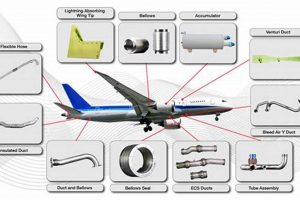

Entities specializing in the creation of components utilized within aircraft, spacecraft, and related systems constitute a vital sector of the aerospace industry. These organizations produce a wide array of items, ranging from structural elements like fuselage sections and wing components to intricate engine parts, avionics systems, and interior cabin features. A commercial example involves the construction of turbine blades for jet engines, requiring precision engineering and adherence to stringent safety standards.

The significance of these specialized firms lies in their contribution to the overall safety, performance, and reliability of air and space vehicles. Their capabilities directly influence the functionality of the aviation and space exploration sectors. Historically, the evolution of flight has been intrinsically linked to advancements in materials science, manufacturing processes, and quality control implemented by these organizations, leading to progressively more sophisticated and dependable aircraft and spacecraft.

The following sections will delve into the intricacies of the supply chain, examining the specific manufacturing processes employed, the rigorous quality assurance measures implemented, and the impact of technological advancements on the production of these essential components.

Guidance for Selecting Aerospace Component Suppliers

The selection of a suitable provider for aerospace-grade hardware demands rigorous due diligence, given the critical nature of these elements in ensuring operational safety and performance.

Tip 1: Prioritize Certifications: Verification of AS9100 or NADCAP certification is paramount. These accreditations demonstrate adherence to stringent quality management systems mandated by the aerospace industry, signifying a commitment to precision and reliability.

Tip 2: Evaluate Manufacturing Capabilities: Assessment of the supplier’s technological capabilities is crucial. The ability to handle complex geometries, exotic materials, and tight tolerances is indicative of a manufacturer equipped to meet demanding specifications.

Tip 3: Scrutinize Material Traceability: A robust material traceability system is non-negotiable. Full documentation of the material’s origin, processing, and testing history is essential for confirming compliance with regulatory requirements and mitigating the risk of counterfeit components.

Tip 4: Audit Quality Control Processes: A thorough audit of the supplier’s quality control protocols should be conducted. This includes an examination of inspection procedures, non-conformance management, and corrective action systems to ensure robust oversight.

Tip 5: Examine Engineering Support: Assess the level of engineering support provided. A qualified supplier should possess the expertise to assist with design optimization, material selection, and problem-solving throughout the product development lifecycle.

Tip 6: Review Past Performance: Obtain and scrutinize performance data, including on-time delivery rates, defect rates, and customer satisfaction scores. This provides valuable insights into the supplier’s reliability and overall track record.

Tip 7: Assess Financial Stability: Evaluation of the supplier’s financial health is prudent. A stable financial foundation reduces the risk of supply chain disruptions and ensures long-term viability.

Careful consideration of these factors can mitigate risks and ensure a reliable source of high-quality aerospace-grade parts. The investment in comprehensive supplier evaluation yields significant returns in the form of enhanced safety, performance, and operational efficiency.

The next section will discuss emerging trends impacting the manufacturing landscape.

1. Precision Engineering

Precision engineering serves as a cornerstone in the creation of aerospace components. Its application is not merely desirable but absolutely essential to the integrity, functionality, and safety of flight vehicles. The tolerances demanded in the construction of aerospace parts far exceed those of most other industries, requiring specialized knowledge, equipment, and processes.

- Dimensional Accuracy of Components

The manufacture of parts like turbine blades or fuel injectors requires adherence to extremely tight dimensional tolerances. Deviations of even a few microns can significantly impact engine performance, fuel efficiency, and overall reliability. Sophisticated machining techniques, such as 5-axis CNC milling and electrical discharge machining (EDM), are routinely employed to achieve these exacting specifications.

- Surface Finish Quality

Surface finish quality is crucial for minimizing friction, wear, and the initiation of fatigue cracks in critical components. Techniques like precision grinding, polishing, and surface coating are applied to ensure optimal surface characteristics. For example, the surface finish of a landing gear strut directly impacts its load-bearing capacity and service life.

- Material Integrity and Microstructure Control

Precision engineering extends to the manipulation of material microstructure during manufacturing. Processes like heat treatment and controlled cooling are employed to optimize the mechanical properties of components. The controlled formation of grain structures in turbine disks, for example, enhances their resistance to high-temperature creep and fatigue.

- Assembly and Integration Accuracy

The precise assembly and integration of individual components into larger sub-assemblies is another critical aspect. This requires specialized tooling, fixtures, and alignment techniques to ensure proper fit and functionality. The precise alignment of optical sensors in a satellite payload, for example, is essential for its mission success.

The dependence on precision engineering underscores the inherent challenges faced by aerospace parts manufacturers. Continuous investment in advanced manufacturing technologies, rigorous quality control protocols, and highly skilled personnel is necessary to meet the stringent demands of the aerospace industry, ensuring the safety and performance of air and space vehicles.

2. Material Science

The relationship between material science and organizations producing aerospace components is one of fundamental interdependence. Material science provides the foundational knowledge base for selecting, processing, and characterizing materials to meet the extreme demands of aerospace applications. In essence, advancements in flight are directly enabled by breakthroughs in material science, with specialized firms translating these discoveries into tangible, flight-worthy hardware. The high strength-to-weight ratio requirements, the need to withstand extreme temperatures, and resistance to corrosion all necessitate sophisticated materials and processing techniques. For instance, the development of titanium alloys and carbon fiber composites has revolutionized aircraft design, enabling lighter, more fuel-efficient aircraft. These advances are directly attributable to material science research and development efforts, subsequently adopted and refined by component manufacturers. The cause-and-effect relationship is clear: progress in materials leads to improved aerospace capabilities.

Consider the practical application of nickel-based superalloys in jet engine turbine blades. Material scientists engineered these alloys to retain their strength and creep resistance at extremely high operating temperatures, directly influencing engine efficiency and thrust. Aerospace parts manufacturers then employ specialized casting, forging, and machining processes to transform these alloys into complex turbine blade geometries. The manufacturing processes themselves are often dictated by the specific material properties, requiring precise control of temperature, pressure, and cooling rates. Furthermore, nondestructive testing methods, developed within the realm of material science, are crucial for detecting flaws and ensuring the structural integrity of finished components. Radiography, ultrasonic testing, and eddy current inspection are routinely used to verify the quality of critical parts.

In summary, the interaction between material science and aerospace parts manufacturers is symbiotic. Material science provides the knowledge and innovation, while manufacturers translate these advancements into real-world components. Challenges remain, particularly in the development of even lighter and stronger materials that can withstand increasingly demanding operational environments. Continued collaboration between researchers and manufacturers is essential for driving future progress in the aerospace industry, further pushing the boundaries of what is possible in flight and space exploration. The ability to develop and implement new materials directly affects the competitive advantage of aerospace parts manufacturers.

3. Regulatory Compliance

Regulatory compliance is a non-negotiable aspect of operations for entities engaged in aerospace component manufacturing. The industry’s safety-critical nature necessitates strict adherence to a complex web of regulations and standards, ensuring the reliability and airworthiness of aircraft and spacecraft. Failure to comply can result in severe consequences, including fines, revoked certifications, and potential grounding of aircraft.

- FAA Regulations (Federal Aviation Administration)

The FAA establishes and enforces regulations governing the design, manufacture, and operation of aircraft within the United States. Aerospace parts manufacturers operating in or supplying to the US market must comply with FAA regulations, including Part 21 (Certification Procedures for Products and Parts) and Part 145 (Repair Stations). These regulations mandate rigorous quality control processes, documentation requirements, and traceability protocols to ensure the safety and reliability of aerospace components. Example: Adherence to FAA regulations in the production of aircraft seats, ensuring they meet flammability and crashworthiness standards.

- EASA Regulations (European Union Aviation Safety Agency)

Similar to the FAA, EASA regulates aviation safety within the European Union. Aerospace parts manufacturers supplying to the European market must comply with EASA regulations, which closely mirror FAA standards but may have specific variations. Compliance with EASA regulations is essential for obtaining the necessary certifications to sell and operate aircraft and related components within the EU. Example: Meeting EASA’s requirements for the production of aircraft landing gear, ensuring it meets stringent safety and performance criteria.

- AS9100 Standards

AS9100 is a widely adopted quality management system standard specifically for the aerospace industry. While not a regulatory requirement in itself, AS9100 certification demonstrates an organization’s commitment to meeting the stringent quality and safety expectations of the aerospace sector. Many aerospace manufacturers and suppliers require AS9100 certification as a prerequisite for doing business. Example: An aerospace parts manufacturer implementing AS9100 to improve its process control, reduce defects, and enhance customer satisfaction.

- ITAR and EAR Regulations (International Traffic in Arms Regulations & Export Administration Regulations)

These regulations govern the export and import of defense-related articles and services. Aerospace parts manufacturers involved in the production of components for military aircraft or spacecraft must comply with ITAR and EAR regulations, which restrict the export of sensitive technologies and materials to certain countries. Compliance with these regulations is essential for national security and preventing the proliferation of advanced technologies. Example: Obtaining the necessary licenses to export inertial navigation systems for military aircraft to allied nations.

The multifaceted nature of regulatory compliance underscores its significance for aerospace parts manufacturers. These regulations impact virtually every aspect of operations, from design and manufacturing to testing and documentation. Adherence to these standards is not merely a legal obligation but a fundamental requirement for ensuring the safety and reliability of flight vehicles. The commitment to meeting these requirements demonstrates a manufacturers dedication to quality, safety, and ethical business practices within the aerospace industry.

4. Supply Chain Management

Effective supply chain management is paramount for entities engaged in producing aerospace components. These organizations operate within intricate networks involving numerous suppliers, manufacturers, distributors, and customers, all contributing to the creation of complex aerospace systems. The integrity and efficiency of this chain directly influence a component’s quality, cost, and timely delivery. A disruption at any point in the supply chainwhether due to material shortages, manufacturing delays, or logistical impedimentscan have cascading effects, potentially leading to production delays, increased costs, and compromised safety. For example, a shortage of specialized titanium alloys, sourced from a limited number of suppliers, can impede the production of aircraft engine components, subsequently affecting aircraft delivery schedules. Similarly, a cyberattack targeting a critical supplier can cripple manufacturing operations, highlighting the importance of robust cybersecurity measures throughout the chain.

The importance of supply chain management extends beyond mere logistics and procurement. It encompasses strategic decision-making regarding supplier selection, risk mitigation, inventory management, and collaboration. Aerospace parts manufacturers must implement rigorous supplier qualification processes, including thorough audits and performance monitoring, to ensure that suppliers meet stringent quality and safety standards. Real-time visibility into the supply chain, enabled by advanced tracking and monitoring technologies, allows manufacturers to proactively identify and address potential disruptions. Furthermore, collaborative partnerships with key suppliers, characterized by open communication and information sharing, can foster innovation and improve overall supply chain resilience. For example, Boeing’s Partnering for Success program aims to improve efficiency and reduce costs across its supply chain by working closely with its suppliers. The program focuses on initiatives such as streamlining processes, improving communication, and leveraging technology to enhance performance.

In conclusion, proficient supply chain management is not merely a supportive function but an integral component of a successful aerospace parts manufacturing operation. By optimizing the flow of materials, information, and resources, manufacturers can enhance efficiency, reduce costs, and mitigate risks. Addressing challenges such as globalization, cybersecurity threats, and increasing regulatory requirements requires a proactive and strategic approach to supply chain management. The understanding and implementation of effective supply chain practices are crucial for maintaining competitiveness and ensuring the delivery of safe, reliable, and high-quality aerospace components.

5. Quality Assurance

Quality assurance constitutes a fundamental pillar underpinning the operations of organizations that specialize in aerospace component manufacturing. The inherent safety-critical nature of flight demands uncompromising standards, rendering quality assurance programs not merely beneficial but absolutely essential. These programs encompass a comprehensive suite of activities designed to prevent defects, ensure compliance, and guarantee the reliability and performance of aerospace parts.

- Non-Destructive Testing (NDT)

NDT methods are employed to evaluate the integrity of aerospace parts without causing damage. Techniques such as radiography, ultrasonic testing, and eddy current inspection are used to detect internal flaws, cracks, and other anomalies that could compromise structural integrity. For example, radiography can identify porosity within a cast turbine blade, while ultrasonic testing can detect subsurface cracks in a landing gear component. The implementation of NDT prevents the use of defective parts, averting potential failures during flight.

- Statistical Process Control (SPC)

SPC involves the use of statistical techniques to monitor and control manufacturing processes, ensuring that they remain within acceptable limits. Control charts are used to track process parameters, such as dimensions, surface finish, and material properties. By monitoring process variation, manufacturers can identify and address potential problems before they lead to defects. For instance, SPC can be used to monitor the diameter of drilled holes in an aircraft fuselage, ensuring that they meet specified tolerances. SPC minimizes variability and improves process consistency, leading to higher quality components.

- First Article Inspection (FAI)

FAI is a comprehensive inspection process conducted on the first production unit of a new or modified part. The purpose of FAI is to verify that the manufacturing process is capable of producing parts that meet all design requirements. FAI involves a detailed examination of all dimensions, material properties, and other critical characteristics. A thorough FAI helps to identify and resolve any issues early in the production cycle, preventing costly errors and rework. For example, FAI is performed on a newly designed wing spar to ensure that it meets all structural requirements before volume production begins.

- Supplier Quality Management

Aerospace parts manufacturers rely on a complex network of suppliers for raw materials, components, and sub-assemblies. Supplier quality management programs are implemented to ensure that suppliers meet the same high standards of quality as the manufacturer itself. These programs involve supplier audits, performance monitoring, and corrective action plans. By effectively managing supplier quality, manufacturers can minimize the risk of receiving defective parts and ensure the overall quality of their products. An example includes regular audits of a supplier providing fasteners to ensure adherence to material specifications and dimensional accuracy.

These components of quality assurance are interconnected, forming a robust system designed to prevent defects and ensure the reliability of aerospace components. The rigor of quality assurance directly correlates with the safety and performance of aircraft and spacecraft, demonstrating its critical role within the aerospace industry. Continuous improvement and investment in advanced quality control technologies are essential for aerospace parts manufacturers to maintain their competitive edge and uphold the highest standards of quality and safety.

6. Technological Innovation

Technological innovation is a driving force reshaping the landscape of aerospace component manufacturing. The relentless pursuit of enhanced performance, reduced weight, improved efficiency, and increased safety fuels a constant stream of advancements. These innovations affect every aspect of component creation, from design and material selection to manufacturing processes and quality control.

- Additive Manufacturing (3D Printing)

Additive manufacturing enables the creation of complex geometries and customized parts with minimal material waste. This technology facilitates the production of lightweight components with optimized structural properties, reducing fuel consumption and improving aircraft performance. Examples include the 3D printing of turbine blades with intricate internal cooling channels and customized brackets for avionics systems. The implications are significant: reduced lead times, lower production costs for low-volume parts, and the ability to create previously unmanufacturable designs.

- Advanced Materials

The development and application of advanced materials, such as carbon fiber composites, ceramic matrix composites, and advanced aluminum alloys, are critical for achieving weight reduction and improved performance. These materials offer superior strength-to-weight ratios, higher temperature resistance, and enhanced corrosion resistance compared to traditional materials. For instance, carbon fiber composites are extensively used in aircraft fuselages and wings, while ceramic matrix composites are employed in jet engine hot section components. The benefits include improved fuel efficiency, increased payload capacity, and extended component lifespan.

- Automation and Robotics

The implementation of automation and robotics in manufacturing processes enhances precision, reduces labor costs, and improves production efficiency. Automated machining, robotic assembly, and automated inspection systems minimize human error and ensure consistent quality. Examples include robotic drilling and fastening of aircraft skin panels and automated inspection of critical dimensions using laser scanning technology. These technologies increase throughput, reduce defects, and improve worker safety.

- Digitalization and Data Analytics

The integration of digital technologies and data analytics enables manufacturers to optimize processes, predict failures, and improve decision-making. Digital twins, predictive maintenance algorithms, and real-time monitoring systems provide valuable insights into component performance and manufacturing efficiency. Examples include the use of digital twins to simulate the performance of engine components under various operating conditions and the implementation of predictive maintenance to anticipate and prevent equipment failures. Data-driven insights enhance quality control, reduce downtime, and improve overall operational efficiency.

The integration of these technological innovations is fundamentally transforming the way aerospace components are designed, manufactured, and maintained. Aerospace parts manufacturers must embrace these advancements to remain competitive, meet evolving customer demands, and uphold the highest standards of safety and performance. The continued pursuit of technological innovation is essential for driving progress and maintaining leadership in the global aerospace industry.

7. Global Competition

Heightened international competition significantly shapes the operational strategies and market dynamics for entities producing aerospace components. The proliferation of manufacturing capabilities across various nations, coupled with advancements in technology and communication, has intensified the pressure on companies to innovate, reduce costs, and enhance efficiency. This competitive environment necessitates a constant pursuit of excellence in all aspects of operations, from design and manufacturing to supply chain management and customer service. The consequence of this increased competition is a downward pressure on prices, forcing manufacturers to find innovative ways to maintain profitability while meeting stringent quality standards. The emergence of new players, particularly in Asia, has disrupted established market structures, requiring established companies to adapt and differentiate themselves.

This competitive landscape manifests in several practical ways. Organizations invest heavily in research and development to create technologically advanced components with superior performance characteristics. They also implement lean manufacturing principles and automation technologies to reduce production costs and improve throughput. Furthermore, companies actively seek strategic alliances and partnerships to expand their market reach and access specialized expertise. For example, smaller entities may partner with larger, well-established aerospace manufacturers to gain access to broader distribution networks and enhanced marketing capabilities. The competitive pressures also drive a greater focus on customer service, with companies striving to build strong relationships and provide tailored solutions to meet the unique needs of their clients. An illustrative example is the intense competition among suppliers of aircraft seating, where companies differentiate themselves through innovative designs, ergonomic features, and customization options, while simultaneously seeking to reduce weight and improve durability.

In summary, global competition is an indelible factor influencing aerospace component manufacturing. The ongoing pressure to innovate, reduce costs, and enhance efficiency necessitates a strategic and proactive approach. Successful organizations are those that embrace technological advancements, cultivate strong supplier relationships, and prioritize customer satisfaction. The ability to navigate this complex competitive environment is essential for long-term sustainability and success in the aerospace industry. Addressing challenges inherent in intense rivalry necessitates a constant reassessment of strategies and investments.

Frequently Asked Questions about Aerospace Parts Manufacturing

The following section addresses common inquiries pertaining to the sector involved in the creation of components for aircraft, spacecraft, and related systems. The objective is to provide clarity and accurate information regarding pertinent aspects of this highly specialized field.

Question 1: What certifications are paramount for an organization producing aerospace components?

AS9100 certification is critical, demonstrating adherence to stringent quality management systems. NADCAP accreditation for specific processes like heat treating or non-destructive testing further validates compliance with industry standards.

Question 2: How are counterfeit parts prevented within the aerospace supply chain?

Stringent material traceability protocols, rigorous supplier audits, and adherence to industry standards (such as AS5553) are implemented. Verification of part authenticity through physical inspection and documentation review is also crucial.

Question 3: What is the significance of non-destructive testing (NDT) in aerospace component manufacturing?

NDT techniques, such as radiography, ultrasonic testing, and eddy current inspection, are used to detect internal flaws and surface defects without damaging the part. This ensures structural integrity and prevents potential failures during operation.

Question 4: How does additive manufacturing (3D printing) impact aerospace component production?

Additive manufacturing enables the creation of complex geometries, customized designs, and lightweight components with minimal material waste. It facilitates rapid prototyping and the production of low-volume parts with optimized performance characteristics.

Question 5: What are the key considerations in selecting materials for aerospace applications?

Strength-to-weight ratio, temperature resistance, corrosion resistance, fatigue resistance, and cost are primary factors. Materials such as titanium alloys, carbon fiber composites, and nickel-based superalloys are commonly used due to their superior properties.

Question 6: How does regulatory compliance affect the manufacturing of aerospace components?

Strict adherence to regulations from organizations such as the FAA and EASA is mandatory. These regulations govern design, manufacturing, testing, and documentation processes to ensure safety and reliability. Non-compliance can result in severe penalties, including fines and revoked certifications.

The responses above highlight the commitment to safety, precision, and regulatory adherence inherent in aerospace component manufacturing.

The subsequent section will explore emerging trends and future directions within the industry.

Conclusion

This examination of aerospace parts manufacturers has revealed a complex and demanding sector. The stringent requirements for safety, precision, and regulatory compliance necessitate unwavering commitment to quality and innovation. From material selection and manufacturing processes to supply chain management and quality assurance, every aspect of operations is subject to intense scrutiny and continuous improvement. These organizations are at the forefront of technological advancement, embracing additive manufacturing, advanced materials, and digital technologies to create components that push the boundaries of flight.

The continued success of the aerospace industry hinges on the capabilities and dedication of aerospace parts manufacturers. Their ability to adapt to evolving technologies, navigate global competition, and maintain the highest standards of quality is paramount. Further research and development, coupled with strategic collaboration between manufacturers, researchers, and regulatory bodies, are essential for ensuring the continued safety, reliability, and advancement of aerospace systems. The future of flight depends on their unwavering commitment to excellence.

![Top Aerospace Parts Manufacturing Companies in India [Guide] Innovating the Future of Flight with Reliable Aviation Solutions Top Aerospace Parts Manufacturing Companies in India [Guide] | Innovating the Future of Flight with Reliable Aviation Solutions](https://mixaerospace.com/wp-content/uploads/2026/01/th-867-300x200.jpg)