Opportunities within the aeronautics and space sectors in the Republic of India encompass a diverse range of technical and managerial roles. These positions involve the design, development, manufacturing, testing, and maintenance of aircraft, spacecraft, and related systems. Examples include roles for aerospace engineers, avionics technicians, and research scientists.

The availability of such employment contributes significantly to the nation’s technological advancement and economic growth. A skilled workforce in this domain strengthens indigenous manufacturing capabilities, reduces reliance on foreign technology, and fosters innovation. Historically, the growth of this sector has been propelled by both governmental initiatives, such as those from the Indian Space Research Organisation (ISRO) and Hindustan Aeronautics Limited (HAL), and increasing private sector participation.

The following sections will delve into specific career paths within the field, the required qualifications, leading employers, and the evolving landscape of this dynamic employment market. This will provide a clearer picture of the possibilities and requirements for individuals seeking professional engagement in this high-technology arena.

Guidance for Securing Positions in the Indian Aeronautics and Space Sectors

The following outlines strategies for individuals seeking employment within India’s expanding aeronautics and space industries. Attention to these points can improve prospects in a competitive job market.

Tip 1: Emphasize Relevant Education and Certifications: Possessing a bachelor’s or master’s degree in aerospace engineering, mechanical engineering, electrical engineering, or a related field is crucial. Specific certifications relevant to avionics, aircraft maintenance, or software development can further enhance candidacy. Provide clear evidence of academic achievements and relevant credentials.

Tip 2: Develop Specialized Skills: Acquire expertise in areas such as CAD/CAM software, computational fluid dynamics (CFD), finite element analysis (FEA), or specific programming languages used in aerospace applications. Proficiency in these areas is highly valued by employers. Consider online courses or workshops to augment skill sets.

Tip 3: Gain Practical Experience: Internships or project experience with aerospace companies, research institutions, or government organizations significantly strengthen applications. These experiences provide practical exposure to industry processes and technologies. Actively seek opportunities to contribute to real-world projects.

Tip 4: Network with Industry Professionals: Attend industry conferences, seminars, and workshops to connect with professionals in the field. Networking can provide valuable insights into job opportunities and industry trends. Develop professional relationships through online platforms such as LinkedIn.

Tip 5: Target Specific Companies and Roles: Research companies such as ISRO, HAL, private aerospace firms, and defense contractors. Tailor applications to the specific requirements of the targeted role. Highlight relevant skills and experiences that align with the company’s mission and objectives.

Tip 6: Prepare a Strong Resume and Cover Letter: Craft a resume and cover letter that clearly articulate qualifications, experience, and career aspirations. Emphasize quantifiable achievements and contributions. Ensure the documents are free of grammatical errors and professionally presented.

Tip 7: Demonstrate Knowledge of the Indian Aerospace Industry: Stay informed about current developments, government policies, and technological advancements in the Indian aerospace sector. Understanding the industry landscape demonstrates a genuine interest and commitment.

Successfully securing a position in this field requires a combination of rigorous academic preparation, targeted skill development, and proactive networking. A focused approach can significantly increase the likelihood of a successful career trajectory.

The subsequent discussion will examine the challenges and future outlook for securing employment in the Indian aeronautics and space domain. This will provide a context for navigating the opportunities and complexities within this sector.

1. Engineering Design

Engineering design constitutes a fundamental pillar within the landscape of aeronautics and space employment in India. It encompasses the processes by which theoretical concepts are transformed into tangible, functional aerospace systems and components, directly influencing the performance, safety, and efficiency of air and space vehicles.

- Conceptual Design and System Architecture

This phase involves defining overall system requirements, creating preliminary layouts, and evaluating various design options. In India, engineering design roles in this area might focus on developing innovative solutions for satellite propulsion systems or advanced aircraft wing designs, demanding a deep understanding of aerodynamics, thermodynamics, and materials science. The output directly impacts overall mission objectives.

- Detailed Design and Component Modeling

Following conceptualization, detailed design involves creating precise specifications for individual components and assemblies. Engineers utilize CAD/CAM software to generate 3D models and manufacturing drawings. For example, detailed design positions within Indian aerospace firms could involve optimizing the structure of a rocket nozzle or developing lightweight yet robust aircraft fuselage sections. This phase requires expertise in stress analysis, material selection, and manufacturing processes.

- Simulation and Analysis

Engineering designs are rigorously tested through computer simulations to predict performance under various operating conditions. Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) are essential tools. Roles in Indian aerospace companies may involve simulating the aerodynamic behavior of a new aircraft design or analyzing the structural integrity of a satellite under extreme thermal loads. The results of these simulations inform design improvements and ensure safety.

- Testing and Validation

Prototypes are built and subjected to physical testing to validate design performance. This may involve wind tunnel testing of aircraft models or vibration testing of spacecraft components. Engineering design roles related to testing in India might include developing test plans, analyzing test data, and identifying areas for design refinement. Feedback from testing is crucial for iterative improvements and final validation of the design.

The integration of conceptualization, detailed design, simulation, and testing underscores the critical role of engineering design in shaping the success of India’s aerospace endeavors. A robust foundation in these facets enhances the employability of engineers and contributes significantly to the technological advancement of the nation’s aeronautics and space sectors.

2. Manufacturing Processes

Manufacturing processes are integral to the realization of aeronautical and space systems, translating designs into physical hardware. These processes directly impact performance, reliability, and cost-effectiveness. The demand for skilled professionals proficient in advanced manufacturing techniques drives significant employment opportunities in India’s aerospace sector.

- Precision Machining of Components

The fabrication of intricate aerospace parts necessitates high-precision machining using CNC (Computer Numerical Control) equipment. Examples include turbine blades for jet engines or structural elements for spacecraft. Roles for machinists, CNC programmers, and quality control inspectors are essential to ensure adherence to stringent dimensional tolerances and surface finish requirements. These functions directly influence component integrity and performance in operational environments.

- Advanced Materials Processing

The use of advanced materials such as composites, titanium alloys, and nickel-based superalloys is widespread in aerospace applications due to their high strength-to-weight ratios and resistance to extreme temperatures. Manufacturing processes include composite layup, vacuum bagging, autoclaving, and specialized welding techniques. Opportunities arise for materials scientists, manufacturing engineers, and technicians skilled in these processes. The proper handling and processing of these materials are critical to structural integrity.

- Additive Manufacturing (3D Printing)

Additive manufacturing offers the ability to create complex geometries and customized parts with reduced material waste. This technology is increasingly used for producing prototypes, tooling, and even end-use components for aircraft and spacecraft. Employment opportunities exist for design engineers, process engineers, and technicians with expertise in 3D printing technologies and materials. The technology enables the production of parts with intricate internal structures that are difficult to manufacture using traditional methods.

- Assembly and Integration

The final stage involves assembling individual components into larger systems or subsystems. This requires meticulous attention to detail and adherence to strict quality control procedures. Roles include assembly technicians, integration engineers, and quality assurance specialists. Examples include assembling aircraft wings or integrating electronic systems into spacecraft. The process demands a deep understanding of mechanical and electrical systems, as well as adherence to safety protocols.

- Quality Control and Testing

Critical aspect of manufacturing processes to ensure components meet specifications. These engineers also conduct stress tests, and non-destructive testing methods to guarantee the materials strength and the reliability of the components.

Effective manufacturing processes are vital for the successful production of high-performance aerospace systems. Proficiency in these areas enhances employment prospects and contributes to the continued advancement of India’s aeronautics and space capabilities. Investment in advanced manufacturing infrastructure and workforce training is essential for sustaining growth and competitiveness.

3. Research and Development

Research and Development (R&D) constitutes a fundamental driver for opportunities within India’s aeronautics and space sectors. R&D activities propel technological advancements, leading to the development of novel aerospace systems and the enhancement of existing technologies. This, in turn, fuels demand for highly skilled professionals capable of conducting cutting-edge research, designing innovative solutions, and translating them into practical applications. A direct correlation exists: increased investment in R&D precipitates a rise in specialized employment opportunities. For instance, ISRO’s Chandrayaan and Mangalyaan missions necessitated extensive R&D in areas such as propulsion systems, materials science, and sensor technologies, generating numerous positions for scientists, engineers, and technicians. Private sector participation in aerospace R&D is also increasing, further expanding the job market.

The significance of R&D is multifaceted. It enables indigenous development of critical aerospace technologies, reducing reliance on foreign imports and fostering self-reliance. Moreover, it promotes innovation, allowing Indian companies and institutions to compete globally. For example, the development of advanced composite materials for aircraft structures within India’s R&D labs allows for the manufacture of lighter and more fuel-efficient aircraft. This capability not only enhances the competitiveness of Indian aerospace companies but also creates new employment opportunities in materials science, manufacturing engineering, and quality control. Furthermore, R&D facilitates the adaptation of existing technologies to meet specific Indian needs, such as developing cost-effective satellite communication systems for rural areas.

In summary, R&D serves as a crucial catalyst for job creation within the Indian aerospace domain. Continued investment in R&D is essential to maintain technological competitiveness and expand the sector’s capacity for innovation. However, challenges remain, including the need for greater collaboration between academia, industry, and government, as well as increased funding for fundamental research. Overcoming these challenges will be critical to unlocking the full potential of R&D to generate high-value employment and contribute to India’s overall economic and technological advancement in the aerospace field.

4. Quality Assurance

Within India’s aeronautics and space sectors, quality assurance (QA) is an indispensable function, directly impacting safety, reliability, and performance. The rigorous demands of aerospace applications necessitate stringent quality control measures throughout the design, manufacturing, and operational phases. Consequently, QA professionals are in considerable demand, creating numerous specialized career opportunities. Defective components or systems can have catastrophic consequences, thereby elevating the role of QA beyond mere compliance to a critical risk mitigation strategy. For example, the failure of a single O-ring in the Space Shuttle Challenger disaster underscores the potential ramifications of inadequate quality control. The Indian Space Research Organisation (ISRO) places a premium on QA processes to ensure the reliability of its launch vehicles and satellites. The effective implementation of QA practices directly correlates with mission success rates and the overall credibility of the Indian aerospace program.

Specific responsibilities within aerospace QA encompass a wide spectrum of activities. These include the development and implementation of quality management systems (QMS) conforming to international standards such as AS9100, a widely adopted standard for aerospace organizations. QA professionals conduct audits to verify compliance with these standards, identify potential weaknesses in processes, and implement corrective actions. They also oversee the inspection and testing of materials, components, and systems to ensure adherence to specifications. This involves utilizing non-destructive testing (NDT) methods such as radiography, ultrasonic testing, and eddy current testing to detect defects without damaging the part. Furthermore, QA personnel analyze data from manufacturing processes to identify trends and patterns that could indicate potential quality problems. For instance, statistical process control (SPC) techniques are used to monitor key process parameters and detect deviations from acceptable ranges. They also evaluate suppliers to confirm that they meet quality requirements.

In summary, quality assurance constitutes a vital component of the Indian aerospace sector, driving demand for skilled QA professionals across various disciplines. Maintaining high standards of quality is paramount to ensuring the safety, reliability, and success of aerospace missions. As the Indian aerospace industry continues to grow and mature, the importance of QA will only increase. Challenges remain, including the need for continuous improvement in QA methodologies, the development of advanced NDT techniques, and the training of a skilled workforce capable of meeting the evolving demands of the sector. Addressing these challenges will be crucial to sustaining the long-term growth and competitiveness of the Indian aerospace industry.

5. Avionics Integration

Avionics integration represents a critical segment within the broader landscape of career opportunities in the Indian aerospace sector. It entails the seamless integration of electronic systems and software to enable the functionality of aircraft and spacecraft. This specialized field demands a combination of engineering expertise and systems-level thinking.

- Systems Design and Architecture

Avionics integration begins with the design of the overall system architecture, defining the interconnections and communication protocols between various electronic components. This phase requires engineers capable of developing robust and reliable systems that meet stringent performance and safety requirements. In India, this could involve designing the flight control system for a new indigenous aircraft or developing the communication architecture for a satellite. Such responsibilities necessitate expertise in areas such as embedded systems, communication networks, and real-time operating systems. The design outcomes directly influence overall mission parameters.

- Hardware and Software Integration

Once the system architecture is defined, the next step involves integrating the hardware and software components. This requires expertise in both hardware interfacing and software development. For example, integrating a navigation system with the flight management system requires engineers capable of developing software drivers and communication protocols to ensure seamless data exchange. Indian aerospace companies seek engineers with skills in C, C++, and other programming languages, as well as experience with hardware description languages (HDLs) such as VHDL or Verilog. The integration outcome directly affects system performance and stability.

- Testing and Validation

Thorough testing and validation are crucial to ensuring the reliability and safety of avionics systems. This involves conducting a range of tests, including hardware-in-the-loop (HIL) simulations and flight testing. Engineers are needed to develop test plans, execute tests, and analyze test data to identify potential problems. In India, opportunities in this area might involve testing the performance of a newly integrated radar system or validating the software for an autopilot system. Test outcomes drive iterative refinement and overall system assurance.

- Certification and Compliance

Avionics systems must meet strict regulatory requirements and industry standards before they can be deployed. This requires expertise in certification processes and compliance requirements. Engineers with knowledge of standards such as DO-178C (for software) and DO-254 (for hardware) are in high demand. Indian aerospace companies require engineers capable of ensuring that avionics systems meet these standards and obtaining the necessary certifications. These certifications are crucial for flight safety and operational authorization.

The aforementioned facets highlight the breadth and depth of the avionics integration field and its direct relevance to various roles within the Indian aerospace job market. As the sector continues to evolve and embrace advanced technologies, the demand for skilled avionics integration professionals is poised to increase.

Frequently Asked Questions

The following addresses common inquiries regarding career opportunities within the Indian aeronautics and space sectors. Information provided aims to offer clarity and factual guidance.

Question 1: What educational qualifications are typically required for entry-level positions?

A bachelor’s degree in aerospace engineering, mechanical engineering, electrical engineering, or a related field is generally the minimum requirement. Certain roles may necessitate a master’s degree or specialized certifications.

Question 2: Are there specific skills that are highly valued by employers in this sector?

Proficiency in CAD/CAM software, computational fluid dynamics (CFD), finite element analysis (FEA), and programming languages relevant to aerospace applications are frequently sought after.

Question 3: Which companies are the primary employers in the Indian aerospace industry?

Key employers include the Indian Space Research Organisation (ISRO), Hindustan Aeronautics Limited (HAL), and various private sector aerospace and defense companies.

Question 4: What is the typical career progression for an aerospace engineer in India?

Career paths often begin with entry-level engineering roles, progressing to senior engineering positions, project management roles, and potentially leadership positions within research or engineering departments.

Question 5: Are there opportunities for international collaboration in the Indian aerospace sector?

Yes, collaborations with international aerospace organizations and companies are increasingly common, providing opportunities for engineers and scientists to work on global projects.

Question 6: What is the long-term outlook for the availability of positions in the Indian aerospace sector?

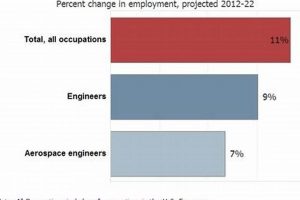

The sector is expected to experience continued growth, driven by government initiatives, increasing private sector investment, and advancements in aerospace technology, resulting in a positive outlook for job availability.

These questions and answers provide a fundamental overview of the Indian aerospace employment landscape. For further information, consult industry-specific resources and company websites.

The subsequent discussion will explore strategies for career advancement within the Indian aerospace sectors. This will provide a roadmap for individuals seeking long-term professional growth.

Conclusion

This article has explored the diverse range of career opportunities within the aeronautics and space sectors in India, emphasizing the vital role of skilled professionals in driving technological advancement and economic growth. Key areas such as engineering design, manufacturing processes, research and development, quality assurance, and avionics integration have been examined, highlighting the specific skills and qualifications required for success.

The sustained expansion and increasing complexity of India’s aerospace endeavors necessitate a commitment to education, training, and innovation. Individuals seeking to contribute to this dynamic field are encouraged to pursue relevant qualifications, develop specialized expertise, and actively engage with the industry. The future of the Indian aerospace sector depends on the collective efforts of a highly skilled and motivated workforce.