuring the structural integrity of aircraft and spacecraft and are critical to maintenance and safety programs. Successful NDT ensures extended life cycles.

These testing methodologies, from simulated environments to real-world flight evaluations and component integrity assessments, represent integral components of various aerospace roles within the United States. The skills and expertise required for planning, conducting, and analyzing test results are highly sought after, influencing the demand and career advancement potential in specific engineering roles.

4. Manufacturing

Within the United States aerospace sector, the “Manufacturing” phase represents a substantial source of employment for engineers. It encompasses the processes and activities required to transform designs into tangible products, from individual components to complete aircraft and spacecraft, demanding a blend of technical expertise and operational efficiency.

- Materials Engineering and Fabrication

This facet centers on the selection, processing, and fabrication of materials used in aerospace components. It involves working with metals, composites, and ceramics to create parts that meet stringent strength, weight, and temperature requirements. An example is the manufacturing of turbine blades for jet engines, which requires precise control of material composition, casting techniques, and surface treatments to ensure optimal performance and durability under extreme operating conditions. This function dictates the expertise of materials engineers, manufacturing engineers, and quality control specialists.

- Precision Machining and Assembly

Aerospace manufacturing demands high levels of precision in machining and assembly processes. This facet involves using Computer Numerical Control (CNC) machines, robotic assembly systems, and skilled technicians to create components with tight tolerances and ensure proper fit. The manufacturing of aircraft wings, for instance, requires precise machining of spars, ribs, and skin panels, followed by careful assembly to achieve the desired aerodynamic profile. Opportunities in this area exist for CNC machinists, manufacturing technicians, and assembly engineers.

- Quality Control and Inspection

Quality control and inspection are critical aspects of aerospace manufacturing, ensuring that all components meet required specifications and safety standards. This involves using non-destructive testing (NDT) methods, such as ultrasonic testing and radiography, to detect flaws and imperfections. The inspection of welds on aircraft fuselage structures, for example, is crucial to ensuring structural integrity and preventing catastrophic failures. This facet creates roles for quality control engineers, inspection technicians, and NDT specialists.

- Supply Chain Management

Effective supply chain management is essential for aerospace manufacturing, coordinating the flow of materials, components, and subassemblies from suppliers to manufacturing facilities. This involves managing inventory levels, negotiating contracts with suppliers, and ensuring timely delivery of parts. The management of the supply chain for a new aircraft program, for instance, requires close coordination with hundreds of suppliers to ensure that all components are available when needed. This generates positions for supply chain managers, procurement specialists, and logistics coordinators.

The manufacturing stage, encompassing materials engineering, precision machining, quality control, and supply chain management, offers diverse avenues for roles in the United States. Skills and expertise in these domains influence the availability and nature of opportunities, as well as the capacity to contribute to the development and production of advanced aerospace systems.

5. Research

The “Research” component forms a foundational pillar of United States aerospace engineering employment. It acts as the catalyst for innovation, driving technological advancements that subsequently create demand for specialized engineering roles. A direct cause-and-effect relationship exists: investment in basic and applied research leads to the development of new aerospace technologies, which, in turn, necessitate expertise in design, analysis, manufacturing, and testing, generating various employment opportunities. Examples abound, such as research into advanced composite materials leading to roles in materials science and structural engineering, or investigations into hypersonic flight resulting in the need for experts in aerodynamics and propulsion. A robust research ecosystem is, therefore, indispensable for a thriving aerospace industry.

The practical significance of understanding the interplay between research and employment cannot be overstated. Individuals seeking careers can strategically target their education and skill development towards areas of active research. Companies can anticipate future workforce needs by monitoring research trends and investing in training programs. Government agencies can formulate policies that foster research and development, ensuring a sustained pipeline of talent for both the defense and commercial aerospace sectors. The practical result of focusing on research are that job requirements change as new technologies and methodologies change.

Challenges exist in translating research breakthroughs into marketable products and services, requiring interdisciplinary collaboration and effective technology transfer mechanisms. Despite these challenges, the ongoing commitment to aerospace research remains crucial for maintaining U.S. competitiveness and leadership in the global aerospace arena. This commitment will ensure that future generations are skilled to handle new technologies in the American aerospace industry.

6. Management

Within the realm of United States aerospace engineering employment, “Management” roles are essential for directing projects, resources, and personnel to achieve specified objectives. The effectiveness of management has a direct causal relationship with project success, organizational efficiency, and ultimately, the competitiveness of aerospace companies. Without capable managers, even the most innovative designs and advanced manufacturing techniques are unlikely to translate into successful outcomes. Management serves as the coordinating force, ensuring that individual engineering efforts align with overarching strategic goals. Examples of management’s crucial role includes project managers overseeing the development of new aircraft, program managers directing multi-billion dollar satellite constellations, and engineering managers leading teams of engineers in the design of propulsion systems. In each instance, effective management is pivotal for on-time, on-budget delivery of critical aerospace capabilities.

Effective management requires technical understanding. Aerospace engineering managers must possess a solid grasp of the engineering principles and technical challenges inherent in their projects. This technical acumen enables them to make informed decisions, assess risks, and effectively communicate with engineers. Simultaneously, management requires a suite of soft skills, including leadership, communication, and problem-solving. Project managers, for example, must balance technical demands with budgetary constraints, while effectively managing stakeholder expectations. An engineering manager must be able to motivate and guide their team, fostering collaboration and resolving conflicts to maintain productivity and morale. Management also includes resource allocation, planning, and logistical management.

The significance of management in aerospace engineering employment cannot be overstated. It is the linchpin that connects engineering expertise with organizational objectives. Aerospace engineers seeking career advancement should consider developing their management skills through formal training, mentorship, and on-the-job experience. Aerospace companies should prioritize the development of effective managers to ensure that their engineering teams are well-led, efficiently organized, and strategically aligned. By recognizing and nurturing management talent, the aerospace industry can enhance its innovative capacity, improve project outcomes, and strengthen its position in the global marketplace.

Frequently Asked Questions Regarding Aerospace Engineering Jobs in USA

This section addresses common inquiries and misconceptions surrounding career opportunities for aerospace engineers within the United States. The information provided aims to clarify key aspects of employment and career development in this specialized field.

Question 1: What are the primary sectors of employment for individuals within the United States holding degrees in aerospace engineering?

Graduates find opportunities in the commercial aviation industry, defense contractors, space exploration companies, and governmental agencies such as NASA and the Department of Defense. These sectors represent the major employers of individuals with expertise in aeronautics and astronautics.

Question 2: What educational qualifications are generally required to secure a position in the aerospace engineering field within the United States?

A bachelor’s degree in aerospace engineering or a closely related field (mechanical, electrical, etc.) is typically the minimum requirement for entry-level positions. Advanced roles, particularly those involving research and development, often necessitate a master’s degree or doctorate.

Question 3: What are the key skills and competencies sought by employers in the aerospace engineering sector in the USA?

Employers value a strong foundation in mathematics, physics, and computer science, coupled with expertise in areas such as aerodynamics, propulsion, structural analysis, and control systems. Proficiency in industry-standard software is also highly desirable.

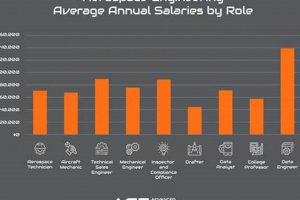

Question 4: What is the typical salary range for aerospace engineers employed within the United States?

Salaries vary depending on experience, education, job location, and employer. However, the median annual salary for aerospace engineers in the U.S. generally falls within a competitive range compared to other engineering disciplines.

Question 5: What are the geographical areas within the United States with the highest concentration of aerospace engineering employment opportunities?

States with a strong aerospace presence include California, Washington, Texas, Florida, and Colorado. These regions host major aerospace companies, government facilities, and research institutions.

Question 6: What are the prospects for career advancement and specialization within the aerospace engineering field in the USA?

Opportunities for career growth exist through specialization in areas such as aircraft design, spacecraft engineering, propulsion systems, or flight control. Advancement to leadership roles, project management positions, and technical specialist positions is also possible with experience and continued professional development.

The aerospace engineering profession provides a pathway for engineers who are eager to excel.

Please continue to the next section for advice on optimizing applications.

Aerospace Engineering Jobs in USA

This exploration has provided an overview of aerospace engineering jobs in USA, highlighting the diverse roles, essential skills, required education, and key employment sectors. It has also identified geographical concentrations, discussed future career development, and addressed common inquiries. A strategic and informed approach to career planning is therefore crucial.

The continued advancement of technology, ongoing investment in space exploration, and sustained emphasis on national security suggest a promising future for qualified individuals within the sector. Proactive engagement with industry trends and a commitment to professional development are essential for sustained success. Therefore, diligent preparation and dedication will lead to a promising career trajectory in the USA.