The confluence of advanced technological development, educational institutions, and manufacturing capabilities within the Buckeye State provides a unique environment for the study and practice of flight vehicle design, construction, and operation. This field encompasses a broad range of specializations, including aerodynamics, propulsion, materials science, and control systems, all contributing to the advancement of air and space travel. For example, several universities offer specialized programs focusing on these areas, while numerous companies within the state contribute to the supply chain for both commercial and military aerospace applications.

The robust presence of this engineering discipline in the region is crucial for economic development, fostering innovation, and ensuring national security. Historically, Ohio has played a significant role in aviation advancements, and its continued investment in this sector strengthens its position as a leader in aerospace technology. Benefits extend beyond the immediate industry, driving advancements in related fields like materials science and computer technology and creating high-paying, skilled jobs. The strategic geographical location and existing infrastructure further contribute to its importance as a center for aerospace activity.

This overview establishes a foundation for exploring key aspects such as the educational institutions, research facilities, and major aerospace companies that contribute to the prominence of this field within the state. Subsequent sections will delve into specific university programs, ongoing research projects, and the economic impact of the aerospace industry in Ohio.

The following offers guidance for those interested in pursuing or engaging with flight vehicle related engineering within the state. These points aim to provide practical insights for prospective students, industry professionals, and those seeking to collaborate within this sector.

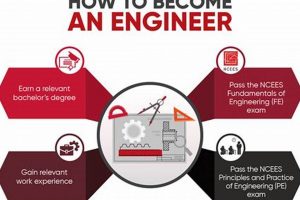

Tip 1: Prioritize ABET-Accredited Programs: Ensure any aerospace engineering program pursued holds accreditation from ABET (Accreditation Board for Engineering and Technology). This accreditation signifies a commitment to quality and ensures the curriculum meets industry standards, increasing employability.

Tip 2: Cultivate Strong Math and Physics Foundations: A solid understanding of mathematics, particularly calculus, differential equations, and linear algebra, and physics is essential. These subjects form the bedrock of aerospace engineering principles; focus on mastering these fundamentals early.

Tip 3: Seek Internship Opportunities: Practical experience is invaluable. Actively pursue internship opportunities with aerospace companies located in Ohio or with related research institutions. This provides hands-on exposure to real-world engineering challenges.

Tip 4: Develop Computational Skills: Proficiency in software tools used for modeling, simulation, and analysis is crucial. Familiarize yourself with software like MATLAB, ANSYS, and computational fluid dynamics (CFD) packages.

Tip 5: Network within the Aerospace Community: Attend industry events, conferences, and workshops held in Ohio. Networking provides opportunities to connect with professionals, learn about industry trends, and potentially identify career prospects.

Tip 6: Consider Specialization: Aerospace engineering encompasses various specializations, such as aerodynamics, propulsion, structures, and control systems. Identify areas of interest and tailor education and experience towards a specific specialization.

Tip 7: Engage in Research: Participate in research projects under the guidance of faculty members at Ohio universities. Research experience enhances critical thinking skills, problem-solving abilities, and provides valuable insights into cutting-edge technologies.

Adherence to these guidelines will significantly enhance opportunities within this specialized field. A strong academic foundation, practical experience, and professional networking are critical for success.

These tips serve as a stepping stone to understanding the unique requirements and potential benefits of engaging with flight vehicle related engineering in Ohio. The subsequent sections will explore resources and opportunities available to further enhance your journey.

1. Skilled workforce availability

The availability of a highly skilled workforce is a critical determinant of the success and continued growth within the aerospace sector in Ohio. This resource directly impacts the ability of companies to innovate, design, manufacture, and maintain advanced aerospace systems. Without a sufficient pool of qualified engineers, technicians, and support staff, the state’s aerospace industry faces significant limitations in its capacity to compete nationally and globally. For example, companies like GE Aviation, with a substantial presence in Ohio, rely on a pipeline of skilled graduates from Ohio’s universities to fill key engineering roles and maintain their technological edge.

Ohio’s educational institutions play a fundamental role in cultivating this talent. Universities offering specialized aerospace engineering programs, along with community colleges providing technical training, are essential for producing graduates equipped with the necessary knowledge and skills. Initiatives like co-op programs and internships further bridge the gap between academic learning and practical application, ensuring that graduates are prepared to contribute effectively upon entering the workforce. Furthermore, ongoing professional development opportunities and retraining programs are vital for maintaining the skills of the existing workforce and adapting to emerging technologies in the aerospace domain. The presence of a skilled workforce attracts aerospace companies to Ohio, creating a positive feedback loop that reinforces the state’s position as a leading center for aerospace activity.

In conclusion, the availability of a skilled workforce is not merely a desirable attribute but rather an indispensable component of a thriving aerospace sector in Ohio. Sustained investment in education, training, and professional development is paramount to ensuring the continued competitiveness and success of this strategically important industry. Addressing potential skill gaps and attracting and retaining talent are critical challenges that require ongoing collaboration between educational institutions, industry, and government to ensure Ohio’s continued leadership in aerospace engineering.

2. Research and Development

Research and Development (R&D) constitutes a critical engine for advancement within flight vehicle related engineering in Ohio. R&D activities drive innovation, resulting in improved designs, enhanced performance, and the development of novel technologies that directly impact the aerospace industry. The presence of robust R&D capabilities within the state fosters a competitive environment, attracting investment and talent, and positioning Ohio as a leader in specific areas within the aerospace sector. For instance, ongoing research at NASA Glenn Research Center in Cleveland, Ohio, focuses on advanced propulsion systems, materials science, and air traffic management, influencing national aerospace policies and industry practices. University-led research projects, often funded by government agencies and private companies, further contribute to this landscape, exploring areas such as unmanned aerial vehicles (UAVs), advanced composite materials, and hypersonic technologies. This research, in turn, fuels the development of new products and services, creating economic opportunities and supporting high-skilled jobs within the state. The collaborative nature of aerospace R&D, involving partnerships between universities, industry, and government, is essential for translating fundamental research into practical applications.

The practical implications of R&D within flight vehicle related engineering in Ohio are significant. For example, advances in materials science resulting from R&D efforts have led to the development of lighter, stronger, and more heat-resistant materials used in aircraft construction. These improvements enhance fuel efficiency, increase payload capacity, and improve overall aircraft safety. Similarly, research into advanced propulsion systems has yielded more efficient and environmentally friendly engines, reducing emissions and noise pollution. Furthermore, R&D efforts focused on autonomous systems and artificial intelligence are paving the way for the development of self-piloting aircraft and advanced air traffic management systems. The state’s strategic location and concentration of expertise make it well-suited for conducting R&D related to specialized areas of aerospace, such as electric propulsion and advanced manufacturing techniques for aerospace components.

In summary, R&D is an indispensable element of flight vehicle related engineering in Ohio, fueling innovation, driving economic growth, and enhancing national security. Sustained investment in R&D is crucial for maintaining Ohio’s leadership position in the aerospace industry. Challenges include ensuring adequate funding for research projects, fostering collaboration between different stakeholders, and attracting and retaining top talent in the field. Addressing these challenges through strategic policies and collaborative initiatives will be essential for maximizing the benefits of R&D and ensuring the long-term success of the aerospace sector in Ohio.

3. Manufacturing infrastructure

The presence of a robust manufacturing infrastructure is inextricably linked to the vitality and advancement of aerospace engineering within Ohio. This infrastructure serves as the physical foundation upon which design concepts are realized, prototypes are developed, and final products are manufactured. Its existence directly influences the state’s ability to compete in the global aerospace market, attract investment, and support high-skilled employment. Deficiencies in manufacturing infrastructure, such as outdated equipment or a lack of specialized facilities, can significantly hinder innovation and limit the capacity to meet the demands of a technologically advanced industry. Ohio’s manufacturing base, encompassing facilities for component fabrication, assembly, testing, and quality control, forms an integral part of its aerospace ecosystem. For example, the capability to produce advanced composites, specialized alloys, and intricate electronic systems within the state directly supports the development and production of sophisticated aerospace systems.

The interaction between manufacturing infrastructure and flight vehicle related engineering extends beyond simply providing physical facilities. The infrastructure also encompasses the skilled workforce required to operate and maintain advanced manufacturing equipment, the logistical networks necessary to transport materials and finished products, and the regulatory frameworks that ensure safety and quality standards are met. The presence of advanced manufacturing technologies, such as additive manufacturing (3D printing) and advanced robotics, further enhances the capabilities of Ohio’s aerospace industry, allowing for the creation of complex geometries and customized components with greater efficiency. Collaboration between aerospace engineering firms and manufacturing facilities is crucial for optimizing designs for manufacturability and ensuring seamless transitions from the design phase to production. Examples can be found in the fabrication of specialized components for military aircraft or the production of satellite components designed and engineered within the state.

In conclusion, the strength of Ohio’s manufacturing infrastructure is a decisive factor in determining the success and sustainability of its aerospace engineering sector. Investment in modernizing facilities, fostering a skilled workforce, and promoting collaboration between engineering and manufacturing entities is essential for maintaining competitiveness in the global aerospace market. Challenges include adapting to rapidly evolving manufacturing technologies, addressing potential supply chain vulnerabilities, and ensuring compliance with stringent regulatory requirements. Effectively addressing these challenges will enable Ohio to leverage its manufacturing infrastructure to support continued innovation and growth within aerospace engineering.

4. University partnerships

University partnerships form a cornerstone of aerospace engineering in Ohio, providing a critical conduit for talent development, research collaboration, and technological advancement. These alliances directly influence the pipeline of qualified engineers entering the workforce and contribute to the state’s capacity for innovation within the aerospace sector. Universities offer specialized degree programs in aerospace engineering, while collaborative relationships with industry facilitate internships, research opportunities, and curriculum alignment to meet industry needs. The presence of these partnerships enables Ohio aerospace companies to access cutting-edge research, test new technologies, and recruit skilled graduates, enhancing their competitiveness in the global market. For instance, collaborative research projects between Ohio State University and local aerospace firms focus on areas such as advanced materials, propulsion systems, and autonomous flight control, directly impacting the design and performance of aerospace vehicles.

The practical significance of university partnerships extends beyond talent acquisition and research. These partnerships facilitate technology transfer, enabling the commercialization of research findings and the development of new products and services. They also foster a culture of innovation, encouraging students and faculty to engage in entrepreneurial activities and develop new ventures in the aerospace field. Ohio universities often host industry-sponsored research centers and innovation hubs, providing a platform for collaboration and knowledge sharing. These centers enable companies to access university resources, collaborate with faculty experts, and mentor students, fostering a dynamic ecosystem of innovation. For example, the University of Cincinnati’s involvement with GE Aviation fosters research in aircraft engine technologies, benefiting both entities. Furthermore, universities often provide customized training programs for aerospace employees, addressing specific skill gaps and ensuring the workforce remains competitive in a rapidly evolving technological landscape.

In conclusion, university partnerships are essential for sustaining and advancing flight vehicle related engineering in Ohio. They provide a critical link between academia and industry, fostering innovation, talent development, and economic growth. Challenges include maintaining adequate funding for collaborative research projects, fostering effective communication between universities and industry, and ensuring that curriculum remains relevant to industry needs. Addressing these challenges through strategic policies and collaborative initiatives will be crucial for maximizing the benefits of university partnerships and ensuring the long-term success of aerospace engineering in Ohio.

5. Government Support

Government support acts as a pivotal catalyst for the prosperity and continued advancement of the aerospace engineering sector within Ohio. This support manifests in various forms, including direct funding for research and development, tax incentives for aerospace companies, infrastructure investments, and the establishment of regulatory frameworks that promote innovation and competitiveness. The availability of government resources enables aerospace companies within Ohio to undertake ambitious research projects, develop cutting-edge technologies, and modernize their manufacturing facilities. For instance, state and federal grants often contribute significantly to research initiatives at institutions like NASA Glenn Research Center, which then spur further advancements across the industry and provide direct benefits for companies operating in Ohio. These initiatives directly impact the ability of Ohio-based aerospace firms to compete on a national and international scale.

Furthermore, government support fosters a conducive environment for aerospace engineering by incentivizing private sector investment and attracting skilled workers to the state. Tax credits offered to aerospace companies reduce their operating costs, allowing them to allocate more resources to research, development, and employee training. Infrastructure investments, such as improvements to transportation networks and utility systems, facilitate the efficient movement of goods and personnel, reducing logistical challenges for aerospace manufacturers. A stable and predictable regulatory environment, established through government policies, provides aerospace companies with the confidence to invest in long-term projects and expand their operations within the state. For example, state-level initiatives promoting STEM education help create a pipeline of qualified graduates who can fill critical roles within Ohio’s aerospace industry. This investment results in a highly trained workforce which attracts high-tech companies and provides further justification for government initiatives.

In conclusion, government support is an indispensable component of the aerospace engineering ecosystem in Ohio. It fosters innovation, attracts investment, and promotes the long-term sustainability of this strategically important industry. Challenges include ensuring that government resources are allocated effectively and efficiently, fostering collaboration between government, industry, and academia, and adapting policies to keep pace with rapid technological advancements. Strategic government action is therefore essential for fostering a vibrant and competitive aerospace industry within the state.

Frequently Asked Questions

This section addresses common inquiries regarding the pursuit of or engagement with flight vehicle related engineering within the State of Ohio. The aim is to provide clear and concise answers to key questions.

Question 1: What are the primary aerospace engineering specializations available at Ohio universities?

Ohio universities typically offer specialization options within aerospace engineering, including aerodynamics, propulsion, structures, control systems, and astrodynamics. The specific specializations available may vary depending on the institution.

Question 2: Which Ohio universities offer ABET-accredited aerospace engineering programs?

Several Ohio universities offer ABET-accredited aerospace engineering programs, including but not limited to The Ohio State University, the University of Cincinnati, and Case Western Reserve University. Prospective students should verify accreditation status directly with the institution.

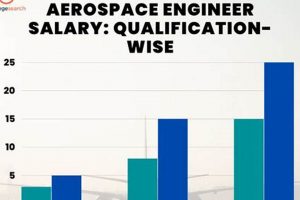

Question 3: What career opportunities are available to aerospace engineers in Ohio?

Career opportunities for aerospace engineers in Ohio span various sectors, including aircraft design and manufacturing, propulsion systems development, space exploration, defense contracting, and research. Common job titles include aerospace engineer, design engineer, systems engineer, and research scientist.

Question 4: What is the role of NASA Glenn Research Center in Ohio’s aerospace industry?

NASA Glenn Research Center plays a significant role in Ohio’s aerospace industry by conducting cutting-edge research in areas such as advanced propulsion, materials science, and space systems. Its research activities foster innovation and collaboration within the state’s aerospace sector.

Question 5: What are the key skills and qualifications sought by aerospace companies in Ohio?

Aerospace companies in Ohio typically seek candidates with a strong foundation in mathematics, physics, and engineering principles, along with proficiency in relevant software tools and practical experience through internships or research projects. Excellent communication, problem-solving, and teamwork skills are also highly valued.

Question 6: How does Ohio’s geographical location benefit the aerospace industry?

Ohio’s central geographical location provides logistical advantages for aerospace companies, facilitating access to major transportation networks and suppliers. The state’s proximity to other industrial centers and research institutions further enhances its attractiveness as a hub for aerospace activity.

This FAQ provides foundational information on flight vehicle related engineering opportunities in Ohio. Further research into specific institutions and companies is encouraged.

The subsequent section will provide an overview of resources and points of contact for those interested in pursuing a career or engaging with the aerospace community in Ohio.

Aerospace Engineering Ohio

This exposition has elucidated the multifaceted nature of flight vehicle related engineering within the state. From its reliance on robust educational institutions and a skilled workforce to its dependence on innovative research and government support, the sector is demonstrably complex and interconnected. Manufacturing infrastructure and university partnerships are similarly critical for sustained growth and competitiveness within the global market. Ohio’s continued prominence in this sector requires ongoing investment and strategic planning.

The information presented serves as a foundation for further exploration and engagement with this vital engineering field. Continued vigilance in fostering a supportive environment for innovation and talent development will ensure Ohio’s enduring role as a leader in the aerospace industry. Future advancements will undoubtedly depend on a concerted effort from academia, industry, and government, working in concert to address emerging challenges and capitalize on new opportunities.

![Why Australian Aerospace Engineering Matters - [Year] Trends Innovating the Future of Flight with Reliable Aviation Solutions Why Australian Aerospace Engineering Matters - [Year] Trends | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/01/th-836-300x200.jpg)